ASTM D3689-90(1995)

(Test Method)Standard Test Method for Individual Piles Under Static Axial Tensile Load (Withdrawn 2005)

Standard Test Method for Individual Piles Under Static Axial Tensile Load (Withdrawn 2005)

SCOPE

1.1 This test method covers procedures for testing vertical or batter piles, individually or in groups, to determine response of the pile or pile group to a static tensile load applied axially to the pile or pile group. This test method is applicable to all deep foundation units that function in a manner similar to piles, regardless of their method of installation. This test method is divided into the following sections: Section Referenced Documents 2 Significance and Use 3 Apparatus for Applying Loads 4 Apparatus for Measuring Movements 5 Safety Precautions 6 Loading Procedures 7 Procedures for Measuring Movements 8 Report 9 Precision and Bias 10

1.2 This test method only describes procedures for testing single piles or pile groups. It does not cover the interpretation or analysis of the test results or the application of the test results to foundation design. See Appendix X1 for comments regarding some of the factors influencing the interpretation of test results. A qualified geotechnical engineer should interpret the test results for predicting pile performance and capacity. The term "failure", as used in this test method, indicates a rapid progressive movement of the pile or pile group in the direction of loading under a constant or decreasing load.

1.3 Apparatus and procedures designated "optional" are to be required only when included in the project specifications and, if not specified, may be used only with the approval of the engineer responsible for the foundation design. The word "shall" indicates a mandatory provision and "should" indicates a recommended or advisory provision. Imperative sentences indicate mandatory provisions. Notes and illustrations included herein are explanatory or advisory.

1.4 Wherever in this test method the term pile is used with reference to the test pile, it shall include test pile groups.

1.5 The values stated in inch-pound units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

WITHDRAWN RATIONALE

This test method covers procedures for testing vertical or batter piles, individually or in groups, to determine response of the pile or pile group to a static tensile load applied axially to the pile or pile group.

Formerly under the jurisdiction of Committee D18 on Soil and Rock, this test method was discontinued in December 2003.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3689–90(Reapproved 1995)

Standard Test Method for

Individual Piles Under Static Axial Tensile Load

This standard is issued under the fixed designation D 3689; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method covers routine procedures to determine uplift capacity of piles. The provisions

permit the introduction of more detailed requirements and procedures, when required to satisfy the

objectives of the test program. While the procedures herein produce a relationship between applied

load and pile movement, the results may not represent long-term performance.

1. Scope a recommended or advisory provision. Imperative sentences

indicatemandatoryprovisions.Notesandillustrationsincluded

1.1 This test method covers procedures for testing vertical

herein are explanatory or advisory.

or batter piles, individually or in groups, to determine response

1.4 Wherever in this test method the term pile is used with

of the pile or pile group to a static tensile load applied axially

reference to the test pile, it shall include test pile groups.

to the pile or pile group. This test method is applicable to all

1.5 The values stated in inch-pound units are to be regarded

deepfoundationunitsthatfunctioninamannersimilartopiles,

as the standard.

regardless of their method of installation. This test method is

1.6 This standard does not purport to address all of the

divided into the following sections:

safety concerns, if any, associated with its use. It is the

Section

responsibility of the user of this standard to establish appro-

Referenced Documents 2

priate safety and health practices and determine the applica-

Significance and Use 3

Apparatus for Applying Loads 4 bility of regulatory limitations prior to use. For specific

Apparatus for Measuring Movements 5

precautionary statements, see Section 6.

Safety Precautions 6

Loading Procedures 7

2. Referenced Documents

Procedures for Measuring Movements 8

Report 9

2.1 ASTM Standards:

Precision and Bias 10

D 1143 Test Method for Piles Under StaticAxial Compres-

1.2 This test method only describes procedures for testing

sive Load

single piles or pile groups. It does not cover the interpretation

D 3966 Test Method for Piles Under Lateral Loads

or analysis of the test results or the application of the test

2.2 ANSI Standard:

results to foundation design. See Appendix X1 for comments

B30.1 Safety Code for Jacks

regarding some of the factors influencing the interpretation of

3. Significance and Use

test results. A qualified geotechnical engineer should interpret

the test results for predicting pile performance and capacity.

