ASTM E10-00

(Test Method)Standard Test Method for Brinell Hardness of Metallic Materials

Standard Test Method for Brinell Hardness of Metallic Materials

SCOPE

1.1 This test method (Test Method A) covers the determination of the Brinell hardness of metallic materials, including methods for the verification of Brinell hardness testing machines (Test Method B) and the calibration of standardized hardness test blocks (Test Method C).

1.2 The values stated in SI units are to be regarded as the standard.

Note 1--In common terminology, the equivalent force in kgf is substituted for N.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 10 – 00 American Association State Highway

and Transportation Officials Standard

AASHTO No.: T70–86

Standard Test Method for

Brinell Hardness of Metallic Materials

This standard is issued under the fixed designation E 10; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Symbols and Designations

1. Scope

1 1

1.1 This test method (Part A) covers the determination of

NOTE 1— Constant 5 5 5 0.102

g 9.806 65

n

the Brinell hardness of metallic materials, including methods

Symbol Designation

for the verification of Brinell hardness testing machines (Part

D Diameter of the ball, mm

B) and the calibration of standardized hardness test blocks

F Test force, N

(Part C).

d Mean diameter of the indentation, mm

1.2 The values stated in SI units are to be regarded as the

h Depth of the indentation, mm

2 2

standard. D 2 D 2 d

=

HBS or Brinell hardness

NOTE 1—In common terminology, the equivalent force in kgf is

HBW

substituted for Newtons.

Test force

5 Constant 3

Surface area of indentation

1.3 This standard does not purport to address all of the

2F

safety concerns, if any, associated with its use. It is the

5 0.102 3

2 2

pD~D 2 D 2 d !

=

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

DISCUSSION 3—For Brinell hardnesses above 450, a signifi-

2. Referenced Documents

cant difference is observed between results obtained using steel

2.1 ASTM Standards:

balls and those obtained using tungsten carbide balls.

E 4 Practices for Force Verification of Testing Machines

3.2 Brinell hardness number—A number which is propor-

E 29 Practice for Using Significant Digits in Test Data to

tional to the quotient obtained by dividing the test force by the

Determine Conformance with Specifications

curved surface area of the indentation which is assumed to be

E 74 Practice for Calibration of Force Measuring Instru-

spherical and of the diameter of the ball.

ments for Verifying the Force Indication of Testing Ma-

2F

chines HBS or HBW 5 0.102 3 ~See Table 1!

2 2

2 p D~D 2 =D 2 d !

E 140 Hardness Conversion Tables for Metals

(1)

3. Terminology

where:

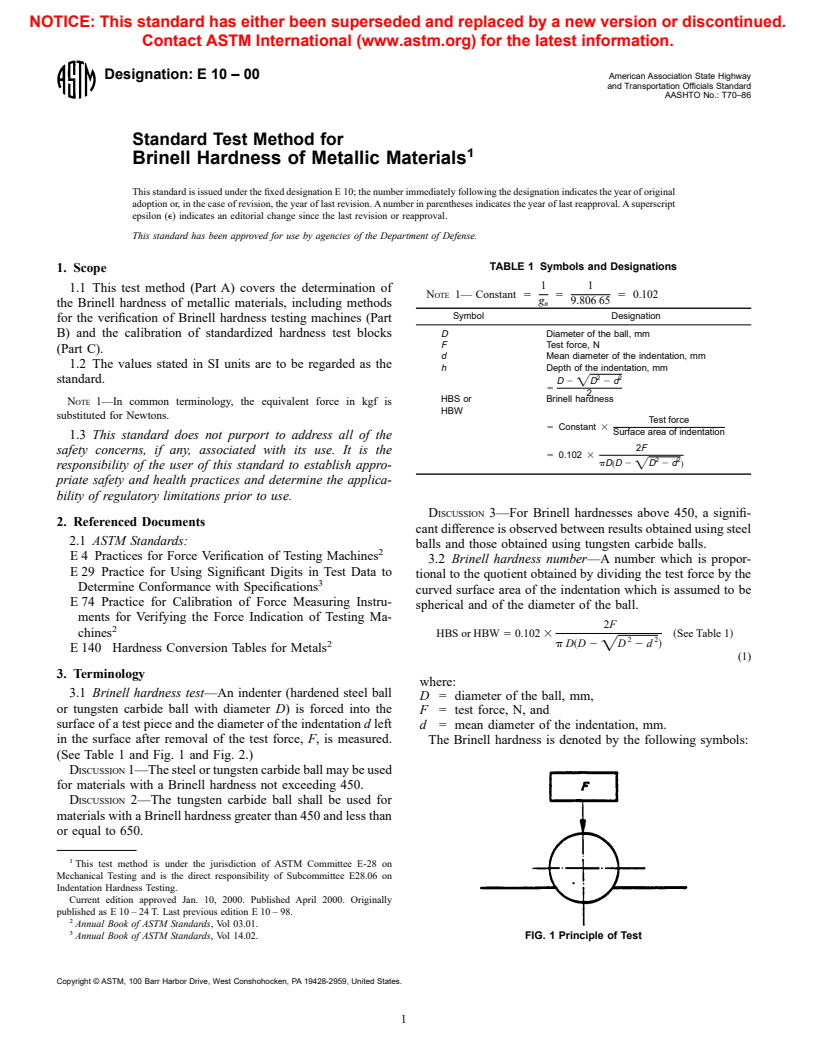

3.1 Brinell hardness test—An indenter (hardened steel ball

D = diameter of the ball, mm,

or tungsten carbide ball with diameter D) is forced into the

F = test force, N, and

surface of a test piece and the diameter of the indentation d left

d = mean diameter of the indentation, mm.

in the surface after removal of the test force, F, is measured.

The Brinell hardness is denoted by the following symbols:

(See Table 1 and Fig. 1 and Fig. 2.)

DISCUSSION 1—The steel or tungsten carbide ball may be used

for materials with a Brinell hardness not exceeding 450.

DISCUSSION 2—The tungsten carbide ball shall be used for

materials with a Brinell hardness greater than 450 and less than

or equal to 650.

This test method is under the jurisdiction of ASTM Committee E-28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

Current edition approved Jan. 10, 2000. Published April 2000. Originally

published as E 10 – 24 T. Last previous edition E 10 – 98.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02. FIG. 1 Principle of Test

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E10

A. GENERAL DESCRIPTION AND TEST

PROCEDURE FOR BRINELL HARDNESS TESTS

5. Apparatus

5.1 Testing Machine—Equipment for Brinell hardness test-

ing usually consists of a testing machine which supports the

test specimen and applies an indenting force to a ball in contact

with the specimen. The design of the testing machines shall be

such that no rocking or lateral movement of the indenter or

specimen occurs while the force is being applied. The design of

the testing machine shall ensure that the force to the indenter

shall be applied smoothly and without impact forces. Precau-

tions shall be taken to prevent a momentary high test force

FIG. 2 Principle of Test

caused by the inertia of the system, hydraulic system over-

shoot, etc. See equipment manufacturer’s instruction manual

for a description of the machine’s characteristics, limitations,

HBS in cases where a steel ball is used.

and respective operating procedure.

HBW in cases where a tungsten carbide ball is used.

5.2 Brinell Balls:

NOTE 2—In former standards, in cases when a steel ball was used, the 5.2.1 The standard ball for Brinell hardness testing shall be

Brinell hardness was denoted by HB.

10.000 mm in diameter with a deviation from this value of not

NOTE 3—The symbol HBS or HBW is preceded by the hardness value.

more than 0.005 mm in any diameter. The ball shall be polished

When conditions other than those specified in 11.1.2 are used, the

and free of surface defects. Smaller balls having the diameters

hardness value is supplemented by an index indicating the test conditions

and tolerances indicated in Table 4 may be also used provided

in the order:

the precautions set forth in 8.1 are observed.

(1) Diameter of the ball, in millimetres,

5.2.2 A hardened steel ball having a hardness of at least 746

(2) A value representing the test force in kilogram-force (see Table 3),

HV10 using a 98.07-N (10-kgf) test force (see Table 8) may be

and

used on material having a Brinell hardness value not over 450,

(3) Duration of loading, in seconds.

or a tungsten carbide ball having a hardness of 1500 HV10 on

Examples:

material over 450.

350 HBS 5/750 = Brinell hardness of 350 determined with a steel

ball of 5-mm diameter and with a test force of 7.355 kN (750 kgf)

NOTE 4—Caution: The Brinell test is not recommended for material

applied for 10 to 15 s.

having hardness over 650 HBW (see 8.1).

600 HBW 1/30/20 = Brinell hardness of 600 determined with a

tungsten carbide ball of 1-mm diameter and with a test force of

5.2.2.1 The chemical composition of tungsten carbide balls

294.2 N (30 kgf) applied for 20 s.

Brinell hardness numbers vary with the test force used; how-

shall be:

ever, test re-

Tungsten Carbide Balance

sults will generally be in agreement when the ratio of the test

(WC)

force to the

Cobalt (Co) 5.0 to 7.0 %

square of the ball diameter is held constant (see Table 3).

