ASTM F51/F51M-00(2007)e1

(Test Method)Standard Test Method for Sizing and Counting Particulate Contaminant In and On Clean Room Garments

Standard Test Method for Sizing and Counting Particulate Contaminant In and On Clean Room Garments

SIGNIFICANCE AND USE

5.1 The test method for particulate sizing and numbers on garments is nondestructive and may be used to evaluate the contamination levels of fibers and particles on and in clean room garments. The test may be used for evaluating the cleanliness levels of new or newly cleaned garments. It also may be used to evaluate the extent of fiber and particulate contamination on garments that have been worn, if necessary. For this application, it is necessary to sample representative areas of the garment fabric.

SCOPE

1.1 This test method covers the determination of detachable particulate contaminant 5 μm or larger, in and on the fabric of clean room garments.

1.2 This test method does not apply to nonporous fabrics such as Tyvek (trademarked) or Gortex (trademarked). It only applies to fabrics that are porous such as cotton or polyester.

1.3 This test method provides not only the traditional optical microscopic analysis but also a size distribution and surface obscuration analysis for particles on a fine-textured membrane filter or in a tape lift sample. It utilizes transmitted illumination to render all particles darker than the background for gray level detection. Particles collected on opaque plates must be transferred to a suitable membrane filter.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F51/F51M − 00(Reapproved 2007)

Standard Test Method for

Sizing and Counting Particulate Contaminant In and On

Clean Room Garments

This standard is issued under the fixed designation F51/F51M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in March 2013.

1. Scope E1216Practice for Sampling for Particulate Contamination

by Tape Lift

1.1 Thistestmethodcoversthedeterminationofdetachable

F25/F25MTest Method for Sizing and Counting Airborne

particulate contaminant 5 µm or larger, in and on the fabric of

ParticulateContaminationinCleanroomsandOtherDust-

clean room garments.

Controlled Areas

1.2 This test method does not apply to nonporous fabrics

2.2 Institute of Environmental Sciences and Technology

such as Tyvek (trademarked) or Gortex (trademarked). It only

(IEST) Document:

applies to fabrics that are porous such as cotton or polyester.

IEST-RP-CC003.2, Garment System Considerations for

1.3 Thistestmethodprovidesnotonlythetraditionaloptical

Cleanrooms and Other Controlled Environments

microscopic analysis but also a size distribution and surface

obscuration analysis for particles on a fine-textured membrane

3. Terminology

filterorinatapeliftsample.Itutilizestransmittedillumination

3.1 Definitions:

torenderallparticlesdarkerthanthebackgroundforgraylevel

3.1.1 fiber, n—particle longer than 100 µm and with a

detection. Particles collected on opaque plates must be trans-

length-to-width ratio exceeding 10:1.

ferred to a suitable membrane filter.

-6

3.1.2 micrometre (µm), n—SIunitoflengthwhichis10 of

1.4 The values stated in either SI units or inch-pound units

a metre or approximately 0.00004 in.

are to be regarded separately as standard. The values stated in

3.1.3 particle size (L) (µm)—majorprojecteddimensionofa

each system may not be exact equivalents; therefore, each

particle.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

with the standard. 4. Summary of Test Method

1.5 This standard may involve hazardous materials,

4.1 Filtered air is drawn through five designated 0.01-m

2 2

operations, and equipment. This standard does not purport to

[1.5-in. or approximately 0.01-ft ] areas of a single thickness

address all of the safety concerns, if any, associated with its

of the garment fabric at a rate of 14 L/min [0.5 cfm] for a

use. It is the responsibility of the user of this standard to

period of 1 min for each area.

establish appropriate safety and health practices and deter-

4.2 The air drawn through the garment subsequently passes

mine the applicability of regulatory limitations prior to use.

through a membrane filter disk, impinging the entrained

particles upon the filter surface.

2. Referenced Documents

4.3 The filter disk is then examined microscopically for

2.1 ASTM Standards:

particles removed from the garment.

4.4 For particles larger than 5 µm, use optical analysis. For

particles smaller than 5 µm, use automated image analysis.

