ASTM C755-10(2015)

(Practice)Standard Practice for Selection of Water Vapor Retarders for Thermal Insulation

Standard Practice for Selection of Water Vapor Retarders for Thermal Insulation

SIGNIFICANCE AND USE

4.1 Experience has shown that uncontrolled water entry into thermal insulation is the most serious factor causing impaired performance. Water entry into an insulation system may be through diffusion of water vapor, air leakage carrying water vapor, and leakage of surface water. Application specifications for insulation systems that operate below ambient dew-point temperatures should include an adequate vapor retarder system. This may be separate and distinct from the insulation system or may be an integral part of it. For selection of adequate retarder systems to control vapor diffusion, it is necessary to establish acceptable practices and standards.

4.2 Vapor Retarder Function—Water entry into an insulation system may be through diffusion of water vapor, air leakage carrying water vapor, and leakage of surface water. The primary function of a vapor retarder is to control movement of diffusing water vapor into or through a permeable insulation system. The vapor retarder system alone is seldom intended to prevent either entry of surface water or air leakage, but it may be considered as a second line of defense.

4.3 Vapor Retarder Performance—Design choice of retarders will be affected by thickness of retarder materials, substrate to which applied, the number of joints, available length and width of sheet materials, useful life of the system, and inspection procedures. Each of these factors will have an effect on the retarder system performance and each must be considered and evaluated by the designer.

4.3.1 Although this practice properly places major emphasis on selecting the best vapor retarders, it must be recognized that faulty installation techniques can impair vapor retarder performance. The effectiveness of installation or application techniques in obtaining design water vapor transmission (WVT) performance must be considered in the selection of retarder materials.

4.3.2 As an example of the evaluation required, it may be impractical to specify a...

SCOPE

1.1 This practice outlines factors to be considered, describes design principles and procedures for water vapor retarder selection, and defines water vapor transmission values appropriate for established criteria. It is intended for the guidance of design engineers in preparing vapor retarder application specifications for control of water vapor flow through thermal insulation. It covers commercial and residential building construction and industrial applications in the service temperature range from −40 to +150°F (−40 to +66°C). Emphasis is placed on the control of moisture penetration by choice of the most suitable components of the system.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C755 − 10 (Reapproved 2015)

Standard Practice for

Selection of Water Vapor Retarders for Thermal Insulation

This standard is issued under the fixed designation C755; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 Thispracticeoutlinesfactorstobeconsidered,describes 3.1 For definitions of terms used in this practice, refer to

design principles and procedures for water vapor retarder Terminology C168.

selection, and defines water vapor transmission values appro-

4. Significance and Use

priate for established criteria. It is intended for the guidance of

design engineers in preparing vapor retarder application speci-

4.1 Experiencehasshownthatuncontrolledwaterentryinto

fications for control of water vapor flow through thermal

thermal insulation is the most serious factor causing impaired

insulation. It covers commercial and residential building con-

performance. Water entry into an insulation system may be

struction and industrial applications in the service temperature

through diffusion of water vapor, air leakage carrying water

range from−40 to+150°F (−40 to+66°C). Emphasis is placed

vapor, and leakage of surface water.Application specifications

on the control of moisture penetration by choice of the most

for insulation systems that operate below ambient dew-point

suitable components of the system.

temperatures should include an adequate vapor retarder sys-

tem. This may be separate and distinct from the insulation

1.2 The values stated in inch-pound units are to be regarded

system or may be an integral part of it. For selection of

as standard. The values given in parentheses are mathematical

adequate retarder systems to control vapor diffusion, it is

conversions to SI units that are provided for information only

necessary to establish acceptable practices and standards.

and are not considered standard.

