ASTM E1049-85(2011)e1

(Practice)Standard Practices for Cycle Counting in Fatigue Analysis

Standard Practices for Cycle Counting in Fatigue Analysis

SIGNIFICANCE AND USE

Cycle counting is used to summarize (often lengthy) irregular load-versus-time histories by providing the number of times cycles of various sizes occur. The definition of a cycle varies with the method of cycle counting. These practices cover the procedures used to obtain cycle counts by various methods, including level-crossing counting, peak counting, simple-range counting, range-pair counting, and rainflow counting. Cycle counts can be made for time histories of force, stress, strain, torque, acceleration, deflection, or other loading parameters of interest.

SCOPE

1.1 These practices are a compilation of acceptable procedures for cycle-counting methods employed in fatigue analysis. This standard does not intend to recommend a particular method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1049 − 85 (Reapproved 2011)

Standard Practices for

Cycle Counting in Fatigue Analysis

This standard is issued under the fixed designation E1049; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reference (12) was editorially corrected in October 2011.

1. Scope 3.1.3.1 Discussion—For purposes related to cycle counting,

a mean crossing may be defined as a crossing of the reference

1.1 These practices are a compilation of acceptable proce-

load level.

duresforcycle-countingmethodsemployedinfatigueanalysis.

This standard does not intend to recommend a particular 3.1.4 mean load, P —in fatigue loading, the algebraic

m

method. average of the maximum and minimum loads in constant

amplitude loading, or of individual cycles in spectrum loading,

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the P 5 P 1P /2 (1)

~ !

m max min

responsibility of the user of this standard to establish appro-

or the integral average of the instantaneous load values or

priate safety and health practices and determine the applica-

the algebraic average of the peak and valley loads of a spec-

bility of regulatory limitations prior to use.

trum loading history.

2. Referenced Documents

3.1.5 peak—in fatigue loading, the point at which the first

derivative of the load-time history changes from a positive to

2.1 ASTM Standards:

a negative sign; the point of maximum load in constant

E912 Definitions of Terms Relating to Fatigue Loading;

amplitude loading (see Fig. 1).

Replaced by E 1150 (Withdrawn 1988)

3.1.6 range—in fatigue loading, the algebraic difference

3. Terminology

between successive valley and peak loads (positive range or

3.1 Definitions: increasing load range), or between successive peak and valley

3.1.1 constant amplitude loading—in fatigue loading,a loads (negative range or decreasing load range); see Fig. 1.

loading in which all of the peak loads are equal and all of the

NOTE 2—In spectrum loading, range may have a different definition,

valley loads are equal.

depending on the counting method used; for example, “overall range” is

defined by the algebraic difference between the largest peak and the

3.1.2 cycle—in fatigue loading, under constant amplitude

smallest valley of a given load-time history.

loading, the load variation from the minimum to the maximum

and then to the minimum load.

3.1.6.1 Discussion—In cycle counting by various methods,

it is common to employ ranges between valley and peak loads,

NOTE 1—In spectrum loading, definition of cycle varies with the

counting method used. or between peak and valley loads, which are not necessarily

successive events. In these practices, the definition of the word

3.1.3 mean crossings—in fatigue loading, the number of

“range” is broadened so that events of this type are also

times that the load-time history crosses the mean-load level

included.

with a positive slope (or a negative slope, or both, as specified)

during a given length of the history (see Fig. 1).

3.1.7 reversal—in fatigue loading, the point at which the

first derivative of the load-time history changes sign (see Fig.

1).

These practices are under the jurisdiction ofASTM Committee E08 on Fatigue

and Fracture and are the direct responsibility of Subcommittee E08.04 on Structural

NOTE 3—In constant amplitude loading, a cycle is equal to two

Applications.

reversals.

Current edition approved Oct. 1, 2011. Published October 2011. Originally

approvedin1985.Lastpreviouseditionapprovedin2005asE1049–85(2005).DOI:

3.1.8 spectrum loading—in fatigue loading, a loading in

10.1520/E1049-85R11E01.

which all of the peak loads are not equal or all of the valley

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

loadsarenotequal,orboth.(Alsoknownasvariableamplitude

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on loading or irregular loading.)

the ASTM website.

