ASTM D6194-97

(Test Method)Standard Test Method for Glow-Wire Ignition of Materials

Standard Test Method for Glow-Wire Ignition of Materials

SCOPE

1.1 This test method covers the minimum temperature required to ignite insulating materials using a glowing heat source. In a preliminary fashion, this test method differentiates between the susceptabilities of different materials with respect to their resistance to ignition due to an electrically-heated source.

General Information

Relations

Standards Content (Sample)

Designation: D 6194 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Glow-Wire Ignition of Materials

This standard is issued under the fixed designation D 6194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 IEC Standard:

IEC 695-2-1/3: Fire Hazard Testing, Part 2: Test Methods,

1.1 This test method covers the minimum temperature

5

Section 1: Glow-Wire Ignitability Test for Materials

required to ignite insulating materials using a glowing heat

2.3 ISO Standard:

source. In a preliminary fashion, this test method differentiates

6

ISO/IEC Guide 52: Glossary of Fire Terms and Definitions

between the susceptibilities of different materials with respect

to their resistance to ignition due to an electrically-heated

3. Terminology

source.

3.1 Definitions:

1.2 This test method applies to molded or sheet materials

3.1.1 Use Terminology E 176 and ISO/IEC Guide 52 for

available in thicknesses ranging from 0.25 to 6.4 mm.

definitions of terms used in this test method and associated

1.3 This test method is not valid for determining the ignition

with fire issues. Where differences exist in definitions, those

behavior of complete electrotechnical equipment, since the

contained in Terminology E 176 shall be used. Use Terminol-

design of the electrotechnical product influences the heat

ogy D 1711 for definitions of terms used in this test method and

transfer between adjacent parts.

associated with electrical insulation materials.

1.4 This test method measures and describes the response or

3.2 Definitions of Terms Specific to This Standard:

materials, products, or assemblies to heat and flame under

3.2.1 glow wire, n—a wire of specified dimensions that can

controlled conditions, but does not by itself incorporate all

be controllably-heated electrically to determine ignitability of a

factors required for fire hazard or fire risk assessment of the

material.

materials, products, or assemblies under actual fire conditions.

3.2.1.1 Discussion—Fig. 1 shows a glow wire and its

1.5 The values stated in SI units are to be regarded as the

positioning.

standard.

3.2.2 ignition, n—initiation of combustion.

1.6 This standard does not purport to address all of the

3.2.2.1 Discussion—Ignition is deemed to have taken place

safety concerns, if any, associated with its use. It is the

when the first of the following occurs: sustained flaming on the

responsibility of the user of this standard to establish appro-

test specimen surface for over5sor falling particles causing

priate safety and health practices and determine the applica-

the appearance of flames on a tissue paper placed underneath

bility of regulatory limitations prior to use. For specific

the test specimen.

precautionary statements, see Section 8.

4. Significance and Use

NOTE 1—Although this test method and IEC 695-2-1/3 differ in

4.1 Under certain conditions of operation, or when malfunc-

approach and in detail, data obtained using either are technically equiva-

lent. tions occur, it is possible that components of electrotechnical

products become overheated. When this happens, a possible

2. Referenced Documents

result is ignition of the adjacent insulation material.

2.1 ASTM Standards:

4.2 This test method assesses the susceptibility of electrical

D 1711 Definitions of Terms Relating to Electrical Insula-

insulating materials to ignition under such conditions.

2

tion

4.3 This test method determines the minimum temperature

3

E 176 Terminology of Fire Standards

required to ignite a material by the effect of a glowing heat

E 220 Method for Calibration of Thermocouples by Com-

source, under the conditions of test.

4

parison Techniques

4.4 Subject to limitations in precision and bias, this test

E 230 Temperature-Electromotive Force (EMF) Tables for

method can be used to categorize materials.

4

Standardized Thermocouples

5. Apparatus

1

This test method is under the jurisdiction of ASTM Committee D-9 on

5.1 Glow-Wire—Nichrome wire (nominal 80 % nickel/

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.12 on Electrical Tests.

5

Current edition approved Nov. 10, 1997. Published January 1998. Available from International Electrotechnical Commission (IEC), 3 Rue de

2

Annual Book of ASTM Standards, Vol 10.01. Varembe, Geneva, Switzerland.

3 6

Annual Book of ASTM Standards, Vol 04.07. Use undyed, soft, strong, lightweight tissue paper weighing between 12 and 30

4 2

Annual Book of ASTM Standards, Vol 14.03. g/m .