This test method is under the jurisdiction of ASTM Committee E21 on Space

Simulation andApplications of SpaceTechnology and is the direct responsibility of

4.5 Cleaning and counting techniques are in accordance

Subcommittee E21.05 on Contamination.

with those established in Section 10.

Current edition approved April 1, 2007. Published April 2007. Originally

ε1

approvedin1965.Lastpreviouseditionapprovedin2002asF51-00(2002) .DOI:

10.1520/F0051_F0051M-00R07E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Institute of Environmental Sciences and Technology (IEST),

Standards volume information, refer to the standard’s Document Summary page on Arlington Place One, 2340 S.Arlington Heights Rd., Suite 100,Arlington Heights,

the ASTM website. IL 60005-4516, http://www.iest.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F51/F51M − 00 (2007)

FIG. 1 Filter Assembly

FIG. 2 Adapter

5. Significance and Use

5.1 The test method for particulate sizing and numbers on

6.5 Binocular Microscope with ocular-objective combina-

garments is nondestructive and may be used to evaluate the

contamination levels of fibers and particles on and in clean tionstoobtain40to45×and90to150×magnifications.Latter

objective shall have a numerical aperture of 0.15 min.

room garments. The test may be used for evaluating the

cleanliness levels of new or newly cleaned garments. It also

6.6 Programmable Image Analyzer, a Computer-Driven Mi-

may be used to evaluate the extent of fiber and particulate

croscope Which Counts and Sizes Particles With Automated

contamination on garments that have been worn, if necessary.

Stage and Automated Focus Interface:

For this application, it is necessary to sample representative

6.6.1 Microscope, with a large glass platform automatic

areas of the garment fabric.

stage and automated focus.

6.6.2 Objectives and Projection Lenses, to generate a pixel

6. Apparatus

dimension of about 5 µm or less.

6.1 Filter Assembly and Adapter, see Fig. 1 and Fig. 2.

6.7 Forceps, with unserrated tips.

6.1.1 Filter Holder, aerosol open type having an effective

filter area of 960 6 25 mm .

6.8 Normal Counter, (2 gang) or equivalent. See Note 1.

6.2 Vacuum Pump or Aspirator, capable of operating at a

NOTE 1—The Veeder Root counter has been found satisfactory for this

pressure of 7 kPa [500 torr] with a flow rate of 14 L/min [0.5

purpose.

cfm].

6.9 Microscope Lamp, 6 V, 5 A high intensity.

6.3 Flowmeter or Orifice, calibrated and having a capacity

6.10 Stage Micrometer, standard 0.01- to 0.1-mm scale.

inexcessof14L/min[0.5cfm],oralimitingorificecalibrated

6.11 Ocular Micrometer Scale, 5-mm linear scale with 100

withthepump,filterholder,andfilterusedforthistestmethod

divisions.

at a flow rate of 14 6 0.5 L/min [0.50 6 0.02 cfm]. Ensure,

visually, that the orifice is free of obstructing matter before 6.12 Standard Counting Specimens.

each test.

7. Sampling Requirements

6.4 Membrane Filters:

7.1 The sample shall be collected by drawing air filtered to

6.4.1 Black, 0.80-µm pore size, 47-mm diameter with

5 µm through the test garment, impinging the garment-borne

3.08-mm imprinted grid for fabric particles.

particles on the membrane filter. The filter surface mounted in

6.4.2 White, 0.80-µm pore size, 47-mm diameter without

the open-type aerosol filter holder shall be placed on the outer

imprinted grid for fabric particles and automated image ana-

surface of the test garment. The garment is firmly clamped to

lyzer.

the filter holder by means of the air-filter adapter. During

6.4.3 White,5.0-µmporesize,47-mmdiameter(airprefilter

sampling, the garment shall be hung or carefully positioned to

used with the filters in 6.4.1 and 6.4.2).

minimize extraneous contamination.

6.4.4 Plastic Petri Slides with Covers , plastic petri dishes,

60-mm diameter or glass microscope slides, 50 by 75 mm.

