ASTM A418/A418M-15(2020)

(Practice)Standard Practice for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

Standard Practice for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

SIGNIFICANCE AND USE

3.1 This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination thereof, which give rise to ultrasonic indications.

3.2 The acceptance criteria shall be clearly stated as order requirements.

SCOPE

1.1 This practice for ultrasonic examination covers turbine and generator steel rotor forgings covered by Specifications A469/A469M, A470/A470M, A768/A768M, and A940/A940M. This practice shall be used for contact testing only.

1.2 This practice describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It does not restrict the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed.

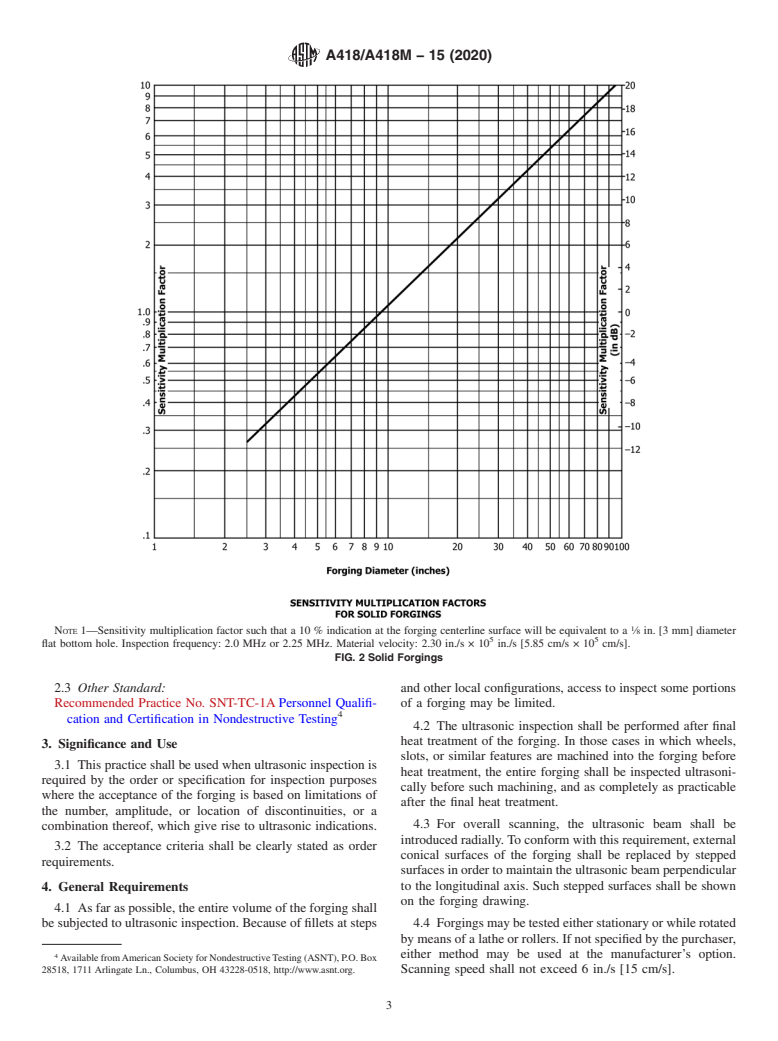

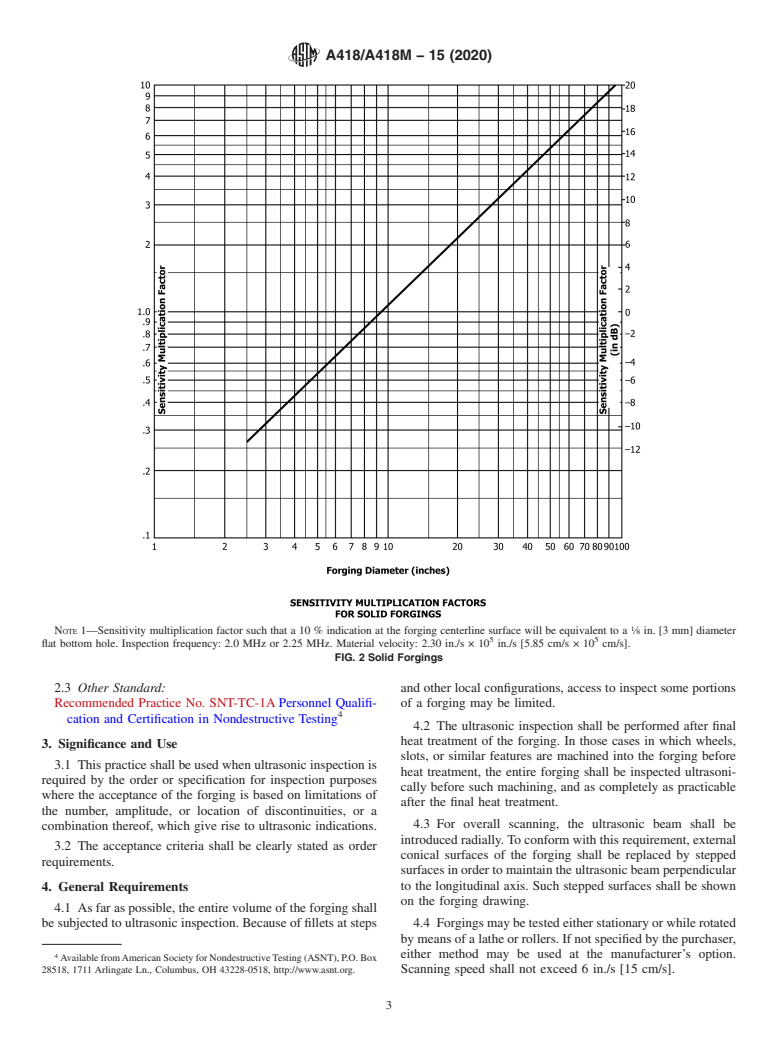

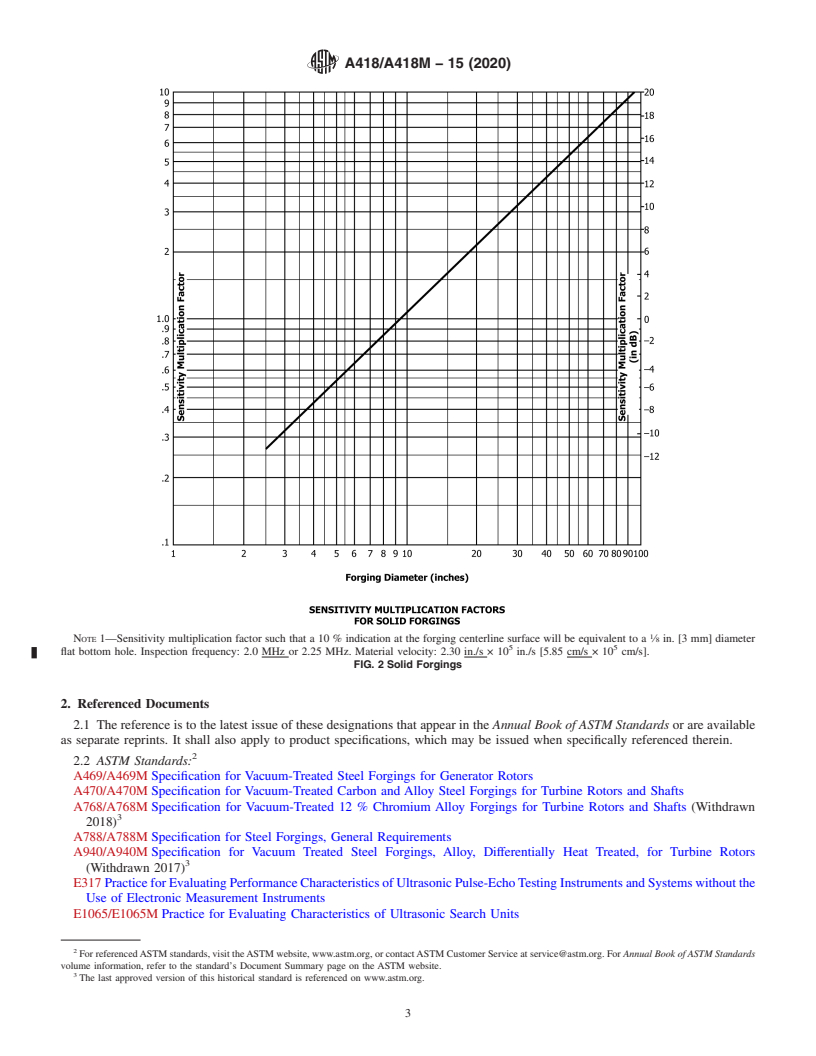

1.3 This practice is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s]. Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

FIG. 1 Bored Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging bore surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 2 Solid Forgings

Note 1: Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a 1/8 in. [3 mm] diameter flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 105 in./s [5.85 cm/s × 105 cm/s].

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes. The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass width if tuned instruments are used, and so forth, tend to reduce the overall inaccuracy which is apt to develop.

1.5 This practice for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. [64 mm] nor greater than 100 in. [2540 mm]. It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses of 2.5 [64 mm] in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. [380 mm] in diameter and for bored cylinders of less than 7.5 in. [190 mm] wall thickness the transducer used for the inspection will be different than the transducer used for larger sections.

1.6 Supplementary requirements of an optional nature are provided for use at the option of the...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A418/A418M − 15 (Reapproved 2020)

Standard Practice for

Ultrasonic Examination of Turbine and Generator Steel

Rotor Forgings

This standard is issued under the fixed designationA418/A418M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* should be recognized as a possibility. Rigid control of the

actual frequency used, the coil bandpass width if tuned

1.1 This practice for ultrasonic examination covers turbine

instruments are used, and so forth, tend to reduce the overall

and generator steel rotor forgings covered by Specifications

inaccuracy which is apt to develop.

A469/A469M, A470/A470M, A768/A768M, and A940/

A940M. This practice shall be used for contact testing only.