1

---------------------- Page: 1 ----------------------

D 6194

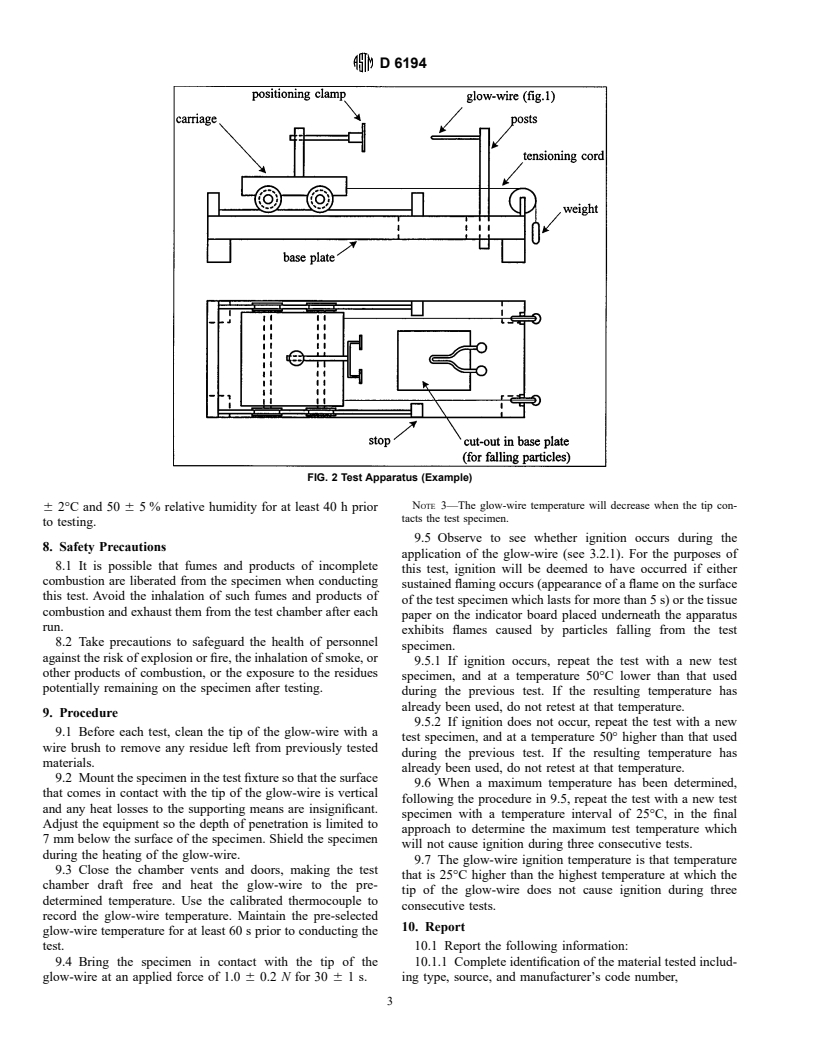

NOTE 1—All dimensions in millimetres.

FIG. 1 Glow-Wire and Positioning of the Thermocou

...

This May Also Interest You

SIGNIFICANCE AND USE

5.1 This test method provides a means to measure a variety of fire-test-response characteristics associated with heat and smoke release and resulting from burning the materials insulating electrical or optical fiber cables, when made into cables and installed on a vertical cable tray. The specimens are allowed to burn freely under well ventilated conditions after ignition by means of a propane gas burner. The ignition source used in this test method is also described as a premixed flame flaming ignition source in Practice E3020, which contains an exhaustive compilation of ignition sources.

5.2 The rate of heat release often serves as an indication of the intensity of the fire generated. General considerations of the importance of heat release rate are discussed in Appendix X1 and considerations for heat release calculations are in Appendix X2.

5.3 Other fire-test-response characteristics that are measurable by this test method are useful to make decisions on fire safety. The test method is also used for measuring smoke obscuration. The apparatus described here is also useful to measure gaseous components of smoke; the most important gaseous components of smoke are the carbon oxides, present in all fires. The carbon oxides are major indicators of the completeness of combustion and are often used as part of fire hazard assessment calculations and to improve the accuracy of heat release measurements.

5.4 Test Limitations:

5.4.1 The fire-test-response characteristics measured in this test are a representation of the manner in which the specimens tested behave under certain specific conditions. Do not assume they are representative of a generic fire performance of the materials tested when made into cables of the construction under consideration.