3.1 Theactualloadcapacityofapile-soilsystemcanbestbe

Theterm“failure”,asusedinthistestmethod,indicatesarapid

determined by testing. Testing measures the response of a

progressive movement of the pile or pile group in the direction

pile-soil system to loads and may provide data for research and

of loading under a constant or decreasing load.

development, engineering design, quality assurance, or accep-

1.3 Apparatus and procedures designated “optional” are to

tance or rejection in accordance with the specifications and

be required only when included in the project specifications

contract documents.

and, if not specified, may be used only with the approval of the

3.2 Testing as covered herein, when combined with an

engineer responsible for the foundation design. The word

acceptance criterion, is suitable for assurance of pile founda-

“shall” indicates a mandatory provision and “should” indicates

tion design and installation under building codes, standards,

and other regulatory statutes.

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

and Rock and is the direct responsibility of Subcommittee D18.11 on Deep

Foundations. Annual Book of ASTM Standards, Vol 04.08.

Current edition approved May 25, 1990. Published July 1990. Originally Available from American National Standards Institute, 1430 Broadway, New

published as D 3689 – 78. Last previous edition D 3689 – 83. York, NY 10018.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3689

4. Apparatus for Applying Loads plan dimensions to transfer the reaction loads to the soil

without settling at a rate that would prevent maintaining the

4.1 General:

applied loads.

4.1.1 The apparatus for applying known tensile loads to the

4.1.4 The clear distance between the test pile and the

test pile shall be as described in 4.3, 4.4, 4.5, or 4.6 and shall

reaction pile(s) or cribbing shall be at least five times the butt

be constructed so that the loads are applied axially minimizing

diameter or diagonal dimension of the test pile, but not less

eccentric loading. The method in 4.3 is recommended. The

than 8 ft (2.5 m).

method in 4.5 should not be used for ultimatetests or for tests

NOTE 3—The reactions should be far enough away from the test pile so

where large upward movements are anticipated.The method in

that there is not significant effect on the performance of the test pile due

4.5 can be used to develop high tensile loads with relatively

to external loading. Factors such as type and depth of reaction, soil

low jacking capacity. See 1.3 for use of the method in 4.6.

conditions, and magnitude of loads should be considered. When testing

large diameter drilled shafts or caissons, the practicality of a spacing of

NOTE 1—When a pile group is subject to vertical test loads, cap

five times the butt diameter or diagonal dimension should be considered

rotations and horizontal displacements may occur.The occurrence of such

and the standard modified as warranted.

horizontal movements, and the necessary reactions to resist such move-

ments if they are to be prohibited, should be considered when designing

4.1.5 Steel bearing plates of appropriate thickness for the

and constructing the load apparatus for the group test.

loads involved shall be used above and below the hydraulic

NOTE 2—If it is not feasible to apply axial test loads to a batter pile, the

jack ram(s) and load cell(s), except if full bearing is provided

results of a test on a similar nearby vertical pile generally may be used to

on steel reaction piles, and between cap beam(s) and the tops

evaluate the uplift capacity of the batter pile.

of concrete or timber reaction piles. The size of the bearing

4.1.2 Where feasible, the immediate area of the test pile or

plates shall be not less than the area covered by the base(s) of

pile group shall be excavated to the proposed pile cut-off

the hydraulic ram(s) or load cell(s) nor less than the total width

elevation. The test pile(s) shall be cut off or built up to the

of the test beam(s), cap beam(s), reaction piles, or any steel

proper grade as necessary to permit construction of the

reaction member(s) so as to provide full bearing and distribu-

load-application apparatus, placement of the necessary testing

tion of the load. Bearing plates supporting the hydraulic jack

and instrumentation equipment, and observations of the instru-

ram(s) on timber cribbing shall have an area not less than five

mentation.

times the base area of the ram(s). Bearing plates that support

4.1.3 Reaction piles, if used, shall be of sufficient number test beam(s) on timber cribbing shall have a side dimension not

and installed so as to provide adequate reactive capacity.When less than 1 ft (0.3 m) greater than the total flange width of the

testing a batter pile, reaction piles shall be battered in the same test beam or overall width of double test beams.

