ASTM E10-00a

(Test Method)Standard Test Method for Brinell Hardness of Metallic Materials

Standard Test Method for Brinell Hardness of Metallic Materials

SCOPE

1.1 This test method (Test Method A) covers the determination of the Brinell hardness of metallic materials, including methods for the verification of Brinell hardness testing machines (Test Method B) and the calibration of standardized hardness test blocks (Test Method C).

1.2 The values stated in SI units are to be regarded as the standard.

Note 1--In common terminology, the equivalent force in kgf is substituted for N.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 10 – 00a American Association State Highway

and Transportation Officials Standard

AASHTO No.: T70–86

Standard Test Method for

1

Brinell Hardness of Metallic Materials

This standard is issued under the fixed designation E 10; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Symbols and Designations

1. Scope

1 1

1.1 This test method (Part A) covers the determination of

NOTE 1— Constant 5 5 5 0.102

g 9.806 65

the Brinell hardness of metallic materials, including methods n

Symbol Designation

for the verification of Brinell hardness testing machines (Part

D Diameter of the ball, mm

B) and the calibration of standardized hardness test blocks

F Test force, N

(Part C).

d Mean diameter of the indentation, mm

1.2 The values stated in SI units are to be regarded as the

h Depth of the indentation, mm

2 2

standard. D 2 =D 2 d

5

2

HBS or Brinell hardness

NOTE 1—In common terminology, the equivalent force in kgf is

HBW

substituted for Newtons.

Test force

5 Constant [m|]P5

Surface area of indentation

1.3 This standard does not purport to address all of the

2F

safety concerns, if any, associated with its use. It is the

5 0.102 [m|]P5

2 2

pD~D 2 =D 2 d !

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

DISCUSSION 3—For Brinell hardnesses above 450, a signifi-

2. Referenced Documents

cant difference is observed between results obtained using steel

2.1 ASTM Standards:

balls and those obtained using tungsten carbide balls.

2

E 4 Practices for Force Verification of Testing Machines

3.2 Brinell hardness number—A number which is propor-

E 29 Practice for Using Significant Digits in Test Data to

tional to the quotient obtained by dividing the test force by the

3

Determine Conformance with Specifications

curved surface area of the indentation which is assumed to be

E 74 Practice for Calibration of Force Measuring Instru-

spherical and of the diameter of the ball.

ments for Verifying the Force Indication of Testing Ma-

2F

2

chines HBS or HBW 5 0.102 [m|]P5 ~See Table 1!

2 2

2

p D~D 2 =D 2 d !

E 140 Hardness Conversion Tables for Metals

(1)

3. Terminology

where:

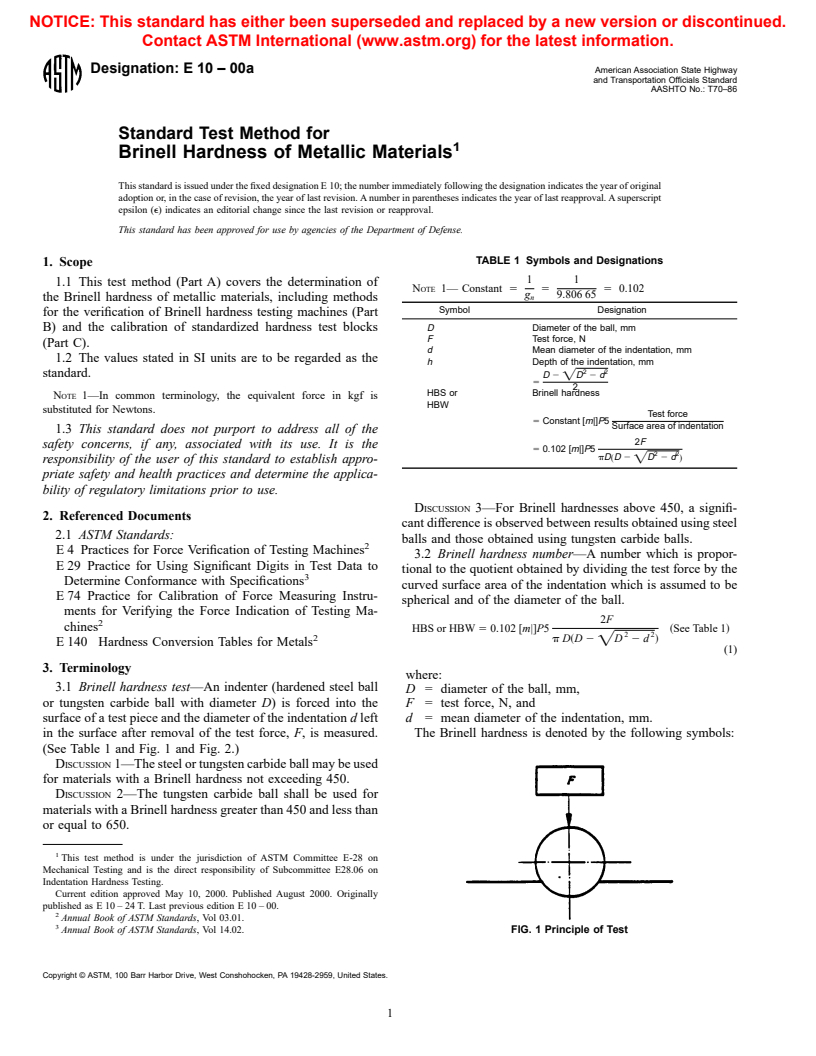

3.1 Brinell hardness test—An indenter (hardened steel ball

D = diameter of the ball, mm,

or tungsten carbide ball with diameter D) is forced into the

F = test force, N, and

surface of a test piece and the diameter of the indentation d left d = mean diameter of the indentation, mm.

in the surface after removal of the test force, F, is measured. The Brinell hardness is denoted by the following symbols:

(See Table 1 and Fig. 1 and Fig. 2.)