5.4.2 In particular, it is unlikely that this test is an adequate representation of the fire behavior of cables in confined spaces, without abundant circulation of air.

5.4.3 This is an intermediate-scale test...

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means to measure the heat released and smoke obscuration by burning the electrical insulating materials contained in electrical or optical fiber cables when the cable specimens, excluding accessories, are subjected to a specified flaming ignition source and burn freely under well ventilated conditions. Flame propagation cable damage, by char length, and mass loss are also measured.

1.3 This test method provides two different protocols for exposing the materials, when made into cable specimens, to an ignition source (approximately 20 kW), for a 20 min test duration. Use it to determine the heat release, smoke release, flame propagation and mass loss characteristics of the materials contained in single and multiconductor electrical or optical fiber cables.

1.4 This test method does not provide information on the fire performance of materials insulating electrical or optical fiber cables in fire conditions other than the ones specifically used in this test method nor does it measure the contribution of the materials in those cables to a developing fire condition.

1.5 Data describing the burning behavior from ignition to the end of the test are obtained.

1.6 This test equipment is suitable for measuring the concentrations of certain toxic gas species in the combustion gases (see Appendix X4).

1.7 The values stated in SI units are to be regarded as standard (see IEEE/ASTM SI-10). The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.8 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions

...

- Standard21 pagesEnglish languagesale 15% off

- Standard21 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method provides a means to measure a variety of fire-test-response characteristics associated with smoke obscuration and resulting from burning the electrical insulating materials contained in electrical or optical fiber cables. The specimens are allowed to burn freely under well ventilated conditions after ignition by means of a propane gas burner.

5.2 Smoke obscuration quantifies the visibility in fires.

5.3 This test method is also suitable for measuring the rate of heat release as an optional measurement. The rate of heat release often serves as an indication of the intensity of the fire generated. Test Method D5537 provides means for measuring heat release with the equipment used in this test method.

5.4 Other optional fire-test-response characteristics that are measurable by this test method are useful to make decisions on fire safety. The most important gaseous components of smoke are the carbon oxides, present in all fires. They are major indicators of the toxicity of the atmosphere and of the completeness of combustion, and are often used as part of fire hazard assessment calculations and to improve the accuracy of heat release measurements. Other toxic gases, which are specific to certain materials, are less crucial for determining combustion completeness.

5.5 Test Limitations:

5.5.1 The fire-test-response characteristics measured in this test method are a representation of the manner in which the specimens tested behave under certain specific conditions. Do not assume they are representative of a generic fire performance of the materials tested when made into cables of the construction under consideration.

5.5.2 In particular, it is unlikely that this test method is an adequate representation of the fire behavior of cables in confined spaces, without abundant circulation of air.

5.5.3 This is an intermediate-scale test, and the predictability of its results to large scale fires has not been determined. Some information ...

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means to measure the smoke obscuration resulting from burning electrical insulating materials contained in electrical or optical fiber cables when the cable specimens, excluding accessories, are subjected to a specified flaming ignition source and burn freely under well ventilated conditions.

1.3 This test method provides two different protocols for exposing the materials, when made into cable specimens, to an ignition source (approximately 20 kW), for a 20 min test duration. Use it to determine the flame propagation and smoke release characteristics of the materials contained in single and multiconductor electrical or optical fiber cables designed for use in cable trays.

1.4 This test method does not provide information on the fire performance of electrical or optical fiber cables in fire conditions other than the ones specifically used in this test method, nor does it measure the contribution of the cables to a developing fire condition.

1.5 Data describing the burning behavior from ignition to the end of the test are obtained.

1.6 The production of light obscuring smoke is measured.

1.7 The burning behavior is documented visually, by photographic or video recordings, or both.

1.8 The test equipment is suitable for making other, optional, measurements, including the rate of heat release of the burning specimen, by an oxygen consumption technique and weight loss.

1.9 Another set of optional measurements are the concentrations of certain toxic gas species in the combustion gases.

1.10 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. (See IEEE/ASTM SI 10.)

1.11 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety...

- Standard21 pagesEnglish languagesale 15% off

- Standard21 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 During operation of electrical equipment, including wires, resistors, and other conductors, it is possible for overheating to occur under certain conditions of operation, or when malfunctions occur. When this happens, a possible result is ignition of the adjacent insulation material.

