ASTM G219-23

(Guide)Standard Guide for Determination of Static Coefficient of Friction of Test Couples Using an Inclined Plane Testing Device

Standard Guide for Determination of Static Coefficient of Friction of Test Couples Using an Inclined Plane Testing Device

SIGNIFICANCE AND USE

5.1 Guide G115 lists a number of ASTM International standards that use the inclined plane test rig to measure the static coefficient of specific tribosystems. This guide applies to any material couple that can be made into test specimens; one being in the form of a rider and the other a plane that can be angled to produce motion of the rider on the plane. Footwear on walkway surfaces is an example of a very important application. Flooring surfaces that are slippery to various types of footwear can produce accidents and testing should be done on candidate flooring surfaces and candidate shoe soles and heels to quantify their relative slip resistance. This guide shows how an inclined plane can be used to make such a comparison.

5.2 The inclined plane method is also very useful in machine design in which parts of components shall slide unassisted down chutes and the like. An inclined plane test can be used to determine the chute angle that is needed to allow motion on all parts that are placed on the chute. The applications are numerous.

SCOPE

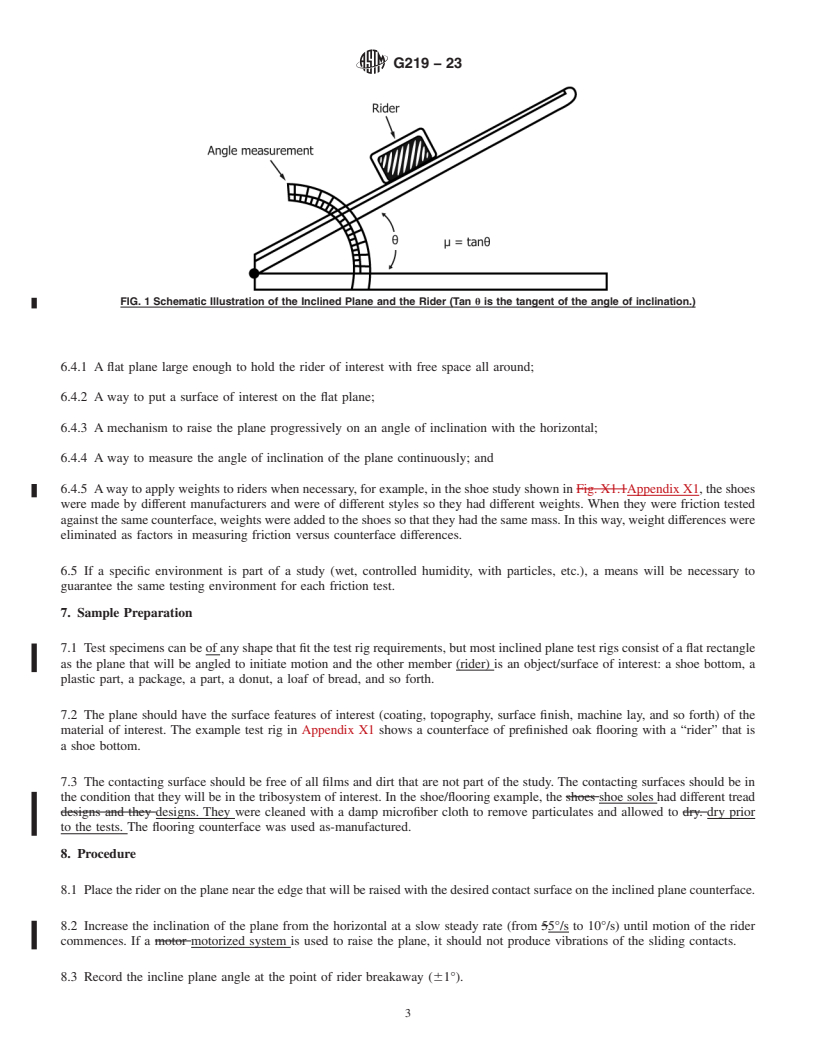

1.1 This guide is intended to standardize the use of an inclined plane testing device to measure the static (breakaway) coefficient of friction between two bodies. One body is in the form of a small “rider” (few centimeters) and the other a rectangular flat plane (50 mm to 75 mm by 400 mm). The rider is placed on the plane and the plane is inclined at an angle to produce motion of the rider. The tangent of the angle at which macroscopic motion of the rider initiates on the angled plane is the breakaway or static coefficient of friction for that sliding couple.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G219 − 23

Standard Guide for

Determination of Static Coefficient of Friction of Test

1

Couples Using an Inclined Plane Testing Device

This standard is issued under the fixed designation G219; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 friction force, n—resisting force tangential to the

interface between two bodies, when under action of an external

1.1 This guide is intended to standardize the use of an

force, one body moves or tends to move relative to the other.

inclined plane testing device to measure the static (breakaway)

G40

coefficient of friction between two bodies. One body is in the

form of a small “rider” (few centimeters) and the other a

3.1.2 static coeffıcient of friction, n—coefficient of friction

rectangular flat plane (50 mm to 75 mm by 400 mm). The rider

corresponding to the maximum friction force that shall be

is placed on the plane and the plane is inclined at an angle to

overcome to initiate macroscopic motion between two bodies.

produce motion of the rider. The tangent of the angle at which

G40

macroscopic motion of the rider initiates on the angled plane is

3.1.2.1 Discussion—Breakaway friction coefficient is syn-

the breakaway or static coefficient of friction for that sliding

onymous with static coefficient of friction.

couple.

