ASTM E1049-85(2017)

(Practice)Standard Practices for Cycle Counting in Fatigue Analysis

Standard Practices for Cycle Counting in Fatigue Analysis

SIGNIFICANCE AND USE

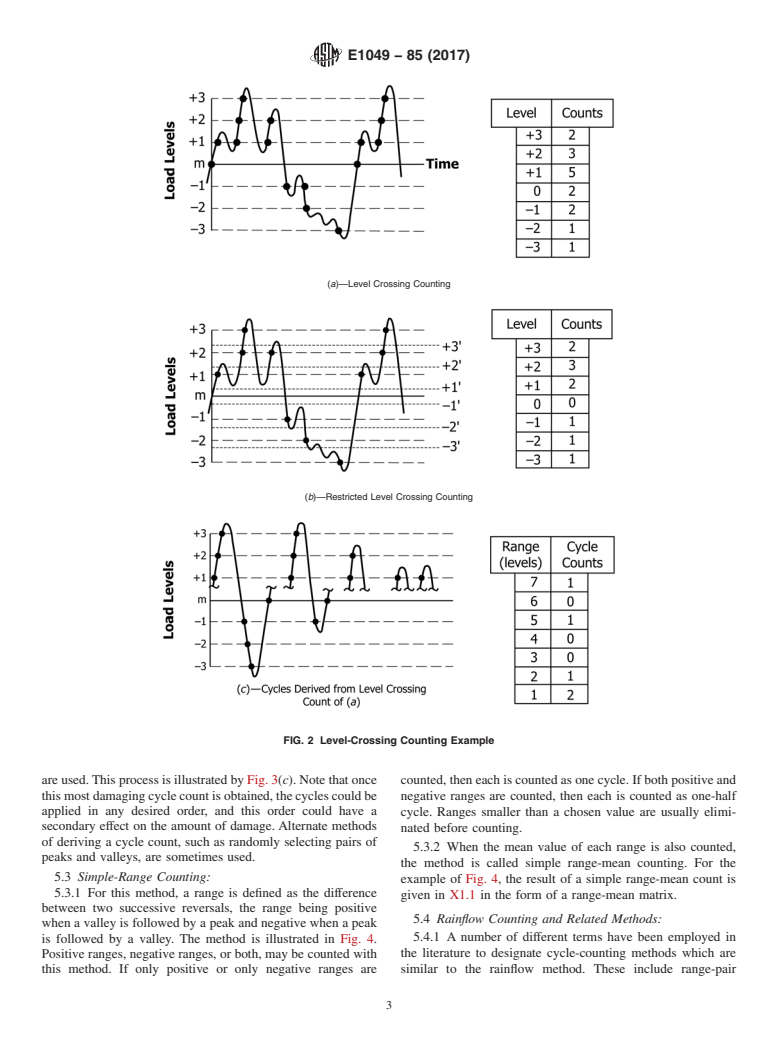

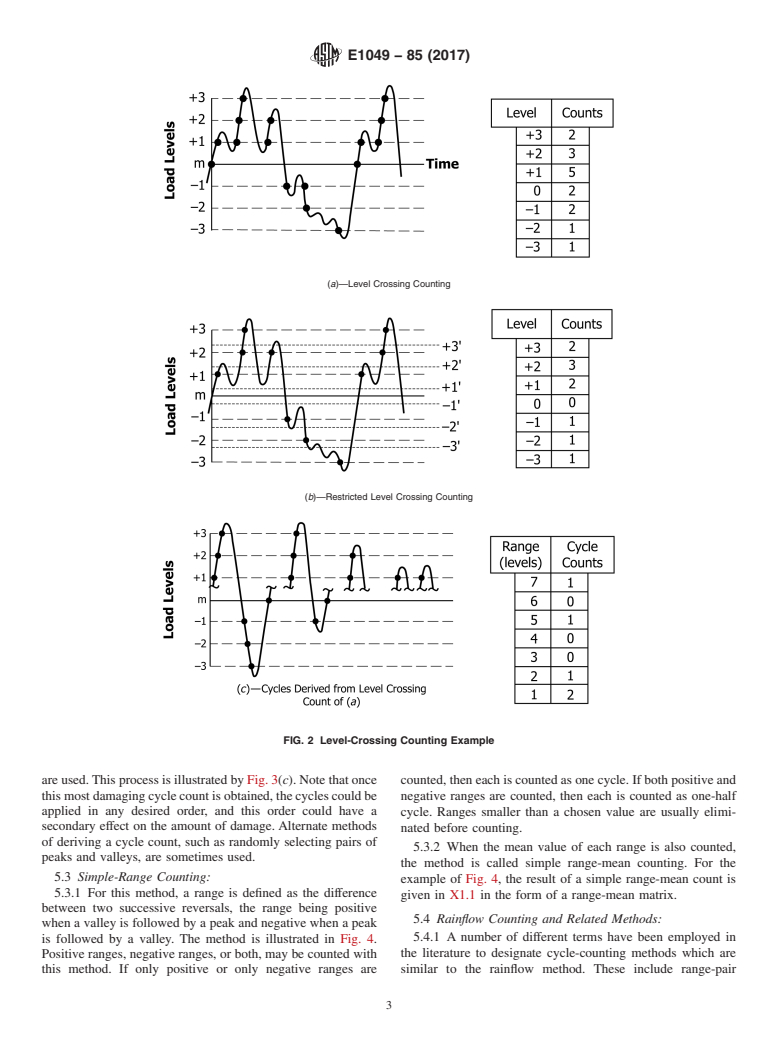

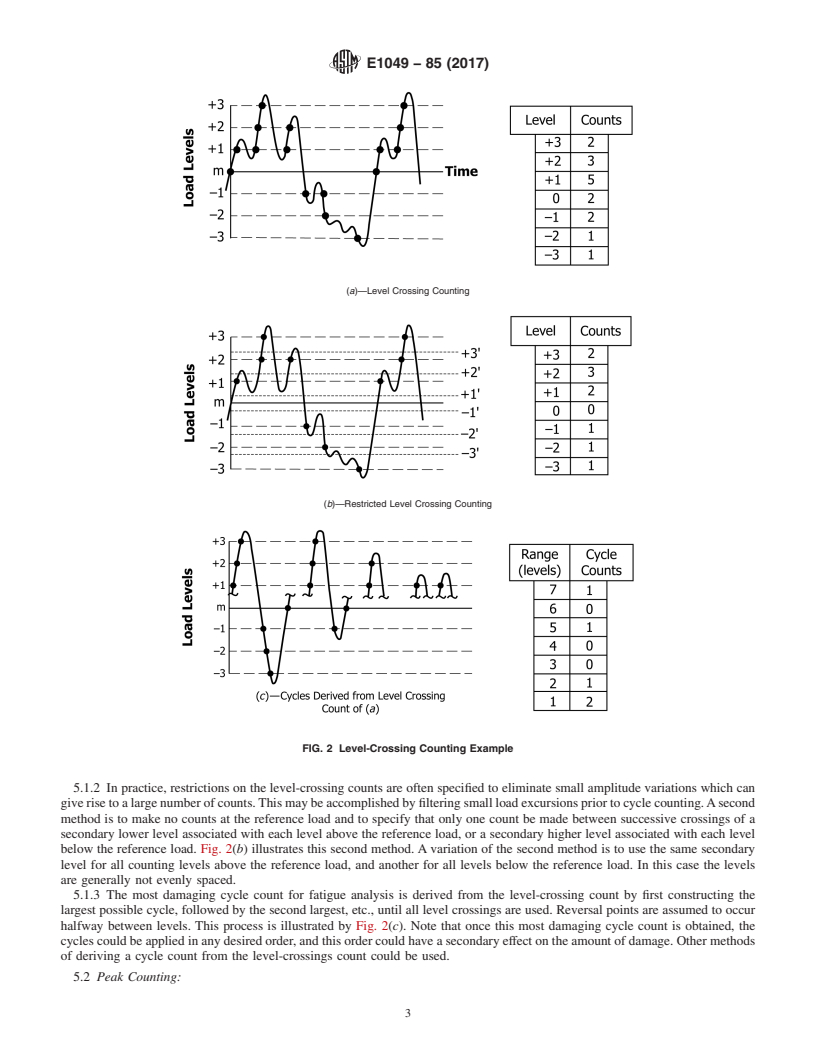

4.1 Cycle counting is used to summarize (often lengthy) irregular load-versus-time histories by providing the number of times cycles of various sizes occur. The definition of a cycle varies with the method of cycle counting. These practices cover the procedures used to obtain cycle counts by various methods, including level-crossing counting, peak counting, simple-range counting, range-pair counting, and rainflow counting. Cycle counts can be made for time histories of force, stress, strain, torque, acceleration, deflection, or other loading parameters of interest.