1.5 This practice for inspection applies to solid cylindrical

forgings having outer diameters of not less than 2.5 in. [64

1.2 This practice describes a basic procedure of ultrasoni-

mm] nor greater than 100 in. [2540 mm]. It also applies to

cally inspecting turbine and generator rotor forgings. It does

cylindrical forgings with concentric cylindrical bores having

not restrict the use of other ultrasonic methods such as

wall thicknesses of 2.5 [64 mm] in. or greater, within the same

reference block calibrations when required by the applicable

outer diameter limits as for solid cylinders. For solid sections

procurement documents nor is it intended to restrict the use of

less than 15 in. [380 mm] in diameter and for bored cylinders

new and improved ultrasonic test equipment and methods as

oflessthan7.5in.[190mm]wallthicknessthetransducerused

they are developed.

for the inspection will be different than the transducer used for

1.3 This practice is intended to provide a means of inspect-

larger sections.

ing cylindrical forgings so that the inspection sensitivity at the

1.6 Supplementary requirements of an optional nature are

forging center line or bore surface is constant, independent of

provided for use at the option of the purchaser. The supple-

the forging or bore diameter.To this end, inspection sensitivity

mentary requirements shall apply only when specified indi-

multiplication factors have been computed from theoretical

vidually by the purchaser in the purchase order or contract.

analysis, with experimental verification. These are plotted in

Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true

1.7 This practice is expressed in both inch-pound units and

inspection frequency of 2.25 MHz, and an acoustic velocity of

in SI units; however, unless the purchase order or contract

5 5

2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s]. Means of

specifies the applicable M specification designation (SI units),

converting to other sensitivity levels are provided in Fig. 3.

the inch-pound units shall apply. The values stated in either

(Sensitivitymultiplicationfactorsforotherfrequenciesmaybe

inch-pound units or SI units are to be regarded separately as

derived in accordance with X1.1 and X1.2 of Appendix X1.)

standard. Within the practice, the SI units are shown in

brackets. The values stated in each system are not necessarily

1.4 Considerableverificationdataforthismethodhavebeen

exact equivalents; therefore, to ensure conformance with the

generated which indicate that even under controlled conditions

standard,eachsystemshallbeusedindependentlyoftheother,

very significant uncertainties may exist in estimating natural

and values from the two systems shall not be combined.

discontinuities in terms of minimum equivalent size flat-

bottom holes. The possibility exists that the estimated mini-

1.8 This standard does not purport to address all of the

mum areas of natural discontinuities in terms of minimum

safety concerns, if any, associated with its use. It is the

areas of the comparison flat-bottom holes may differ by 20 dB

responsibility of the user of this standard to establish appro-

(factorof10)intermsofactualareasofnaturaldiscontinuities.

priate safety, health, and environmental practices and deter-

This magnitude of inaccuracy does not apply to all results but

mine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

ization established in the Decision on Principles for the

A01.06 on Steel Forgings and Billets.

Development of International Standards, Guides and Recom-

Current edition approved March 1, 2020. Published March 2020. Originally

mendations issued by the World Trade Organization Technical

approved in 1957. Last previous edition approved in 2015 as A418/A418M–15.

DOI: 10.1520/A0418_A0418M–15R20. Barriers to Trade (TBT) Committee.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10% indication at the forging bore surface will be equivalent to a ⁄8 in. [3 mm] diameter flat

5 5

bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 1 Bored Forgings

2. Referenced Documents A768/A768MSpecificationforVacuum-Treated12%Chro-

mium Alloy Forgings for Turbine Rotors and Shafts

2.1 The reference is to the latest issue of these designations

(Withdrawn 2018)

that appear in the Annual Book of ASTM Standards or are

A788/A788MSpecification for Steel Forgings, General Re-

available as separate reprints. It shall also apply to product

quirements

specifications, which may be issued when specifically refer-

A940/A940M Specification for Vacuum Treated Steel

enced therein.

Forgings, Alloy, Differentially Heat Treated, for Turbine

2.2 ASTM Standards: 3

Rotors (Withdrawn 2017)

A469/A469MSpecification for Vacuum-Treated Steel Forg-

E317PracticeforEvaluatingPerformanceCharacteristicsof

ings for Generator Rotors

Ultrasonic Pulse-Echo Testing Instruments and Systems

A470/A470MSpecificationforVacuum-TreatedCarbonand

without the Use of Electronic Measurement Instruments

Alloy Steel Forgings for Turbine Rotors and Shafts

E1065/E1065MPractice for Evaluating Characteristics of

Ultrasonic Search Units

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a ⁄8 in. [3 mm] diameter

5 5

flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 2 Solid Forgings

2.3 Other Standard: and other local configurations, access to inspect some portions

Recommended Practice No. SNT-TC-1APersonnel Qualifi- of a forging may be limited.

cation and Certification in Nondestructive Testing

4.2 The ultrasonic inspection shall be performed after final

heat treatment of the forging. In those cases in which wheels,

3. Significance and Use

slots, or similar features are machined into the forging before

3.1 Thispracticeshallbeusedwhenultrasonicinspectionis

heat treatment, the entire forging shall be inspected ultrasoni-

required by the order or specification for inspection purposes

cally before such machining, and as completely as practicable

where the acceptance of the forging is based on limitations of

after the final heat treatment.

the number, amplitude, or location of discontinuities, or a

4.3 For overall scanning, the ultrasonic beam shall be

combination thereof, which give rise to ultrasonic indications.

introducedradially.Toconformwiththisrequirement,external

3.2 The acceptance criteria shall be clearly stated as order

conical surfaces of the forging shall be replaced by stepped

requirements.

surfacesinordertomaintaintheultrasonicbeamperpendicular

to the longitudinal axis. Such stepped surfaces shall be shown

4. General Requirements

on the forging drawing.