direction and angle as the test pile; the test beam(s) shall be 4.1.6 Bearing plates, hydraulic jack ram(s), and load cell(s)

perpendicular to the direction of batter. If two or more reaction shall be centered on test beam(s), cap beam(s), reaction

piles are used at each end of the test beam(s), they shall be member(s), reactions piles, or cribbing. Bearing plates shall be

capped with a suitable steel beam(s) set on steel bearing plates set perpendicular to the longitudinal axis of the pile. Plates

shall be set in high-strength, quick-setting grout for concrete

or directly on and welded to steel reaction piles (Fig. 1, Fig. 2,

andFig.3).Cribbing,ifusedasareaction,shallbeofsufficient reaction piles, or welded to steel reaction piles, or, in the case

NOTE 1—Use stiffener plates between flanges of all beams where structurally required.

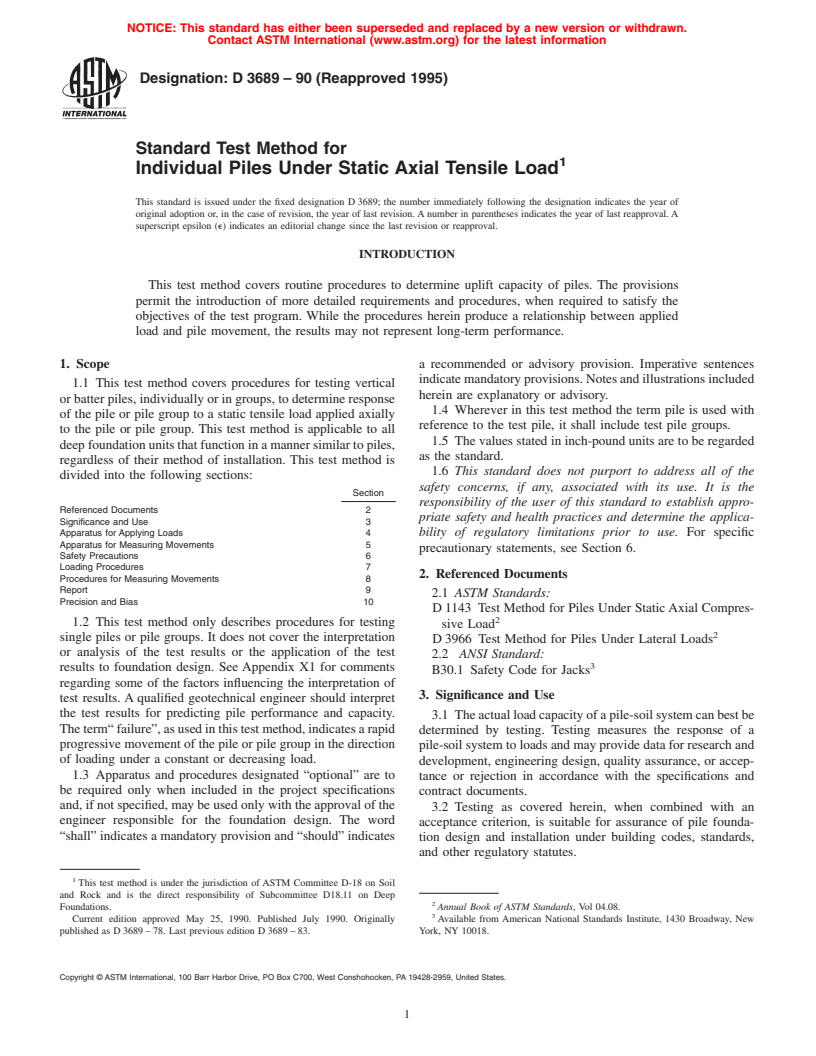

FIG. 1 Typical Arrangement Where Two or More Reaction Piles are Used at End of Test Beam Using Set-Up Shown in Fig. 4

D3689

NOTE 1—Use stiffener plates between flanges of all beams where structurally required.