1.3 This standard does not purport to address all of the 4.2 Vapor Retarder Function—Water entry into an insula-

safety concerns, if any, associated with its use. It is the tion system may be through diffusion of water vapor, air

responsibility of the user of this standard to establish appro- leakage carrying water vapor, and leakage of surface water.

priate safety and health practices and determine the applica- The primary function of a vapor retarder is to control move-

bility of regulatory limitations prior to use. ment of diffusing water vapor into or through a permeable

insulation system. The vapor retarder system alone is seldom

2. Referenced Documents

intendedtopreventeitherentryofsurfacewaterorairleakage,

but it may be considered as a second line of defense.

2.1 ASTM Standards:

C168Terminology Relating to Thermal Insulation

4.3 Vapor Retarder Performance—Design choice of retard-

C647Guide to Properties and Tests of Mastics and Coating

erswillbeaffectedbythicknessofretardermaterials,substrate

Finishes for Thermal Insulation

to which applied, the number of joints, available length and

C921Practice for Determining the Properties of Jacketing

width of sheet materials, useful life of the system, and

Materials for Thermal Insulation

inspectionprocedures.Eachofthesefactorswillhaveaneffect

C1136Specification for Flexible, Low Permeance Vapor

on the retarder system performance and each must be consid-

Retarders for Thermal Insulation

ered and evaluated by the designer.

E96/E96MTest Methods for Water Vapor Transmission of

4.3.1 Althoughthispracticeproperlyplacesmajoremphasis

Materials

onselectingthebestvaporretarders,itmustberecognizedthat

faulty installation techniques can impair vapor retarder perfor-

mance. The effectiveness of installation or application tech-

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

niques in obtaining design water vapor transmission (WVT)

Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation

performance must be considered in the selection of retarder

Finishes and Moisture.

materials.

Current edition approved Sept. 1, 2015. Published October 2015. Originally

ɛ1

4.3.2 As an example of the evaluation required, it may be

approved in 1973. Last previous edition approved in 2010 as C755–10 . DOI:

10.1520/C0755-10R15.

impractical to specify a lower “as installed” value, because

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

difficultiesoffieldapplicationoftenwillpreclude“asinstalled”

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

attainment of the inherent WVT values of the vapor retarder

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. materials used. The designer could approach this requirement

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C755 − 10 (2015)

