ASTM F2118-03(2009)

(Test Method)Test Method for Constant Amplitude of Force Controlled Fatigue Testing of Acrylic Bone Cement Materials

Test Method for Constant Amplitude of Force Controlled Fatigue Testing of Acrylic Bone Cement Materials

SIGNIFICANCE AND USE

This test method describes a uniaxial, constant amplitude, fully reversed fatigue test to characterize the fatigue performance of a uniform cylindrical waisted specimen manufactured from acrylic bone cement.

This test method considers two approaches to evaluating the fatigue performance of bone cement:

Testing is conducted at three stress levels to characterize the general fatigue behavior of a cement over a range of stresses. The stress level and resultant cycles to failure of the specimens are plotted on an S-N diagram.

Another approach is to determine the fatigue strength of a particular cement. The fatigue strength for orthopaedic bone cement is to be determined at 5 million (5 × 106) cycles. The “two-point method” is the specified procedure for conducting fatigue testing to determine fatigue strength (1).

This test method does not define or suggest required levels of performance of bone cement. This fatigue test method is not intended to represent the clinical use of orthopaedic bone cement, but rather to characterize the material using standard and well-established methods. The user is cautioned to consider the appropriateness of this test method in view of the material being tested and its potential application.

It is widely reported that multiple clinical factors affect the fatigue performance of orthopaedic bone cement; however, the actual mechanisms involved are not well understood. Clinical factors which may affect the performance of bone cement include: temperature and humidity, mixing method, time of application, surgical technique, bone preparation, implant design, and patient factors, among others. This test method does not specifically address these clinical factors. The test method can be used to compare different acrylic bone cement formulations and products and different mixing methods and environments (that is, mixing temperature, vacuum, centrifugation, and so forth).

SCOPE

1.1 This test method describes test procedures for evaluating the constant amplitude, uniaxial, tension-compression uniform fatigue performance of acrylic bone cement materials.

1.2 This test method is relevant to orthopaedic bone cements based on acrylic resins, as specified in Specification F 451. The procedures in this test method may or may not apply to other surgical cement materials.

1.3 It is not the intention of this test method to define levels of performance of these materials. Furthermore, it is not the intention of this test method to directly simulate the clinical use of these materials.

1.4 A rationale is given in Appendix X1.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2118–03 (Reapproved 2009)

Standard Test Method for

Constant Amplitude of Force Controlled Fatigue Testing of

Acrylic Bone Cement Materials

This standard is issued under the fixed designation F2118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ISO7206-8 ImplantsforSurgery,PartialandTotalHipJoint

Prostheses, Part 8—Endurance Performance of Stemmed

1.1 This test method describes test procedures for evaluat-

Femoral Components with Application of Torsion

ing the constant amplitude, uniaxial, tension-compression uni-

form fatigue performance of acrylic bone cement materials.

3. Terminology

1.2 This test method is relevant to orthopaedic bone ce-

3.1 Unless otherwise given, the definitions for fatigue ter-

ments based on acrylic resins, as specified in Specification

minology given in Terminology E1823 will be used.

F451.Theproceduresinthistestmethodmayormaynotapply

3.2 median fatigue strength at N cycles—The maximum

to other surgical cement materials.

stress at which 50 % of the specimens of a given sample would

1.3 It is not the intention of this test method to define levels

be expected to survive N loading cycles. For the purposes of

of performance of these materials. Furthermore, it is not the

this test method, the fatigue strength will be determined at 5

intentionofthistestmethodtodirectlysimulatetheclinicaluse

million load cycles. A rationale for this is provided in the

of these materials.

Appendix X1.4.

1.4 A rationale is given in Appendix X1.

3.3 runout—Apredeterminednumberofcyclesatwhichthe

1.5 The values stated in SI units are to be regarded as

testing on a particular specimen will be stopped, and no further

standard. No other units of measurement are included in this

testingonthatspecimenwillbeperformed.Forthepurposesof

standard.

this test method, the runout will be 5 million load cycles.