3.1.9 valley—in fatigue loading, the point at which the first

The last approved version of this historical standard is referenced on

www.astm.org. derivative of the load-time history changes from a negative to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1049 − 85 (2011)

FIG. 1 Basic Fatigue Loading Parameters

a positive sign (also known as trough); the point of minimum counting. A second method is to make no counts at the

load in constant amplitude loading (see Fig. 1).

reference load and to specify that only one count be made

between successive crossings of a secondary lower level

3.2 Definitions of Terms Specific to This Standard:

associated with each level above the reference load, or a

3.2.1 load—used in these practices to denote force, stress,

secondary higher level associated with each level below the

strain, torque, acceleration, deflection, or other parameters of

reference load. Fig. 2(b) illustrates this second method. A

interest.

variation of the second method is to use the same secondary

3.2.2 reference load—for spectrum loading, used in these

level for all counting levels above the reference load, and

practices to denote the loading level that represents a steady-

another for all levels below the reference load. In this case the

state condition upon which load variations are superimposed.

levels are generally not evenly spaced.

The reference load may be identical to the mean load of the

5.1.3 The most damaging cycle count for fatigue analysis is

history, but this is not required.

derived from the level-crossing count by first constructing the

3.3 For other definitions of terms used in these practices

largest possible cycle, followed by the second largest, etc.,

refer to Definitions E912.

until all level crossings are used. Reversal points are assumed

to occur halfway between levels. This process is illustrated by

4. Significance and Use

Fig. 2(c). Note that once this most damaging cycle count is

4.1 Cycle counting is used to summarize (often lengthy)

obtained, the cycles could be applied in any desired order, and

irregularload-versus-timehistoriesbyprovidingthenumberof

this order could have a secondary effect on the amount of

times cycles of various sizes occur. The definition of a cycle

damage. Other methods of deriving a cycle count from the

varieswiththemethodofcyclecounting.Thesepracticescover

level-crossings count could be used.

the procedures used to obtain cycle counts by various methods,

including level-crossing counting, peak counting, simple-range

5.2 Peak Counting:

counting, range-pair counting, and rainflow counting. Cycle

5.2.1 Peak counting identifies the occurrence of a relative

counts can be made for time histories of force, stress, strain,

maximum or minimum load value. Peaks above the reference

torque, acceleration, deflection, or other loading parameters of

load level are counted, and valleys below the reference load

interest.

level are counted, as shown in Fig. 3(a). Results for peaks and

valleys are usually reported separately. A variation of this

5. Procedures for Cycle Counting

method is to count all peaks and valleys without regard to the

5.1 Level-Crossing Counting:

reference load.