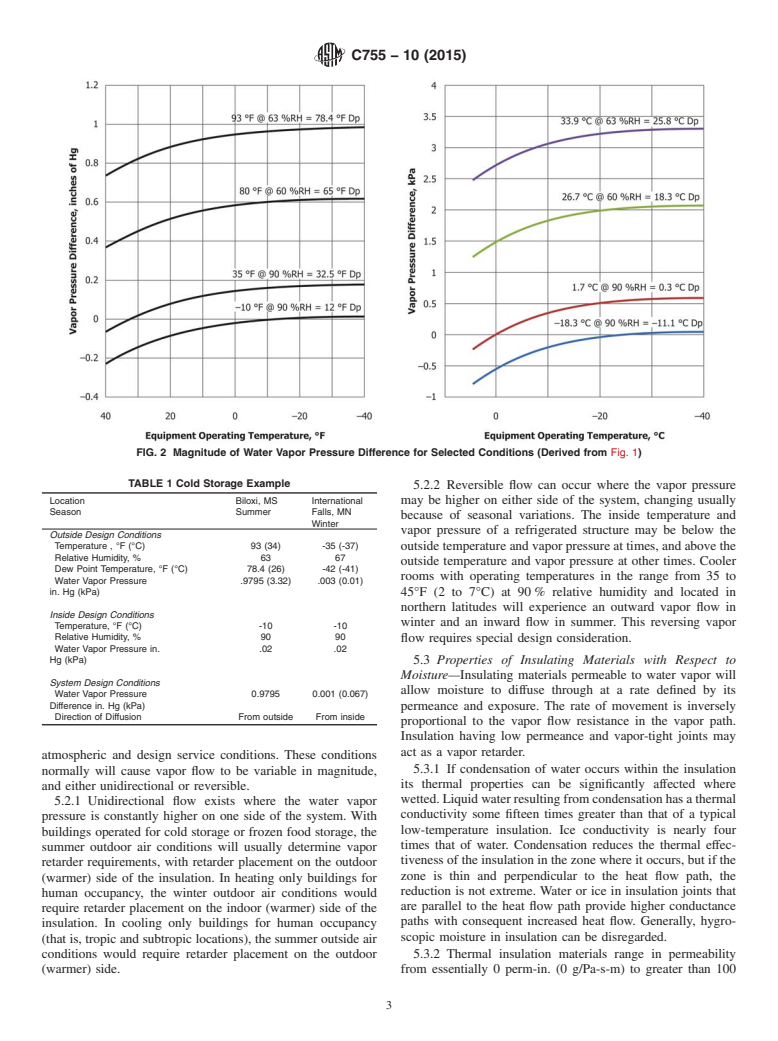

FIG. 1 Dew Point (Dp) Relation to Water Vapor Pressure

by selecting a membrane retarder material that has a lower 5.1.1 Fig. 1 shows the variation of dew-point temperature

permeance manufactured in 5-ft (1.5-m) width or a sheet with water vapor pressure.

material 20 ft (6.1 m) wide having a higher permeance. These 5.1.2 Fig. 2 illustrates the magnitude of water vapor pres-

alternatives may be approximately equivalent on an installed sure differences for four ambient air conditions and cold-side

basis since the wider material has fewer seams and joints. operating temperatures between +40 and −40°F (+4.4

4.3.3 Foranotherexample,whenselectingmasticorcoating and−40°C).

retarder materials, the choice of a product having a permeance 5.1.3 At a stated temperature the water vapor pressure is

value somewhat higher than the lowest obtainable might be proportional to relative humidity but at a stated relative

justified on the basis of its easier application techniques, thus humidity the vapor pressure is not proportional to temperature.

ensuring “as installed” system attainment of the specified 5.1.4 Outdoor design conditions vary greatly depending

permeance. The permeance of the substrate and its effects on upongeographiclocationandseasonandcanhaveasubstantial

theapplicationoftheretardermaterialmustalsobeconsidered impactonsystemdesignrequirements.Itisthereforenecessary

in this case. to calculate the actual conditions rather than rely on estimates.

As an example, consider the cold-storage application shown in

5. Factors to Be Considered in Choosing Water Vapor Table 1. The water vapor pressure difference for the facility

Retarders

located in Biloxi, MS is 0.96 in. Hg (3.25 kPa) as compared to

a 0.001 in. Hg (3 Pa) pressure difference if the facility was

5.1 Water Vapor Pressure Difference is the difference in the

located in International Falls, MN. In the United States the

pressure exerted on each side of an insulation system or

design dew point temperature seldom exceeds 75°F (24°C)

insulated structure that is due to the temperature and moisture

(1).

content of the air on each side of the insulated system or

5.1.5 The expected vapor pressure difference is a very

structure.Thispressuredifferencedeterminesthedirectionand

importantfactorthatmustbebasedonrealisticdesigndata(not

magnitude of the driving force for the diffusion of the water

estimated) to determine vapor retarder requirements.

vapor through the insulated system or structure. In general, for

a given permeable structure, the greater the water vapor

5.2 Service Conditions—The direction and magnitude of

pressure difference, the greater the rate of diffusion. Water water vapor flow are established by the range of ambient

vapor pressure differences for specific conditions can be

calculated by numerical methods or from psychrometric tables

The boldface numbers in parentheses refer to the list of references at the end of

showing thermodynamic properties of water at saturation. this practice.