1.6 This standard does not purport to address all of the

3.4 stress level—The value of stress at which a series of

safety concerns associated with its use. It is the responsibility

duplicate tests are performed. For the purposes of this test

oftheuserofthisstandardtoconsultandestablishappropriate

method, the stress level is reported as the maximum stress

safety and health practices and determine the applicability of

applied to the specimen.

regulatory limitations prior to use.

3.5 specimen failure—The condition at which the specimen

2. Referenced Documents completelybreaksorisdamagedtosuchanextentthattheload

2 frame is no longer able to apply the intended stress within the

2.1 ASTM Standards:

required limits.

E466 Practice for Conducting Force Controlled Constant

Amplitude Axial Fatigue Tests of Metallic Materials

4. Summary of Test Method

E467 Practice for Verification of Constant Amplitude Dy-

4.1 Uniformcylindricalreducedgagesectiontestspecimens

namic Forces in an Axial Fatigue Testing System

are manufactured from acrylic bone cement and mounted in a

E1823 Terminology Relating to Fatigue and Fracture Test-

uniaxial fatigue frame. The specimen is subjected to fully

ing

reversed tensile and compressive loading in a sinusoidal cyclic

F451 Specification for Acrylic Bone Cement

manner at a specified frequency in phosphate buffered saline

2.2 ISO Standard:

(PBS).Thefatigueloadingiscontinueduntilthespecimenfails

or a predetermined number of cycles (runout limit) is reached.

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

5. Significance and Use

F04.15 on Material Test Methods.

5.1 This test method describes a uniaxial, constant ampli-

Current edition approved April 1, 2009. Published April 2009. Originally

approved in 2001. Last previous edition approved in 2003 as F2118 – 03. DOI: tude, fully reversed fatigue test to characterize the fatigue

10.1520/F2118-03R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2118–03 (2009)

performance of a uniform cylindrical waisted specimen manu- 6. Apparatus

factured from acrylic bone cement.

6.1 Uniaxial Load Frame—A testing machine capable of

5.2 Thistestmethodconsiderstwoapproachestoevaluating

applying cyclic sinusoidal tensile and compressive loads.

the fatigue performance of bone cement:

6.1.1 The crossheads of the load frame shall be aligned such

5.2.1 Testing is conducted at three stress levels to charac-

that the alignment meets the requirements of 8.2 of Practice

terize the general fatigue behavior of a cement over a range of

E466. The alignment should be checked at both the maximum

stresses. The stress level and resultant cycles to failure of the

tensileandminimumcompressiveloadtobeappliedduringthe

specimens are plotted on an S-N diagram.

course of a test program.

5.2.2 Another approach is to determine the fatigue strength

6.2 Cycle Counter—Adevice capable of counting the num-

of a particular cement. The fatigue strength for orthopaedic

ber of loading cycles applied to a specimen during the course

bone cement is to be determined at 5 million (5 3 10 ) cycles.

of a fatigue test.

The “two-point method” is the specified procedure for con-

6.3 Load Cell—A load cell capable of measuring dynamic

ducting fatigue testing to determine fatigue strength (1).

tensile and compressive loads in accordance with Practice

5.3 This test method does not define or suggest required

E467.

levels of performance of bone cement.This fatigue test method

6.4 Limit—A device capable of detecting when a test

isnotintendedtorepresenttheclinicaluseoforthopaedicbone

parameter (for example, load magnitude, actuator displace-

cement, but rather to characterize the material using standard

ment,DCerror,andsoforth)reachesalimitingvalue,atwhich

and well-established methods. The user is cautioned to con-

time the test is stopped and the current cycle count recorded.

sider the appropriateness of this test method in view of the

6.5 Environmental Chamber—A chamber designed to im-

material being tested and its potential application.

merse the fatigue specimen completely in a solution. The

5.4 It is widely reported that multiple clinical factors affect

chamber should have provisions for maintaining a constant

the fatigue performance of orthopaedic bone cement; however,

temperature to an accuracy of 62°C.

the actual mechanisms involved are not well understood.

