ASTM F2516-22

(Test Method)Standard Test Method for Tension Testing of Nickel-Titanium Superelastic Materials

Standard Test Method for Tension Testing of Nickel-Titanium Superelastic Materials

SIGNIFICANCE AND USE

5.1 Tension tests provide information on the strength and the elastic and plastic properties of materials under uniaxial tensile stresses.

5.2 Tension tests, as described in this test method, also provide information on the superelasticity, as defined in Terminology F2005, of the material at the test temperature.

SCOPE

1.1 This test method covers the tension testing of superelastic nickel-titanium (nitinol) materials, specifically the methods for determination of upper plateau strength, lower plateau strength, residual elongation, tensile strength, and elongation.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2516 − 22

Standard Test Method for

1

Tension Testing of Nickel-Titanium Superelastic Materials

This standard is issued under the fixed designation F2516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1876 Test Method for Dynamic Young’s Modulus, Shear

Modulus, and Poisson’s Ratio by Impulse Excitation of

1.1 This test method covers the tension testing of superelas-

Vibration

tic nickel-titanium (nitinol) materials, specifically the methods

E3098 Test Method for Mechanical Uniaxial Pre-strain and

for determination of upper plateau strength, lower plateau

Thermal Free Recovery of Shape Memory Alloys

strength, residual elongation, tensile strength, and elongation.

F2004 Test Method for Transformation Temperature of

1.2 The values stated in SI units are to be regarded as

Nickel-Titanium Alloys by Thermal Analysis

standard. No other units of measurement are included in this

F2005 Terminology for Nickel-Titanium Shape Memory

standard.

Alloys

1.3 This standard does not purport to address all of the F2082/F2082M Test Method for Determination of Transfor-

safety concerns, if any, associated with its use. It is the

mation Temperature of Nickel-Titanium Shape Memory

responsibility of the user of this standard to establish appro- Alloys by Bend and Free Recovery

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3. Terminology

1.4 This international standard was developed in accor-

3.1 The definitions of terms relating to tension testing

dance with internationally recognized principles on standard-

appearing in Terminology E6 and the terms relating to nickel-

ization established in the Decision on Principles for the

titanium shape memory alloys appearing in Terminology

Development of International Standards, Guides and Recom-

F2005 shall be considered as applying to the terms used in this

mendations issued by the World Trade Organization Technical

test method. Engineering stress and strain are assumed unless

Barriers to Trade (TBT) Committee.