4.1 Asfaraspossible,theentirevolumeoftheforgingshall

besubjectedtoultrasonicinspection.Becauseoffilletsatsteps

4.4 Forgingsmaybetestedeitherstationaryorwhilerotated

bymeansofalatheorrollers.Ifnotspecifiedbythepurchaser,

either method may be used at the manufacturer’s option.

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. Scanning speed shall not exceed 6 in./s [15 cm/s].

A418/A418M − 15 (2020)

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

4.5 To ensure complete coverage of the forging volume, the either a broadband transducer, or a narrow-band tuned trans-

search unit shall be indexed no more than 75% of the ducer of known and matching frequency.

transducerwidthwitheachpassofthesearchunit.Mechanized

6.1.1 Apparatus Qualification and Calibration—Basic

inspection of the rotating forging wherein the search unit is

qualification of the ultrasonic test instrument shall be per-

mechanically controlled is an aid in meeting this requirement.

formed at intervals not to exceed 12 months or whenever

maintenance is performed that affects the equipment function.

4.6 Frequencies of 1, 2.25, and 5 MHz may be used for

Thedateofthelastcalibrationandthedateofthenextrequired

accurately locating, determining orientation, and defining spe-

calibration shall be displayed on the test equipment.

cific discontinuities detected during overall scanning as de-

6.1.2 Thehorizontallinearityshallbecheckedonadistance

scribed in 4.4.

calibration bar using the multiple order technique (see Practice

4.7 Axial scanning, if required, shall be performed at that

E317). The horizontal linearity shall be 62% of the metal

frequency and transducer diameter which minimizes interfer-

path.

ing ultrasonic reflections due to forging geometry and which

6.1.3 If the rotor has a coupling or similar thin axial section

gives optimum resolution. (Axial tests are normally used as a

with parallel sides, the accuracy of the linearity shall be

supplement to radial tests.)

checked by ultrasonically verifying the thickness of the cou-

pling or axial section. If necessary, minor adjustments for

5. Personnel Requirements

differences in the ultrasonic velocities between the calibration

5.1 Personnelperformingtheultrasonicexaminationstothis

bar and the forging shall then be made.

practice shall be qualified and certified in accordance with a

written procedure conforming to Recommended Practice No. 6.2 Amplifier—The amplifier and display shall provide lin-

SNT-TC-1A or another national standard that is acceptable to ear response within 62%, up to 100% of full screen height.

both the purchaser and the supplier.

6.2.1 Amplifier Calibration—An amplifier vertical linearity

check shall be made prior to performing the test by observing

6. Pulsed Ultrasonic Reflection Equipment and

a multiple order pattern from a calibration block using a 2.25

Accessories

MHz transducer (see Practice E317). The first back reflection

6.1 Electronic Apparatus—Apulse-echo instrument permit- shall be set at 100% of full screen height. The higher order

ting inspection frequencies of 1, 2.25, and 5 MHz is required. back reflections, 10% and higher in amplitude, shall also be

The accuracy of discontinuity amplitude analysis using this positioned on the screen and their amplitudes noted. The first

practice involves a knowledge of the true operating frequency back reflection shall be reduced to 50% and then 25% of full

of the complete inspection system. One of the best ways to screen height. The amplitudes of the higher order back reflec-

obtain the desired accuracy is by use of a tuned pulser and tions shall be noted at each step. The vertical linearity will be

narrow band amplifier of known frequency response, with considered acceptable if the signal heights of the higher order

A418/A418M − 15 (2020)

reflections decrease in proportion to the decrease set for the in. [380 mm] in diameter and bored sections having wall

first back reflection. The maximum acceptable error for the thicknesses of less than 7.5 in. [190 mm].

decrease of the higher order reflections is the greater of 65%

8.1.1.2 Use a ⁄4 in. by 1 in. [6 mm by 24 mm] (or 1 in. [24

of the expected back reflection height or 62% of full screen

mm] diameter), 2.0 MHz or 2.25 MHz transducer to inspect

height.

solidsections15in.[380mm]orgreaterindiameterandbored

sectionshavingwallthicknessesof7.5in.[190mm]orgreater.

6.3 Signal Attenuator—The instrument shall contain a cali-

8.1.2 The reference signal shall be the signal reflected from

brated gain control or signal attenuator that meets the require-

the diametrically opposed surface for solid (unbored) forgings

ments of Practice E317 (in each case, accurate within 65%)

and from the bore surface of bored forgings. The signal

that will allow indications beyond the linear range of the

amplitude shall be set to 100% full screen height while

instrument to be measured. It is recommended that these

scanning in an indication-free area.

controls permit signal adjustments up to 25 to 1 (28 dB) (see

Fig. 1 and Fig. 2). 8.1.3 The required evaluation sensitivity shall be obtained

by increasing the 100% full screen height reference signal by

6.4 Search Units—Longitudinalwavesearchunitsofknown

the appropriate multiplication factor calculated as follows.

effectivefrequencyshouldbeusedforradialscanning.A ⁄4in.