Clinical factors which may affect the performance of bone

7. Test Specimen

cement include: temperature and humidity, mixing method,

time of application, surgical technique, bone preparation, 7.1 Test specimens shall be fabricated from cement that is

representative of the final product with regard to materials,

implant design, and patient factors, among others. This test

method does not specifically address these clinical factors.The manufacturing processes, sterilization, and packaging. Steril-

ization methods have been shown to have an effect on fatigue

test method can be used to compare different acrylic bone

cement formulations and products and different mixing meth- performance. Any deviations of the test cement from the

clinically used product must be reported.

ods and environments (that is, mixing temperature, vacuum,

centrifugation, and so forth). 7.2 Cylindrical reduced gage section test specimens with a

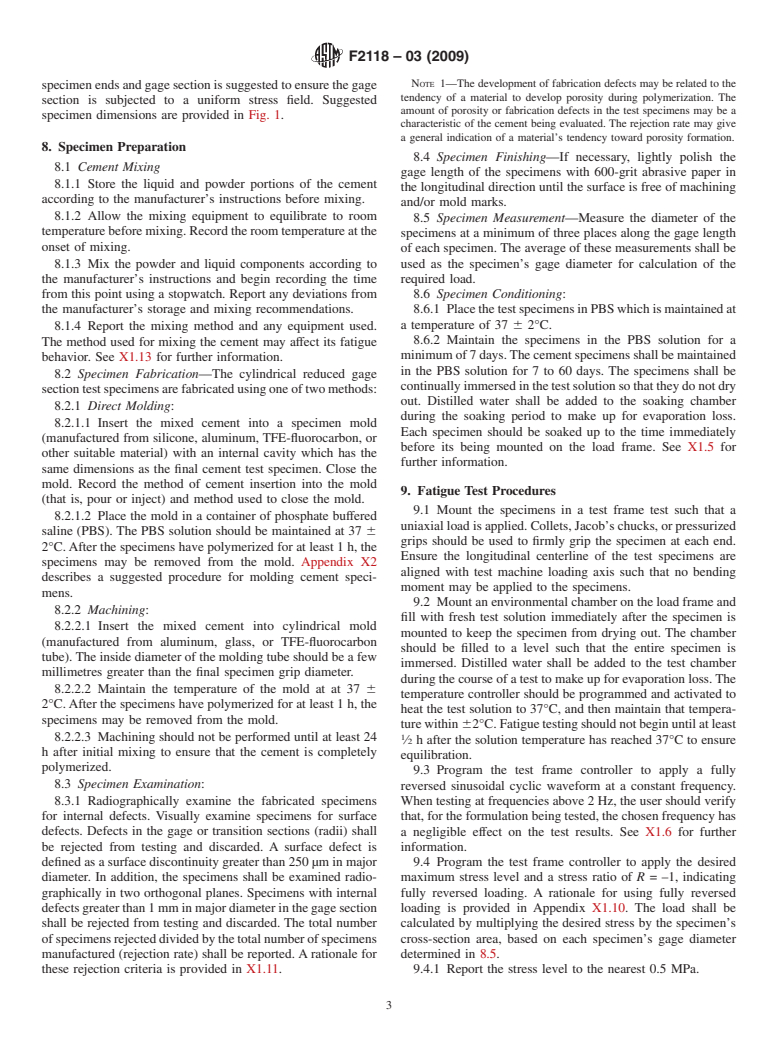

straight 5-mm diameter by 10-mm-long gage section shall be

used. The diameter of the specimen ends shall be substantially

greater than the gage diameter to ensure that fracture occurs in

The boldface numbers in parentheses refer to a list of references at the end of the gage section. A smooth radius or taper between the

this standard.