5.2 This test method assesses the susceptibility of electrical insulating materials to ignition as a result of exposure to a glowing wire.

5.3 This test method determines the minimum temperature required to ignite a material by the effect of a glowing heat source, under the specified conditions of test.

5.4 This method is suitable, subject to the appropriate limitations of an expected precision of ±15 %, to categorize materials.

5.5 In this procedure, the specimens are subjected to one or more specific sets of laboratory conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure.

SCOPE

1.1 This test method covers the minimum temperature required to ignite insulating materials using a glowing heat source. In a preliminary fashion, this test method differentiates between the susceptibilities of different materials with respect to their resistance to ignition due to an electrically-heated source.

1.2 This test method applies to molded or sheet materials available in thicknesses ranging from 0.25 mm to 6.4 mm.

1.3 This test method is not valid for determining the ignition behavior of complete electrotechnical equipment, since the design of the electrotechnical product influences the heat transfer between adjacent parts.

1.4 This test method measures and describes the response or materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. (See IEEE/ASTM SI-10 for further details.)For specific precautionary statements, see Section 9.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 9.

1.7 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

Note 1: Although this test method and IEC 60695-2-12 differ in approach and in detail, data obtained to determine the glow-wire flammability index (GWFI) using either test method are technically similar. Although this test method and IEC 60695-2-13 differ in approach and in detail, data obtained to determine the glow-wire ignition temperature (GWIT) using either test method are technically similar.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Test Method A is the required flammability test for: crosslinked chlorinated polyolefin heat-shrinkable tubing for electrical insulation (Specification D2903), crosslinked poly(vinylidene fluoride) heat-shrinkable tubing for electrical insulation (Specification D3144), and crosslinked and noncrosslinked poly(vinyl chloride) heat-shrinkable tubing for electrical insulation (Specification D3150).

5.2 Test Method A is also one of the flammability tests used for nonrigid vinyl chloride polymer tubing used for electrical insulation (in Test Methods D876), flexible treated sleeving used for electrical insulation (Test Methods D350), and heat-shrinkable tubing for electrical use (Test Methods D2671).

5.3 Test Method B is another flammability test (together with Test Method A) used for flexible treated sleeving used for electrical insulation (Test Methods D350).

5.4 Test Methods C and D are other flammability tests (together with Test Method A) used for heat-shrinkable tubing for electrical use (Test Methods D2671). In both tests the electrical insulating material is fitted with a metallic core. The electrical insulating material is tested after shrinking, but using different mandrels.

5.5 In these test methods, the test specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. The results are therefore valid only for the fire-test-exposure conditions described in this procedure.

SCOPE

1.1 This is a fire-test-response standard.

1.2 This fire test response standard contains various tests applicable to electrical insulation materials used for sleeving or for tubing (including heat-shrinkable tubing).

1.2.1 Test methods C and D are applicable to heat-shrinkable tubing only.

1.3 Use the values stated in SI units in referee decisions; see IEEE/ASTM SI-10. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard8 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This vertical flame test provides information regarding the flammability performance of electrical insulating materials.

5.2 This test method is used to assess the vertical flame test performance of electrical insulation materials used in wires or cables in Test Methods D2633 and D3032 (Test A), as well as in Specifications D2219 and D2220.

5.3 In this test method, the test specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. The results are therefore valid only for the fire-test exposure conditions described in this procedure.

SCOPE

1.1 This is a fire-test-response standard.

1.2 This fire test method is applicable to electrical insulation materials used for wires or cables. The materials are tested as plastic specimens on their own or installed on the wires or cables.

1.3 The ignition source is a gas burner fueled by methane or natural gas.

1.4 Use the values stated in SI units in referee decisions; see IEEE/ASTM SI-10. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is used to determine the heat release rate and a number of other fire-test-response characteristics as a result of exposing insulating materials contained in electrical or optical cables to a prescribed initial test heat flux in the cone calorimeter apparatus.

5.2 Quantitative heat release measurements provide information that is potentially useful for design of electrical or optical cables, and product development.

5.3 Heat release measurements provide useful information for product development by giving a quantitative measure of specific changes in fire performance caused by component and composite modifications. Heat release data from this test method will not be predictive of product behavior if the product will not spread flame over its surface under the fire exposure conditions of interest.

5.4 The fire-test-response characteristics determined by this test method are affected by the thickness of the material used as test specimen, whether as a plaque or as coating on a wire or cable. The diameter of the wire or cable used will also affect the test results.

