ASTM G28-22

(Test Method)Standard Test Methods for Detecting Susceptibility to Intergranular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys

Standard Test Methods for Detecting Susceptibility to Intergranular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys

SIGNIFICANCE AND USE

3.1 The boiling ferric sulfate-sulfuric acid test may be applied to the following alloys in the wrought condition:

Alloy

Testing Time, h

N06007

120

N06022

24

N06030

120

N06059

24

N06200

24

N06455

24

N06600

24

N06625

120

N06686

24

N06985

120

N08020

120

N08367

24

Alloy

Testing Time, h

N08800

120

N08825A

120

N10276

24(A) While the ferric sulfate-sulfuric acid test does detect susceptibility to inter- granular corrosion in Alloy N08825, the boiling 65 % nitric acid test, Practices A262, Practice C, for detecting susceptibility to intergranular corrosion in stainless steels is more sensitive and should be used if the intended service is nitric acid.

3.2 This test method may be used to evaluate as-received material and to evaluate the effects of subsequent heat treatments. In the case of nickel-rich, chromium-bearing alloys, the test method may be applied to wrought and weldments of products. The test method is not applicable to cast products.

SCOPE

1.1 These test methods cover two tests as follows:

1.1.1 Method A, Ferric Sulfate-Sulfuric Acid Test (Sections 3 – 10, inclusive)—This test method describes the procedure for conducting the boiling ferric sulfate—50 % sulfuric acid test which measures the susceptibility of certain nickel-rich, chromium-bearing alloys to intergranular corrosion (see Terminology G193), which may be encountered in certain service environments. The uniform corrosion rate obtained by this test method, which is a function of minor variations in alloy composition, may easily mask the intergranular corrosion components of the overall corrosion rate on alloys N10276, N06022, N06059, and N06455.

1.1.2 Method B, Mixed Acid-Oxidizing Salt Test (Sections 11 – 18, inclusive)—This test method describes the procedure for conducting a boiling 23 % sulfuric + 1.2 % hydrochloric + 1 % ferric chloride + 1 % cupric chloride test which measures the susceptibility of certain nickel-rich, chromium-bearing alloys to display a step function increase in corrosion rate when there are high levels of grain boundary precipitation.

1.2 The purpose of these two test methods is to detect susceptibility to intergranular corrosion as influenced by variations in processing or composition, or both. Materials shown to be susceptible may or may not be intergranularly corroded in other environments. This must be established independently by specific tests or by service experience.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Some desired corrosion rate units in 8.1.1 are given in inch-pound units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Warning statements are given in 5.1.1, 5.1.3, 5.1.9, 13.1.1, and 13.1.11.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G28 − 22

Standard Test Methods for

Detecting Susceptibility to Intergranular Corrosion in

1

Wrought, Nickel-Rich, Chromium-Bearing Alloys

ThisstandardisissuedunderthefixeddesignationG28;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 These test methods cover two tests as follows:

responsibility of the user of this standard to establish appro-

1.1.1 Method A, Ferric Sulfate-Sulfuric Acid Test (Sections

priate safety, health, and environmental practices and deter-

3–10, inclusive)—This test method describes the procedure

mine the applicability of regulatory limitations prior to use.

for conducting the boiling ferric sulfate—50 % sulfuric acid

Warning statements are given in 5.1.1, 5.1.3, 5.1.9, 13.1.1, and

test which measures the susceptibility of certain nickel-rich,

13.1.11.

chromium-bearing alloys to intergranular corrosion (see Ter-

1.5 This international standard was developed in accor-

minology G193), which may be encountered in certain service

dance with internationally recognized principles on standard-

environments. The uniform corrosion rate obtained by this test

ization established in the Decision on Principles for the

method, which is a function of minor variations in alloy

Development of International Standards, Guides and Recom-

composition, may easily mask the intergranular corrosion

mendations issued by the World Trade Organization Technical

components of the overall corrosion rate on alloys N10276,

Barriers to Trade (TBT) Committee.

N06022, N06059, and N06455.

1.1.2 Method B, Mixed Acid-Oxidizing Salt Test (Sections

2. Referenced Documents

11–18, inclusive)—This test method describes the procedure

2

2.1 ASTM Standards:

for conducting a boiling 23 % sulfuric + 1.2 % hydrochlo-

A262 Practices for Detecting Susceptibility to Intergranular

ric+1% ferric chloride+1% cupric chloride test which

Attack in Austenitic Stainless Steels

measures the susceptibility of certain nickel-rich, chromium-

D1193 Specification for Reagent Water

bearing alloys to display a step function increase in corrosion

G193 Terminology and Acronyms Relating to Corrosion

rate when there are high levels of grain boundary precipitation.

