ASTM D6643-01

(Test Method)Standard Test Method for Testing Wood-Base Panel Corner Impact Resistance

Standard Test Method for Testing Wood-Base Panel Corner Impact Resistance

SCOPE

1.1 This test method shall be used to measure the relative corner impact resistance and other damage that may occur during the rough handling of wood-base panels or composite materials. This test method is suitable for all wood-base panels such as plywood, oriented strand board, hardboard, particleboard and medium density fiberboard as well as other composite panel products.

1.2 This test method covers determination and evaluation of the effects of panels being dropped from various heights with a predetermined amount of dead load and angle of impact to simulate an equivalent field application.

1.3 The values of all information will be stated in English units and regarded as standard. The SI values are written in parentheses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6643–01

Standard Test Method for

Testing Wood-Base Panel Corner Impact Resistance

This standard is issued under the fixed designation D 6643; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Corner impact resistance may be an important property for wood-base panel applications such as

pallets, cargo crates, concrete form boards, fruit and vegetable boxes and furniture. There is a need to

have suitable corner impact resistance in such products to ensure satisfactory end–use performance.

This test method provides a technique to assess relative corner impact resistance of wood-base panels.

This test method uses a vertical test frame to create corner impact on a panel specimen. The test

specimen is held in a fixture that free-falls to the floor. The test specimen is examined for distance of

impact damage and for qualitative damage.

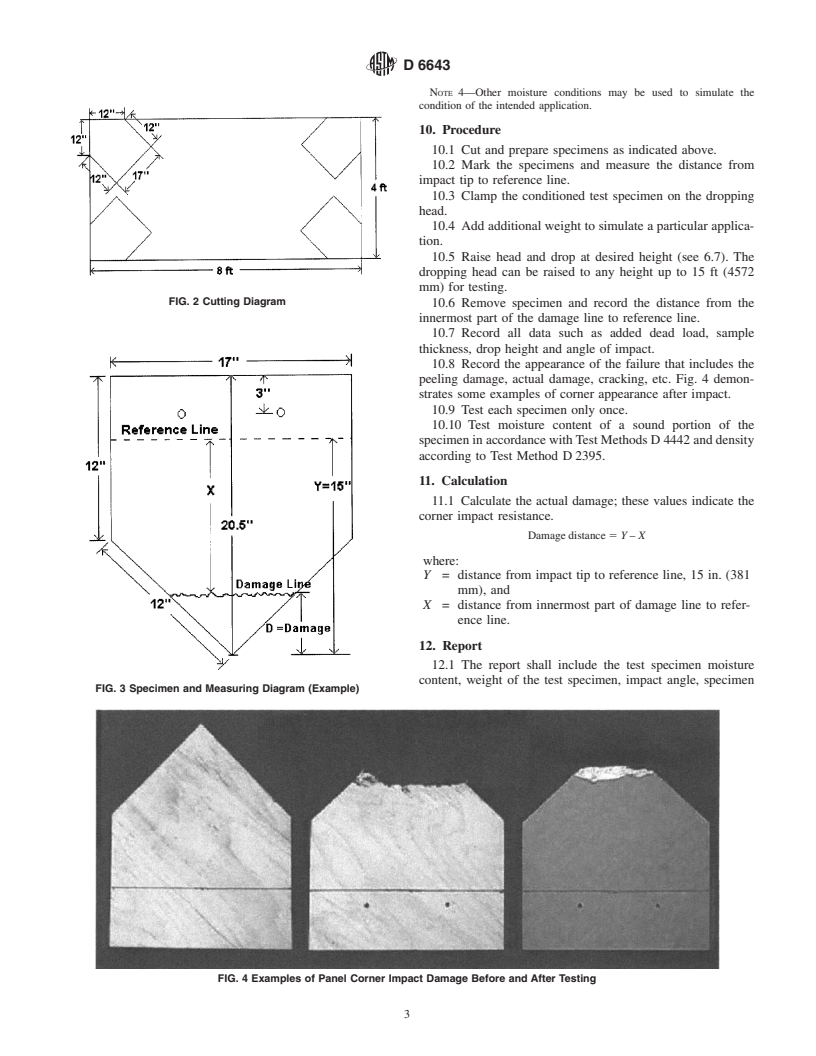

1. Scope 3.1.1 actual damage, n—distance of damage counted from

tip to damage line after dropping.

1.1 This test method shall be used to measure the relative

3.1.2 damage line, n—the innermost line where crushing

corner impact resistance and other damage that may occur

occurs.

during the rough handling of wood-base panels or composite

3.1.3 dropping head, n—the part of the machine connected

materials. This test method is suitable for all wood-base panels

to the quick release mechanism that holds the test specimen

such as plywood, oriented strand board, hardboard, particle-

andaddedamountofdeadload.Thedroppingheadfree-fallsto

board and medium density fiberboard as well as other compos-

create the impact between the panel specimen and the floor.

ite panel products.

3.1.4 impact tip, n—the part of the specimen that will make

1.2 This test method covers determination and evaluation of

initial contact with the floor after dropping.

the effects of panels being dropped from various heights with

3.1.5 peeling, n—the furthermost splintering from the dam-

a predetermined amount of dead load and angle of impact to

age line. This provides additional understanding of damage

simulate an equivalent field application.

characteristics.

1.3 The values of all information will be stated in English

3.1.6 pull cord, n—cord that is connected to the quick

units and regarded as standard. The SI values are written in

release mechanism that allows a quick release of the dropping

parentheses.

head by pulling.

