ASTM A997-07

(Practice)Standard Practice for Investment Castings, Surface Acceptance Standards, Visual Examination

Standard Practice for Investment Castings, Surface Acceptance Standards, Visual Examination

ABSTRACT

This practice covers the acceptance criteria for surface inspection of investment castings through visual examination. The material shall conform to Levels II, III, and IV acceptance criteria for features of surface pits, positive metal, parting line and ejector pin marks, gate height, and surface roughness. The material shall be free of any linear discontinuity.

SCOPE

1.1 This practice covers the acceptance criteria for surface inspection of investment castings by visual examination.

1.2 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A997–07

Standard Practice for

Investment Castings, Surface Acceptance Standards, Visual

1

Examination

This standard is issued under the fixed designation A 997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.5 Additional acceptance criteria as applicable to all or

portions of the casting surface.

1.1 This practice covers the acceptance criteria for surface

inspection of investment castings by visual examination.

4. Acceptance Criteria

1.2 The values stated in SI units are to be regarded as the

4.1 Levels of acceptance for visual inspection are listed in

standard.

Table 1.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

A,B

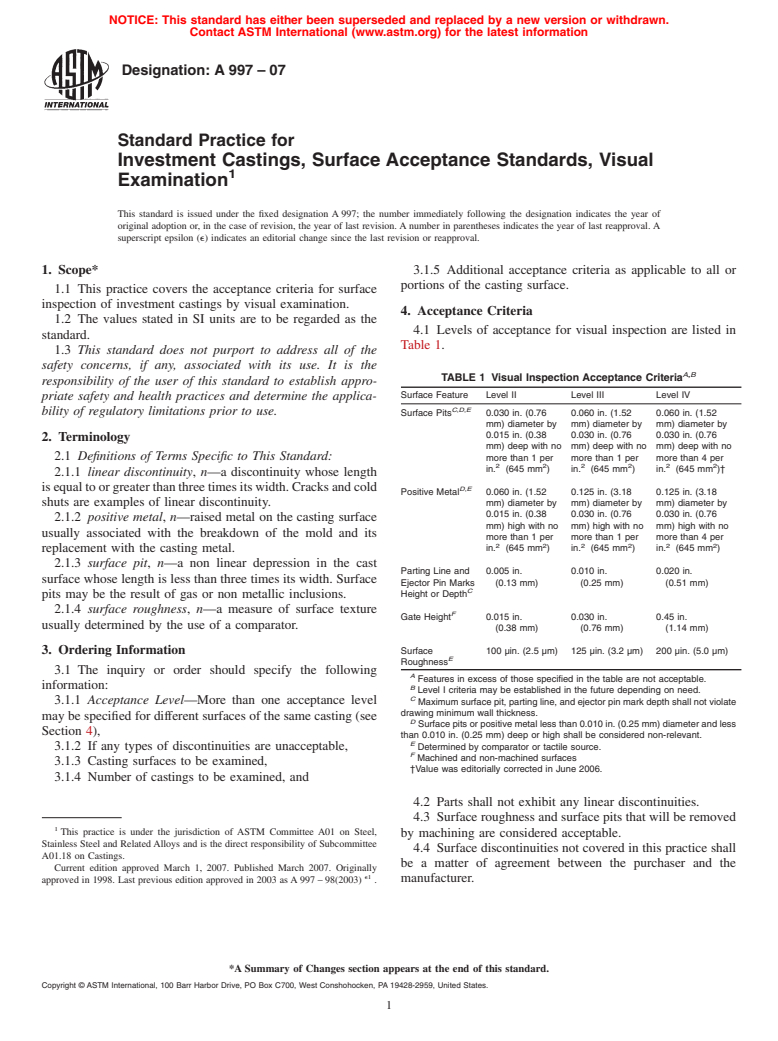

TABLE 1 Visual Inspection Acceptance Criteria

responsibility of the user of this standard to establish appro-

Surface Feature Level II Level III Level IV

priate safety and health practices and determine the applica-

C,D,E

bility of regulatory limitations prior to use.

