ASTM F3401-19

(Test Method)Standard Test Method for Wax Binder Removal from Equestrian Synthetic Track Surfaces

Standard Test Method for Wax Binder Removal from Equestrian Synthetic Track Surfaces

SIGNIFICANCE AND USE

5.1 Wax binders are critical for synthetic equestrian surfaces to stay together at consistencies desired. Surfaces are designed to prevent injuries and the wax binders are critical to ensure that this happens. Soxhlet extraction of wax binder is an efficient method to determine the amount of wax binder present in a synthetic equestrian surface.

SCOPE

1.1 Equine surfaces containing wax-oil based coatings/binders must be treated and cleaned prior to the subsequent material tests described for sand and fiber surfaces. Note: skip this test for surfaces that are not wax coated.

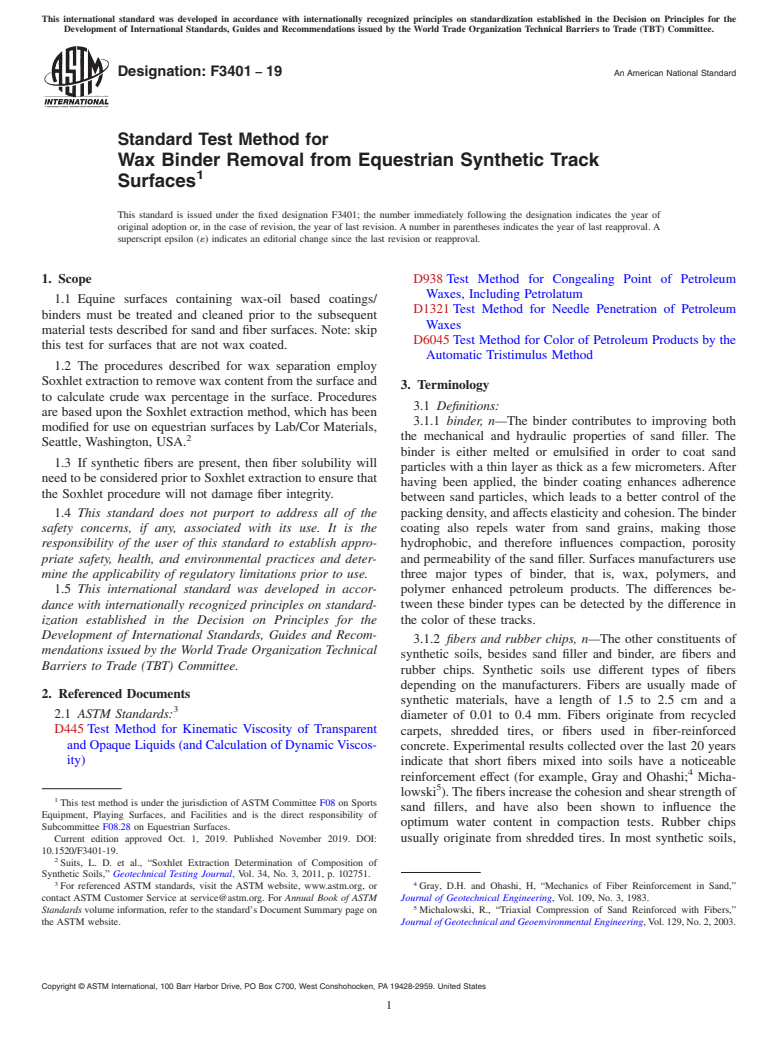

1.2 The procedures described for wax separation employ Soxhlet extraction to remove wax content from the surface and to calculate crude wax percentage in the surface. Procedures are based upon the Soxhlet extraction method, which has been modified for use on equestrian surfaces by Lab/Cor Materials, Seattle, Washington, USA.2

1.3 If synthetic fibers are present, then fiber solubility will need to be considered prior to Soxhlet extraction to ensure that the Soxhlet procedure will not damage fiber integrity.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3401 − 19 An American National Standard

Standard Test Method for

Wax Binder Removal from Equestrian Synthetic Track

1

Surfaces

This standard is issued under the fixed designation F3401; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D938Test Method for Congealing Point of Petroleum

Waxes, Including Petrolatum

1.1 Equine surfaces containing wax-oil based coatings/

D1321Test Method for Needle Penetration of Petroleum

binders must be treated and cleaned prior to the subsequent

Waxes

material tests described for sand and fiber surfaces. Note: skip

D6045Test Method for Color of Petroleum Products by the

this test for surfaces that are not wax coated.

Automatic Tristimulus Method

1.2 The procedures described for wax separation employ

Soxhletextractiontoremovewaxcontentfromthesurfaceand

3. Terminology

to calculate crude wax percentage in the surface. Procedures

3.1 Definitions:

are based upon the Soxhlet extraction method, which has been

3.1.1 binder, n—The binder contributes to improving both

modified for use on equestrian surfaces by Lab/Cor Materials,

the mechanical and hydraulic properties of sand filler. The

2

Seattle, Washington, USA.

binder is either melted or emulsified in order to coat sand

1.3 If synthetic fibers are present, then fiber solubility will

particles with a thin layer as thick as a few micrometers.After

needtobeconsideredpriortoSoxhletextractiontoensurethat

having been applied, the binder coating enhances adherence

the Soxhlet procedure will not damage fiber integrity.

between sand particles, which leads to a better control of the

1.4 This standard does not purport to address all of the packingdensity,andaffectselasticityandcohesion.Thebinder

safety concerns, if any, associated with its use. It is the coating also repels water from sand grains, making those

hydrophobic, and therefore influences compaction, porosity

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- and permeability of the sand filler. Surfaces manufacturers use

three major types of binder, that is, wax, polymers, and

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor- polymer enhanced petroleum products. The differences be-

dance with internationally recognized principles on standard- tween these binder types can be detected by the difference in

ization established in the Decision on Principles for the the color of these tracks.

