ASTM D4827-03(2009)

(Test Method)Standard Test Method for Determining the Unreacted Monomer Content of Latexes Using Capillary Column Gas Chromatography

Standard Test Method for Determining the Unreacted Monomer Content of Latexes Using Capillary Column Gas Chromatography

SIGNIFICANCE AND USE

Excessive amounts of unreacted monomer may cause concerns relating to toxicity and odor. This test method is designed to measure the unreacted monomer content of latexes. The results may be used to monitor the extent of polymerization during manufacture, as well as to establish maximum unreacted monomer content for regulatory purposes.

SCOPE

1.1 This test method is for the determination of the unreacted monomer content of acrylic latexes. Monomers that have been successfully determined by this procedure include n-butyl methacrylate, n-butyl acrylate, styrene, and methyl methacrylate. The determination of other monomers has not been evaluated, but this test method is believed to be applicable. The established working range of this test method is from 100 to 1000 μ g/g, but there is no reason to believe it will not work outside of this range, provided that appropriate dilutions and adjustments in specimen size are made.

1.2 The unreacted monomer in acrylic latexes is expected to change with time and environmental factors. This time dependence of the determination may be seen as an artificially large deviation of results, making the test method mostly applicable for in-house quality control, where sampling and analysis conditions can be better controlled.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4827 − 03(Reapproved 2009)

Standard Test Method for

Determining the Unreacted Monomer Content of Latexes

Using Capillary Column Gas Chromatography

This standard is issued under the fixed designation D4827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 A suitable aliquot of the latex is internally standardized

1.1 This test method is for the determination of the unre-

with isobutyl acrylate, diluted with water, and then injected

acted monomer content of acrylic latexes. Monomers that have

onto a capillary gas chromatographic column containing a

beensuccessfullydeterminedbythisprocedureinclude n-butyl

stationary phase that separates the internal standard and mono-

methacrylate, n-butyl acrylate, styrene, and methyl methacry-

mers in question from each other and from other volatile

late. The determination of other monomers has not been

compounds.

evaluated,butthistestmethodisbelievedtobeapplicable.The

established working range of this test method is from 100 to

4. Significance and Use

1000 µg/g, but there is no reason to believe it will not work

outside of this range, provided that appropriate dilutions and

4.1 Excessive amounts of unreacted monomer may cause

adjustments in specimen size are made.

concerns relating to toxicity and odor. This test method is

designedtomeasuretheunreactedmonomercontentoflatexes.

1.2 The unreacted monomer in acrylic latexes is expected to

The results may be used to monitor the extent of polymeriza-

change with time and environmental factors. This time depen-

tion during manufacture, as well as to establish maximum

dence of the determination may be seen as an artificially large

unreacted monomer content for regulatory purposes.

deviation of results, making the test method mostly applicable

for in-house quality control, where sampling and analysis

5. Apparatus

conditions can be better controlled.

5.1 Gas Chromatograph—Any gas-liquid chromatographic

1.3 The values stated in SI units are to be regarded as

instrument having a flame ionization detector and linear

standard. No other units of measurement are included in this

temperature programming and a capillary column inlet capable

standard.

of split operation.The split liner should be constructed of glass

andbereplacedorcleanedasneeded.On-columninjectioninto

1.4 This standard does not purport to address all of the

awideborecapillarycolumnwasnotevaluatedbutisexpected

safety concerns, if any, associated with its use. It is the

to also be satisfactory for this procedure.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.2 Column—30-m by 0.25-mm inside diameter fused silica

bility of regulatory limitations prior to use. For specific hazard

coated witha1µm thick film of a phenyl methyl silicone

statements, see Section 7.

polymer. A bonded phase is preferred. Other columns having

equivalent or superior performance may also be used.

2. Referenced Documents

5.3 Recorder—A recording potentiometer with a full-scale

2.1 ASTM Standards: deflection of 10 mV, a full-scale response time of 2 s or less,

D1193 Specification for Reagent Water

and a maximum noise level of 60.03 % of full scale. The use

of a recording integrator or other data-handling device is

preferred.