3.2 Definitions of Terms Specific to This Standard:

1.2 Units—The values stated in SI units are to be regarded

3.2.1 inclined plane device, n—mechanism with a flat hori-

as the standard. No other units of measurement are included in

zontal surface to be made of or covered with a material of

this standard.

interest on which a second member made of a material of

1.3 This standard does not purport to address all of the

interest can be placed and the mechanism is then actuated such

safety concerns, if any, associated with its use. It is the

that the horizontal plane is increasingly angled with respect to

responsibility of the user of this standard to establish appro-

its original horizontal position until motion is produced on the

priate safety, health, and environmental practices and deter-

member placed on the raising plane.

mine the applicability of regulatory limitations prior to use.

3.2.1.1 Discussion—The device allows for the continuous

1.4 This international standard was developed in accor-

measurement of the angle of inclination and the angle at which

dance with internationally recognized principles on standard-

motion of the rider commences.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.2.2 rider, n—body to be placed on the inclined plane.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Guide

2. Referenced Documents

4.1 The technique of placing an object on a flat and

2

horizontal “plane” such as a piece of sheet metal and raising

2.1 ASTM Standards:

one end of the sheet until the body placed on the sheet starts to

G40 Terminology Relating to Wear and Erosion

slide has been used for centuries to compare the ease with

G115 Guide for Measuring and Reporting Friction Coeffi-

which different objects or materials slide on each other.

cients

Quantitative comparison of various couples can be made by

3. Terminology

measuring the angle at which the body placed on the plane

3.1 Definitions:

starts to slide. The angle at which motion commences is the test

metric. The test couple is the plane surface and the surface that

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and

contacts the plane. For example, if a shoe is placed on a

Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

flooring sample on the inclined plane, the test couple is the

Current edition approved Dec. 15, 2023. Published February 2024. Originally

shoe sole versus the type of flooring. Different shoe bottoms

approved in 2018. Last previous edition approved in 2018 as G219 – 18. DOI:

10.1520/G0219-23.

can be compared for their ability to slip on a particular flooring.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

The materials of construction as well as the nature of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

contacting surfaces determine the breakaway angle. When

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ranking, for ex

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G219 − 18 G219 − 23

Standard Guide for

Determination of Static Coefficient of Friction of Test

1

Couples Using an Inclined Plane Testing Device

This standard is issued under the fixed designation G219; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide is intended to standardize the use of an inclined plane testing device to measure the breakaway friction (static)

coefficient of mating couples that are of such size and shape that they can be made into a rider (one member of the sliding couple)

on a flat surface (the second member of the sliding couple) that can bestatic (breakaway) coefficient of friction between two bodies.

One body is in the form of a small “rider” (few centimeters) and the other a rectangular flat plane (50 mm to 75 mm by 400 mm).

The rider is placed on the plane and the plane is inclined at an angle to produce motion of the rider. The tangent of the angle at

which breakawaymacroscopic motion of the rider occursinitiates on the angled plane is the breakaway or static coefficient of

friction for that sliding couple.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

G40 Terminology Relating to Wear and Erosion

G115 Guide for Measuring and Reporting Friction Coefficients

3. Terminology

3.1 Definitions:

3.1.1 friction force, n—resisting force tangential to the interface between two bodies, when under action of an external force, one

body moves or tends to move relative to the other. G40

3.1.2 static coeffıcient of friction, n—coefficient of friction corresponding to the maximum friction force that shall be overcome

to initiate macroscopic motion between two bodies. G40

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved Aug. 1, 2018Dec. 15, 2023. Published August 2018February 2024. Originally approved in 2018. Last previous edition approved in 2018 as

G219DOI: 10.1520/G0219-18. – 18. DOI: 10.1520/G0219-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G219 − 23

3.1.2.1 Discussion—

Breakaway friction coefficient is synonymous with static coefficient of friction.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 inclined plane device, n—mechanism with a flat horizontal surface to be made of or covered with a material of interest on

which a second member made of a material of interest can be placed and the mechanism is then actuated such that the horizontal

plane is increasingly angled with respect to its original horizontal position until motion is produced on the member placed on the

raising plane.

3.2.1.1 Discussion—

The device allows for the continuous measurement of the angle of inclination and the angle at which motion of the rider

commences.

3.2.2 rider, n—body to be placed on the inclined plane.

4. Summary of Guide

4.1 The technique of placing an object on a flat and horizontal “plane” such as a piece of sheet metal and raising one end of the

sheet until the body placed on the sheet starts to slide has been used for centuries to compare the ease with which different objects

or materials slide on each other. Quantitative comparison of var

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.