ASTM C150-07

(Specification)Standard Specification for Portland Cement

Standard Specification for Portland Cement

ABSTRACT

This specification covers eight types of portland cement: Type I, Type IA, Type II, Type IIA, Type III, Type IIIA, Type IV, and Type V. The cement covered by this specification shall only contain the following ingredients: portland cement clinker; water or calcium sulfate, or both; limestone; processing additions; and air-entraining addition for air-entraining portland cement. Portland cements must meet various physical and chemical requirements which are detailed in this specification. Examples include limits on aluminum oxide, ferric oxide, magnesium oxide, sulfur trioxide, tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite. Applicable properties enumerated in this specification will be determined by the following test methods: air content of mortar, chemical analysis, compressive strength, false set, fineness by air permeability, fineness by turbidimeter, heat of hydration, autoclave expansion, time of setting by Gillmore needles, time of setting by Vicat needles, sulfate resistance, calcium sulfate, and compressive strength. The cement shall be stored in such a manner as to permit easy access for proper inspection and identification of each shipment, and in a suitable weather-tight building that will protect the cement from dampness and minimize warehouse set.

SCOPE

1.1 This specification covers eight types of portland cement, as follows (see Note 2):

1.1.1 Type I - For use when the special properties specified for any other type are not required.

1.1.2 Type IA - Air-entraining cement for the same uses as Type I, where air-entrainment is desired.

1.1.3 Type II - For general use, more especially when moderate sulfate resistance or moderate heat of hydration is desired.

1.1.4 Type IIA - Air-entraining cement for the same uses as Type II, where air-entrainment is desired.

1.1.5 Type III - For use when high early strength is desired.

1.1.6 Type IIIA - Air-entraining cement for the same use as Type III, where air-entrainment is desired.

1.1.7 Type IV - For use when a low heat of hydration is desired.

1.1.8 Type V - For use when high sulfate resistance is desired.Note 2

Some cements are designated with a combined type classification, such as Type I/II, indicating that the cement meets the requirements of the indicated types and is being offered as suitable for use when either type is desired.Note 0

Cement conforming to the requirements for all types are not carried in stock in some areas. In advance of specifying the use of cement other than Type I, determine whether the proposed type of cement is, or can be made, available.

1.2 When both SI and inch-pound units are present, the SI units are the standard. The inch-pound units are approximations listed for information only.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 150 – 07

Standard Specification for

1

Portland Cement

This standard is issued under the fixed designation C 150; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