This test method is under the jurisdiction of ASTM Committee D01 on Paint 5.4 Liquid Charging Devices—A microsyringe, 1.0-µL

and Related Coatings, Materials, andApplications and is the direct responsibility of

capacity, or an automatic liquid sampling device using a

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

suitable syringe and appropriate change in split ratio.

Current edition approved Feb. 1, 2009. Published February 2009. Originally

approved in 1988. Last previous edition approved in 2003 as D4827 – 03. DOI:

5.5 Dropper Pipettes, glass, disposable.

10.1520/D4827-03R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.6 Vials,approximately7mLcapacity,withcaps.Opentop

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

screw-cap vials fitted with PTFE/silicone septa are preferred.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.7 Autosampler Vials, 2 mL capacity (optional).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4827 − 03 (2009)

TABLE 1 Instrument Conditions

5.8 Analytical Balance, accurate to 0.1 mg.

Detector flame ionization

A

Airflow, mL/min 240

6. Reagents

Hydrogen flow, mL/min 30

6.1 Purity of Reagents—Reagent grade chemicals shall be Makeup gas 30

Helium

used in all tests. Unless otherwise indicated, it is intended that

B

Column:

all reagents shall conform to the specifications of the Commit-

Length, m 30

tee onAnalytical Reagents of theAmerican Chemical Society,

Inside diameter, mm 0.25

Film thickness, µm 1

where such specifications are available. Other grades may be

Carrier gas helium

used, provided it is first ascertained that the reagent is of

Flow rate 0.5 mL/min

sufficiently high purity to permit its use without lessening the

Temperatures:

Injection port, °C 220

accuracy of the determination.

Detector block, °C 250

6.2 Purity of Water—Unless otherwise indicated, references Column:

Initial, °C 60

to water shall be understood to mean reagent water as defined

Hold time, min 4

by Type II of Specification D1193.

Program rate, °C/min 8

Final, °C 200 (or higher as needed)

6.3 Carrier Gas—Helium of 99.995 % or higher purity.

Final hold, min 10 (or longer)

High purity nitrogen may also be used.

Injection volume, µL 0.5

Split ratio 20:1

6.4 Acetone.

A

Set at recommended flow according to the instrument manufacturer.

B

6.5 Isobutyl Acrylate (internal standard), 99 + % pure. Cross-linked 50 % phenyl 50 % methyl silicone.Acolumn of equivalent or better

performance may also be used.

NOTE 1—Isobutyl acrylate was found to be a suitable internal standard,

but any other monomer not found in the sample may be substituted. The

internal standard chosen should yield a clear chromatographic separation,

and should be free of interferences.

6.6 Monomers of Interest, 99+ % pure.

6.7 Methanol.

7. Hazards

7.1 Acrylic and methacrylic monomers are considered haz-

ardous. All sample preparations should be done in a well

ventilated area, such as a fume hood.

8. Preparation of Apparatus

8.1 Column Conditioning—Attach one end of the column to

the inlet side of the instrument leaving the exit end of the

column disconnected. This prevents the contamination of the

detector due to column bleed. Set the helium flow rate at 0.5

mL/min (approximately equivalent to a linear velocity of 20

cm/s) and purge the column at 220°C for 1 h.