FIG. 1 Specimen Dimensions

F2118–03 (2009)

NOTE 1—The development of fabrication defects may be related to the

specimenendsandgagesectionissuggestedtoensurethegage

tendency of a material to develop porosity during polymerization. The

section is subjected to a uniform stress field. Suggested

amount of porosity or fabrication defects in the test specimens may be a

specimen dimensions are provided in Fig. 1.

characteristic of the cement being evaluated. The rejection rate may give

a general indication of a material’s tendency toward porosity formation.

8. Specimen Preparation

8.4 Specimen Finishing—If necessary, lightly polish the

8.1 Cement Mixing

gage length of the specimens with 600-grit abrasive paper in

8.1.1 Store the liquid and powder portions of the cement

the longitudinal direction until the surface is free of machining

according to the manufacturer’s instructions before mixing.

and/or mold marks.

8.1.2 Allow the mixing equipment to equilibrate to room

8.5 Specimen Measurement—Measure the diameter of the

temperaturebeforemixing.Recordtheroomtemperatureatthe

specimens at a minimum of three places along the gage length

onset of mixing.

of each specimen. The average of these measurements shall be

8.1.3 Mix the powder and liquid components according to used as the specimen’s gage diameter for calculation of the

the manufacturer’s instructions and begin recording the time required load.

8.6 Specimen Conditioning:

from this point using a stopwatch. Report any deviations from

the manufacturer’s storage and mixing recommendations. 8.6.1 PlacethetestspecimensinPBSwhichismaintainedat

a temperature of 37 6 2°C.

8.1.4 Report the mixing method and any equipment used.

8.6.2 Maintain the specimens in the PBS solution for a

The method used for mixing the cement may affect its fatigue

minimumof7days.Thecementspecimensshallbemaintained

behavior. See X1.13 for further information.

in the PBS solution for 7 to 60 days. The specimens shall be

8.2 Specimen Fabrication—The cylindrical reduced gage

continuallyimmersedinthetestsolutionsothattheydonotdry

sectiontestspecimensarefabricatedusingoneoftwomethods:

out. Distilled water shall be added to the soaking chamber

8.2.1 Direct Molding:

during the soaking period to make up for evaporation loss.

8.2.1.1 Insert the mixed cement into a specimen mold

Each specimen should be soaked up to the time immediately

(manufactured from silicone, aluminum, TFE-fluorocarbon, or

before its being mounted on the load frame. See X1.5 for

other suitable material) with an internal cavity which has the

further information.

same dimensions as the final cement test specimen. Close the

mold. Record the method of cement insertion into the mold

9. Fatigue Test Procedures

(that is, pour or inject) and method used to close the mold.

9.1 Mount the specimens in a test frame test such that a

8.2.1.2 Place the mold in a container of phosphate buffered

uniaxial load is applied. Collets, Jacob’s chucks, or pressurized

saline (PBS). The PBS solution should be maintained at 37 6

grips should be used to firmly grip the specimen at each end.

2°C.After the specimens have polymerized for at least 1 h, the

Ensure the longitudinal centerline of the test specimens are

specimens may be removed from the mold. Appendix X2

aligned with test machine loading axis such that no bending

describes a suggested procedure for molding cement speci-

moment may be applied to the specimens.

mens.

9.2 Mount an environmental chamber on the load frame and

8.2.2 Machining:

fill with fresh test solution immediately after the specimen is

8.2.2.1 Insert the mixed cement into cylindrical mold

mounted to keep the specimen from drying out. The chamber

(manufactured from aluminum, glass, or TFE-fluorocarbon

should be filled to a level such that the entire specimen is

tube).The inside diameter of the molding tube should be a few

immersed. Distilled water shall be added to the test chamber

millimetres greater than the final specimen grip diameter.

during the course of a test to make up for evaporation loss.The

8.2.2.2 Maintain the temperature of the mold at at 37 6

temperature controller should be programmed and activated to

2°C.After the specimens have polymerized for at least 1 h, the

heat the test solution to 37°C, and then maintain that tempera-

specimens may be removed from the mold.

turewithin 62°C.Fatiguetestingshouldnotbeginuntilatleast

8.2.2.3 Machining should not be performed until at least 24

⁄2 h after the solution temperature has reached 37°C to ensure

h after initial mixing to ensure that the cement is completely

equilibration.

polymerized.