FIG. 2 Typical Arrangement Where Two or More Reaction Piles are Used at End of Test Beam Using Set-Up Shown in Fig. 5 or Fig. 6

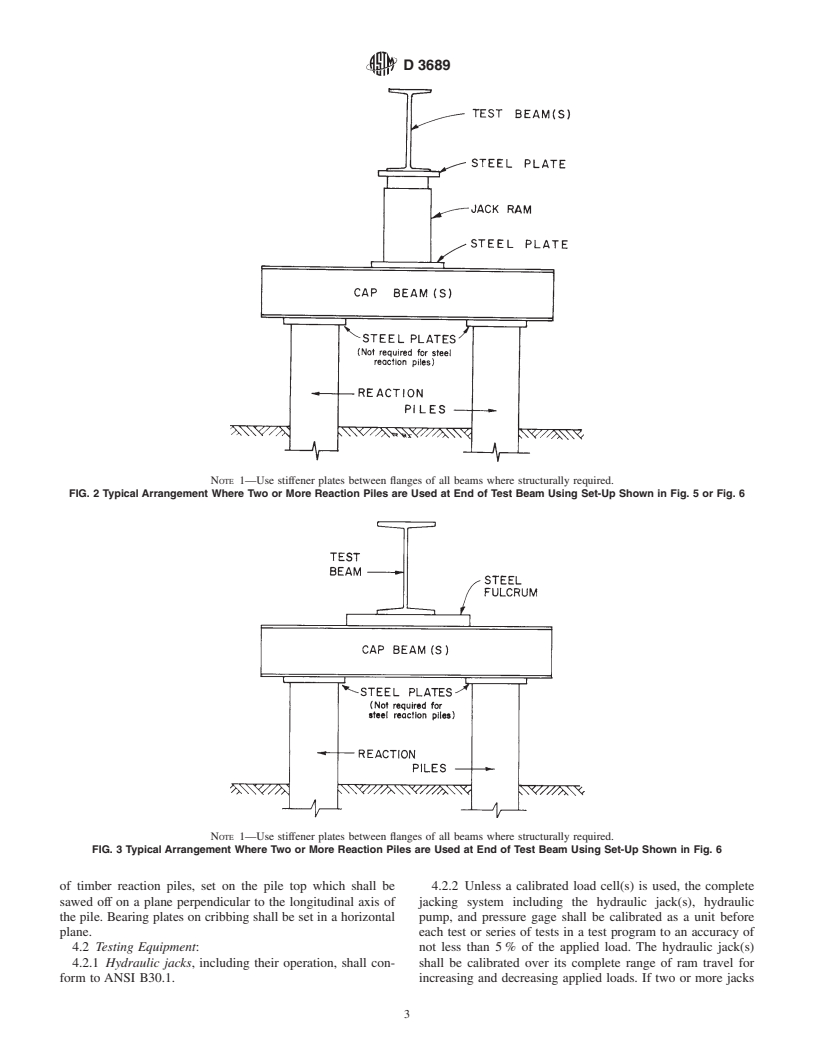

NOTE 1—Use stiffener plates between flanges of all beams where structurally required.

FIG. 3 Typical Arrangement Where Two or More Reaction Piles are Used at End of Test Beam Using Set-Up Shown in Fig. 6

of timber reaction piles, set on the pile top which shall be 4.2.2 Unless a calibrated load cell(s) is used, the complete

sawed off on a plane perpendicular to the longitudinal axis of jacking system including the hydraulic jack(s), hydraulic

the pile. Bearing plates on cribbing shall be set in a horizontal pump, and pressure gage shall be calibrated as a unit before

plane. each test or series of tests in a test program to an accuracy of

4.2 Testing Equipment: not less than 5 % of the applied load. The hydraulic jack(s)

4.2.1 Hydraulic jacks, including their operation, shall con- shall be calibrated over its complete range of ram travel for

form to ANSI B30.1. increasing and decreasing applied loads. If two or more jacks

D3689

NOTE 5—Considerations should be given to employing a dual load-

are to be used to apply the test load, they shall be of the same

measuring system (pressure gage and load cell) to provide as a check and

ram diameter, connected to a common manifold and pressure

as a backup in case one system malfunctions. Hydraulic jack rams should

gage, and operated by a single hydraulic pump.