Total other Carbides 2.0 % max

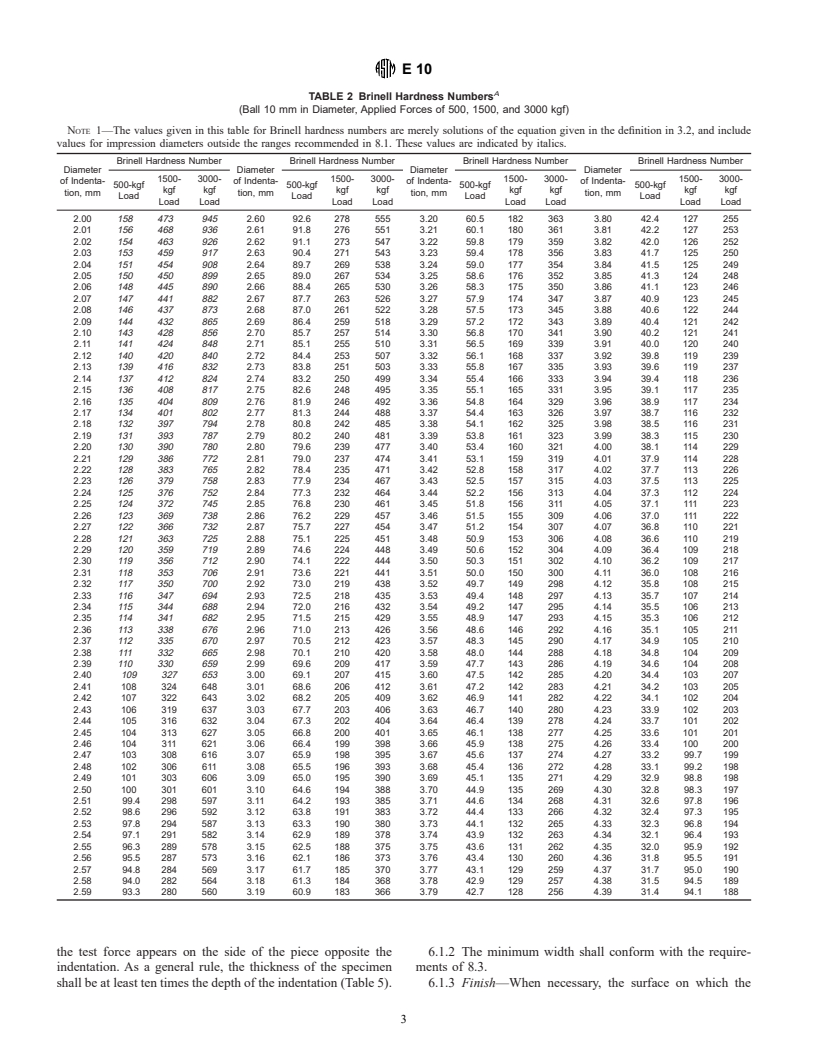

Table 2 lists the Brinell hardness numbers corresponding to various diam-

eters of indentations for 29.4 kN (3000 kgf), 14.7 kN (1500 kgf), and 4.90

NOTE 5—In order to conform with future ISO standards there will be a

kN (500 kgf) test forces making it unnecessary to calculate for each test

proposal to eliminate the use of steel balls and only use tungsten carbide

the value of the Brinell hardness number by the above equation in Table 1

balls for this test method.

when these forces are used with a 10-mm diameter ball.

5.2.3 If a ball is used in a test of a specimen which shows a

3.3 verification—checking or testing to assure conformance

with the specification. Brinell hardness number greater than the limit for the ball as

detailed in 5.2.2, the results of the test shall be considered

3.4 calibration—adjustment of the significant parameters

by comparison with values indicated by a reference instrument invalid and the ball shall be discarded.