5.5 A radiant exposure is used as an energy source for this test method. This type of source has been used for comparison with heat release rate and flame spread studies of insulating materials constructed into cables when burning in a vertical cable tray configuration (Test Methods D5424 and D5537) (2-9). No definitive relationships have been established.

5.6 The value of heat release rate corresponding to the critical limit between propagating cable fires and non-propagating fires is not known.

5.7 This test method does not determine the net heat of combustion.

5.8 It has not been demonstrated that this test method is capable of predicting the response of electrical or optical fiber cables in a full scale fire. In particular, this test method does not address the self-extinguishing characteristics of the cables in a full scale fire.

SCOPE

1.1 This is a fire-test-response standard.

1.2 Several fire-test-response characteristics, including the time to sustained flaming, heat release rate, total heat released, effective heat of combustion, and specific extinction area; are measured or calculated by this test method at a constant radiant heat flux. For specific limitations see also 5.7 and Section 6.

1.3 The tests are conducted by burning the electrical insulating materials contained in electrical or optical fiber cables when the cable test specimens, excluding accessories, are subjected to radiant heat.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

1.6 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.7 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard21 pagesEnglish languagesale 15% off

- Standard21 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This horizontal flame test method measures the ability of the material to cease flaming when the source of ignition used is removed.

5.2 This test method also provides a measure of the capability of the material to spread flame by dripping of flaming particles.

5.3 This test method is used to assess the horizontal flame test performance of electrical insulation materials in Test Methods D470.

5.4 In this test method, the test specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. The results are therefore valid only for the fire-test-exposure conditions described in this test method.

SCOPE

1.1 This is a fire-test-response standard.

1.2 This fire test method is applicable to the electrical insulation materials contained in wires or cables.

1.3 The ignition source is a gas burner fueled by methane or natural gas.

1.4 Use the values stated in SI units in referee decisions; see IEEE/ASTM SI-10. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 During operation of electrical equipment, including wires, resistors, and other conductors, it is possible for overheating to occur, under certain conditions of operation or when malfunctions occur. When this happens, a possible result is ignition of the insulation material.

5.2 This test method assesses the relative resistance of electrical insulating materials to ignition by the effect of hot wire sources.

5.3 This test method determines the average time, in seconds, required for material specimens to ignite under the specified conditions of test.

5.4 This method is suitable to characterize materials, subject to the appropriate limitations of an expected precision of ±15 %, to categorize materials.

5.5 In this procedure the specimens are subjected to one or more specific sets of laboratory conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure.

SCOPE

1.1 This test method is intended to differentiate, in a preliminary fashion, among materials with respect to their resistance to ignition because of their proximity to electrically-heated wires and other heat sources.2

1.2 This test method applies to molded or sheet materials available in thicknesses up to and including 13.0 mm (0.51 in.).

1.3 This test method applies to materials that are rigid or flexible at normal room temperatures. It is important to minimize deformation during preparation, especially during the wire-wrapping step described in 10.1, by following the method outlined under Clause 10, Sample Preparation. Examples of deformation include bowing, in either a transverse or a longitudinal direction, twisting of the specimen, and indentation of the wire into the specimen during the wire-wrapping step, to a degree visible to the eye.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard. (See SI10 for further details.)

1.5 This test method measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

Note 1: Although this test method and IEC TS 60695-2-20 (withdrawn) differ in approach and in detail, data obtained using either are technically equivalent.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method provides a means to measure a variety of fire-test-response characteristics associated with heat and smoke release and resulting from burning the materials insulating electrical or optical fiber cables, when made into cables and installed on a vertical cable tray. The specimens are allowed to burn freely under well ventilated conditions after ignition by means of a propane gas burner. The ignition source used in this test method is also described as a premixed flame flaming ignition source in Practice E3020, which contains an exhaustive compilation of ignition sources.

5.2 The rate of heat release often serves as an indication of the intensity of the fire generated. General considerations of the importance of heat release rate are discussed in Appendix X1 and considerations for heat release calculations are in Appendix X2.

5.3 Other fire-test-response characteristics that are measurable by this test method are useful to make decisions on fire safety. The test method is also used for measuring smoke obscuration. The apparatus described here is also useful to measure gaseous components of smoke; the most important gaseous components of smoke are the carbon oxides, present in all fires. The carbon oxides are major indicators of the completeness of combustion and are often used as part of fire hazard assessment calculations and to improve the accuracy of heat release measurements.