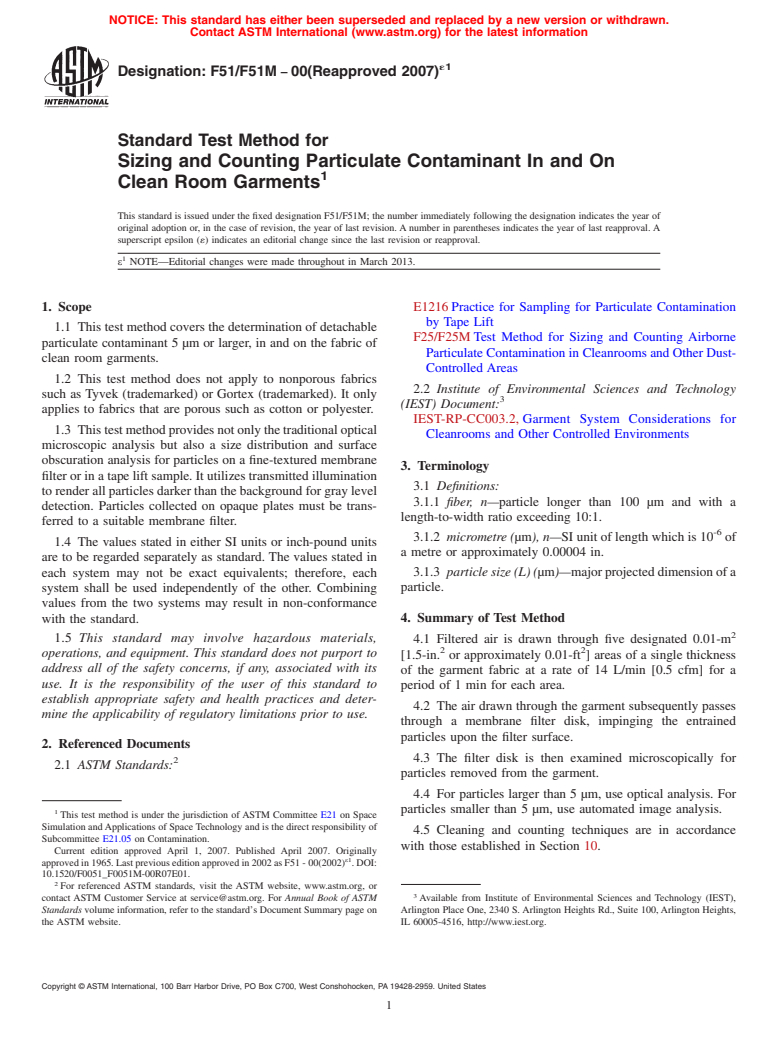

7.2 The standard sample of this test method is secured with

thepassageof14L[0.5ft ]ofairthroughthetestfabricduring

The sole source of supply of the apparatus (Analyslides) known to the

a 1-min period at each of five sampling areas as shown in Fig.

committee at this time is Gelman Sciences, Ann Arbor, MI. If you are aware of

3. One sampling area is adequate for caps, helmets, towels,

alternative suppliers, please provide this information to ASTM International

wipers,andbootieswithplasticsoles.Twoareasaresuggested

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. for all-fabric booties.

´1

F51/F51M − 00 (2007)

FIG. 3 Clean Room Garment Sampling Locations

7.3 Locations are approximate and may be modified to suit 40 to 50× magnifications through the microscope will reveal

a specific design factor by agreement. low or high background count.