C755 − 10 (2015)

FIG. 2 Magnitude of Water Vapor Pressure Difference for Selected Conditions (Derived from Fig. 1)

TABLE 1 Cold Storage Example

5.2.2 Reversible flow can occur where the vapor pressure

Location Biloxi, MS International may be higher on either side of the system, changing usually

Season Summer Falls, MN

because of seasonal variations. The inside temperature and

Winter

vapor pressure of a refrigerated structure may be below the

Outside Design Conditions

Temperature , °F (°C) 93 (34) -35 (-37) outsidetemperatureandvaporpressureattimes,andabovethe

Relative Humidity, % 63 67

outside temperature and vapor pressure at other times. Cooler

Dew Point Temperature, °F (°C) 78.4 (26) -42 (-41)

rooms with operating temperatures in the range from 35 to

Water Vapor Pressure .9795 (3.32) .003 (0.01)

in. Hg (kPa)

45°F (2 to 7°C) at 90% relative humidity and located in

northern latitudes will experience an outward vapor flow in

Inside Design Conditions

winter and an inward flow in summer. This reversing vapor

Temperature, °F (°C) -10 -10

Relative Humidity, % 90 90

flow requires special design consideration.

Water Vapor Pressure in. .02 .02

Hg (kPa)

5.3 Properties of Insulating Materials with Respect to

Moisture—Insulating materials permeable to water vapor will

System Design Conditions

allow moisture to diffuse through at a rate defined by its

Water Vapor Pressure 0.9795 0.001 (0.067)

Difference in. Hg (kPa) permeance and exposure. The rate of movement is inversely

Direction of Diffusion From outside From inside

proportional to the vapor flow resistance in the vapor path.

Insulation having low permeance and vapor-tight joints may

act as a vapor retarder.

atmospheric and design service conditions. These conditions

5.3.1 If condensation of water occurs within the insulation

normally will cause vapor flow to be variable in magnitude,

its thermal properties can be significantly affected where

and either unidirectional or reversible.

wetted.Liquidwaterresultingfromcondensationhasathermal

5.2.1 Unidirectional flow exists where the water vapor

conductivity some fifteen times greater than that of a typical

pressure is constantly higher on one side of the system. With

low-temperature insulation. Ice conductivity is nearly four

buildings operated for cold storage or frozen food storage, the

times that of water. Condensation reduces the thermal effec-

summer outdoor air conditions will usually determine vapor

tiveness of the insulation in the zone where it occurs, but if the

retarder requirements, with retarder placement on the outdoor

zone is thin and perpendicular to the heat flow path, the

(warmer) side of the insulation. In heating only buildings for

reduction is not extreme. Water or ice in insulation joints that

human occupancy, the winter outdoor air conditions would

are parallel to the heat flow path provide higher conductance

require retarder placement on the indoor (warmer) side of the

paths with consequent increased heat flow. Generally, hygro-

insulation. In cooling only buildings for human occupancy

scopic moisture in insulation can be disregarded.

(that is, tropic and subtropic locations), the summer outside air

conditions would require retarder placement on the outdoor 5.3.2 Thermal insulation materials range in permeability

(warmer) side. from essentially 0 perm-in. (0 g/Pa-s-m) to greater than 100

C755 − 10 (2015)

-7

perm-in. (1.45 × 10 g/Pa-s-m) Because insulation is supplied 5.5.4 Inanyinsulationsystemwherethereisapossibilityof

inpiecesofvarioussizeandthickness,vapordiffusionthrough condensationduetoairleakage,thedesignershouldattemptto

joints must be considered in the permeance of the materials as ensure that there is a continuous unbroken air barrier on the

applied. The effect of temperature changes on dimensions and warm side of the insulation. Often this can be provided by the

vapor retarder system, but sometimes it can best be provided

other physical characteristics of all materials of the assembly

mustbeconsideredasitrelatestovaporflowintothejointsand by a separate element. Particular attention should be given to

providing airtightness at discontinuities in the system, such as

into the insulation.

at intersections of walls, roofs and floors, at the boundaries of

5.4 Properties of Boundary or Finish Materials at the Cold

structural elements forming part of an enclosure, and around

Side of Insulation—When a vapor pressure gradient exists the

windowandserviceopenings.Theinsulationsystemshouldbe

lower vapor pressure value usually will be on the lower

designedsothatitispracticaltoobtainacontinuousairbarrier

temperature side of the system, but not always. (There are few

undertheconditionsthatwillprevailonthejobsite,keepingin

exceptions,butthesemustbeconsideredasspecialcases.)The

mind the problem of ensuring good workmanship.

