ASTM D6778-05

(Classification)Standard Classification for Polyoxymethylene (POM, Acetal) Molding and Extrusion Materials

Standard Classification for Polyoxymethylene (POM, Acetal) Molding and Extrusion Materials

SCOPE

1.1 This classification covers polyoxymethylene materials suitable for molding and extrusion. This specification allows for the use of polyoxymethylene plastic materials that are recycled, reconstituted, recycled-regrind, recovered, or reprocessed, or combination thereof, provided that the requirements as stated in this specification are met. It is the responsibility of the supplier and the buyer of recycled, reconstituted, recycled-regrind, recovered, or reprocessed polyoxymethylene plastic materials, or combination thereof, to ensure compliance. (See Guide D 5033).

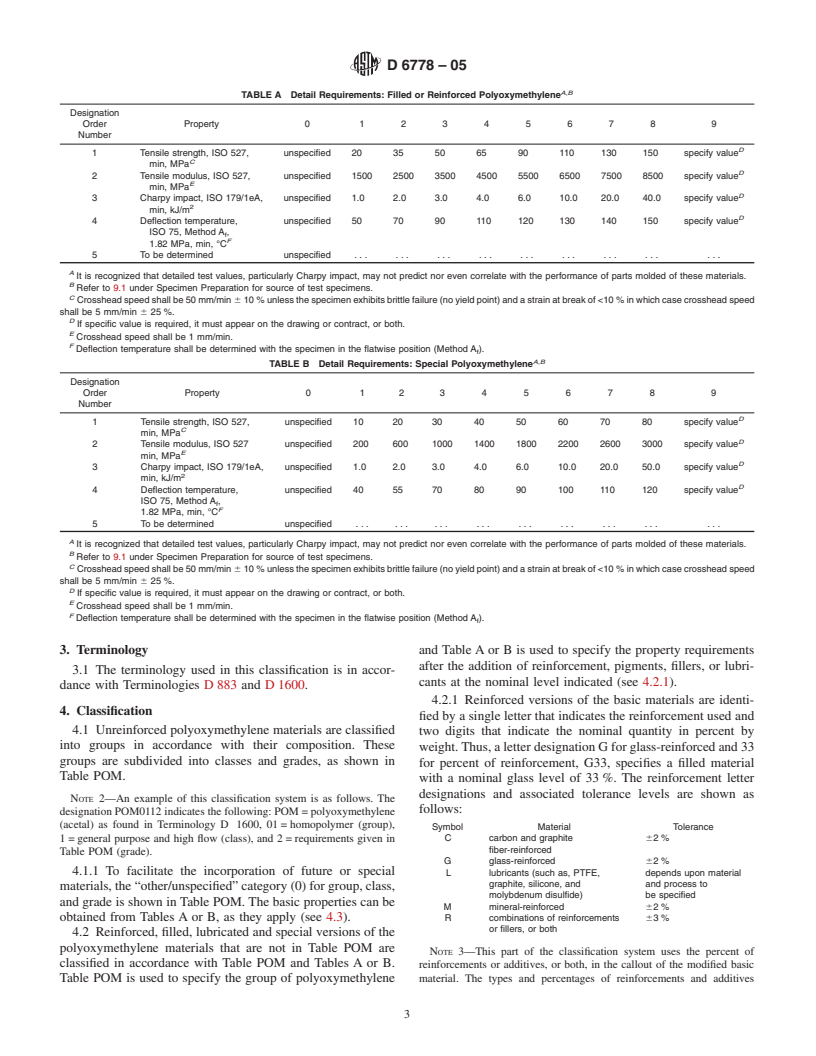

1.2 The properties included in this classification are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These may be specified by using the suffixes as given in Section 5.