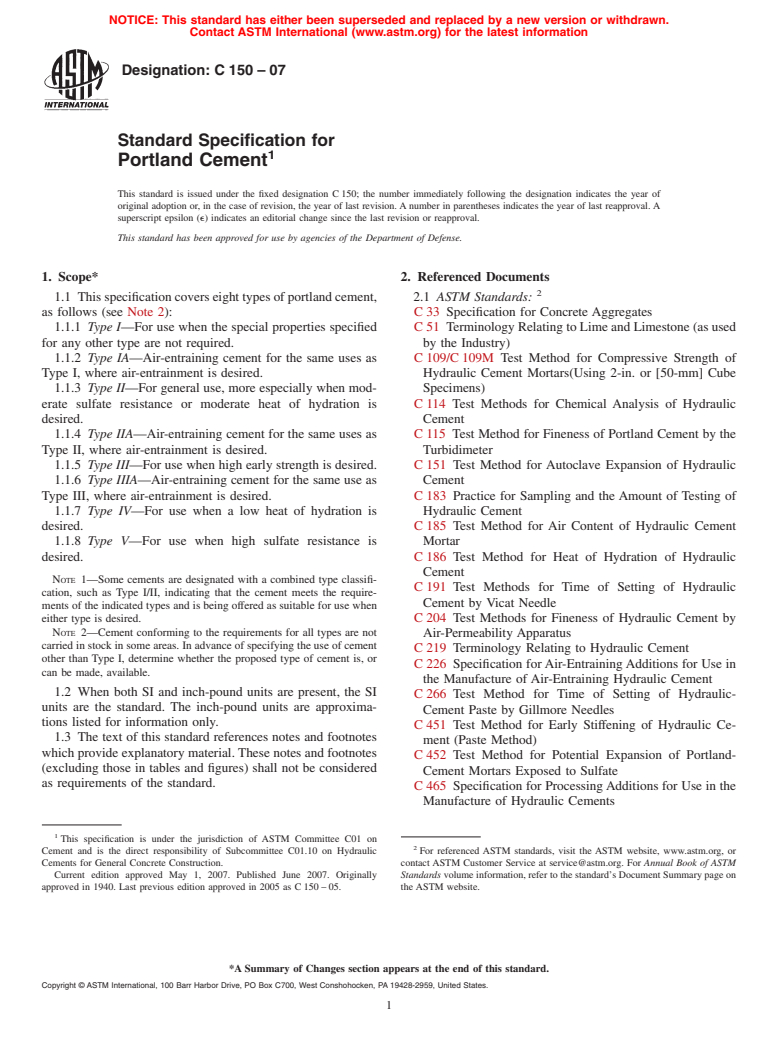

1. Scope* 2. Referenced Documents

2

1.1 Thisspecificationcoverseighttypesofportlandcement, 2.1 ASTM Standards:

as follows (see Note 2): C33 Specification for Concrete Aggregates

1.1.1 Type I—For use when the special properties specified C51 Terminology Relating to Lime and Limestone (as used

for any other type are not required. by the Industry)

1.1.2 Type IA—Air-entraining cement for the same uses as C 109/C 109M Test Method for Compressive Strength of

Type I, where air-entrainment is desired. Hydraulic Cement Mortars(Using 2-in. or [50-mm] Cube

1.1.3 Type II—For general use, more especially when mod- Specimens)

erate sulfate resistance or moderate heat of hydration is C114 Test Methods for Chemical Analysis of Hydraulic

desired. Cement

1.1.4 Type IIA—Air-entraining cement for the same uses as C115 Test Method for Fineness of Portland Cement by the

Type II, where air-entrainment is desired. Turbidimeter

1.1.5 Type III—For use when high early strength is desired. C 151 Test Method for Autoclave Expansion of Hydraulic

1.1.6 Type IIIA—Air-entraining cement for the same use as Cement

Type III, where air-entrainment is desired. C 183 Practice for Sampling and the Amount of Testing of

1.1.7 Type IV—For use when a low heat of hydration is Hydraulic Cement

desired. C 185 Test Method for Air Content of Hydraulic Cement

1.1.8 Type V—For use when high sulfate resistance is Mortar

desired. C 186 Test Method for Heat of Hydration of Hydraulic

Cement

NOTE 1—Some cements are designated with a combined type classifi-

C 191 Test Methods for Time of Setting of Hydraulic

cation, such as Type I/II, indicating that the cement meets the require-

Cement by Vicat Needle

ments of the indicated types and is being offered as suitable for use when

C 204 Test Methods for Fineness of Hydraulic Cement by

either type is desired.

NOTE 2—Cement conforming to the requirements for all types are not

Air-Permeability Apparatus

carried in stock in some areas. In advance of specifying the use of cement

C 219 Terminology Relating to Hydraulic Cement

other than Type I, determine whether the proposed type of cement is, or

C 226 Specification forAir-EntrainingAdditions for Use in

can be made, available.

the Manufacture of Air-Entraining Hydraulic Cement

1.2 When both SI and inch-pound units are present, the SI

C 266 Test Method for Time of Setting of Hydraulic-

units are the standard. The inch-pound units are approxima-

Cement Paste by Gillmore Needles

tions listed for information only.

C 451 Test Method for Early Stiffening of Hydraulic Ce-

1.3 The text of this standard references notes and footnotes

ment (Paste Method)

which provide explanatory material. These notes and footnotes

C 452 Test Method for Potential Expansion of Portland-

(excluding those in tables and figures) shall not be considered

Cement Mortars Exposed to Sulfate

as requirements of the standard.