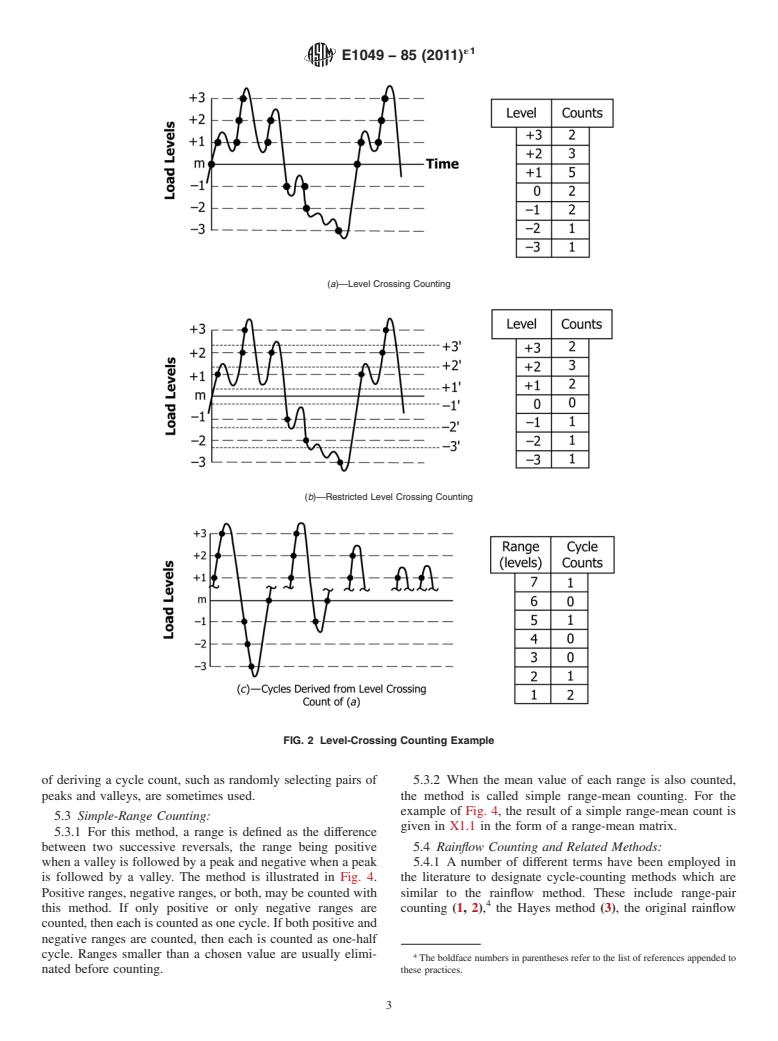

5.1.1 Results of a level-crossing count are shown in Fig.

5.2.2 To eliminate small amplitude loadings, mean-crossing

2(a). One count is recorded each time the positive sloped

peak counting is often used. Instead of counting all peaks and

portion of the load exceeds a preset level above the reference

valleys, only the largest peak or valley between two successive

load, and each time the negative sloped portion of the load

mean crossings is counted as shown in Fig. 3(b).

exceeds a preset level below the reference load. Reference load

5.2.3 The most damaging cycle count for fatigue analysis is

crossings are counted on the positive sloped portion of the

derived from the peak count by first constructing the largest

loading history. It makes no difference whether positive or

possible cycle, using the highest peak and lowest valley,

negative slope crossings are counted. The distinction is made

followed by the second largest cycle, etc., until all peak counts

only to reduce the total number of events by a factor of two.

are used.This process is illustrated by Fig. 3(c). Note that once

5.1.2 In practice, restrictions on the level-crossing counts

are often specified to eliminate small amplitude variations thismostdamagingcyclecountisobtained,thecyclescouldbe

applied in any desired order, and this order could have a

which can give rise to a large number of counts. This may be

accomplished by filtering small load excursions prior to cycle secondary effect on the amount of damage. Alternate methods

´1

E1049 − 85 (2011)

(a)—Level Crossing Counting

(b)—Restricted Level Crossing Counting

FIG. 2 Level-Crossing Counting Example

of deriving a cycle count, such as randomly selecting pairs of 5.3.2 When the mean value of each range is also counted,

peaks and valleys, are sometimes used. the method is called simple range-mean counting. For the

example of Fig. 4, the result of a simple range-mean count is

5.3 Simple-Range Counting:

given in X1.1 in the form of a range-mean matrix.

5.3.1 For this method, a range is defined as the difference

between two successive reversals, the range being positive 5.4 Rainflow Counting and Related Methods:

when a valley is followed by a peak and negative when a peak 5.4.1 A number of different terms have been employed in

is followed by a valley. The method is illustrated in Fig. 4. the literature to designate cycle-counting methods which are

Positive ranges, negative ranges, or both, may be counted with similar to the rainflow method. These include range-pair

this method. If only positive or only negative ranges are counting (1, 2), the Hayes method (3), the original rainflow

counted, then each is counted as one cycle. If both positive and

negative ranges are counted, then each is counted as one-half

cycle. Ranges smaller than a chosen value are usually elimi-

The boldface numbers in parentheses refer to the list of references appended to

nated before counting. these practices.