1.3 This classification and subsequent line callout are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the field of plastics design after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the costs involved, and the inherent properties of the material other than those covered by this classification.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 The following precautionary caveat pertains only to the test method portion, Section 11, of this classification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

Note 1—This classification is similar to ISO 9988-1 and 9988-2, although the technical content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6778 – 05

Standard Classification for

Polyoxymethylene (POM, Acetal) Molding and Extrusion

1

Materials

This standard is issued under the fixed designation D 6778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This classification covers polyoxymethylene materials 2.1 ASTM Standards:

suitable for molding and extrusion. This specification allows D 618 Practice for Conditioning Plastics for Testing

for the use of polyoxymethylene plastic materials that are D 883 Terminology Relating to Plastics

recycled, reconstituted, recycled-regrind, recovered, or repro- D 1600 Terminology for Abbreviated Terms Relating to

cessed, or combination thereof, provided that the requirements Plastics

as stated in this specification are met. It is the responsibility of D 3641 Practice for Injection Molding Test Specimens of

the supplier and the buyer of recycled, reconstituted, recycled- Thermoplastic Molding and Extrusion Materials

regrind, recovered, or reprocessed polyoxymethylene plastic D 3892 Practice for Packaging/Packing of Plastics

materials, or combination thereof, to ensure compliance. (See D 4000 Classification System for Specifying Plastic Mate-

Guide D 5033). rials

1.2 The properties included in this classification are those D 5033 Guide for the Development of ASTM Standards

required to identify the compositions covered. There may be Relating to Recycling and Use of Recycled Plastics

other requirements necessary to identify particular character- E29 Practice for Using Significant Digits in Test Data to

istics important to specialized applications. These may be Determine Conformance with Specifications

3

specified by using the suffixes as given in Section 5. 2.2 ISO Standards:

1.3 This classification and subsequent line callout are in- ISO 75-1 Plastics and Ebonite—Determination of Tempera-

tended to provide a means of calling out plastic materials used ture of Deflection under Load—Part 1: General Test

inthefabricationofenditemsorparts.Itisnotintendedforthe Methods

selection of materials. Material selection should be made by ISO 75-2 Plastics—Determination of Temperature of De-

those having expertise in the field of plastics design after flection under Load—Part 2: Plastics and Ebonite

careful consideration of the design and the performance ISO 179-1 Plastics—Determination of Charpy Impact

required of the part, the environment to which it will be Properties—Part 1: Non-instrumented Impact Test

exposed, the fabrication process to be employed, the costs ISO 294-1 Plastics—Injection Moulding OfTest Specimens

involved, and the inherent properties of the material other than Of Thermoplastic Materials—Part 1: General Principles,

those covered by this classification. and Moulding of Multipurpose and Bar Test Specimens

1.4 The values stated in SI units are to be regarded as the ISO 527-1 Plastics—Determination of Tensile Properties—

standard. Part 1: General Principals

1.5 The following precautionary caveat pertains only to the ISO 527-2 Plastics—Determination of Tensile Properties—

test method portion, Section 11, of this classification. This Part 2: Test Conditions for Moulding and Extrusion

standard does not purport to address all of the safety concerns, Plastics

if any, associated with its use. It is the responsibility of the user ISO 1133 Plastics—Determination of the Melt Mass Flow

of this standard to establish appropriate safety and health Rate (MFR) and the Melt Volume-Flow Rate (MVR) of

practicesanddeterminetheapplicabilityofregulatoryrequire- Thermoplastics

ments prior to use. ISO 11357-3 Plastics—Differential Scanning Calorimetry

(DSC)—Part 3: Determination of Temperature and En-

NOTE 1—This classification is similar to ISO 9988-1 and 9988-2,

thalpy of Melting and Crystallization

although the technical content is significantly different.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This classification is under the jurisdiction of ASTM Committee D20 on contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Standards volume information, refer to the standard’s Document Summary page on

Materials (Section D20.15.18). the ASTM website.

3

Current edition approved July 1, 2005. Published July 2005. Originally approved Available from American National Standards Institute, 25 W. 43rd St., 4th

in 2002. Last previous edition approved in 2002 as D 6778 - 02. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.