Establish the inspection sensitivity in accordance with the

by 1 in. [6 mm by 24 mm], 2.0 MHz or 2.25 MHz transducer,

curves in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), which

used with the 1 in. [24 mm] dimension parallel to the forging

show the multiplication factors that shall be used to adjust a

axis, will give a desirable combination of resolution and beam

100% full screen height, bore, or back reflection to the

width on large sections

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A418/A418M − 15 (Reapproved 2020)

Standard Practice for

Ultrasonic Examination of Turbine and Generator Steel

Rotor Forgings

This standard is issued under the fixed designation A418/A418M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* should be recognized as a possibility. Rigid control of the

actual frequency used, the coil bandpass width if tuned

1.1 This practice for ultrasonic examination covers turbine

instruments are used, and so forth, tend to reduce the overall

and generator steel rotor forgings covered by Specifications

inaccuracy which is apt to develop.

A469/A469M, A470/A470M, A768/A768M, and A940/

A940M. This practice shall be used for contact testing only.

1.5 This practice for inspection applies to solid cylindrical

forgings having outer diameters of not less than 2.5 in. [64

1.2 This practice describes a basic procedure of ultrasoni-

mm] nor greater than 100 in. [2540 mm]. It also applies to

cally inspecting turbine and generator rotor forgings. It does

cylindrical forgings with concentric cylindrical bores having

not restrict the use of other ultrasonic methods such as

wall thicknesses of 2.5 [64 mm] in. or greater, within the same

reference block calibrations when required by the applicable

outer diameter limits as for solid cylinders. For solid sections

procurement documents nor is it intended to restrict the use of

less than 15 in. [380 mm] in diameter and for bored cylinders

new and improved ultrasonic test equipment and methods as

of less than 7.5 in. [190 mm] wall thickness the transducer used

they are developed.

for the inspection will be different than the transducer used for

1.3 This practice is intended to provide a means of inspect-

larger sections.

ing cylindrical forgings so that the inspection sensitivity at the

1.6 Supplementary requirements of an optional nature are

forging center line or bore surface is constant, independent of

provided for use at the option of the purchaser. The supple-

the forging or bore diameter. To this end, inspection sensitivity

mentary requirements shall apply only when specified indi-

multiplication factors have been computed from theoretical

vidually by the purchaser in the purchase order or contract.

analysis, with experimental verification. These are plotted in

Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true

1.7 This practice is expressed in both inch-pound units and

inspection frequency of 2.25 MHz, and an acoustic velocity of

in SI units; however, unless the purchase order or contract

5 5

2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s]. Means of

specifies the applicable M specification designation (SI units),

converting to other sensitivity levels are provided in Fig. 3.

the inch-pound units shall apply. The values stated in either

(Sensitivity multiplication factors for other frequencies may be

inch-pound units or SI units are to be regarded separately as

derived in accordance with X1.1 and X1.2 of Appendix X1.)

standard. Within the practice, the SI units are shown in

brackets. The values stated in each system are not necessarily

1.4 Considerable verification data for this method have been

exact equivalents; therefore, to ensure conformance with the

generated which indicate that even under controlled conditions

standard, each system shall be used independently of the other,

very significant uncertainties may exist in estimating natural

and values from the two systems shall not be combined.

discontinuities in terms of minimum equivalent size flat-

bottom holes. The possibility exists that the estimated mini-

1.8 This standard does not purport to address all of the

mum areas of natural discontinuities in terms of minimum

safety concerns, if any, associated with its use. It is the

areas of the comparison flat-bottom holes may differ by 20 dB

responsibility of the user of this standard to establish appro-

(factor of 10) in terms of actual areas of natural discontinuities.

priate safety, health, and environmental practices and deter-

This magnitude of inaccuracy does not apply to all results but

mine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

ization established in the Decision on Principles for the

A01.06 on Steel Forgings and Billets.

Development of International Standards, Guides and Recom-

Current edition approved March 1, 2020. Published March 2020. Originally

mendations issued by the World Trade Organization Technical

approved in 1957. Last previous edition approved in 2015 as A418/A418M–15.

Barriers to Trade (TBT) Committee.

DOI: 10.1520/A0418_A0418M–15R20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10 % indication at the forging bore surface will be equivalent to a ⁄8 in. [3 mm] diameter flat

5 5

bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 1 Bored Forgings

2. Referenced Documents A768/A768M Specification for Vacuum-Treated 12 % Chro-

mium Alloy Forgings for Turbine Rotors and Shafts

2.1 The reference is to the latest issue of these designations

(Withdrawn 2018)

that appear in the Annual Book of ASTM Standards or are

A788/A788M Specification for Steel Forgings, General Re-

available as separate reprints. It shall also apply to product

quirements

specifications, which may be issued when specifically refer-

A940/A940M Specification for Vacuum Treated Steel

enced therein.