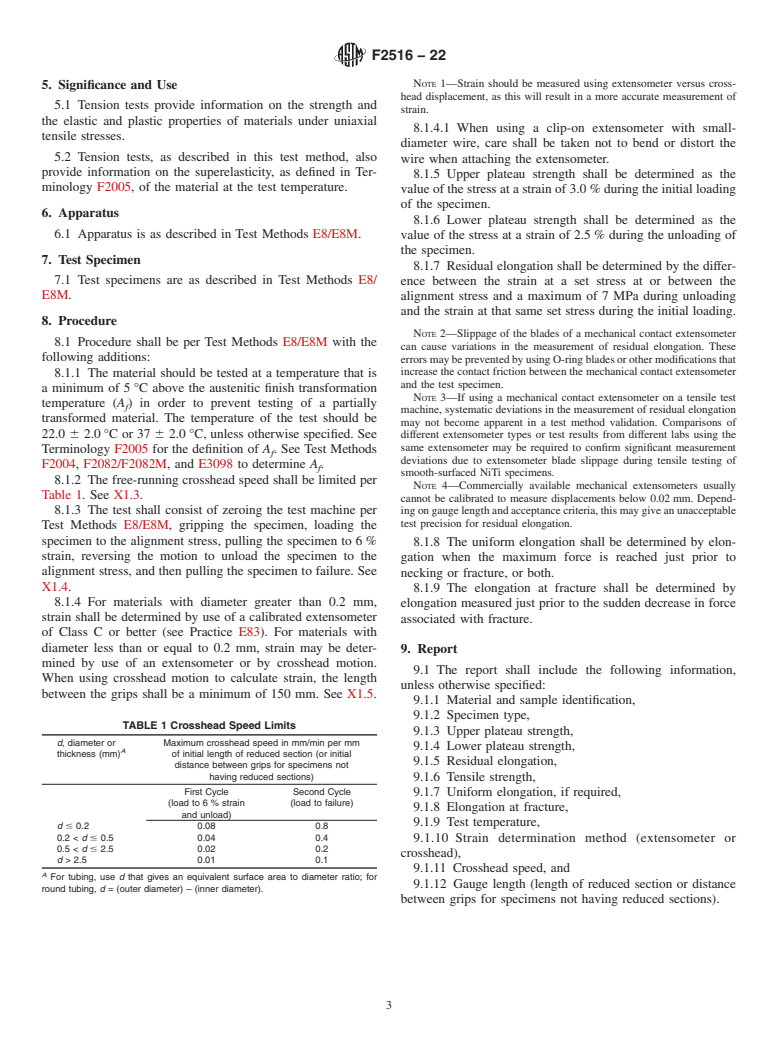

otherwise noted.Additional terms being defined are as follows

(see Fig. 1):

2. Referenced Documents

3.2 Definitions:

2

2.1 ASTM Standards:

3.2.1 alignment stress, n—stress (not to exceed 7 MPa)

E6 Terminology Relating to Methods of Mechanical Testing

appliedtothespecimenafteritisinstalledinthegripstoensure

E8/E8M Test Methods for Tension Testing of Metallic Ma-

that the specimen is straight and aligned to the grips.

terials

3.2.2 elongation at fracture (El ), n—elongation measured

fr

E83 Practice for Verification and Classification of Exten-

just prior to the sudden decrease in force associated with

someter Systems

fracture. See Fig. 1 and X1.2. E6

E111 Test Method for Young’s Modulus, Tangent Modulus,

and Chord Modulus

3.2.2.1 Discussion—Elongation at fracture results may be

E177 Practice for Use of the Terms Precision and Bias in

very sensitive to test variables such as test speed, specimen

ASTM Test Methods

geometry, heat dissipation, surface finish, and alignment. See

E691 Practice for Conducting an Interlaboratory Study to

Test Methods E8/E8M.

Determine the Precision of a Test Method

3.2.2.2 Discussion—Corrections for nonuniform strains be-

tween the extensometer attachments, including in the necked

region,arebeyondthescopeofthisstandard.SeeTestMethods

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

E8/E8M.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

3.2.3 fracture ductility (ɛ ), n—trueplasticstrainatfracture.

fr

F04.15 on Material Test Methods.

See X1.2. E6

Current edition approved June 1, 2022. Published June 2022. Originally

approved in 2005. Last previous edition approved in 2018 as F2516 – 18. DOI:

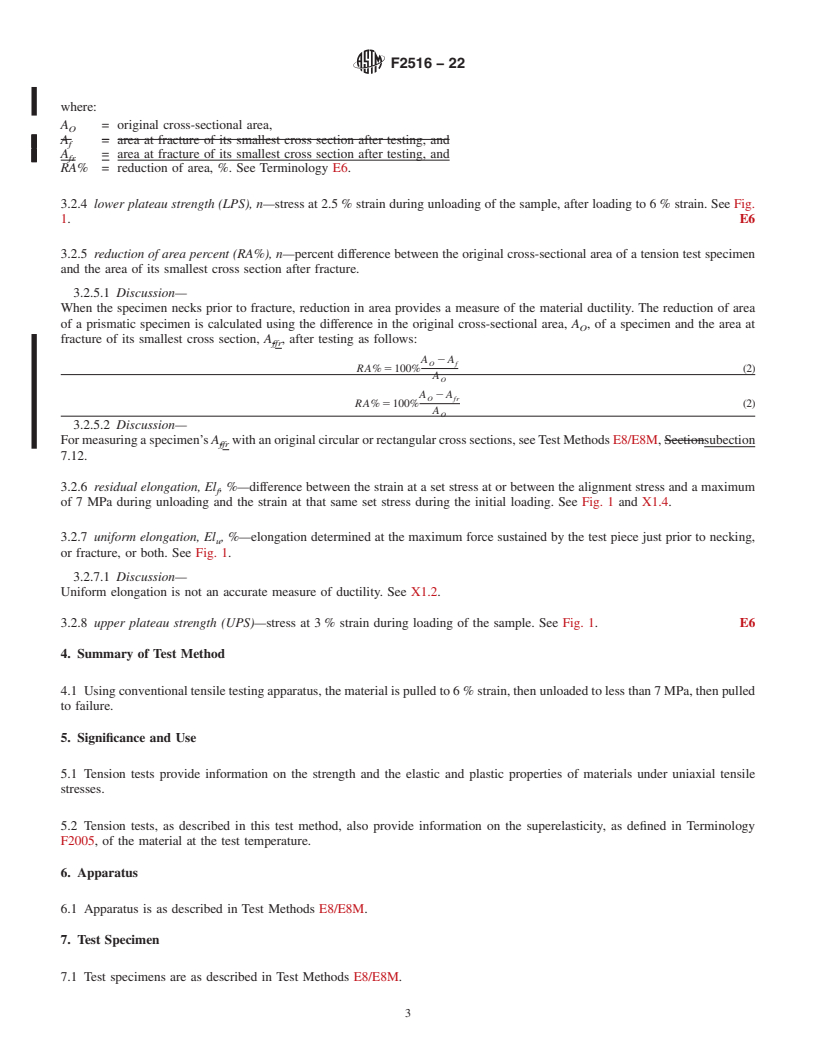

3.2.3.1 Discussion—For prismatic specimens, the fracture

10.1520/F2516-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ductility is calculated as follows:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A 1

Standards volume information, refer to the standard’s Document Summary page on O

ε 5 ln 5 ln (1)

S D S D

fr

the ASTM website. A 1 2RA%⁄100

fr

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2516 − 22

FIG. 1 Terms Illustrated on Typical Stress-Strain Diagram of Superela

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2516 − 18 F2516 − 22

Standard Test Method for

1

Tension Testing of Nickel-Titanium Superelastic Materials

This standard is issued under the fixed designation F2516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the tension testing of superelastic nickel-titanium (nitinol) materials, specifically the methods for

determination of upper plateau strength, lower plateau strength, residual elongation, tensile strength, and elongation.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods for Tension Testing of Metallic Materials

E83 Practice for Verification and Classification of Extensometer Systems

E111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1876 Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration

E3098 Test Method for Mechanical Uniaxial Pre-strain and Thermal Free Recovery of Shape Memory Alloys

F2004 Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis

F2005 Terminology for Nickel-Titanium Shape Memory Alloys

F2082/F2082M Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by

Bend and Free Recovery

3. Terminology

3.1 The definitions of terms relating to tension testing appearing in Terminology E6 and the terms relating to nickel-titanium shape

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Oct. 1, 2018June 1, 2022. Published October 2018June 2022. Originally approved in 2005. Last previous edition approved in 20142018 as

F2516 – 14.F2516 – 18. DOI: 10.1520/F2516-18.10.1520/F2516-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2516 − 22

memory alloys appearing in Terminology F2005 shall be considered as applying to the terms used in this test method. Engineering

stress and strain are assumed unless otherwise noted. Additional terms being defined are as follows (see Fig. 1):

3.2 Definitions:

3.2.1 alignment stress, n—stress (not to exceed 7 MPa) applied to the specimen after it is installed in the grips to ensure that the

specimen is straight and aligned to the grips.

3.2.2 elongation at fracture (El ), n—elongation measured just prior to the sudden decrease in force associated with fracture. See

Ffr

Fig. 1 and X1.2. E6

3.2.2.1 Discussion—

Elongation at fracture results may be very sensitive to test variables such as test speed, specimen geometry, heat dissipation, surface

finish, and alignment. See Test Methods E8/E8M.

3.2.2.2 Discussion—

Corrections for non-uniformnonuniform strains between the extensometer attachments, including in the necked region, are beyond

the scope of this standard. See Test Methods E8/E8M.

3.2.3 fracture ductility (ɛ ), n—true plastic strain at fracture. See X1.2. E6

ffr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.