9.3 Program the test frame controller to apply a fully

8.3 Specimen Examination:

reversed sinusoidal cyclic waveform at a constant frequency.

8.3.1 Radiographically examine the fabricated specimens When testing at frequencies above 2 Hz, the user should verify

for internal defects. Visually examine specimens for surface that, for the formulation being tested, the chosen frequency has

defects. Defects in the gage or transition sections (radii) shall a negligible effect on the test results. See X1.6 for further

be rejected from testing and discarded. A surface defect is information.

defined as a surface discontinuity greater than 250 µm in major 9.4 Program the test frame controller to apply the desired

diameter. In addition, the specimens shall be examined radio- maximum stress level and a stress ratio of R = –1, indicating

graphically in two orthogonal planes. Specimens with internal fully reversed loading. A rationale for using fully reversed

defectsgreaterthan1mminmajordiameterinthegagesection loading is provided in Appendix X1.10. The load shall be

shall be rejected from testing and discarded. The total number calculated by multiplying the desired stress by the specimen’s

ofspecimensrejecteddividedbythetotalnumberofspecimens cross-section area, based on each specimen’s gage diameter

manufactured (rejection rate) shall be reported. A rationale for determined in 8.5.

these rejection criteria is provided in X1.11. 9.4.1 Report the stress level to the nearest 0.5 MPa.

F2118–03 (2009)

9.4.2 When developing an S-N curve, it is recommended The probability of survival for each specimen is determined

that testing be conducted at the following maximum stress using the following equation:

levels: 15, 12.5, and 10 MPa. Other stress levels may also be

P~y! 51–[y – 0.3]/[n 1 0.4] (5)

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2118–01a

Test Method for Designation:F2118–03 (Reapproved 2009)

Standard Test Method for

Constant Amplitude of Force Controlled Fatigue Testing of

Acrylic Bone Cement Materials

This standard is issued under the fixed designation F 2118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard test method describes test procedures for evaluating the constant amplitude, uniaxial, tension-compression

uniform fatigue performance of acrylic bone cement materials.

1.2 This standard test method is relevant to orthopaedic bone cements based on acrylic resins, as specified in Specification

F 451. The procedures in this guide test method may or may not apply to other surgical cement materials.

1.3 It is not the intention of this standard test method to define levels of performance of these materials. Furthermore, it is not

the intention of this standardtest method to directly simulate the clinical use of these materials.

1.4 A rationale is given in Appendix X1.

1.5The values stated in SI units are to be regarded as the standard.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the

user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E 467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

E 1823 Terminology Relating to Fatigue and Fracture Testing

F 451 Standard Specification for Acrylic Bone Cement

2.2 ISO Standard:

ISO 7206-8 Implants for Surgery, Partial andTotal Hip Joint Prostheses, Part 8—Endurance Performance of Stemmed Femoral

Components with Application of Torsion

3. Terminology Unless

3.1 Unless otherwise given, the definitions for fatigue terminology given in Terminology E 1823 will be used.

3.13.2 Median Fatigue Strengthmedian fatigue strength at N Cyclescycles—The maximum stress at which 50 % of the

specimens of a given sample would be expected to survive N loading cycles. For the purposes of this test method, the fatigue

strength will be determined at 5 million load cycles. A rationale for this is provided in the Appendix X1.4.

3.2Runout—A predetermined number of cycles at which the testing on a particular specimen will be stopped, and no further

testing on that specimen will be performed. For the purposes of this test method, the runout will be 5 million load cycles.

3.3 Stress Level—The value of stress at which a series of duplicate tests are performed. For the purposes of this method, the

stress level is reported as the maximum stress applied to the specimen. runout—A predetermined number of cycles at which the

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved October 10, 2001. Published November 2001. Originally published as F2118-01. Last previous edition F2118-01.