´1

E1049 − 85 (2011)

(a)—Peak Counting

(b)—Mean Crossing Peak Counting

(c)—Cycles Derived from Peak Count of (a)

FIG. 3 Peak Counting Example

method (4-6), range-pair-range counting (7), ordered overall they are referred to as two-parameter methods.When the mean

range counting (8), racetrack counting (9), and hysteresis loop value is ignored, they are one-parameter methods, as are

counting (10). If the load history begins and ends with its simple-range counting, peak counting, etc.

maximum peak, or with its minimum valley, all of these give 5.4.3 Range-Pair Counting—The range-paired method

identical counts. In other cases, the counts are similar, but not counts a range as a cycle if it can be paired with a subsequent

generally identical. Three methods in this class are defined loading in the opposite direction. Rules for this method are as

here: range-pair counting, rainflow counting, and a simplified follows:

method for repeating histories. 5.4.3.1 Let X denote range under consideration; and Y,

5.4.2 The various methods similar to the rainflow method previous range adjacent to X.

may be used to obtain cycles and the mean value of each cycle; (1) Read next peak or valley. If out of data, go to Step 5.

´1

E1049 − 85 (2011)

FIG. 4 Simple Range Counting Example—Both Positive and Negative Ranges Counted

(2) If there are less than three points, go to Step 1. Form (8) End of counting. See the table in Fig. 5 for a summary

ranges X and Y using the three most recent peaks and valleys of the cycles counted in this example, and see Appendix X1.2

that have not been discarded. for this cycle count in the form of a range-mean matrix.

(3) Compare the absolute values of ranges X and Y. 5.4.4 Rainflow Counting:

(a)If X < Y, go to Step 1. 5.4.4.1 Rules for this method are as follows: let X denote

(b)If X ≥ Y, go to Step 4. rangeunderconsideration; Y,previousrangeadjacentto X;and

(4) Count range Y as one cycle and discard the peak and S, starting point in the history.

valley of Y; go to Step 2. (1) Read next peak or valley. If out of data, go to Step 6.

(5) The remaining cycles, if any, are counted by starting at (2) If there are less than three points, go to Step 1. Form

the end of the sequence and counting backwards. If a single ranges X and Y using the three most recent peaks and valleys

range remains, it may be counted as a half or full cycle. that have not been discarded.

5.4.3.2 The load history in Fig. 4 is replotted as Fig. 5(a) (3) Compare the absolute values of ranges X and Y.

and is used to illustrate the process. Details of the cycle (a)IfX

counting are as follows: (b)If X ≥ Y, go to Step 4.

(1) Y =|A-B |; X =|B-C|; andX>Y. Count |A-B|asone (4) If range Y contains the starting point S, go to Step 5;

cycle and discard points A and B. (See Fig. 5(b). Note that a otherwise, count range Y as one cycle; discard the peak and

cycle is formed by pairing range A-B and a portion of range valley of Y; and go to Step 2.

B-C.) (5) Count range Y as one-half cycle; discard the first point

(2) Y = |C-D|; X = |D-E|; andX

(3) Y = |D-E|; X = |E-F|; andX

(4) Y = |E-F|; X = |F-G|; andX>Y. Count |E-F|asone (6) Count each range that has not been previously counted

cycle and discard points E and F. (See Fig. 5(c).) as one-half cycle.

(5) Y = |C-D|; X = |D-G|; andX>Y. Count |C-D| as one 5.4.4.2 The load history of Fig. 4 is replotted as Fig. 6(a)

cycle and discard points C and D. (See Fig. 5(d).) and is used to illustrate the process. Details of the cycle

(6) Y = |G-H|; X = |H-I|; andX

count backwards. (1)S=A;Y = |A-B|;X = |B-C|;X>Y.YcontainsS,thatis,

(7) Y = |H-I|; X = |G-H|; andX>Y. Count |H-I|asone point A. Count |A-B| as one-half cycle and discard point A;

cycle and discard points H and I. (See Fig. 5(e).) S=B. (See Fig. 6(b).)

´1

E1049 − 85 (2011)

(a)(b)

(c)(d)

FIG. 5 Range-Pair Counting Example

(2) Y = |B-C|; X = |C-D|;X>Y.Y contains S, that is, point (10) Endofcounting.See

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.