ASTM D5941-96

(Test Method)Standard Test Method for Determination of Izod Impact Strength (Withdrawn 1998)

Standard Test Method for Determination of Izod Impact Strength (Withdrawn 1998)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5941 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Determining the Izod Impact Strength of Plastics

This standard is issued under the fixed designation D 5941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

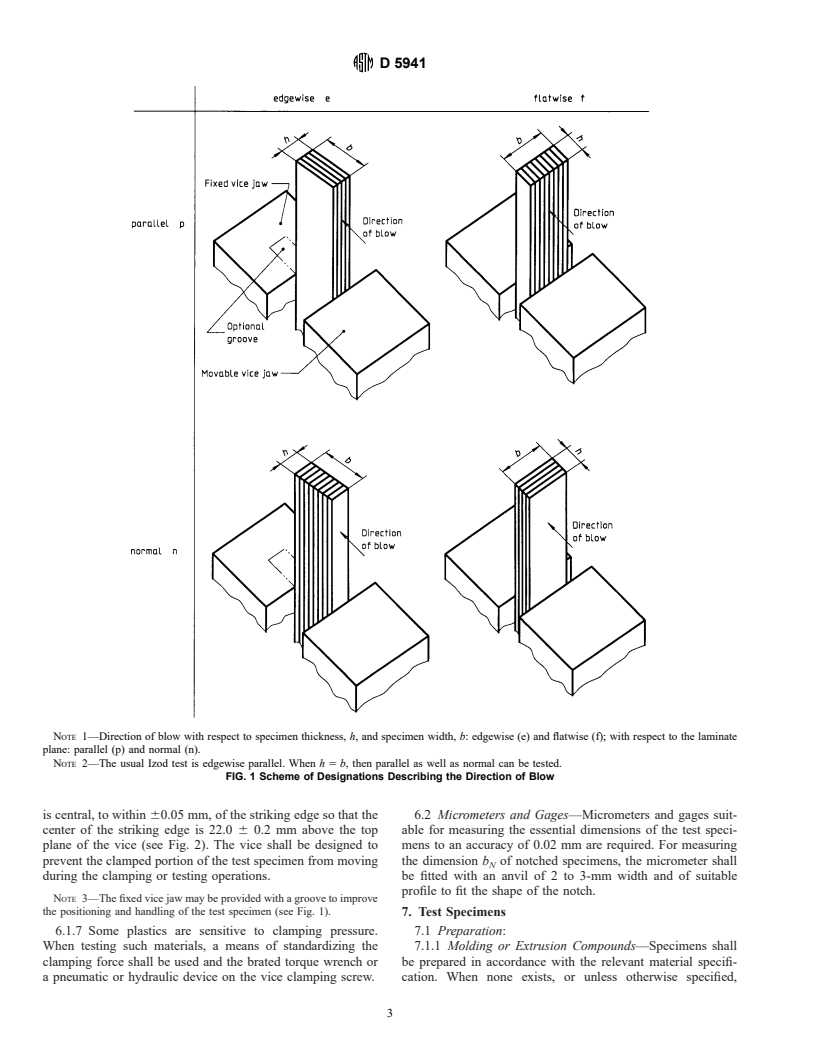

1. Scope of the pendulum, its impact velocity, and the conditioning of

the specimens, can also influence the results. Consequently,

1.1 This test method covers a procedure for determining the

when comparative data are required, these factors must be

Izod impact strength of plastics under defined conditions. A

controlled and recorded carefully.

number of different types of specimen and test configurations

1.7 The procedure should not be used as a source of data for

are defined. Different test parameters are specified according to

design calculations of components. Information on the typical

the type of material, type of test specimen, and type of notch.

behavior of a material can be obtained, however, by testing at

1.2 The procedure is used for investigating the behavior of

different temperatures, by varying the notch radius or the

specified types of specimens under the impact conditions

thickness, or both, and by testing specimens prepared under

defined and for estimating the brittleness or toughness of

different conditions.

specimens within the limitations inherent in the test conditions.

1.8 This test method is identical to ISO 180. This test

1.3 The procedure is suitable for use with the following

method is comparable to Test Method D 256, but neither test

range of materials:

method should be substituted for the other. The two test

1.3.1 Rigid thermoplastics molding and extrusion materials,

methods may differ with respect to test specimen dimensions,

including filled and reinforced compounds in addition to

test specimen conditioning, test equipment, testing conditions,

unfilled types; rigid thermoplastics sheet;

etc. The two test methods may not give the same results.

1.3.2 Rigid thermosetting molding materials, including

1.9 The values stated in SI units are to be regarded as the

filled and reinforced compounds; rigid thermosetting sheet,

standard. The values given in parentheses are for information

including laminates;

only.

1.3.3 Fiber-reinforced thermoset and thermoplastics com-

1.10 This standard does not purport to address all of the

posites incorporating unidirectional or nonunidirectional rein-

safety concerns, if any, associated with its use. It is the

forcements such as mat, woven fabrics, woven rovings,

responsibility of the user of this standard to establish appro-

chopped strands, combination and hybrid reinforcements, rov-

priate safety and health practices and determine the applica-

ings and milled fibers; sheet made from pre-impregnated

bility of regulatory limitations prior to use.

materials (prepregs).

1.3.4 Thermotropic liquid-crystal polymers.

2. Referenced Documents

1.4 The procedure is not normally suitable for use with rigid

2.1 ASTM Standards:

cellular materials and sandwich structures containing cellular

D 256 Test Method for Determining the Pendulum Impact

material. Also, notched specimens are not normally used for

2

Resistance of Notched Specimens of Plastics

long-fiber-reinforced composites or for thermotropic liquid-

D 5936 Specification for Multipurpose Test Specimens

crystal polymers.

3

Used for Testing Plastics

1.5 The procedure is adapted to the use of specimens that

D 5939 Practice for Preparing Multipurpose Test Specimens

may be either molded to the chosen dimensions, machined

3

and Bars of Thermoplastics by Injection Moulding

from the central portion of a standard multipurpose test

D 5940 Practice for Preparing Small Plate Test Specimens

specimen (see ISO 3167 (Specification D 5936)), or machined

3

of Thermoplastics by Injection Moulding

from finished and semifinished products such as moldings,

4

2.2 ISO Standards:

laminates, and extruded or cast sheet.

ISO 180 Determination of Izod Impact Strength

1.6 The procedure specifies preferred dimensions for the

ISO 291:1977 Plastics—Standard Atmospheres for Condi-

test specimen. Tests that are conducted on specimens of

tioning and Testing

different dimensions and notches, or on specimens that are

ISO 293:1986 Plastics—Compression Moulding Test

prepared under different conditions, may produce results that

Specimens of Thermoplastic Materials

are not comparable. Other factors, such as the energy capacity

1 2

This test method is under the jurisdiction of ASTM Committee D-20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.