Forgings, Alloy, Differentially Heat Treated, for Turbine

2.2 ASTM Standards:

Rotors (Withdrawn 2017)

A469/A469M Specification for Vacuum-Treated Steel Forg-

E317 Practice for Evaluating Performance Characteristics of

ings for Generator Rotors

Ultrasonic Pulse-Echo Testing Instruments and Systems

A470/A470M Specification for Vacuum-Treated Carbon and

without the Use of Electronic Measurement Instruments

Alloy Steel Forgings for Turbine Rotors and Shafts

E1065/E1065M Practice for Evaluating Characteristics of

Ultrasonic Search Units

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a ⁄8 in. [3 mm] diameter

5 5

flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 2 Solid Forgings

2.3 Other Standard: and other local configurations, access to inspect some portions

Recommended Practice No. SNT-TC-1A Personnel Qualifi- of a forging may be limited.

cation and Certification in Nondestructive Testing

4.2 The ultrasonic inspection shall be performed after final

heat treatment of the forging. In those cases in which wheels,

3. Significance and Use

slots, or similar features are machined into the forging before

3.1 This practice shall be used when ultrasonic inspection is

heat treatment, the entire forging shall be inspected ultrasoni-

required by the order or specification for inspection purposes

cally before such machining, and as completely as practicable

where the acceptance of the forging is based on limitations of

after the final heat treatment.

the number, amplitude, or location of discontinuities, or a

4.3 For overall scanning, the ultrasonic beam shall be

combination thereof, which give rise to ultrasonic indications.

introduced radially. To conform with this requirement, external

3.2 The acceptance criteria shall be clearly stated as order

conical surfaces of the forging shall be replaced by stepped

requirements.

surfaces in order to maintain the ultrasonic beam perpendicular

to the longitudinal axis. Such stepped surfaces shall be shown

4. General Requirements

on the forging drawing.

4.1 As far as possible, the entire volume of the forging shall

be subjected to ultrasonic inspection. Because of fillets at steps 4.4 Forgings may be tested either stationary or while rotated

by means of a lathe or rollers. If not specified by the purchaser,

4 either method may be used at the manufacturer’s option.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. Scanning speed shall not exceed 6 in./s [15 cm/s].

A418/A418M − 15 (2020)

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

4.5 To ensure complete coverage of the forging volume, the either a broadband transducer, or a narrow-band tuned trans-

search unit shall be indexed no more than 75 % of the ducer of known and matching frequency.

transducer width with each pass of the search unit. Mechanized

6.1.1 Apparatus Qualification and Calibration—Basic

inspection of the rotating forging wherein the search unit is

qualification of the ultrasonic test instrument shall be per-

mechanically controlled is an aid in meeting this requirement.

formed at intervals not to exceed 12 months or whenever

maintenance is performed that affects the equipment function.

4.6 Frequencies of 1, 2.25, and 5 MHz may be used for

The date of the last calibration and the date of the next required

accurately locating, determining orientation, and defining spe-

calibration shall be displayed on the test equipment.

cific discontinuities detected during overall scanning as de-

6.1.2 The horizontal linearity shall be checked on a distance

scribed in 4.4.

calibration bar using the multiple order technique (see Practice

4.7 Axial scanning, if required, shall be performed at that

E317). The horizontal linearity shall be 62 % of the metal

frequency and transducer diameter which minimizes interfer-

path.

ing ultrasonic reflections due to forging geometry and which

6.1.3 If the rotor has a coupling or similar thin axial section

gives optimum resolution. (Axial tests are normally used as a

with parallel sides, the accuracy of the linearity shall be

supplement to radial tests.)

checked by ultrasonically verifying the thickness of the cou-

pling or axial section. If necessary, minor adjustments for

5. Personnel Requirements

differences in the ultrasonic velocities between the calibration

5.1 Personnel performing the ultrasonic examinations to this

bar and the forging shall then be made.

practice shall be qualified and certified in accordance with a

written procedure conforming to Recommended Practice No. 6.2 Amplifier—The amplifier and display shall provide lin-

SNT-TC-1A or another national standard that is acceptable to ear response within 62 %, up to 100% of full screen height.

both the purchaser and the supplier.

6.2.1 Amplifier Calibration—An amplifier vertical linearity

check shall be made prior to performing the test by observing

6. Pulsed Ultrasonic Reflection Equipment and

a multiple order pattern from a calibration block using a 2.25

Accessories

MHz transducer (see Practice E317). The first back reflection

6.1 Electronic Apparatus—A pulse-echo instrument permit- shall be set at 100 % of full screen height. The higher order

ting inspection frequencies of 1, 2.25, and 5 MHz is required. back reflections, 10 % and higher in amplitude, shall also be

The accuracy of discontinuity amplitude analysis using this positioned on the screen and their amplitudes noted. The first

practice involves a knowledge of the true operating frequency back reflection shall be reduced to 50 % and then 25 % of full

of the complete inspection system. One of the best ways to screen height. The amplitudes of the higher order back reflec-

obtain the desired accuracy is by use of a tuned pulser and tions shall be noted at each step. The vertical linearity will be

narrow band amplifier of known frequency response, with considered acceptable if the signal heights of the higher order

A418/A418M − 15 (2020)

reflections decrease in proportion to the decrease set for the in. [380 mm] in diameter and bored sections having wall

first back reflection. The maximum acceptable error for the thicknesses of less than 7.5 in. [190 mm].

decrease of the higher order reflections is the greater of 65 %

8.1.1.2 Use a ⁄4 in. by 1 in. [6 mm by 24 mm] (or 1 in. [24

of the expected back reflection height or 62 % of full screen

mm] diameter), 2.0 MHz or 2.25 MHz transducer to inspect

height.

solid sections 15 in. [380 mm] or greater in diameter and bored

sections having wall thicknesses of 7.5 in. [190 mm] or greater.