C 465 Specification for ProcessingAdditions for Use in the

Manufacture of Hydraulic Cements

1

This specification is under the jurisdiction of ASTM Committee C01 on

2

Cement and is the direct responsibility of Subcommittee C01.10 on Hydraulic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Cements for General Concrete Construction. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2007. Published June 2007. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1940. Last previous edition approved in 2005 as C 150 – 05. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

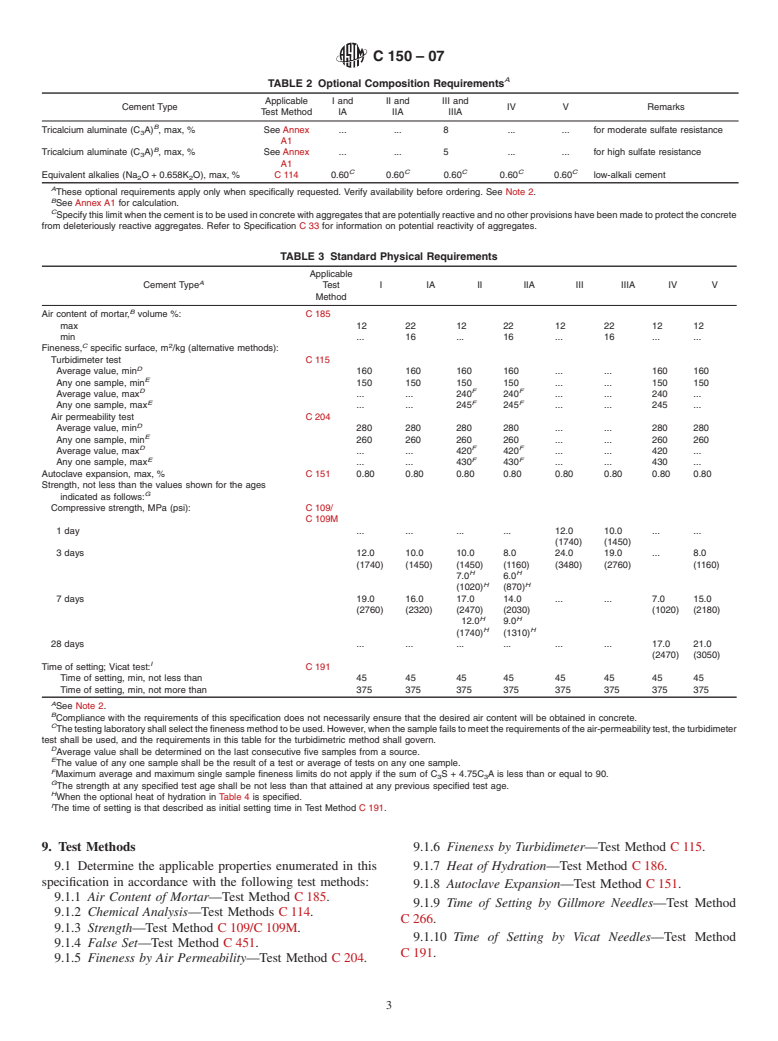