Current edition approved April 1, 2009. Published April 2009. Originally approved in 2001. Last previous edition approved in 2003 as F2118 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 13.01.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2118–03 (2009)

testing on a particular specimen will be stopped, and no further testing on that specimen will be performed. For the purposes of

this test method, the runout will be 5 million load cycles.

3.4 Specimen Failurestress level—The value of stress at which a series of duplicate tests are performed. For the purposes of

this test method, the stress level is reported as the maximum stress applied to the specimen.

3.5 specimen failure—The condition at which the specimen completely breaks or is damaged to such an extent that the load

frame is no longer able to apply the intended stress within the required limits.

4. Summary of Test Method

4.1 Uniform cylindrical reduced gage section test specimens are manufactured from acrylic bone cement and mounted in a

uniaxial fatigue frame. The specimen is subjected to fully reversed tensile and compressive loading in a sinusoidal cyclic manner

at a specified frequency in phosphate buffered saline (PBS). The fatigue loading is continued until the specimen fails or a

predetermined number of cycles (runout limit) is reached.

5. Significance and Use

5.1 This test method describes a uniaxial, constant amplitude, fully reversed fatigue test to characterize the fatigue performance

of a uniform cylindrical waisted specimen manufactured from acrylic bone cement.

5.2 This test method considers two approaches to evaluating the fatigue performance of bone cement:

5.2.1 Testing is conducted at three stress levels to characterize the general fatigue behavior of a cement over a range of stresses.

The stress level and resultant cycles to failure of the specimens are plotted on an S-N diagram.

5.2.2 Another approach is to determine the fatigue strength of a particular cement. The fatigue strength for orthopaedic bone

cement is to be determined at 5 million (5 3 10 ) cycles.The “two-point method” is the specified procedure for conducting fatigue

testing to determine fatigue strength [(1]).

5.3 Thisstandardtestmethoddoesnotdefineorsuggestrequiredlevelsofperformanceofbonecement.Thisfatiguetestmethod

is not intended to represent the clinical use of orthopaedic bone cement, but rather to characterize the material using standard and

well-established methods. The user is cautioned to consider the appropriateness of this test method in view of the material being

tested and its potential application.

5.4 It is widely reported that multiple clinical factors affect the fatigue performance of orthopaedic bone cement; however, the

actual mechanisms involved are not well understood. Clinical factors which may affect the performance of bone cement include:

temperature and humidity, mixing method, time of application, surgical technique, bone preparation, implant design, and patient

factors,amongothers.Thistestmethoddoesnotspecificallyaddresstheseclinicalfactors.Thetestmethodcanbeusedtocompare

different acrylic bone cement formulations and products and different mixing methods and environments (that is, mixing

temperature, vacuum, centrifugation, and so forth).

6. Apparatus

6.1 Uniaxial Load Frame—A testing machine capable of applying cyclic sinusoidal tensile and compressive loads.

6.1.1 The crossheads of the load frame shall be aligned such that the alignment meets the requirements of 8.2 of Practice E 466.

The alignment should be checked at both the maximum tensile and minimum compressive load to be applied during the course

of a test program.

6.2 Cycle Counter— A device capable of counting the number of loading cycles applied to a specimen during the course of a

fatigue test.

6.3 Load Cell—A load cell capable of measuring dynamic tensile and compressive loads in accordance with Practice E 467.

6.4 Limit—Adevice capable of detecting when a test parameter (for example, load magnitude, actuator displacement, DC error,

and so forth) reaches a limiting value, at which time the test is stopped and the current cycle count recorded.

6.5 Environmental Chamber—A chamber designed to immerse the fatigue specimen completely in a solution. The chamber

should have provisions for maintaining a constant temperature to an accuracy of 62°C.

7. Test Specimen

7.1 Test specimens shall be fabricated from cement that is representative of the final product with regard to materials,

manufacturing processes, sterilization, and packaging. Sterilization methods have been shown to have an effect on fatigue

performance. Any deviations of the test cement from the clinically used product must be reported.