6.3 Signal Attenuator—The instrument shall contain a cali-

8.1.2 The reference signal shall be the signal reflected from

brated gain control or signal attenuator that meets the require-

the diametrically opposed surface for solid (unbored) forgings

ments of Practice E317 (in each case, accurate within 65 %)

and from the bore surface of bored forgings. The signal

that will allow indications beyond the linear range of the

amplitude shall be set to 100 % full screen height while

instrument to be measured. It is recommended that these

scanning in an indication-free area.

controls permit signal adjustments up to 25 to 1 (28 dB) (see

Fig. 1 and Fig. 2). 8.1.3 The required evaluation sensitivity shall be obtained

by increasing the 100 % full screen height reference signal by

6.4 Search Units—Longitudinal wave search units of known

the appropriate multiplication factor calculated as follows.

effective frequency should be used for radial scanning. A ⁄4 in.

Establish the inspection sensitivity in accordance with the

by 1 in. [6 mm by 24 mm], 2.0 MHz or 2.25 MHz transducer,

curves in Fig. 1 (bored rotors) and Fig. 2 (solid rotors), which

used with the 1 in. [24 mm] dimension parallel to the forging

show the multiplication factors that shall be used to adjust a

axis, will give a des

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A418/A418M − 15 A418/A418M − 15 (Reapproved 2020)

Standard Practice for

Ultrasonic Examination of Turbine and Generator Steel

Rotor Forgings

This standard is issued under the fixed designation A418/A418M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice for ultrasonic examination covers turbine and generator steel rotor forgings covered by Specifications

A469/A469M, A470/A470M, A768/A768M, and A940/A940M. This standardpractice shall be used for contact testing only.

1.2 This practice describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It does not restrict

the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents

nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed.

1.3 This practice is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging

center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication

factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig. 1 (bored rotors) and

Fig. 2 (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 in./s × 10 in./s [5.85 cm/s ×

10 cm/s]. Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other

frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions

very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes.

The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison

flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy

does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass

width if tuned instruments are used, and so forth, tend to reduce the overall inaccuracy which is apt to develop.

1.5 This practice for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. [64 mm] nor

greater than 100 in. [2540 mm]. It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses

of 2.5 [64 mm] in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. [380

mm] in diameter and for bored cylinders of less than 7.5 in. [190 mm] wall thickness the transducer used for the inspection will

be different than the transducer used for larger sections.

1.6 Supplementary requirements of an optional nature are provided for use at the option of the purchaser. The supplementary

requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.7 This practice is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies

the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units

or SI units are to be regarded separately as standard. Within the practice, the SI units are shown in brackets. The values stated in

each system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in nonconformance with the

standard.shall not be combined.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved May 1, 2015March 1, 2020. Published May 2015March 2020. Originally approved in 1957. Last previous edition approved in 20102015 as

A418/A418M – 10.A418/A418M–15. DOI: 10.1520/A0418_A0418M-15.10.1520/A0418_A0418M–15R20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10 % indication at the forging bore surface will be equivalent to a ⁄8 in. [3 mm] diameter flat

5 5

bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 1 Bored Forgings

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

A418/A418M − 15 (2020)

NOTE 1—Sensitivity multiplication factor such that a 10 % indication at the forging centerline surface will be equivalent to a ⁄8 in. [3 mm] diameter

5 5

flat bottom hole. Inspection frequency: 2.0 MHz or 2.25 MHz. Material velocity: 2.30 in./s × 10 in./s [5.85 cm/s × 10 cm/s].

FIG. 2 Solid Forgings

2. Referenced Documents

2.1 The reference is to the latest issue of these designations that appear in the Annual Book of ASTM Standards or are available

as separate reprints. It shall also apply to product specifications, which may be issued when specifically referenced therein.

2.2 ASTM Standards:

A469/A469M Specification for Vacuum-Treated Steel Forgings for Generator Rotors

A470/A470M Specification for Vacuum-Treated Carbon and Alloy Steel Forgings for Turbine Rotors and Shafts

A768/A768M Specification for Vacuum-Treated 12 % Chromium Alloy Forgings for Turbine Rotors and Shafts (Withdrawn

2018)

A788/A788M Specification for Steel Forgings, General Requirements

A940/A940M Specification for Vacuum Treated Steel Forgings, Alloy, Differentially Heat Treated, for Turbine Rotors

(Withdrawn 2017)

E317 Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems without the

Use of Electronic Measurement Instruments

E1065/E1065M Practice for Evaluating Characteristics of Ultrasonic Search Units

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

A418/A418M − 15 (2020)

FIG. 3 Conversion Factors to Be Used in Conjunction with Fig. 1 and Fig. 2 if a Change in the Reference Reflector Diameter is Required

2.3 Other Standards:Standard:

Recommended Practice No. SNT-TC-1A Personnel Qualification and Certification in Nondestructive Testing

3. Significance and Use

3.1 This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where

the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination

thereof, which give rise to ultrasonic indications.

3.2 The acceptance criteria shall be clearly stated as order requirements.

4. General Requirements

4.1 As far as possible, the entire volume of the forging shall be subjected to ultrasonic inspection. Because of fillets at steps

and other local configurations, access to inspect some portions of a forging may be limited.