SCOPE

1.1 These practices are a compilation of acceptable procedures for cycle-counting methods employed in fatigue analysis. This standard does not intend to recommend a particular method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1049 − 85 (Reapproved 2017)

Standard Practices for

1

Cycle Counting in Fatigue Analysis

This standard is issued under the fixed designation E1049; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 mean crossings—in fatigue loading, the number of

times that the load-time history crosses the mean-load level

1.1 These practices are a compilation of acceptable proce-

with a positive slope (or a negative slope, or both, as specified)

duresforcycle-countingmethodsemployedinfatigueanalysis.

during a given length of the history (see Fig. 1).

This standard does not intend to recommend a particular

3.1.3.1 Discussion—For purposes related to cycle counting,

method.

a mean crossing may be defined as a crossing of the reference

1.2 This standard does not purport to address all of the

load level.

safety concerns, if any, associated with its use. It is the

3.1.4 mean load, P —in fatigue loading, the algebraic

responsibility of the user of this standard to establish appro- m

average of the maximum and minimum loads in constant

priate safety and health practices and determine the applica-

amplitude loading, or of individual cycles in spectrum loading,

bility of regulatory limitations prior to use.

1.3 This international standard was developed in accor-

P 5 P 1P /2 (1)

~ !

m max min

dance with internationally recognized principles on standard-

or the integral average of the instantaneous load values or

ization established in the Decision on Principles for the

the algebraic average of the peak and valley loads of a spec-

Development of International Standards, Guides and Recom-

trum loading history.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 3.1.5 peak—in fatigue loading, the point at which the first

derivative of the load-time history changes from a positive to

2. Referenced Documents

a negative sign; the point of maximum load in constant

2

amplitude loading (see Fig. 1).

2.1 ASTM Standards:

E912 Definitions of Terms Relating to Fatigue Loading;

3.1.6 range—in fatigue loading, the algebraic difference

3

Replaced by E 1150 (Withdrawn 1988)

between successive valley and peak loads (positive range or

increasing load range), or between successive peak and valley

3. Terminology

loads (negative range or decreasing load range); see Fig. 1.

3.1 Definitions:

NOTE 2—In spectrum loading, range may have a different definition,

3.1.1 constant amplitude loading—in fatigue loading,a

depending on the counting method used; for example, “overall range” is

loading in which all of the peak loads are equal and all of the

defined by the algebraic difference between the largest peak and the

valley loads are equal.

smallest valley of a given load-time history.

3.1.2 cycle—in fatigue loading, under constant amplitude

3.1.6.1 Discussion—In cycle counting by various methods,

loading, the load variation from the minimum to the maximum

it is common to employ ranges between valley and peak loads,

and then to the minimum load.

or between peak and valley loads, which are not necessarily

successive events. In these practices, the definition of the word

NOTE 1—In spectrum loading, definition of cycle varies with the

counting method used.

“range” is broadened so that events of this type are also

included.

1

These practices are under the jurisdiction ofASTM Committee E08 on Fatigue

3.1.7 reversal—in fatigue loading, the point at which the

and Fracture and are the direct responsibility of Subcommittee E08.04 on Structural

first derivative of the load-time history changes sign (see Fig.

Applications.

1).

Current edition approved June 1, 2017. Published June 2017. Originally

ɛ1

approved in 1985. Last previous edition approved in 2011 as E1049–85(2011) .

NOTE 3—In constant amplitude loading, a cycle is equal to two

DOI: 10.1520/E1049-85R17.

reversals.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.8 spectrum loading—in fatigue loading, a loading in

Standards volume information, refer to the standard’s Document Summary page on

which all of the peak loads are not equal or all of the valley

the ASTM website.

3

loadsarenotequal,orboth.(Alsoknownasvariableamplitude

The last approved version of this historical standard is referenced on

www.astm.org. loading or irregular loading.)

Copyright © ASTM International, 100 Barr Harbor Drive, P

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1049 − 85 (Reapproved 2017)

Standard Practices for

1

Cycle Counting in Fatigue Analysis

This standard is issued under the fixed designation E1049; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 mean crossings—in fatigue loading, the number of

times that the load-time history crosses the mean-load level

1.1 These practices are a compilation of acceptable proce-

with a positive slope (or a negative slope, or both, as specified)

dures for cycle-counting methods employed in fatigue analysis.

during a given length of the history (see Fig. 1).