5.3 Measuring Device—The divisions of the micrometer

or by a set of reference standards.

scale of the microscope or other measuring devices used for the

4. Significance and Use measurement of the diameter of the indentations shall be such

as to permit the direct measuring of the diameter to 0.1 mm and

4.1 The Brinell hardness test is an empirical indentation

the estimation of the diameter to 0.05 mm.

hardness test. Brinell hardness tests provide useful information

about metallic materials. This information may correlate to

NOTE 6—This requirement applies to the construction of the device

tensile strength, wear resistance, ductility, or other physical only and is not a requirement for measurement of the indentation.

characteristics of metallic materials, and may be useful in

6. Test Specimen

quality control and selection of materials. Brinell hardness

testing at the specific location on a part may not represent the 6.1 There is no standard shape or size for a Brinell test

physical characteristics of the whole part or end product. specimen. The specimen upon which the indentation is made

Brinell hardness tests are considered satisfactory for accep- shall conform to the following:

tance testing of commercial shipments, and they have been 6.1.1 Thickness—The thickness of the specimen tested shall

used extensively in industry for this purpose. be such that no bulge or other marking showing the effect of

E10

A

TABLE 2 Brinell Hardness Numbers

(Ball 10 mm in Diameter, Applied Forces of 500, 1500, and 3000 kgf)

NOTE 1—The values given in this table for Brinell hardness numbers are merely solutions of the equation given in the definition in 3.2, and include

values for impression diameters outside the ranges recommended in 8.1. These values are indicated by italics.

Brinell Hardness Number Brinell Hardness Number Brinell Hardness Number Brinell Hardness Number