8.2 Afterconditioning,connecttheexitendofthecolumnto

the detector and establish the operating conditions required to

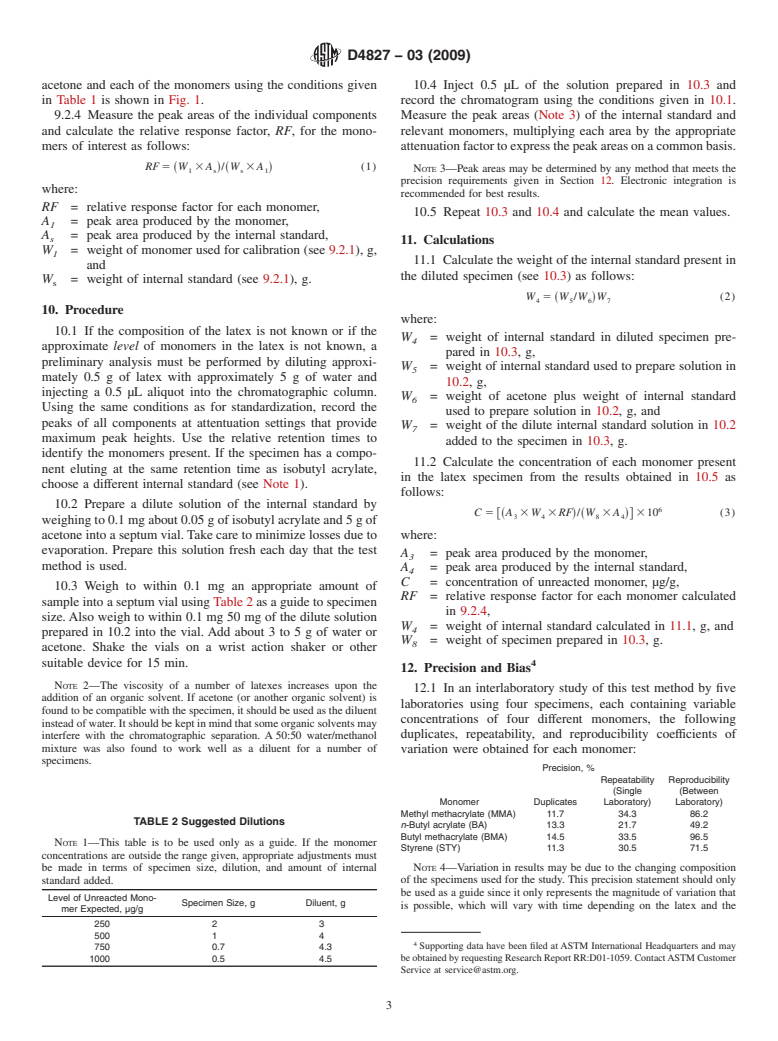

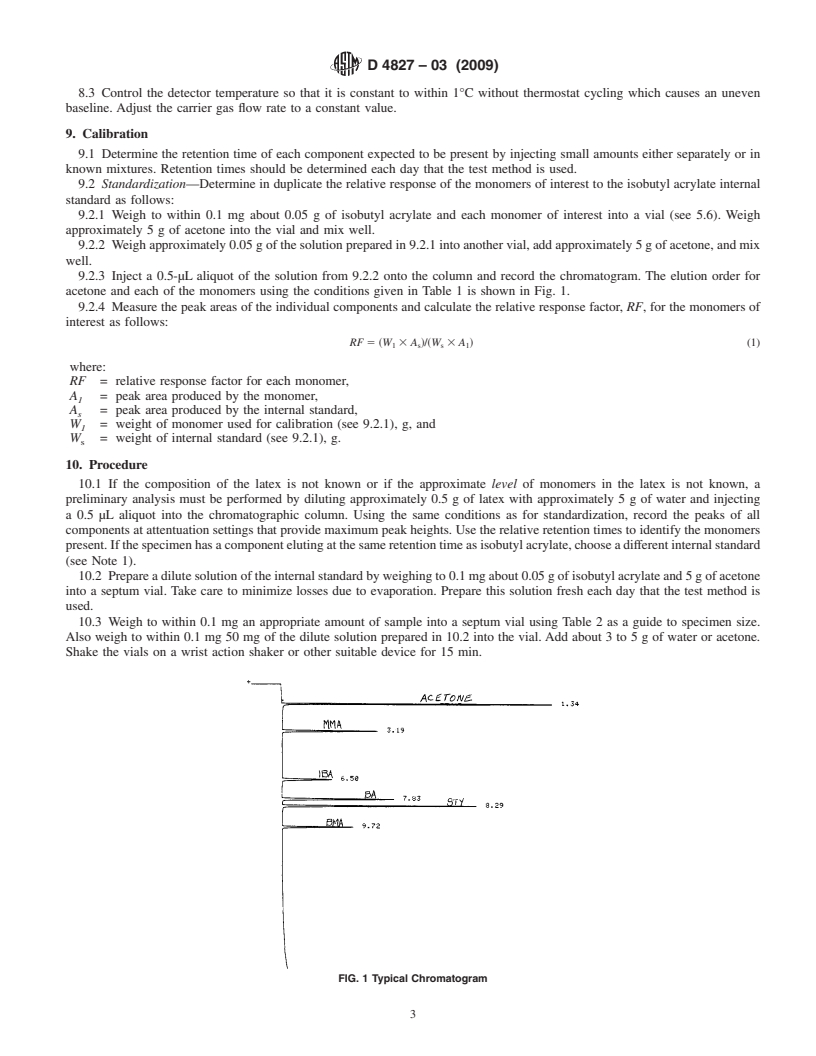

FIG. 1 Typical Chromatogram

give the desired separation (see Table 1).Allow sufficient time

for the instrument to reach equilibrium as indicated by a stable

baseline.

8.3 Control the detector temperature so that it is constant to

rately or in known mixtures. Retention times should be

within 1°C without thermostat cycling which causes an uneven

determined each day that the test method is used.

baseline. Adjust the carrier gas flow rate to a constant value.

9.2 Standardization—Determine in duplicate the relative

9. Calibration response of the monomers of interest to the isobutyl acrylate

internal standard as follows:

9.1 Determine the retenti

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4827–93 (Reapproved l998) Designation:D4827–03(Reapproved2009)

Standard Test Method for

Determining the Unreacted Monomer Content of Latexes

Using Capillary Column Gas Chromatography

This standard is issued under the fixed designation D 4827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is for the determination of the unreacted monomer content of acrylic latexes. Monomers that have been

successfully determined by this procedure include n-butyl methacrylate, n-butyl acrylate, styrene, and methyl methacrylate. The

determinationofothermonomershasnotbeenevaluated,butthistestmethodisbelievedtobeapplicable.Theestablishedworking

range of this test method is from 100 to 1000 µ g/g, but there is no reason to believe it will not work outside of this range, provided

that appropriate dilutions and adjustments in specimen size are made.