finish on the cold side of the insulation-enclosing refrigerated

5.5.5 Recirculationofairbetweenspacesonthecoldsideof

spacesshouldhavehighpermeancerelativetothatofthewarm

the insulation and a region of low vapor pressure (usually on

side construction, so that water vapor penetrating the system

the cold side of the insulation system) can be utilized advan-

can flow through the insulation system without condensing.

tageously to maintain continuity of vapor flow, whether due to

This moisture should be free to move to the refrigerating

diffusion or air leakage, and thus to avoid condensation. This

surfaceswhereitisremovedascondensate.Whenthecoldside

will often be the only practical approach to the control of

permeance is zero, as with insulated cold piping, water vapor

condensation and maintenance of dry conditions within the

that enters the insulation system usually will condense within

system. In thus venting the insulation system, whether by

the assembly and remain as an accumulation of water, frost, or

natural or mechanical means, care must be taken to avoid

ice.

adverse thermal effects.

5.5 Effect of Air Leakage—Water vapor can be transported

5.6 Other Factors—Other physical properties of retarder

readily as a component of air movement into and out of an

material, insulations, and structures that are not within the

air-permeable insulation system. This fact must be taken into

scope of this practice may affect choice of barrier. These

account in the design and construction of any system in which

include such properties as combustibility, compatibility of

moisture control is a requirement. The quantity of water vapor

systemcomponents,damageresistance,andsurfaceroughness.

that can be transported by air leakage through cracks or

air-permeable construction can eas

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C755 − 10 C755 − 10 (Reapproved 2015)

Standard Practice for

Selection of Water Vapor Retarders for Thermal Insulation

This standard is issued under the fixed designation C755; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Table 2 and Table X1.1 were editorially corrected in September 2015.

1. Scope

1.1 This practice outlines factors to be considered, describes design principles and procedures for water vapor retarder selection,

and defines water vapor transmission values appropriate for established criteria. It is intended for the guidance of design engineers

in preparing vapor retarder application specifications for control of water vapor flow through thermal insulation. It covers

commercial and residential building construction and industrial applications in the service temperature range from −40 to +150°F

(−40 to +66°C). Emphasis is placed on the control of moisture penetration by choice of the most suitable components of the

system.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C647 Guide to Properties and Tests of Mastics and Coating Finishes for Thermal Insulation

C921 Practice for Determining the Properties of Jacketing Materials for Thermal Insulation

C1136 Specification for Flexible, Low Permeance Vapor Retarders for Thermal Insulation

E96/E96M Test Methods for Water Vapor Transmission of Materials

3. Terminology

3.1 For definitions of terms used in this practice, refer to Terminology C168.

4. Significance and Use

4.1 Experience has shown that uncontrolled water entry into thermal insulation is the most serious factor causing impaired

performance. Water entry into an insulation system may be through diffusion of water vapor, air leakage carrying water vapor, and

leakage of surface water. Application specifications for insulation systems that operate below ambient dew-point temperatures

should include an adequate vapor retarder system. This may be separate and distinct from the insulation system or may be an

integral part of it. For selection of adequate retarder systems to control vapor diffusion, it is necessary to establish acceptable

practices and standards.

4.2 Vapor Retarder Function—Water entry into an insulation system may be through diffusion of water vapor, air leakage

carrying water vapor, and leakage of surface water. The primary function of a vapor retarder is to control movement of diffusing

water vapor into or through a permeable insulation system. The vapor retarder system alone is seldom intended to prevent either

entry of surface water or air leakage, but it may be considered as a second line of defense.

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation Finishes

and Moisture.