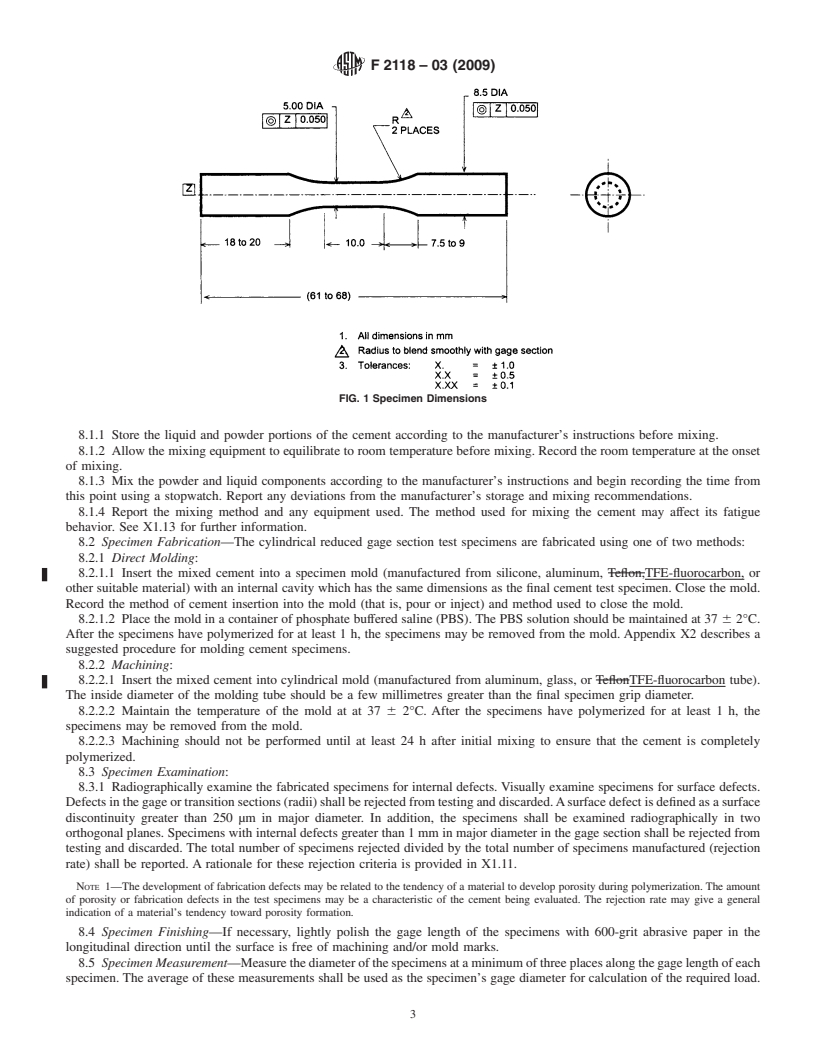

7.2 Cylindrical reduced gage section test specimens with a straight 5-mm diameter by 10-mm-long gage section shall be used.

The diameter of the specimen ends shall be substantially greater than the gage diameter to ensure that fracture occurs in the gage

section.Asmooth radius or taper between the specimen ends and gage section is suggested to ensure the gage section is subjected

to a uniform stress field. Suggested specimen dimensions are provided in Fig. 1.

8. Specimen Preparation

8.1 Cement Mixing

Available from American National Standards Institute, 25 W. 43rd St, 4th Floor, New York, NY 10036.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

F2118–03 (2009)

FIG. 1 Specimen Dimensions

8.1.1 Store the liquid and powder portions of the cement according to the manufacturer’s instructions before mixing.

8.1.2 Allow the mixing equipment to equilibrate to room temperature before mixing. Record the room temperature at the onset

of mixing.

8.1.3 Mix the powder and liquid components according to the manufacturer’s instructions and begin recording the time from

this point using a stopwatch. Report any deviations from the manufacturer’s storage and mixing recommendations.