1.2 The unreacted monomer in acrylic latexes is expected to change with time and environmental factors.This time dependence

of the determination may be seen as an artificially large deviation of results, making the test method mostly applicable for in-house

quality control, where sampling and analysis conditions can be better controlled.

1.3

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

3. Summary of Test Method

3.1 A suitable aliquot of the latex is internally standardized with isobutyl acrylate, diluted with water, and then injected onto

a capillary gas chromatographic column containing a stationary phase that separates the internal standard and monomers in

question from each other and from other volatile compounds.

4. Significance and Use

4.1 Excessive amounts of unreacted monomer may cause concerns relating to toxicity and odor. This test method is designed

to measure the unreacted monomer content of latexes. The results may be used to monitor the extent of polymerization during

manufacture, as well as to establish maximum unreacted monomer content for regulatory purposes.

5. Apparatus

5.1 Gas Chromatograph—Any gas-liquid chromatographic instrument having a flame ionization detector and linear tempera-

ture programming and a capillary column inlet capable of split operation. The split liner should be constructed of glass and be

replaced or cleaned as needed. On-column injection into a wide bore capillary column was not evaluated but is expected to also

be satisfactory for this procedure.

5.2 Column—30-m by 0.25-mm inside diameter fused silica coated witha1µm thick film of a phenyl methyl silicone polymer.

A bonded phase is preferred. Other columns having equivalent or superior performance may also be used.