Current edition approved Oct. 1, 2010Sept. 1, 2015. Published November 2010October 2015. Originally approved in 1973. Last previous edition approved in 20032010

ɛ1

as C755 – 03.C755 – 10 . DOI: 10.1520/C0755-10E01.10.1520/C0755-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C755 − 10 (2015)

4.3 Vapor Retarder Performance—Design choice of retarders will be affected by thickness of retarder materials, substrate to

which applied, the number of joints, available length and width of sheet materials, useful life of the system, and inspection

procedures. Each of these factors will have an effect on the retarder system performance and each must be considered and evaluated

by the designer.

4.3.1 Although this practice properly places major emphasis on selecting the best vapor retarders, it must be recognized that

faulty installation techniques can impair vapor retarder performance. The effectiveness of installation or application techniques in

obtaining design water vapor transmission (WVT) performance must be considered in the selection of retarder materials.

4.3.2 As an example of the evaluation required, it may be impractical to specify a lower “as installed” value, because difficulties

of field application often will preclude “as installed” attainment of the inherent WVT values of the vapor retarder materials used.

The designer could approach this requirement by selecting a membrane retarder material that has a lower permeance manufactured

in 5-ft (1.5-m) width or a sheet material 20 ft (6.1 m) wide having a higher permeance. These alternatives may be approximately

equivalent on an installed basis since the wider material has fewer seams and joints.

4.3.3 For another example, when selecting mastic or coating retarder materials, the choice of a product having a permeance

value somewhat higher than the lowest obtainable might be justified on the basis of its easier application techniques, thus ensuring

“as installed” system attainment of the specified permeance. The permeance of the substrate and its effects on the application of

the retarder material must also be considered in this case.

5. Factors to Be Considered in Choosing Water Vapor Retarders

5.1 Water Vapor Pressure Difference is the difference in the pressure exerted on each side of an insulation system or insulated

structure that is due to the temperature and moisture content of the air on each side of the insulated system or structure. This

pressure difference determines the direction and magnitude of the driving force for the diffusion of the water vapor through the

insulated system or structure. In general, for a given permeable structure, the greater the water vapor pressure difference, the greater

the rate of diffusion. Water vapor pressure differences for specific conditions can be calculated by numerical methods or from

psychrometric tables showing thermodynamic properties of water at saturation.