This standard does not intend to recommend a particular

3.1.3.1 Discussion—For purposes related to cycle counting,

method.

a mean crossing may be defined as a crossing of the reference

1.2 This standard does not purport to address all of the

load level.

safety concerns, if any, associated with its use. It is the

3.1.4 mean load, P —in fatigue loading, the algebraic

responsibility of the user of this standard to establish appro- m

average of the maximum and minimum loads in constant

priate safety and health practices and determine the applica-

amplitude loading, or of individual cycles in spectrum loading,

bility of regulatory limitations prior to use.

1.3 This international standard was developed in accor-

P 5 ~P 1P !/2 (1)

m max min

dance with internationally recognized principles on standard-

or the integral average of the instantaneous load values or

ization established in the Decision on Principles for the

the algebraic average of the peak and valley loads of a spec-

Development of International Standards, Guides and Recom-

trum loading history.

mendations issued by the World Trade Organization Technical

3.1.5 peak—in fatigue loading, the point at which the first

Barriers to Trade (TBT) Committee.

derivative of the load-time history changes from a positive to

2. Referenced Documents

a negative sign; the point of maximum load in constant

2

amplitude loading (see Fig. 1).

2.1 ASTM Standards:

E912 Definitions of Terms Relating to Fatigue Loading;

3.1.6 range—in fatigue loading, the algebraic difference

3

Replaced by E 1150 (Withdrawn 1988)

between successive valley and peak loads (positive range or

increasing load range), or between successive peak and valley

3. Terminology

loads (negative range or decreasing load range); see Fig. 1.

3.1 Definitions:

NOTE 2—In spectrum loading, range may have a different definition,

3.1.1 constant amplitude loading—in fatigue loading, a

depending on the counting method used; for example, “overall range” is

loading in which all of the peak loads are equal and all of the

defined by the algebraic difference between the largest peak and the

valley loads are equal.

smallest valley of a given load-time history.

3.1.2 cycle—in fatigue loading, under constant amplitude

3.1.6.1 Discussion—In cycle counting by various methods,

loading, the load variation from the minimum to the maximum

it is common to employ ranges between valley and peak loads,

and then to the minimum load.

or between peak and valley loads, which are not necessarily

NOTE 1—In spectrum loading, definition of cycle varies with the successive events. In these practices, the definition of the word

counting method used.

“range” is broadened so that events of this type are also

included.

1

These practices are under the jurisdiction of ASTM Committee E08 on Fatigue 3.1.7 reversal—in fatigue loading, the point at which the

and Fracture and are the direct responsibility of Subcommittee E08.04 on Structural

first derivative of the load-time history changes sign (see Fig.

Applications.

1).

Current edition approved June 1, 2017. Published June 2017. Originally

ɛ1

approved in 1985. Last previous edition approved in 2011 as E1049–85(2011) .

NOTE 3—In constant amplitude loading, a cycle is equal to two

DOI: 10.1520/E1049-85R17.

reversals.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.8 spectrum loading—in fatigue loading, a loading in

Standards volume information, refer to the standard’s Document Summary page on

which all of the peak loads are not equal or all of the valley

the ASTM website.

3 loads are not equal, or both. (Also known as variable amplitude

The last approved version of this historical standard is referenced on

www.astm.org. loading or irregular loading.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1049 −

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1049 − 85 (Reapproved 2011) E1049 − 85 (Reapproved 2017)

Standard Practices for

1

Cycle Counting in Fatigue Analysis

This standard is issued under the fixed designation E1049; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Reference (12) was editorially corrected in October 2011.

1. Scope

1.1 These practices are a compilation of acceptable procedures for cycle-counting methods employed in fatigue analysis. This

standard does not intend to recommend a particular method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

E912 Definitions of Terms Relating to Fatigue Loading; Replaced by E 1150 (Withdrawn 1988)

3. Terminology

3.1 Definitions:

3.1.1 constant amplitude loading—in fatigue loading, a loading in which all of the peak loads are equal and all of the valley

loads are equal.

3.1.2 cycle—in fatigue loading, under constant amplitude loading, the load variation from the minimum to the maximum and

then to the minimum load.

NOTE 1—In spectrum loading, definition of cycle varies with the counting method used.