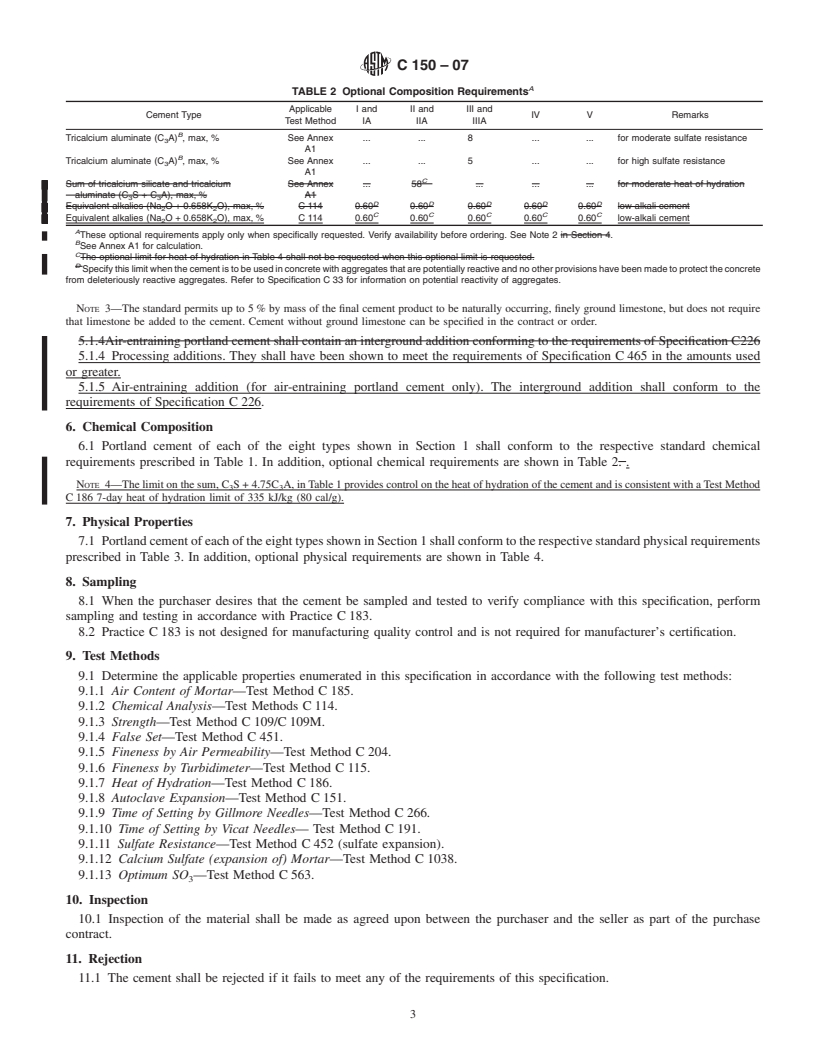

C150–07

NOTE 3—The standard permits up to 5 % by mass of the final cement

C 563 Test Method for Approximation of Optimum SO in

3

product to be naturally occurring, finely ground limestone, but does not

Hydraulic Cement Using Compressive Strength

require that limestone be added to the cement. Cement without ground

C 1038 Test Method for Expansion of Hydraulic Cement

limestone can be specified in the contract or order.

Mortar Bars Stored in Water

E29 Practice for Using Significant Digits in Test Data to

5.1.4 Processing additions. They shall have

...