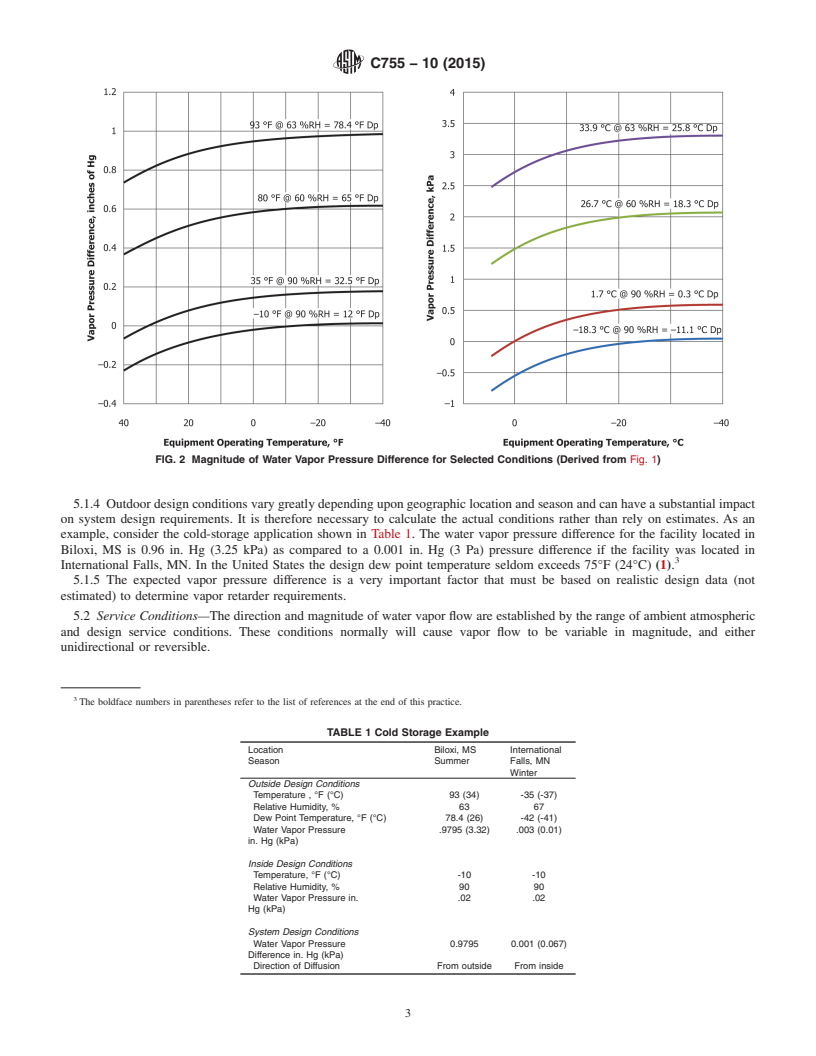

5.1.1 Fig. 1 shows the variation of dew-point temperature with water vapor pressure.

5.1.2 Fig. 2 illustrates the magnitude of water vapor pressure differences for four ambient air conditions and cold-side operating

temperatures between +40 and −40°F (+4.4 and −40°C).

5.1.3 At a stated temperature the water vapor pressure is proportional to relative humidity but at a stated relative humidity the

vapor pressure is not proportional to temperature.

FIG. 1 Dew Point (Dp) Relation to Water Vapor Pressure

C755 − 10 (2015)

FIG. 2 Magnitude of Water Vapor Pressure Difference for Selected Conditions (Derived from Fig. 1)

5.1.4 Outdoor design conditions vary greatly depending upon geographic location and season and can have a substantial impact

on system design requirements. It is therefore necessary to calculate the actual conditions rather than rely on estimates. As an

example, consider the cold-storage application shown in Table 1. The water vapor pressure difference for the facility located in

Biloxi, MS is 0.96 in. Hg (3.25 kPa) as compared to a 0.001 in. Hg (3 Pa) pressure difference if the facility was located in

International Falls, MN. In the United States the design dew point temperature seldom exceeds 75°F (24°C) (1).

5.1.5 The expected vapor pressure difference is a very important factor that must be based on realistic design data (not

estimated) to determine vapor retarder requirements.

5.2 Service Conditions—The direction and magnitude of water vapor flow are established by the range of ambient atmospheric

and design service conditions. These conditions normally will cause vapor flow to be variable in magnitude, and either

unidirectional or reversible.

The boldface numbers in parentheses refer to the list of references at the end of this practice.

TABLE 1 Cold Storage Example

Location Biloxi, MS International

Season Summer Falls, MN

Winter

Outside Design Conditions

Temperature , °F (°C) 93 (34) -35 (-37)

Relative Humidity, % 63 67

Dew Point Temperature, °F (°C) 78.4 (26) -42 (-41)

Water Vapor Pressure .9795 (3.32) .003 (0.01)

in. Hg (kPa)

Inside Design Conditions

Temperature, °F (°C) -10 -10

Relative Humidity, % 90 90

Water Vapor Pressure in. .02 .02

Hg (kPa)

System Design Conditions

Water Vapor Pressure 0.9795 0.001 (0.067)

Difference in. Hg (kPa)

Direction of Diffusion From outside From inside

C755 − 10 (2015)

5.2.1 Unidirectional flow exists where the water vapor pressure is constantly higher on one side of the system. With buildings

operated for cold storage or frozen food storage, the summer outdoor air conditions will usually determine vapor retarder

requirements, with retarder placement on the outdoor (warmer) side of the insulation. In heating only buildings for human

occupancy, the winter outdoor air conditions would require retarder placement on the indoor (warmer) side of the insulation. In

cooling only buildings for human occupancy (that is, tropic and subtropic locations), the summer outside air conditions would

require retarder placement on the outdoor (warmer) side.