4.2 The ultrasonic inspection shall be performed after final heat treatment of the forging. In those cases in which wheels, slots,

or similar features are machined into the forging before heat treatment, the entire forging shall be inspected ultrasonically before

such machining, and as completely as practicable after the final heat treatment.

4.3 For overall scanning, the ultrasonic beam shall be introduced radially. To conform with this requirement, external conical

surfaces of the forging shall be replaced by stepped surfaces in order to maintain the ultrasonic beam perpendicular to the

longitudinal axis. Such stepped surfaces shall be shown on the forging drawing.

4.4 Forgings may be tested either stationary or while rotated by means of a lathe or rollers. If not specified by the purchaser,

either method may be used at the manufacturer’smanufacturer’s option. Scanning speed shall not exceed 6 in./s [15 cm/s].

4.5 To ensure complete coverage of the forging volume, the search unit shall be indexed no more than 75 % of the transducer

width with each pass of the search unit. Mechanized inspection of the rotating forging wherein the search unit is mechanically

controlled is an aid in meeting this requirement.

4.6 Frequencies of 1, 2.25, and 5 MHz may be used for accurately locating, determining orientation, and defining specific

discontinuities detected during overall scanning as described in 4.4.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

A418/A418M − 15 (2020)

4.7 Axial scanning, if required, shall be performed at that frequency and transducer diameter which minimizes interfering

ultrasonic reflections due to forging geometry and which gives optimum resolution. (Axial tests are normally used as a supplement

to radial tests.)

5. Personnel Requirements

5.1 Personnel performing the ultrasonic examinations to this practice shall be qualified and certified in accordance with a written

procedure conforming to Recommended Practice No. SNT-TC-1A or another national standard that is acceptable to both the

purchaser and the supplier.

6. Pulsed Ultrasonic Reflection Equipment and Accessories

6.1 Electronic Apparatus—A pulse-echo instrument permitting inspection frequencies of 1, 2.25, and 5 MHz is required. The

accuracy of discontinuity amplitude analysis using this practice involves a knowledge of the true operating frequency of the

complete inspection system. One of the best ways to obtain the desired accuracy is by use of a tuned pulser and narrow band

amplifier of known frequency response, with either a broadband transducer, or a narrow-band tuned transducer of known and

matching frequency.

6.1.1 Apparatus Qualification and Calibration—Basic qualification of the ultrasonic test instrument shall be performed at

intervals not to exceed 12 months or whenever maintenance is performed that affects the equipment function. The date of the last

calibration and the date of the next required calibration shall be displayed on the test equipment.

6.1.2 The horizontal linearity shall be checked on a distance calibration bar using the multiple order technique (see Practice

E317). The horizontal linearity shall be 62 % of the metal path.

6.1.3 If the rotor has a coupling or similar thin axial section with parallel sides, the accuracy of the linearity shall be checked

by ultrasonically verifying the thickness of the coupling or axial section. If necessary, minor adjustments for differences in the

ultrasonic velocities between the calibration bar and the forging shall then be made.

6.2 Amplifier—The amplifier and display shall provide linear response within 62 %, up to 100% of full screen height.

6.2.1 Amplifier Calibration—An amplifier vertical linearity check shall be made prior to performing the test by observing a

multiple order pattern from a calibration block using a 2.25 MHz transducer (see Practice E317). The first back reflection shall be

set at 100 % of full screen height. The higher order back reflections, 10 % and higher in amplitude, shall also be positioned on the

screen and their amplitudes noted. The first back reflection shall be reduced to 50 % and then 25 % of full screen height. The

amplitudes of the higher order back reflections shall be noted at each step. The vertical linearity will be considered acceptable if

the signal heights of the higher order reflections decrease in proportion to the decrease set for the first back reflection. The

maximum acceptable error for the decrease of the higher order reflections is the greater of 65 % of the expected back reflection

height or 62 % of full screen height.

6.3 Signal Attenuator—The instrument shall contain a calibrated gain control or signal attenuator that meets the requirements

of Practice E317 (in each case, accurate within 65 %) that will allow indications beyond the linear range of the instrument to be

measured. It is recommended that these controls permit signal adjustments up to 25 to 1 (28 dB) (see Fig. 1 and Fig. 2).

6.4 Search Units—Longitudinal wave search units of known effective frequency should be used for radial scanning. A ⁄4 in. by

1 in. [6 mm by 24 mm], 2.0 MHz or 2.25 MHz transducer, used with the 1-in. [24-mm] 1 in. [24 mm] dimension parallel to the

forging axis, will give a desirable combination of resolution and beam width on large sections 15 in. [380 mm] in diameter or larger

if solid or 7.5 in. [190 mm] or greater wall thickness if bored. A 1-in. [24-mm] 1 in. [24 mm] diameter, 2.0 MHz or 2.25 MHz

transducer may be used. If a transducer with dimension circumferentially oriented to the forging, larger than ⁄4 in. [6 mm] is used,

additional inspection at lower frequency is recommended to provide a wide beam for off-axis inspection. A 0.5-in. [10-mm] 0.5

in. [10 mm] diameter 2.0 MHz or 2.25 MHz transducer is suitable for solid sections under 15 in. [380 mm] in diameter and bored

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.