DISCUSSION 1—The steel or tungsten carbide ball may be used

for materials with a Brinell hardness not exceeding 450.

DISCUSSION 2—The tungsten carbide ball shall be used for

materials with a Brinell hardness greater than 450 and less than

or equal to 650.

1

This test method is under the jurisdiction of ASTM Committee E-28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

Current edition approved May 10, 2000. Published August 2000. Originally

published as E 10 – 24 T. Last previous edition E 10 – 00.

2

Annual Book of ASTM Standards, Vol 03.01.

3

Annual Book of ASTM Standards, Vol 14.02. FIG. 1 Principle of Test

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

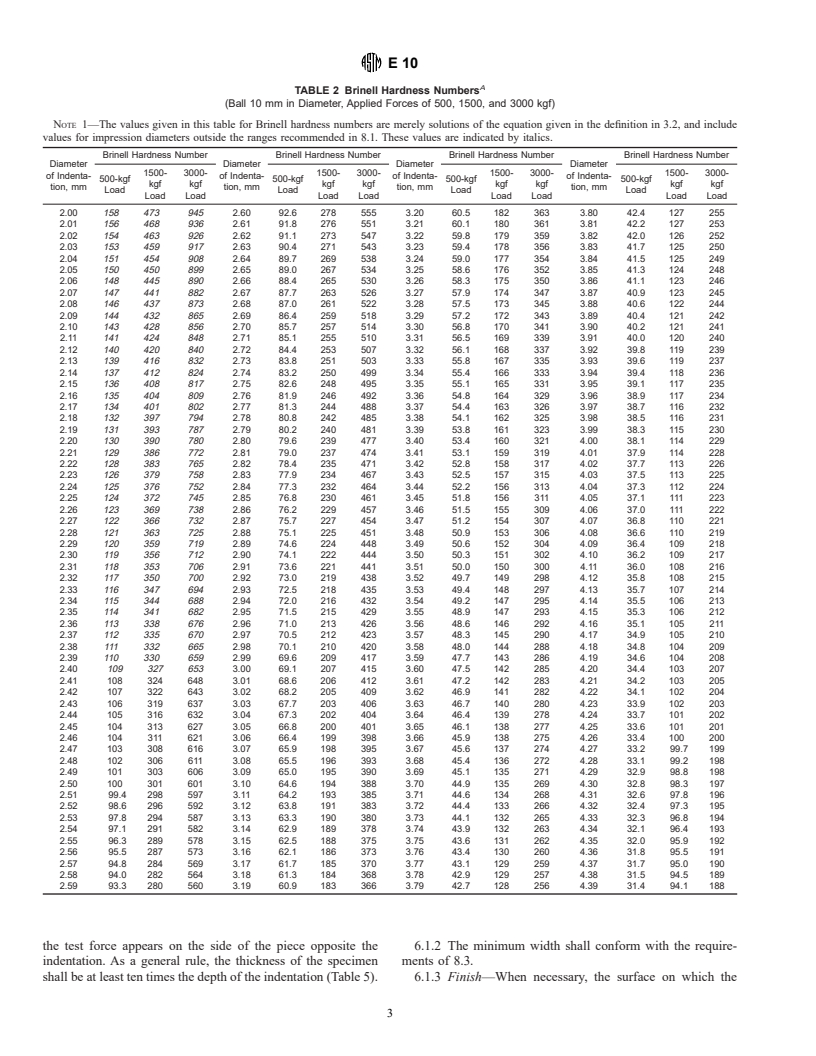

E10

A. GENERAL DESCRIPTION AND TEST

PROCEDURE FOR BRINELL HARDNESS TESTS

5. Apparatus

5.1 Testing Machine—Equipment for Brinell hardness test-

ing usually consists of a testing machine which supports the

test specimen and applies an indenting force to a ball in contact

with the specimen. The design of the testing machines shall be

such that no rocking or lateral movement of the indenter or

specimen occurs while the force is being applied. The design of

the testing machine shall ensure that the force to the indenter

shall be applied smoothly and without impact forces. Precau-

tions shall be taken to prevent a momentary high test force

FIG. 2 Principle of Test

caused by the inertia of the system, hydraulic system over-

shoot, etc. See equipment manufacturer’s instruction manual

for a description of the machine’s characteristics, limitations,

HBS in cases where a steel ball is used.

and respective operating procedure.

HBW in cases where a tungsten carbide ball is used.

5.2 Brinell Balls:

NOTE 2—In form

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.