Diameter Diameter Diameter Diameter

1500- 3000- 1500- 3000- 1500- 3000- 1500- 3000-

of Indenta- of Indenta- of Indenta- of Indenta-

500-kgf 500-kgf 500-kgf 500-kgf

kgf kgf kgf kgf kgf kgf kgf kgf

tion, mm tion, mm tion, mm tion, mm

Load Load Load Load

Load Load Load Load Load Load Load Load

2.00 158 473 945 2.60 92.6 278 555 3.20 60.5 182 363 3.80 42.4 127 255

2.01 156 468 936 2.61 91.8 276 551 3.21 60.1 180 361 3.81 42.2 127 253

2.02 154 463 926 2.62 91.1 273 547 3.22 59.8 179 359 3.82 42.0 126 252

2.03 153 459 917 2.63 90.4 271 543 3.23 59.4 178 356 3.83 41.7 125 250

2.04 151 454 908 2.64 89.7 269 538 3.24 59.0 177 354 3.84 41.5 125 249

2.05 150 450 899 2.65 89.0 267 534 3.25 58.6 176 352 3.85 41.3 124 248

2.06 148 445 890 2.66 88.4 265 530 3.26 58.3 175 350 3.86 41.1 123 246

2.07 147 441 882 2.67 87.7 263 526 3.27 57.9 174 347 3.87 40.9 123 245

2.08 146 437 873 2.68 87.0 261 522 3.28 57.5 173 345 3.88 40.6 122 244

2.09 144 432 865 2.69 86.4 259 518 3.29 57.2 172 343 3.89 40.4 121 242

2.10 143 428 856 2.70 85.7 257 514 3.30 56.8 170 341 3.90 40.2 121 241

2.11 141 424 848 2.71 85.1 255 510 3.31 56.5 169 339 3.91 40.0 120 240

2.12 140 420 840 2.72 84.4 253 507 3.32 56.1 168 337 3.92 39.8 119 239

2.13 139 416 832 2.73 83.8 251 503 3.33 55.8 167 335 3.93 39.6 119 237

2.14 137 412 824 2.74 83.2 250 499 3.34 55.4 166 333 3.94 39.4 118 236

2.15 136 408 817 2.75 82.6 248 495 3.35 55.1 165 331 3.95 39.1 117 235

2.16 135 404 809 2.76 81.9 246 492 3.36 54.8 164 329 3.96 38.9 117 234

2.17 134 401 802 2.77 81.3 244 488 3.37 54.4 163 326 3.97 38.7 116 232

2.18 132 397 794 2.78 80.8 242 485 3.38 54.1 162 325 3.98 38.5 116 231

2.19 131 393 787 2.79 80.2 240 481 3.39 53.8 161 323 3.99 38.3 115 230

2.20 130 390 780 2.80 79.6 239 477 3.40 53.4 160 321 4.00 38.1 114 229

2.21 129 386 772 2.81 79.0 237 474 3.41 53.1 159 319 4.01 37.9 114 228

2.22 128 383 765 2.82 78.4 235 471 3.42 52.8 158 317 4.02 37.7 113 226

2.23 126 379 758 2.83 77.9 234 467 3.43 52.5 157 315 4.03 37.5 113 225

2.24 125 376 752 2.84 77.3 232 464 3.44 52.2 156 313 4.04 37.3 112 224

2.25 124 372 745 2.85 76.8 230 461 3.45 51.8 156 311 4.05 37.1 111 223

2.26 123 369 738 2.86 76.2 229 457 3.46 51.5 155 309 4.06 37.0 111 222

2.27 122 366 732 2.87 75.7 227 454 3.47 51.2 154 307 4.07 36.8 110 221

2.28 121 363 725 2.88 75.1 225 451 3.48 50.9 153 306 4.08 36.6 110 219

2.29 120 359 719 2.89 74.6 224 448 3.49 50.6 152 304 4.09 36.4 109 218

2.30 119 356 712 2.90 74.1 222 444 3.50 50.3 151 302 4.10 36.2 109 217

2.31 118 353 706 2.91 73.6 221 441 3.51 50.0 150 300 4.11 36.0 108 216

2.32 117 350 700 2.92 73.0 219 438 3.52 49.7 149 298 4.12 35.8 108 215

2.33 116 347 694 2.93 72.5 218 435 3.53 49.4 148 297 4.13 35.7 107 214

2.34 115 344 688 2.94 72.0 216 432 3.54 49.2 147 295 4.14 35.5 106 213

2.35 114 341 682 2.95 71.5 215 429 3.55 48.9 147 293 4.15 35.3 106 212

2.36 113 338 676 2.96 71.0 213 426 3.56 48.6 146 292 4.16 35.1 105 211

2.37 112 335 670 2.97 70.5 212 423 3.57 48.3 145 290 4.17 34.9 105 210

2.38 111 332 665 2.98 70.1 210 420 3.58 48.0 144 288 4.18 34.8 104 209

2.39 110 330 659 2.99 69.6 209 417 3.59 47.7 143 286 4.19 34.6 104 208

2.40 109 327 653 3.00 69.1 207 415 3.60 47.5 142 285 4.20 34.4 103 207

2.41 108 324 648 3.01 68.6 206 412 3.61 47.2 142 283 4.21 34.2 103 205

2.42 107 322 643 3.02 68.2 205 409 3.62 46.9 141 282 4.22 34.1 102 204

2.43 106 319 637 3.03 67.7 203 406 3.63 46.7 140 280 4.23 33.9 102 203

2.44 105 316 632 3.04 67.3 202 404 3.64 46.4 139 278 4.24 33.7 101 202

2.45 104 313 627 3.05 66.8 200 401 3.65 46.1 138 277 4.25 33.6 101 201

2.46 104 311 621 3.06 66.4 199 398 3.66 45.9 138 275 4.26 33.4 100 200

2.47 103 308 616 3.07 65.9 198 395 3.67 45.6 137 274 4.27 33.2 99.7 199

2.48 102 306 611 3.08 65.5 196 393 3.68 45.4 136 272 4.28 33.1 99.2 198

2.49 101 303 606 3.09 65.0 195 390 3.69 45.1 135 271 4.29 32.9 98.8 198

2.50 100 301 601 3.10 64.6 194 388 3.70 44.9 135 269 4.30 32.8 98.3 197

2.51 99.4 298 597 3.11 64.2 193 385 3.71 44.6 134 268 4.31 32.6 97.8 196

2.52 98.6 296 592 3.12 63.8 191 383 3.72 44.4 133 266 4.32 32.4 97.3 195

2.53 97.8 294 587 3.13 63.3 190 380 3.73 44.1 132 265 4.33 32.3 96.8 194

2.54 97.1 291 582 3.14 62.9 189 378 3.74 43.9 132 263 4.34 32.1 96.4 193

2.55 96.3 289 578 3.15 62.5 188 375 3.75 43.6 131 262 4.35 32.0 95.9 192

2.56 95.5 287 573 3.16 62.1 186 373 3.76 43.4 130 260 4.36 31.8 95.5 191

2.57 94.8 284 569 3.17 61.7 185 370 3.77 43.1 129 259 4.37 31.7 95.0 190

2.58 94.0 282 564 3.18 61.3 184 368 3.78 42.9 129 257 4.38 31.5 94.5 189

2.59 93.3 280 560 3.19 60.9 183 366 3.79 42.7 128 256 4.39 31.4 94.1 188

the test force appears on the side of the piece opposite the 6.1.2 The minimum width shall conform with the require-

indentation. As a general rule, the thickness of the specimen ments of 8.3.

shall be at least ten times the depth of the indentation (Table 5). 6.1.3 Finish—When necessary, the surface on which the

E10

TABLE 2 Continued

Brinell Hardness Number Brinell Hardness Number Brinell Hardness Number Brinell Hardness Number

Diameter Diameter Diameter Diameter

1500- 3000- 1500- 3000- 1500- 3000- 1500- 3000-

of Indenta- of Indenta- of Indenta- of Indenta-

500-kgf 500-kgf 500-kgf 500-kgf

kgf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.