5.4 Test Limitations:

5.4.1 The fire-test-response characteristics measured in this test are a representation of the manner in which the specimens tested behave under certain specific conditions. Do not assume they are representative of a generic fire performance of the materials tested when made into cables of the construction under consideration.

5.4.2 In particular, it is unlikely that this test is an adequate representation of the fire behavior of cables in confined spaces, without abundant circulation of air.

5.4.3 This is an intermediate-scale test...

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means to measure the heat released and smoke obscuration by burning the electrical insulating materials contained in electrical or optical fiber cables when the cable specimens, excluding accessories, are subjected to a specified flaming ignition source and burn freely under well ventilated conditions. Flame propagation cable damage, by char length, and mass loss are also measured.

1.3 This test method provides two different protocols for exposing the materials, when made into cable specimens, to an ignition source (approximately 20 kW), for a 20 min test duration. Use it to determine the heat release, smoke release, flame propagation and mass loss characteristics of the materials contained in single and multiconductor electrical or optical fiber cables.

1.4 This test method does not provide information on the fire performance of materials insulating electrical or optical fiber cables in fire conditions other than the ones specifically used in this test method nor does it measure the contribution of the materials in those cables to a developing fire condition.

1.5 Data describing the burning behavior from ignition to the end of the test are obtained.

1.6 This test equipment is suitable for measuring the concentrations of certain toxic gas species in the combustion gases (see Appendix X4).

1.7 The values stated in SI units are to be regarded as standard (see IEEE/ASTM SI-10). The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.8 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions

...

- Standard21 pagesEnglish languagesale 15% off

- Standard21 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method provides a means to measure a variety of fire-test-response characteristics associated with smoke obscuration and resulting from burning the electrical insulating materials contained in electrical or optical fiber cables. The specimens are allowed to burn freely under well ventilated conditions after ignition by means of a propane gas burner.

5.2 Smoke obscuration quantifies the visibility in fires.

5.3 This test method is also suitable for measuring the rate of heat release as an optional measurement. The rate of heat release often serves as an indication of the intensity of the fire generated. Test Method D5537 provides means for measuring heat release with the equipment used in this test method.

5.4 Other optional fire-test-response characteristics that are measurable by this test method are useful to make decisions on fire safety. The most important gaseous components of smoke are the carbon oxides, present in all fires. They are major indicators of the toxicity of the atmosphere and of the completeness of combustion, and are often used as part of fire hazard assessment calculations and to improve the accuracy of heat release measurements. Other toxic gases, which are specific to certain materials, are less crucial for determining combustion completeness.

5.5 Test Limitations:

5.5.1 The fire-test-response characteristics measured in this test method are a representation of the manner in which the specimens tested behave under certain specific conditions. Do not assume they are representative of a generic fire performance of the materials tested when made into cables of the construction under consideration.

5.5.2 In particular, it is unlikely that this test method is an adequate representation of the fire behavior of cables in confined spaces, without abundant circulation of air.

5.5.3 This is an intermediate-scale test, and the predictability of its results to large scale fires has not been determined. Some information ...

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method provides a means to measure the smoke obscuration resulting from burning electrical insulating materials contained in electrical or optical fiber cables when the cable specimens, excluding accessories, are subjected to a specified flaming ignition source and burn freely under well ventilated conditions.

1.3 This test method provides two different protocols for exposing the materials, when made into cable specimens, to an ignition source (approximately 20 kW), for a 20 min test duration. Use it to determine the flame propagation and smoke release characteristics of the materials contained in single and multiconductor electrical or optical fiber cables designed for use in cable trays.

1.4 This test method does not provide information on the fire performance of electrical or optical fiber cables in fire conditions other than the ones specifically used in this test method, nor does it measure the contribution of the cables to a developing fire condition.

1.5 Data describing the burning behavior from ignition to the end of the test are obtained.

1.6 The production of light obscuring smoke is measured.

1.7 The burning behavior is documented visually, by photographic or video recordings, or both.

1.8 The test equipment is suitable for making other, optional, measurements, including the rate of heat release of the burning specimen, by an oxygen consumption technique and weight loss.

1.9 Another set of optional measurements are the concentrations of certain toxic gas species in the combustion gases.

1.10 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. (See IEEE/ASTM SI 10.)

1.11 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety...

- Standard21 pagesEnglish languagesale 15% off

- Standard21 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.