1.2 The purpose of these two test methods is to detect

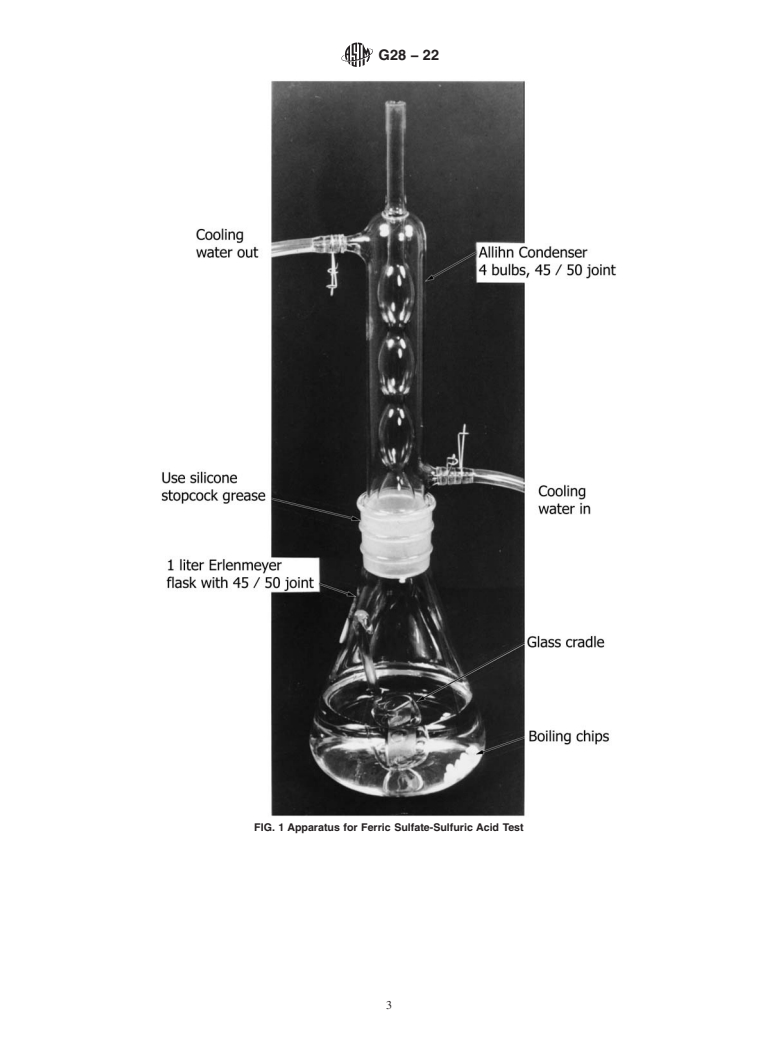

METHOD A—Ferric Sulfate—Sulfuric Acid Test

susceptibility to intergranular corrosion as influenced by varia-

3. Significance and Use

tionsinprocessingorcomposition,orboth.Materialsshownto

be susceptible may or may not be intergranularly corroded in

3.1 The boiling ferric sulfate-sulfuric acid test may be

other environments.This must be established independently by

applied to the following alloys in the wrought condition:

specific tests or by service experience.

Alloy Testing Time, h

1.3 The values stated in SI units are to be regarded as

N06007 120

standard. No other units of measurement are included in this

N06022 24

N06030 120

standard.

N06059 24

1.3.1 Exception—Some desired corrosion rate units in 8.1.1

N06200 24

are given in inch-pound units.

N06455 24

N06600 24

N06625 120

N06686 24

N06985 120

N08020 120

N08367 24

1

These test methods are under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and are the direct responsibility of Subcommittee G01.05 on

2

Laboratory Corrosion Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2022. Published January 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1971. Last previous edition approved in 2015 as G28–02 (2015). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0028-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G28−22

5.1.3 Then measure 236 mL of reagent-grade sulfuric acid

Alloy Testing Time, h

(H SO ) of a concentration which must be in the range from

2 4

N08800 120

95.0 weight percent to 98.0 weight percent in a 250 mL

A

N08825 120

graduate.Add the acid slowly to the water in the flask to avoid

N10276 24

boiling by the heat evolved (Note 3). Externally cooling the

A

While the ferric sulfate-sulfuric aci

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G28 − 02 (Reapproved 2015) G28 − 22

Standard Test Methods for

Detecting Susceptibility to Intergranular Corrosion in

1

Wrought, Nickel-Rich, Chromium-Bearing Alloys

This standard is issued under the fixed designation G28; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover two tests as follows:

1.1.1 Method A, Ferric Sulfate-Sulfuric Acid Test (Sections 3 – 10, inclusive)—This test method describes the procedure for

conducting the boiling ferric sulfate—50 % sulfuric acid test which measures the susceptibility of certain nickel-rich,

chromium-bearing alloys to intergranular corrosion (see Terminology G15G193), which may be encountered in certain service

environments. The uniform corrosion rate obtained by this test method, which is a function of minor variations in alloy

composition, may easily mask the intergranular corrosion components of the overall corrosion rate on alloys N10276, N06022,

N06059, and N06455.