5.3 Recorder—A recording potentiometer with a full-scale deflection of 10 mV, a full-scale response time of2sor less, and

a maximum noise level of 60.03 % of full scale. The use of a recording integrator or other data-handling device is preferred.

This test method is under the jurisdiction of ASTM Committee D-1D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved May 15, 1993.Feb. 1, 2009. Published July 1993.February 2009. Originally published as D4827–88.approved in 1988. Last previous edition

D4827–88.approved in 2003 as D 4827 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4827–03 (2009)

5.4 Liquid Charging Devices—Amicrosyringe, 1.0-µLcapacity, or an automatic liquid sampling device using a suitable syringe

and appropriate change in split ratio.

5.5 Dropper Pipettes, glass, disposable.

5.6 Vials, approximately 7 mL capacity, with caps. Open top screw-cap vials fitted with PTFE/silicone septa are preferred.

5.7 Autosampler Vials, 2 mL capacity (optional).

5.8 Analytical Balance, accurate to 0.1 mg.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type II of Specification D 1193.

6.3 Carrier Gas—Helium of 99.995 % or higher purity. High purity nitrogen may also be used.

6.4 Acetone.

6.5 Isobutyl Acrylate (internal standard), 99 + % pure.

NOTE 1—Isobutylacrylatewasfoundtobeasuitableinternalstandard,butanyothermonomernotfoundinthesamplemaybesubstituted.Theinternal

standard chosen should yield a clear chromatographic separation, and should be free of interferences.

6.6 Monomers of Interest, 99+ % pure.

6.7 Methanol.

7. Hazards

7.1 Acrylic and methacrylic monomers are considered hazardous. All sample preparations should be done in a well ventilated

area, such as a fume hood.

8. Preparation of Apparatus

8.1 Column Conditioning—Attach one end of the column to the inlet side of the instrument leaving the exit end of the column

disconnected. This prevents the contamination of the detector due to column bleed. Set the helium flow rate at 0.5 mL/min

(approximately equivalent to a linear velocity of 20 cm/s) and purge the column at 220°C for 1 h.

8.2 After conditioning, connect the exit end of the column to the detector and establish the operating conditions required to give

the desired separation (see Table 1).Allow sufficient time for the instrument to reach equilibrium as indicated by a stable baseline.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

TABLE 1 Instrument Conditions

Detector flame ionization

A

Airflow, mL/min 240

Hydrogen flow, mL/min 30

Makeup gas 30

Helium

B

Column:

Length, m 30

Inside diameter, mm 0.25

Film thickness, µm 1

Carrier gas helium

Flow rate 0.5 mL/min

Temperatures:

Injection port, °C 220

Detector block, °C 250

Column:

Initial, °C 60

Hold time, min 4

Program rate, °C/min 8

Final, °C 200 (or higher as needed)

Final hold, min 10 (or longer)

Injection volume, µL 0.5

Split ratio 20:1

A

Set at recommended flow according to the instrument manufacturer.

B

Cross-linked

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4827–03 Designation:D4827–03(Reapproved2009)

Standard Test Method for

Determining the Unreacted Monomer Content of Latexes

Using Capillary Column Gas Chromatography

This standard is issued under the fixed designation D 4827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is for the determination of the unreacted monomer content of acrylic latexes. Monomers that have been

successfully determined by this procedure include n-butyl methacrylate, n-butyl acrylate, styrene, and methyl methacrylate. The

determinationofothermonomershasnotbeenevaluated,butthistestmethodisbelievedtobeapplicable.Theestablishedworking

range of this test method is from 100 to 1000 µ g/g, but there is no reason to believe it will not work outside of this range, provided

that appropriate dilutions and adjustments in specimen size are made.

1.2 The unreacted monomer in acrylic latexes is expected to change with time and environmental factors.This time dependence

of the determination may be seen as an artificially large deviation of results, making the test method mostly applicable for in-house

quality control, where sampling and analysis conditions can be better controlled.