havesufficienttraveltoprovideforanticipatedpilemovementsdeflections

4.2.3 When an accuracy greater than that obtainable withthe

of the test beam and elongation of connections to the test pile. The use of

jacking system is required, a properly constructed load cell(s)

a single high-capacity jack is preferred to the use of multiple jacks. If a

or equivalent device(s) shall be used in series with the

multiple jacking system is used, each jack should be fitted with a

hydraulic jack(s). Load cell(s) or equivalent device(s) shall be calibrated pressure gage (in addition to the master gage) in order to detect

malfunctions and imbalances.

calibrated prior to the test to an accuracy of not less than 2 %

of the applied load and shall be equipped with a spherical

4.3 Load Applied to Pile by Hydraulic Jack(s) Acting

bearing(s). Calibration of load cells shall include eccentric

Between Supported Test Beam(s) and a Reaction Frame

loading of 1:100 with an off-center of 1 in. (25 mm). After

Anchored to the Pile (Fig. 4):

calibration, load cells shall not be subjected to impact loads.

4.3.1 Center over the test pile a test beam(s) of sufficient

4.2.4 Calibration reports shall be furnished for all testing

size and strength to avoid excessive deflection under load with

equipment for which calibration is required, and shall show the

adequate space between the bottom flange(s) of the test

temperature at which the calibration was done.

beam(s) (including any projecting parts of the connection

system to the reaction frame) and the top of the test pile to

NOTE 4—Unless the hydraulic jack pump is attended at all times, it is

provide for the total anticipated upward movement of the test

recommended that the jacking system be equipped with an automatic

regulator to hold the load constant as pile movement occurs. pile under test. Support the ends of the test beam(s) with

NOTE 1—Load on pile equals applied load.

NOTE 2—Use same type reaction (piles or cribbing) at both ends of test beam.

NOTE 3—Plate not required for steel reaction pile.

NOTE 4—Use stiffener plates between flanges of all beams where structurally required.

FIG. 4 Typical Set-Up for Applying Tensile Loads to Pile Using Hydraulic Jack Acting Between Test Beam and Reaction Frame

Anchored to Pile

D3689

reactionpilesorcribbing.Iftwoormorereactionpilesareused to avoid excessive deflection under load. Anchor the test

at each end of the test beam(s), they shall be capped with a beam(s) to the test pile by means of steel straps, bars, cables,

suitable steel beam(s) set on the piles or on bearing plates (Fig. or other devices so that the connection between test pile and

1). test beam(s) will resist the maximum required test load without

4.3.2 Center over the test pile and on the test beam(s) a slippage, rupture, or excessive elongation. Support one of the

hydraulic jack ram(s) (and load cell(s), if used) of sufficient test beam(s) on a hydraulic jack ram(s) (and load cell(s), if

capacity for the required load. Center a reaction frame over the used) with the jack ram(s) supported on a reaction pile(s) or

jack ram(s) (or load cell(s), if used). cribbing. Support the other end of the test beam(s) on a steel

4.3.3 Anchor the reaction frame to the test pile by means of fulcrum or similar device placed on a steel plate supported on

straps or bars welded to the pile or by bars or cables embedded a reaction pile(s) or cribbing.

in the pile. Tension connections between test pile and reaction 4.6 Load Applied to Pile by Hydraulic Jack(s) Acting

frame shall be constructed so as to prevent slippage, rupture, or Against Top of A-Frame or Tripod (Fig. 7) (Optional):

excessive elongation of the connection under the maximum 4.6.1 Center over the test pile an A-frame or tripod of

required test load. sufficient size and strength to avoid excessive deflection under

4.4 LoadApplied to Pile by Hydraulic JacksActing at Both load. Support the A-frame or tripod on concrete footings,

Ends of Test Beam(s) Anchored to the Pile (Fig. 5)—Center cribbing, or reaction piles. Tie together the bottoms of the

over the test pile a test beam(s) of sufficient size and strength A-frame or tripod legs or their supports, with tension members

to avoid excessive deflection under load. Anchor the test of sufficient streng

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.