8.7 Make a background count (Note 2) following the

8. Preparation of Apparatus

microscopic methods outlined in this test method, upon any

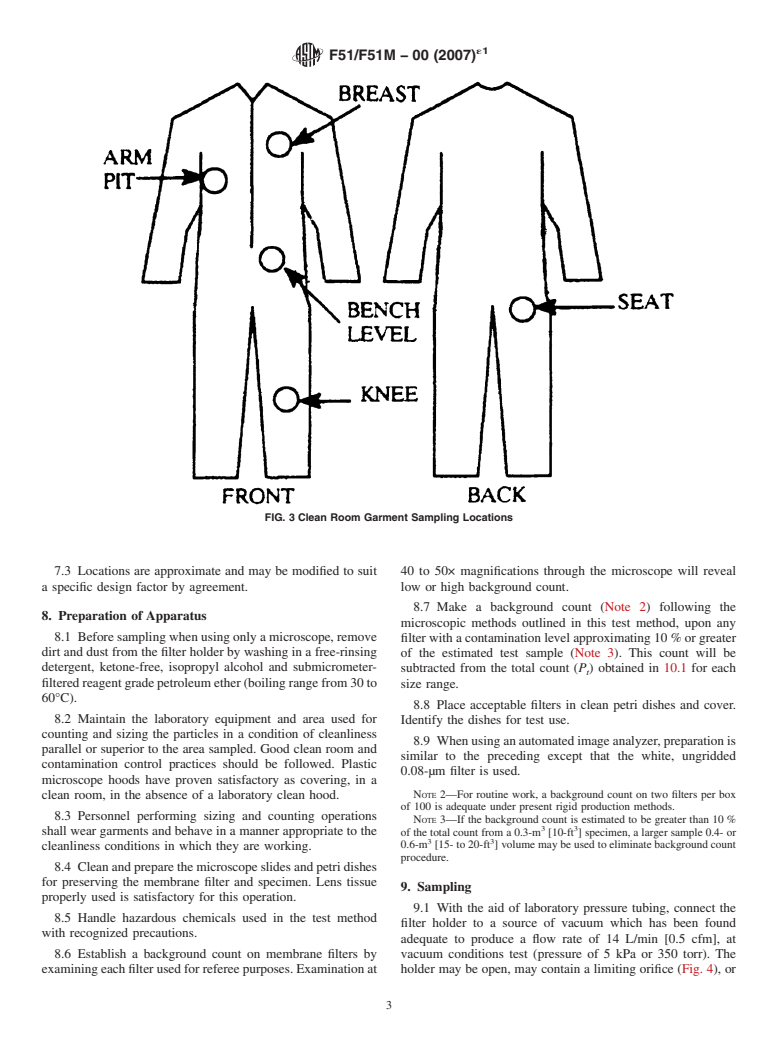

8.1 Beforesamplingwhenusingonlyamicroscope,remove filterwithacontaminationlevelapproximating10%orgreater

dirtanddustfromthefilterholderbywashinginafree-rinsing

of the estimated test sample (Note 3). This count will be

detergent, ketone-free, isopropyl alcohol and submicrometer- subtracted from the total count (P) obtained in 10.1 for each

t

filteredreagentgradepetroleumether(boilingrangefrom30to

size range.

60°C).

8.8 Place acceptable filters in clean petri dishes and cover.

8.2 Maintain the laboratory equipment and area used for

Identify the dishes for test use.

counting and sizing the particles in a condition of cleanliness

8.9 Whenusinganautomatedimageanalyzer,preparationis

parallel or superior to the area sampled. Good clean room and

similar to the preceding except that the white, ungridded

contamination control practices should be followed. Plastic

0.08-µm filter is used.

microscope hoods have proven satisfactory as covering, in a

NOTE 2—For routine work, a background count on two filters per box

clean room, in the absence of a laboratory clean hood.

of 100 is adequate under present rigid production methods.

8.3 Personnel performing sizing and counting operations

NOTE 3—If the background count is estimated to be greater than 10%

3 3

shall wear garments and behave in a manner appropriate to the

of the total count from a 0.3-m [10-ft ] specimen, a larger sample 0.4- or

3 3

0.6-m [15-to20-ft ]volumemaybeusedtoeliminatebackgroundcount

cleanliness conditions in which they are working.

procedure.

8.4 Cleanandpreparethemicroscopeslidesandpetridishes

for preserving the membrane filter and specimen. Lens tissue

9. Sampling

properly used is satisfactory for this operation.