Surface Pits 0.030 in. (0.76 0.060 in. (1.52 0.060 in. (1.52

mm) diameter by mm) diameter by mm) diameter by

0.015 in. (0.38 0.030 in. (0.76 0.030 in. (0.76

2. Terminology

mm) deep with no mm) deep with no mm) deep with no

2.1 Definitions of Terms Specific to This Standard:

more than 1 per more than 1 per more than 4 per

2 2 2 2 2 2

in. (645 mm ) in. (645 mm ) in. (645 mm )†

2.1.1 linear discontinuity, n—a discontinuity whose length

is equal to or greater than three times its width. Cracks and cold D,E

Positive Metal 0.060 in. (1.52 0.125 in. (3.18 0.125 in. (3.18

shuts are examples of linear discontinuity. mm) diameter by mm) diameter by mm) diameter by

0.015 in. (0.38 0.030 in. (0.76 0.030 in. (0.76

2.1.2 positive metal, n—raised metal on the casting surface

mm) high with no mm) high with no mm) high with no

usually associated with the breakdown of the mold and its

more than 1 per more than 1 per more than 4 per

2 2 2 2 2 2

replacement with the casting metal. in. (645 mm ) in. (645 mm ) in. (645 mm )

2.1.3 surface pit, n—a non linear depression in the cast

Parting Line and 0.005 in. 0.010 in. 0.020 in.

surface whose length is less than three times its width. Surface

Ejector Pin Marks (0.13 mm) (0.25 mm) (0.51 mm)

C

pits may be the result of gas or non metallic inclusions. Height or Depth

2.1.4 surface roughness, n—a measure of surface texture

F

Gate Height 0.015 in. 0.030 in. 0.45 in.

usually determined by the use of a comparator.

(0.38 mm) (0.76 mm) (1.14 mm)

Surface 100 µin. (2.5 µm) 125 µin. (3.2 µm) 200 µin. (5.0 µm)

3. Ordering Information

E

Roughness

3.1 The inquiry or order should specify the following

A

Features in excess of those specified in the table are not acceptable.

information: B

Level I criteria may be established in the future dep

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A 997 – 07

Standard Practice for

Investment Castings, Surface Acceptance Standards, Visual

1

Examination

This standard is issued under the fixed designation A 997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the acceptance criteria for surface inspection of investment castings by visual examination.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

2.1.1 linear discontinuity, n—a discontinuity whose length is equal to or greater than three times its width. Cracks and cold

shuts are examples of linear discontinuity.

2.1.2 positive metal, n—raised metal on the casting surface usually associated with the breakdown of the mold and its

replacement with the casting metal.

2.1.3 surface pit, n—a non linear depression in the cast surface whose length is less than three times its width. Surface pits may

be the result of gas or non metallic inclusions.

2.1.4 surface roughness, n—a measure of surface texture usually determined by the use of a comparator.

3. Ordering Information

3.1 The inquiry or order should specify the following information:

3.1.1 Acceptance Level— More than one acceptance level may be specified for different surfaces of the same casting (see

Section 4),

3.1.2 If any types of discontinuities are unacceptable,

3.1.3 Casting surfaces to be examined,

3.1.4 Number of castings to be examined, and

3.1.5 Additional acceptance criteria as applicable to all or portions of the casting surface.

4. Acceptance Criteria

4.1 Levels of acceptance for visual inspection are listed in Table 1.

4.2 Parts shall not exhibit any linear discontinuities.

4.3 Surface roughness and surface pits that will be removed by machining are considered acceptable.

4.4 Surface discontinuities not covered in this practice shall be a matter of agreement between the purchaser and the

manufacturer.

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

e1

Current edition approved March 1, 2007. Published March 2007. Originally approved in 1998. Last previous edition approved in 2003 as A 997 – 98(2003) .

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.