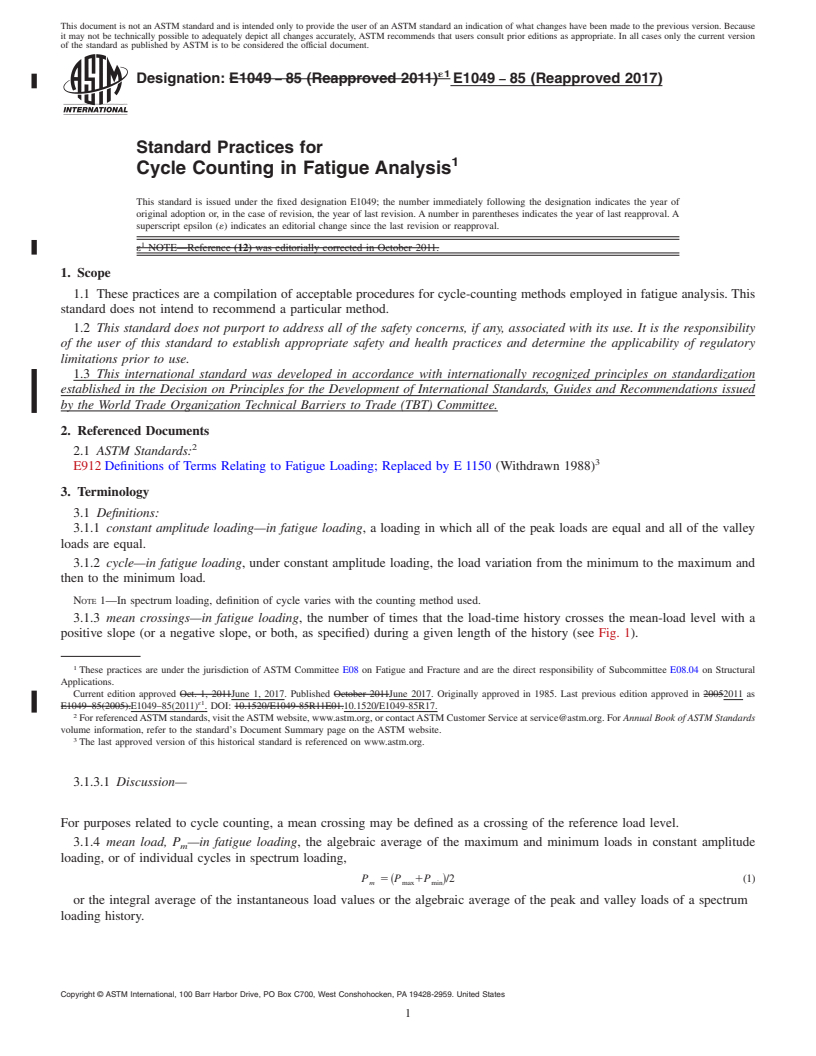

3.1.3 mean crossings—in fatigue loading, the number of times that the load-time history crosses the mean-load level with a

positive slope (or a negative slope, or both, as specified) during a given length of the history (see Fig. 1).

1

These practices are under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and are the direct responsibility of Subcommittee E08.04 on Structural

Applications.

Current edition approved Oct. 1, 2011June 1, 2017. Published October 2011June 2017. Originally approved in 1985. Last previous edition approved in 20052011 as

ɛ1

E1049–85(2005).E1049–85(2011) . DOI: 10.1520/E1049-85R11E01.10.1520/E1049-85R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

3.1.3.1 Discussion—

For purposes related to cycle counting, a mean crossing may be defined as a crossing of the reference load level.

3.1.4 mean load, P —in fatigue loading, the algebraic average of the maximum and minimum loads in constant amplitude

m

loading, or of individual cycles in spectrum loading,

P 5 ~P 1P !/2 (1)

m max min

or the integral average of the instantaneous load values or the algebraic average of the peak and valley loads of a spectrum

loading history.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1049 − 85 (2017)

FIG. 1 Basic Fatigue Loading Parameters

3.1.5 peak—in fatigue loading, the point at which the first derivative of the load-time history changes from a positive to a

negative sign; the point of maximum load in constant amplitude loading (see Fig. 1).

3.1.6 range—in fatigue loading, the algebraic difference between successive valley and peak loads (positive range or increasing

load range), or between successive peak and valley loads (negative range or decreasing load range); see Fig. 1.

NOTE 2—In spectrum loading, range may have a different definition, depending on the counting method used; for example, “overall range” is defined

by the algebraic difference between the largest peak and the smallest valley of a given load-time history.

3.1.6.1 Discussion—

In cycle counting by various methods, it is common to employ ranges between valley and peak loads, or between peak and valley

loads, which are not necessarily successive events. In these practices, the definition of the word “range” is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.