9.1 With the aid of laboratory pressure tubing, connect the

8.5 Handle hazardous chemicals used in the test method

filter holder to a source of vacuum which has been found

with recognized precautions.

adequate to produce a flow rate of 14 L/min [0.5 cfm], at

8.6 Establish a background count on membrane filters by vacuum conditions test (pressure of 5 kPa or 350 torr). The

examiningeachfilterusedforrefereepurposes.Examinationat holder may be open, may contain a limiting orifice (Fig. 4), or

´1

F51/F51M − 00 (2007)

FIG. 5 Placing the Filter on a Typical Screen Support

FIG. 4 Inserting a Typical Orifice

may be connected to the flowmeter. If a flowmeter is used

between the filter holder and vacuum source, correction to the

standard temperature and pressure must be made to determine

actual standard temperature and pressure flow.

9.2 With clean forceps, carefully remove the appropriate

membrane filter from the container and place, with grid side

up, when appropriate, on the screen support of the filter holder

(Fig. 5). Twist the locking ring in place after placing the

taperedadapterinposition.Similarly,placethe5.0-µmairfilter

in the top portion of the adapter by removing the O-ring from

the adapter top, placing a 47-mm white filter on the support

screen and replacing the O-ring. (This filter may be used for

many tests.)

9.3 See IEST-RP-CC003.2 for additional recommendations

on the sampling of garments.

9.4 Whenreadytosample,placetheoutersurfaceofthetest

garment over the tapered (male) adapter. Firmly lock into test

position by placing the air-filter tapered (female) adapter over

FIG. 6 Typical Counting and Sizing Microscope and Illuminator

the test portion of fabric.

(see Test Method F25/F25M)

9.5 Apply vacuum at the predetermined flow rate of 14

L/min [0.5 cfm] for a period of 1 min for each area. Sample

required areas (Fig. 3) by repeating 9.2. 10.3 Remove the petri dish cover, then remove the filter

from the petri dish and place it, with filtering surface up, on a

9.6 Removethefilterfromtheholderwithforcepsandplace

50- by 76-mm [2- by 3-in.] microscope slide. Greasing the

it between the clean microscope slides, in a clean transport

slide lightly with silicone stopcock lubricant before mounting

container(see6.4.4)orinacleanpetridishfortransporttothe

the filter will assist in holding the filter flat in place.

microscope counting area. The membrane must be cleaned

before placing it in the transport container. 10.4 Adjust the external light source to obtain maximum

particle definition with an illumination angle of approximately

10. Microscope Analysis Procedure

45°. High-intensity illumination is a critical requirement.

10.1 Place the ocular micrometer in one eyepiece. Using a

10.5 Useamagnificationofapproximately45×forcounting

stage micrometer, calibrate the measuring eyepiece (ocular

particles 50 µm or larger and approximately 100× for particles

micrometer) for each magnification (Fig. 6). A whipple disk

smaller than 50 µm. Greater magnifications may be advanta-

similarly calibrated is satisfactory for many inplant investiga-

geous for examination to identify particles.

tions.

NOTE 5—Analysis for particles in the 0.5- to 5.0-µm size range may be

10.2 Knowing the subdivisions of the stage micrometer

achieved by using transmitted light techniques, after rendering the white

(top),thedivisionsofthemeasuringeyepiece(bottom)maybe filter transparent by placing the filter on immersion oil of refractive index

1.515. A magnification of at least 500× is required. For transmitted light

sized from it (Fig. 7).

microscopy, a white filter must be used (instead of black filter) since only

NOTE4—Example:Stagethemicrometer100µmpermajordivision,10 the white filter can be rendered transparent with immersion oil. If a

µm per minor division: 100 divisions of the measuring eyepiece subtend smaller pore size filter is used, the flowmeter used and the limiting orifice

1050 µm, one division of the measuring eyepiece = 10.5 µm. will require calibration with the filter holder and filter in place.

´1

F51/F51M − 00 (2007)

FIG. 7 Calibrating the Measuring Eyepiece

10.6 Particles should be counted and tabulated in two size counting,countingalloftheparticlesinthe5-to50-µmrange,

ranges: particles greater than 50 µm and particles 5 to 50 µm. andthensimilarlycountingadditionalunitareasinaccordance

Particlessmallerthan5µmarenottobecountedbythemanual with the counting plan of Fig. 8 until the statistical require-

counting method. The size of particles is determined by its ments are met.

greater projected dimension. Fibers are counted as particles

10.9.2 After establi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.