Development of International Standards, Guides and Recom-

3.1.2 fibers and rubber chips, n—The other constituents of

mendations issued by the World Trade Organization Technical

synthetic soils, besides sand filler and binder, are fibers and

Barriers to Trade (TBT) Committee.

rubber chips. Synthetic soils use different types of fibers

depending on the manufacturers. Fibers are usually made of

2. Referenced Documents

synthetic materials, have a length of 1.5 to 2.5 cm and a

3

2.1 ASTM Standards:

diameter of 0.01 to 0.4 mm. Fibers originate from recycled

D445Test Method for Kinematic Viscosity of Transparent

carpets, shredded tires, or fibers used in fiber-reinforced

and Opaque Liquids (and Calculation of DynamicViscos-

concrete. Experimental results collected over the last 20 years

ity)

indicate that short fibers mixed into soils have a noticeable

4

reinforcement effect (for example, Gray and Ohashi; Micha-

5

lowski ).Thefibersincreasethecohesionandshearstrengthof

1

This test method is under the jurisdiction ofASTM Committee F08 on Sports

sand fillers, and have also been shown to influence the

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

optimum water content in compaction tests. Rubber chips

Subcommittee F08.28 on Equestrian Surfaces.

Current edition approved Oct. 1, 2019. Published November 2019. DOI: usually originate from shredded tires. In most synthetic soils,

10.1520/F3401-19.

2

Suits, L. D. et al., “Soxhlet Extraction Determination of Composition of

Synthetic Soils,” Geotechnical Testing Journal, Vol. 34, No. 3, 2011, p. 102751.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Gray, D.H. and Ohashi, H, “Mechanics of Fiber Reinforcement in Sand,”

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Journal of Geotechnical Engineering, Vol. 109, No. 3, 1983.

5

Standards volume information, refer to the standard’

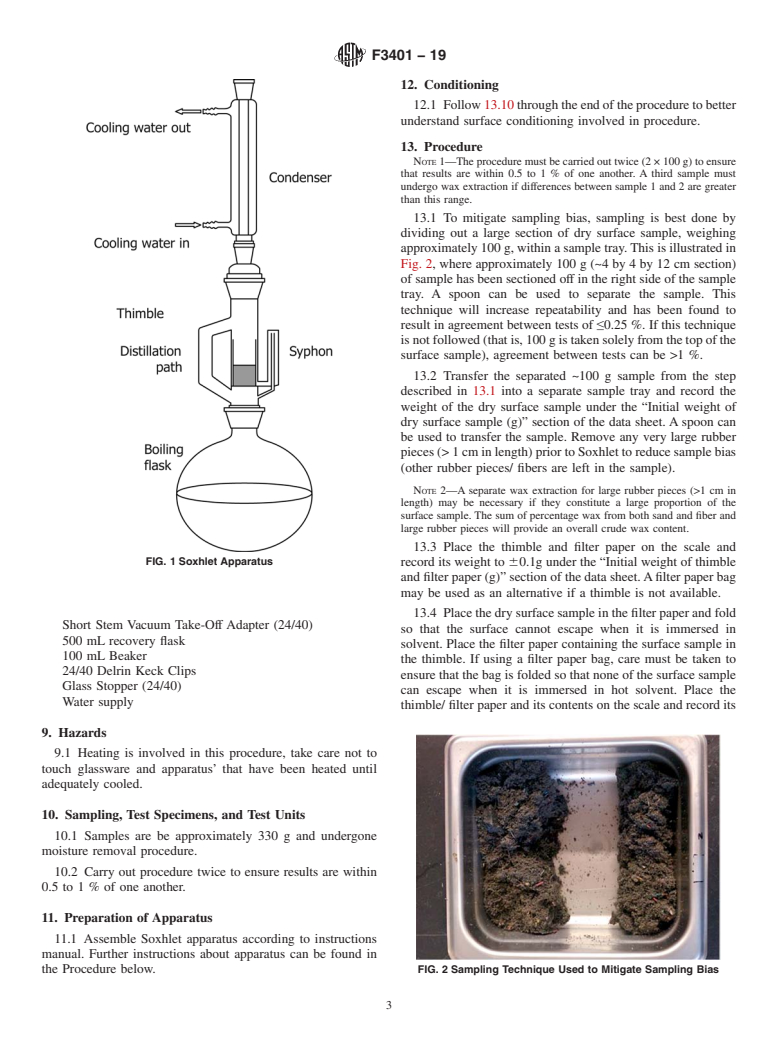

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.