8.1.4 Report the mixing method and any equipment used. The method used for mixing the cement may affect its fatigue

behavior. See X1.13 for further information.

8.2 Specimen Fabrication—The cylindrical reduced gage section test specimens are fabricated using one of two methods:

8.2.1 Direct Molding:

8.2.1.1 Insert the mixed cement into a specimen mold (manufactured from silicone, aluminum, Teflon,TFE-fluorocarbon, or

other suitable material) with an internal cavity which has the same dimensions as the final cement test specimen. Close the mold.

Record the method of cement insertion into the mold (that is, pour or inject) and method used to close the mold.

8.2.1.2 Place the mold in a container of phosphate buffered saline (PBS). The PBS solution should be maintained at 37 6 2°C.

After the specimens have polymerized for at least 1 h, the specimens may be removed from the mold. Appendix X2 describes a

suggested procedure for molding cement specimens.

8.2.2 Machining:

8.2.2.1 Insert the mixed cement into cylindrical mold (manufactured from aluminum, glass, or TeflonTFE-fluorocarbon tube).

The inside diameter of the molding tube should be a few millimetres greater than the final specimen grip diameter.

8.2.2.2 Maintain the temperature of the mold at at 37 6 2°C. After the specimens have polymerized for at least 1 h, the

specimens may be removed from the mold.

8.2.2.3 Machining should not be performed until at least 24 h after initial mixing to ensure that the cement is completely

polymerized.

8.3 Specimen Examination:

8.3.1 Radiographically examine the fabricated specimens for internal defects. Visually examine specimens for surface defects.

Defectsinthegageortransitionsections(radii)shallberejectedfromtestinganddiscarded.Asurfacedefectisdefinedasasurface

discontinuity greater than 250 µm in major diameter. In addition, the specimens shall be examined radiographically in two

orthogonal planes. Specimens with internal defects greater than 1 mm in major diameter in the gage section shall be rejected from

testing and discarded. The total number of specimens rejected divided by the total number of specimens manufactured (rejection

rate) shall be reported. A rationale for these rejection criteria is provided in X1.11.

NOTE 1—The development of fabrication defects may be related to the tendency of a material to develop porosity during polymerization. The amount

of porosity or fabrication defects in the test specimens may be a characteristic of the cement being evaluated. The rejection rate may give a general

indication of a material’s tendency toward porosity formation.

8.4 Specimen Finishing—If necessary, lightly polish the gage length of the specimens with 600-grit abrasive paper in the

longitudinal direction until the surface is free of machining and/or mold marks.

8.5 Specimen Measurement—Measurethediameterofthespecimensataminimumofthreeplacesalongthegagelengthofeach

specimen. The average of these measurements shall be used as the specimen’s gage diameter for calculation of the required load.

F2118–03 (2009)

8.6 Specimen Conditioning:

8.6.1 Place the test specimens in PBS which is maintained at a temperature of 37 6 2°C.

8.6.2 Maintain the specimens in the PBS solution for a minimum of 7 days. The cement specimens shall be maintained in the

PBSsolutionfor7to60days.Thespecimensshallbecontinuallyimmersedinthetestsolutionsothattheydonotdryout.Distilled

water shall be added to the soaking chamber during the soaking period to make up for evaporation loss. Each specimen should

be soaked up to the time immediately before its being mounted on the load frame. See X1.5 for further information.

9. Fatigue Test Procedures

9.1 Mount the specimens in a test frame test such that a uniaxial load is applied. Collets, Jacob’s chucks, or pressurized grips

should be used to firmly grip the specimen at each end. Ensure the longitudinal centerline of the test specimens are aligned with

test machine loading axis such that no bending moment may be applied to the specimens.

9.2 Mount an environmental chamber on the load frame and fill with fresh test solution immediately after the specimen is

mounted to keep the specimen from drying out. The chamber should be filled to a level such that the entire specimen is immersed.

Distilled water shall be added to the test chamber during the course of a test to make up for evaporation loss. The temperature

controller shou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.