1.3The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

3. Summary of Test Method

3.1 A suitable aliquot of the latex is internally standardized with isobutyl acrylate, diluted with water, and then injected onto

a capillary gas chromatographic column containing a stationary phase that separates the internal standard and monomers in

question from each other and from other volatile compounds.

4. Significance and Use

4.1 Excessive amounts of unreacted monomer may cause concerns relating to toxicity and odor. This test method is designed

to measure the unreacted monomer content of latexes. The results may be used to monitor the extent of polymerization during

manufacture, as well as to establish maximum unreacted monomer content for regulatory purposes.

5. Apparatus

5.1 Gas Chromatograph—Any gas-liquid chromatographic instrument having a flame ionization detector and linear tempera-

ture programming and a capillary column inlet capable of split operation. The split liner should be constructed of glass and be

replaced or cleaned as needed. On-column injection into a wide bore capillary column was not evaluated but is expected to also

be satisfactory for this procedure.

5.2 Column—30-m by 0.25-mm inside diameter fused silica coated witha1µm thick film of a phenyl methyl silicone polymer.

A bonded phase is preferred. Other columns having equivalent or superior performance may also be used.

5.3 Recorder—A recording potentiometer with a full-scale deflection of 10 mV, a full-scale response time of2sor less, and

a maximum noise level of 60.03 % of full scale. The use of a recording integrator or other data-handling device is preferred.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Dec.Feb. 1, 2003.2009. Published January 2004.February 2009. Originally approved in 1988. Last previous edition approved in 19932003 as

D4827–93(1998). D 4827 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4827–03 (2009)

5.4 Liquid Charging Devices—Amicrosyringe, 1.0-µLcapacity, or an automatic liquid sampling device using a suitable syringe

and appropriate change in split ratio.

5.5 Dropper Pipettes, glass, disposable.

5.6 Vials, approximately 7 mL capacity, with caps. Open top screw-cap vials fitted with PTFE/silicone septa are preferred.

5.7 Autosampler Vials, 2 mL capacity (optional).

5.8 Analytical Balance, accurate to 0.1 mg.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type II of Specification D 1193.

6.3 Carrier Gas—Helium of 99.995 % or higher purity. High purity nitrogen may also be used.

6.4 Acetone.

6.5 Isobutyl Acrylate (internal standard), 99 + % pure.

NOTE 1—Isobutylacrylatewasfoundtobeasuitableinternalstandard,butanyothermonomernotfoundinthesamplemaybesubstituted.Theinternal

standard chosen should yield a clear chromatographic separation, and should be free of interferences.

6.6 Monomers of Interest, 99+ % pure.

6.7 Methanol.

7. Hazards

7.1 Acrylic and methacrylic monomers are considered hazardous. All sample preparations should be done in a well ventilated

area, such as a fume hood.

8. Preparation of Apparatus

8.1 Column Conditioning—Attach one end of the column to the inlet side of the instrument leaving the exit end of the column

disconnected. This prevents the contamination of the detector due to column bleed. Set the helium flow rate at 0.5 mL/min

(approximately equivalent to a linear velocity of 20 cm/s) and purge the column at 220°C for 1 h.

8.2 After conditioning, connect the exit end of the column to the detector and establish the operating conditions required to give

the desired separation (see Table 1).Allow sufficient time for the instrument to reach equilibrium as indicated by a stable baseline.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

TABLE 1 Instrument Conditions

Detector flame ionization

A

Airflow, mL/min 240

Hydrogen flow, mL/min 30

Makeup gas 30

Helium

B

Column:

Length, m 30

Inside diameter, mm 0.25

Film thickness, µm 1

Carrier gas helium

Flow rate 0.5 mL/min

Temperatures:

Injection port, °C 220

Detector block, °C 250

Column:

Initial, °C 60

Hold time, min 4

Program rate, °C/min 8

Final, °C 200 (or higher as needed)

Final hold, min 10 (or longer)

Injection volume, µL 0.5

Split ratio 20:1

A

Set at recommended

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.