5.2.2 Reversible flow can occur where the vapor pressure may be higher on either side of the system, changing usually because

of seasonal variations. The inside temperature and vapor pressure of a refrigerated structure may be below the outside temperature

and vapor pressure at times, and above the outside temperature and vapor pressure at other times. Cooler rooms with operating

temperatures in the range from 35 to 45°F (2 to 7°C) at 90 % relative humidity and located in northern latitudes will experience

an outward vapor flow in winter and an inward flow in summer. This reversing vapor flow requires special design consideration.

5.3 Properties of Insulating Materials with Respect to Moisture—Insulating materials permeable to water vapor will allow

moisture to diffuse through at a rate defined by its permeance and exposure. The rate of movement is inversely proportional to the

vapor flow resistance in the vapor path. Insulation having low permeance and vapor-tight joints may act as a vapor retarder.

5.3.1 If condensation of water occurs within the insulation its thermal properties can be significantly affected where wetted.

Liquid water resulting from condensation has a thermal conductivity some fifteen times greater than that of a typical

low-temperature insulation. Ice conductivity is nearly four times that of water. Condensation reduces the thermal effectiveness of

the insulation in the zone where it occurs, but if the zone is thin and perpendicular to the heat flow path, the reduction is not

extreme. Water or ice in insulation joints that are parallel to the heat flow path provide higher conductance paths with consequent

increased heat flow. Generally, hygroscopic moisture in insulation can be disregarded.

5.3.2 Thermal insulation materials range in permeability from essentially 0 perm-in. (0 g/Pa-s-m) to greater than 100 perm-in.

-7

(1.45 × 10 g/Pa-s-m) Because insulation is supplied in pieces of various size and thickness, vapor diffusion through joints must

be considered in the permeance of the materials as applied. The effect of temperature changes on dimensions and other physical

characteristics of all materials of the assembly must be considered as it relates to vapor flow into the joints and into the insulation.

5.4 Properties of Boundary or Finish Materials at the Cold Side of Insulation—When a vapor pressure gradient exists the lower

vapor pressure value usually will be on the lower temperature side of the system, but not always. (There are few exceptions, but

these must be considered as special cases.) The finish on the cold side of the insulation-enclosing refrigerated spaces should have

high permeance relative to that of the warm side construction, so that water vapor penetrating the system can flow through the

insulation system without condensing. This moisture should be free to move to the refrigerating surfaces where it is removed as

condensate. When the cold side permeance is zero, as with insulated cold piping, water vapor that enters the insulation system

usually will condense within the assembly and remain as an accumulation of water, frost, or ice.

5.5 Effect of Air Leakage—Water vapor can be transported readily as a component of air movement into and out of an

air-permeable insulation system. This fact must be taken into account in the design and construction of any system in which

moisture control is a requirement. The quantity of water vapor that can be transported by air leakage through cracks or

air-permeable construction can easily be several times greater than that which occurs by vapor diffusion alone.

5.5.1 Air movement occurs as a result of air pressure differences. In insulated structures these may be due to wind action,

buoyancy forces due to temperature difference between interconnected spaces, volume changes due to fluctuations in temperature

and barometric pressure, and the operation of mechanical air supply or exhaust systems. Air leakage occurs through openings or

through air-permeable construction across which the air pressure differences occur. Water vapor in air flowing from a warm

humidified region to a colder zone in an insulation system will condense in the same way as water vapor moving only by diffusion.

5.5.2 If there is no opportunity for dilution with air at lower vapor pressure along the flow path, there will be no vapor pressure

gradient. Condensation may occur when the air stream passes through a region in the insulation system where the temperature is

equal to or lower than the dew point of the warm regi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.