ASTM F548-03a

(Test Method)Standard Test Method for Intensity of Scratches on Aerospace Transparent Plastics

Standard Test Method for Intensity of Scratches on Aerospace Transparent Plastics

SCOPE

1.1 This test method covers the visual inspection of shallow or superficial scratches on the surface of aerospace transparent plastic materials.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F548–03a

Standard Test Method for

1

Intensity of Scratches on Aerospace Transparent Plastics

This standard is issued under the fixed designation F 548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope toward the observer. The light level shall be a minimum of 80

lux. Either natural or artificial light may be used. Place the

1.1 This test method covers the visual inspection of shallow

scratch in the visual comparison standard beside and parallel to

or superficial scratches on the surface of aerospace transparent

the scratch on the plastic material. Rotate the part or viewing

plastic materials.

angle to get the best definition of the scratch. Disregarding the

1.2 This standard does not purport to address all of the

length of the scratch on the plastic material and on the

safety concerns, if any, associated with its use. It is the

standard, select and record the highest standard scratch that

responsibility of the user of this standard to establish appro-

most clearly matches the appearance of the scratch on the

priate safety and health practices and determine the applica-

plasticmaterial.Measureandrecordthelengthofthescratchto

bility of regulatory limitations prior to use.

the nearest 1 mm (0.04 in.).

2. Summary of Test Method

6. Interpretation

2.1 A visual comparison is made between a set of graded

6.1 Customer specifications for transparent plastic materials

scratch standards and the scratch on the plastic material to

and parts may detail allowable frequency, location, length, and

determine the relative intensity of the scratch.

standard number for scratches and they may assign maximum

3. Significance and Use

scratch limits for critical and noncritical optical viewing areas.

3.1 Scratches exist on all transparent plastic surfaces. Usu-

7. Report

ally they are very fine scratches from cleaning operations that

7.1 For each scratch within the scope of the plastic scratch

are not visible when looking through the plastic. Deeper

standard, report its standard number, length, frequency, and

scratches may result from careless cleaning or handling. While

location.

these may not be deep enough to affect the structural integrity

of the part, their appearance in certain locations may be

8. Precision and Bias

distracting to the observer looking through the plastic. There-

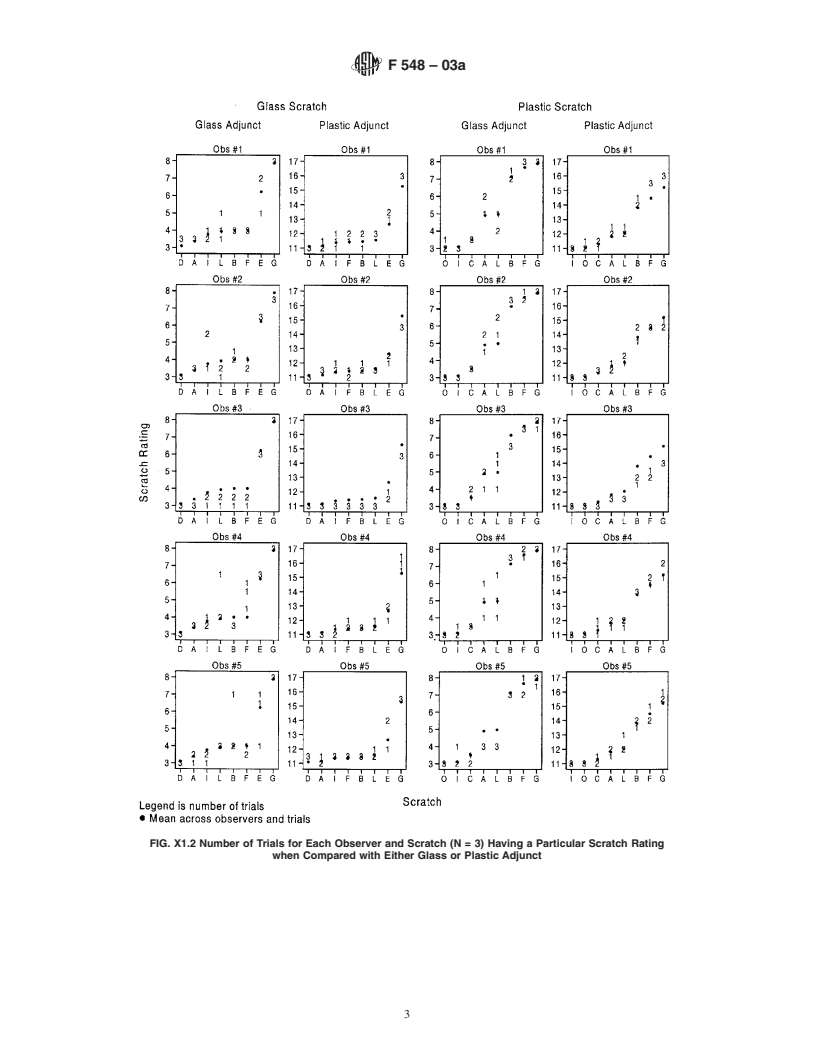

8.1 Precision:

fore, a procedure to define these scratches is useful.

8.1.1 The repeatability of judging the intensity of a scratch

4. Reference Materials within one scratch value, for the same observer, is 92 % or

better.

NOTE 1—The committee is in the process of developing new visual

8.1.2 The reproducibility (between observers) of judging

comparison standards. Adjuncts are not currently available.

the intensity of a scratch within one scratch value is 90 % or

5. Procedure better for scratch values 14 and above. The reproducibility of

judging the intensity of a scratch within two scratch values is

5.1 Place the part in a suitable inspection position.This may

92 %orbetterforscratchvaluesbelow14.Thedatareflectthat

be horizontal on a padded table, vertical against a neutral

it is more difficult to judge finer scratches.

background, or at an angle. The scratched surface shall be

8.2 Bias—The procedure in this test method has no bias

beca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.