1.1.2 Method B, Mixed Acid-Oxidizing Salt Test (Sections 11 – 18, inclusive)—This test method describes the procedure for

conducting a boiling 23 % sulfuric + 1.2 % hydrochloric + 1 % ferric chloride + 1 % cupric chloride test which measures the

susceptibility of certain nickel-rich, chromium-bearing alloys to display a step function increase in corrosion rate when there are

high levels of grain boundary precipitation.

1.2 The purpose of these two test methods is to detect susceptibility to intergranular corrosion as influenced by variations in

processing or composition, or both. Materials shown to be susceptible may or may not be intergranularly corroded in other

environments. This must be established independently by specific tests or by service experience.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Some desired corrosion rate units in 8.1.1 are given in inch-pound units.

1

These test methods are under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and are the direct responsibility of Subcommittee G01.05 on Laboratory

Corrosion Tests.

Current edition approved Nov. 1, 2015Dec. 1, 2022. Published November 2015January 2023. Originally approved in 1971. Last previous edition approved in 20082015

as G28–02 (2008).(2015). DOI: 10.1520/G0028-02R15.10.1520/G0028-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G28 − 22

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Warning statements are given in 5.1.1, 5.1.3, 5.1.9, 13.1.1, and 13.1.11.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

D1193 Specification for Reagent Water

G15G193 Terminology and Acronyms Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

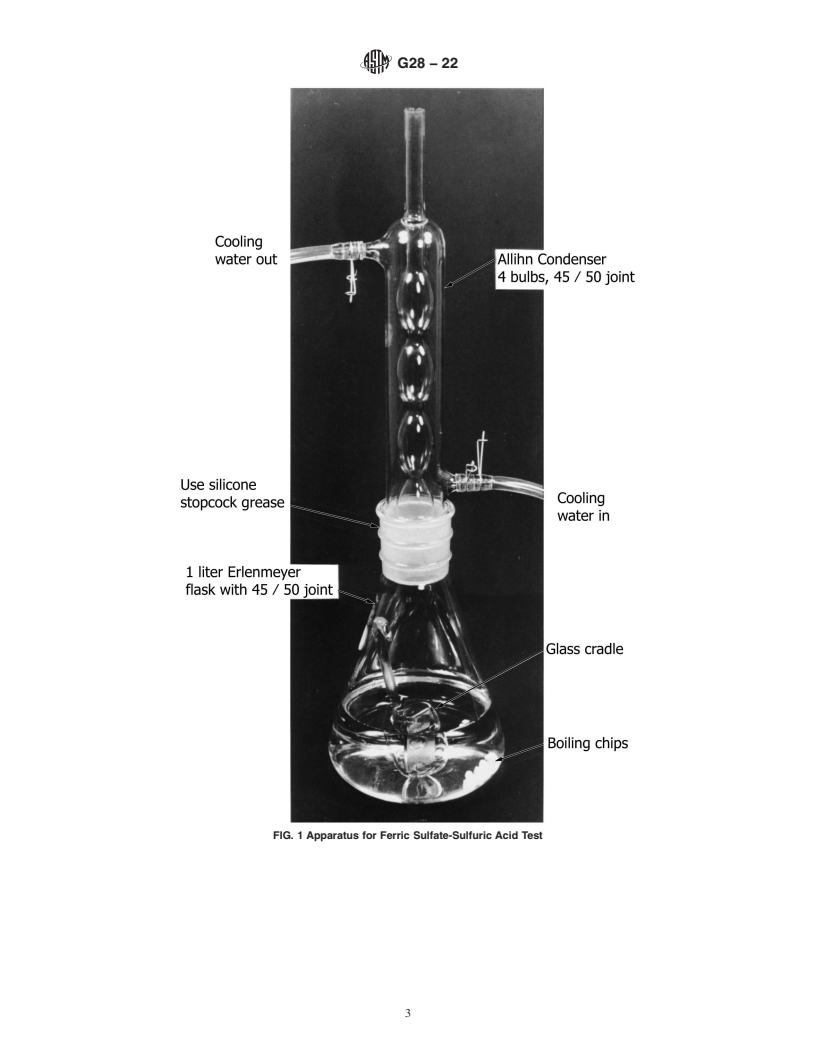

METHOD A—Ferric Sulfate—Sulfuric Acid Test

3. Significance and Use

3.1 The boiling ferric sulfate-sulfuric acid test may be applied to the following alloys in the wrought condition:

Alloy Testing Time, h

N06007 120

N06007 120

N06022 24

N06030 120

N06059 24

N06200 24

N06455 24

N06600 24

N06625 120

N06686 24

N06985 120

N08020 120

N08367 24

Alloy Testing Time, h

N08800 120

A

N08825 120

N10276 24

A

While the ferric sulfate-sulfuric acid test does detect susceptibility to inter- granular corrosion in Alloy N08825, the boiling 65 % nitric acid test, Practices A262, Practice

C, for detecting susceptibility to intergranular corrosion in stainless steels is more sensitive and sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.