1.4 This standard does not purport to address all of the

3.1.7 quick release mechanism, n—the equipment that al-

safety concerns, if any, associated with its use. It is the

lows for free release of the head when the pull cord is

responsibility of the user of this standard to establish appro-

activated.

priate safety and health practices and determine the applica-

3.1.8 reference line, n—line from which all measurements

bility of regulatory limitations prior to use.

are taken. This allows samples to be cut to approximate size

2. Referenced Documents and still ensure accurate values.

2.1 ASTM Standards:

4. Summary of Test Method

D 2395 Test Method for Specific Gravity of Wood and

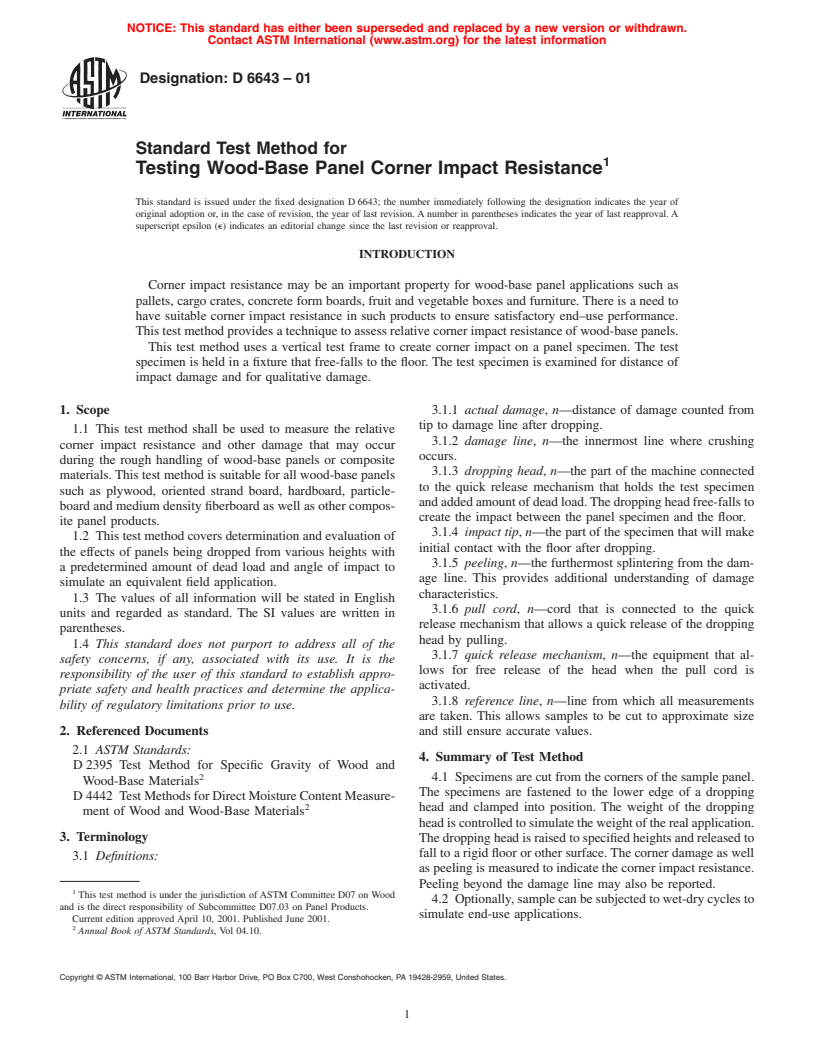

4.1 Specimens are cut from the corners of the sample panel.

Wood-Base Materials

The specimens are fastened to the lower edge of a dropping

D 4442 TestMethodsforDirectMoistureContentMeasure-

head and clamped into position. The weight of the dropping

ment of Wood and Wood-Base Materials

headiscontrolledtosimulatetheweightoftherealapplication.

3. Terminology

The dropping head is raised to specified heights and released to

fall to a rigid floor or other surface. The corner damage as well

3.1 Definitions:

as peeling is measured to indicate the corner impact resistance.

Peeling beyond the damage line may also be reported.

This test method is under the jurisdiction of ASTM Committee D07 on Wood

4.2 Optionally, sample can be subjected to wet-dry cycles to

and is the direct responsibility of Subcommittee D07.03 on Panel Products.

simulate end-use applications.

Current edition approved April 10, 2001. Published June 2001.

Annual Book of ASTM Standards, Vol 04.10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6643

NOTE 1—The weight of the dropping head may be adjusted to target a

5. Significance and Use

different weight if relevant to a specific intended application. This

5.1 This test method determines the corner impact damage

typically requires additional weight to be added to the dropping head.

that could be used to measure the relative corner impact

6.3 Metal bars should support the dropping head while

resistance.

changing specimens and the dead load to ensure no accidents

occur during adjustments. The test specimen should be

6. Apparatus

clamped to the bottom of the dropping head to make sure the

6.1 The drop test frame shall accommodate the test speci-

corner of the specimen will contact the floor first. A hook is

mensasdefinedinSection8.Atestframe15-ft(4572-mm)tall,

mounted at the top of the dropping head to attach to the quick

27-in. (686-mm) wide and 15-in. (381-mm) deep has been

release mechanism.

found suitable. The drop test frame shall be made of steel or

6.4 Attached to the quick release mechanism is a pull cord

other suitable material with two guide poles placed on either

for the operator to start the test. A hand winch with a cable is

side to allow for smooth, low friction dropping from controlled

also connected to the quick release mechanism to winch the

heights. The lower half of the frame should be covered with a

dropping head and test specimen to the desired height.

metal mesh to provide protection from flying debris. A door

6.5 The test frame is equipped with a measuring device to

should be placed at the bot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.