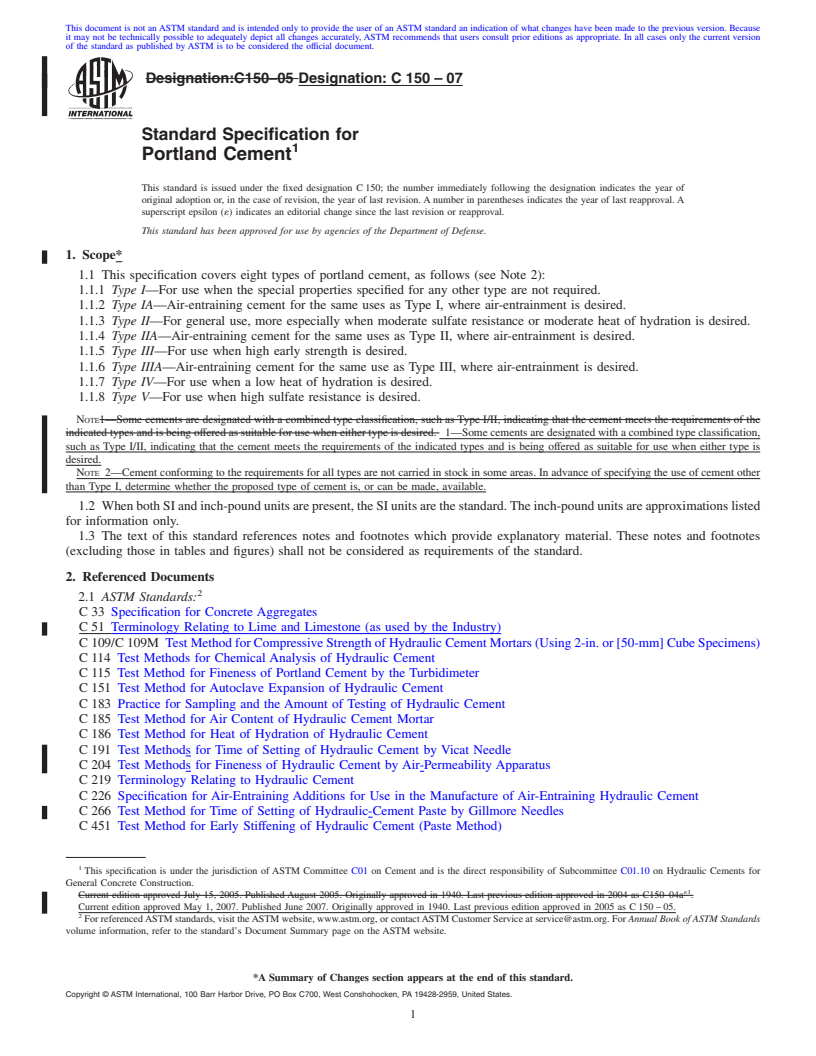

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C150–05 Designation: C 150 – 07

Standard Specification for

1

Portland Cement

This standard is issued under the fixed designation C 150; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers eight types of portland cement, as follows (see Note 2):

1.1.1 Type I—For use when the special properties specified for any other type are not required.

1.1.2 Type IA—Air-entraining cement for the same uses as Type I, where air-entrainment is desired.

1.1.3 Type II—For general use, more especially when moderate sulfate resistance or moderate heat of hydration is desired.

1.1.4 Type IIA—Air-entraining cement for the same uses as Type II, where air-entrainment is desired.

1.1.5 Type III—For use when high early strength is desired.

1.1.6 Type IIIA—Air-entraining cement for the same use as Type III, where air-entrainment is desired.

1.1.7 Type IV—For use when a low heat of hydration is desired.

1.1.8 Type V—For use when high sulfate resistance is desired.

NOTE1—Some cements are designated with a combined type classification, such as Type I/II, indicating that the cement meets the requirements of the

indicated types and is being offered as suitable for use when either type is desired. 1—Some cements are designated with a combined type classification,

such as Type I/II, indicating that the cement meets the requirements of the indicated types and is being offered as suitable for use when either type is

desired.

NOTE 2—Cement conforming to the requirements for all types are not carried in stock in some areas. In advance of specifying the use of cement other

than Type I, determine whether the proposed type of cement is, or can be made, available.

1.2 WhenbothSIandinch-poundunitsarepresent,theSIunitsarethestandard.Theinch-poundunitsareapproximationslisted

for information only.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

C51 Terminology Relating to Lime and Limestone (as used by the Industry)

C 109/C 109M TestMethodforCompressiveStrengthofHydraulicCementMortars(Using2-in.or[50-mm]CubeSpecimens)

C114 Test Methods for Chemical Analysis of Hydraulic Cement

C115 Test Method for Fineness of Portland Cement by the Turbidimeter

C 151 Test Method for Autoclave Expansion of Hydraulic Cement

C 183 Practice for Sampling and the Amount of Testing of Hydraulic Cement

C 185 Test Method for Air Content of Hydraulic Cement Mortar

C 186 Test Method for Heat of Hydration of Hydraulic Cement

C 191 Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle

C 204 Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus

C 219 Terminology Relating to Hydraulic Cement

C 226 Specification for Air-Entraining Additions for Use in the Manufacture of Air-Entraining Hydraulic Cement

C 266 Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles

C 451 Test Method for Early Stiffening of Hydraulic Cement (Paste Method)

1

This specification is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.10 on Hydraulic Cements for

General Concrete Construction.

´1

Current edition approved July 15, 2005. Published August 2005. Originally approved in 1940. Last previous edition approved in 2004 as C150–04a .

Current edition approved May 1, 2007. Published June 2007. Originally approved in 1940. Last previous edition approved in 2005 as C 150 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C150–07

C 452 Test Method for Potential Expansion of Portland-Cement Mortars Exposed to S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.