ASTM F1677-96

(Test Method)Standard Test Method for Using a Portable Inclineable Articulated Strut Slip Tester (PIAST)

Standard Test Method for Using a Portable Inclineable Articulated Strut Slip Tester (PIAST)

SCOPE

1.1 This test method covers the operational procedures for using a portable inclinable articulated strut slip tester (PIAST) for determining the slip resistance of footwear sole, heel, or related materials (test feet) against planar walkway surfaces or walkway surrogates (test surfaces) in either the laboratory or field under dry, wet, or contaminated conditions. This test method does not address all methodological issues (for example, test surface and test foot material selection and preparation, experimental design, or report preparation).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F1677–96

Standard Test Method for

Using a Portable Inclineable Articulated Strut Slip Tester

(PIAST)

This standard is issued under the fixed designation F 1677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the operational procedures for 4.1 The PIAST is a tribometer designed to determine the

using a portable inclinable articulated strut slip tester (PIAST) slip resistance of footwear materials, walkway surfaces, or

for determining the slip resistance of footwear sole, heel, or surrogates under field or laboratory conditions so that their slip

related materials (test feet) against planar walkway surfaces or resistant qualities may be evaluated.

walkway surrogates (test surfaces) in either the laboratory or 4.2 The measurements made by this apparatus relate to slip

field under dry, wet, or contaminated conditions. This test resistance. Other factors can affect slip resistance. When this

method does not address all methodological issues (for ex- test method is used in field tests, relevant factors shall be

ample, test surface and test foot material selection and prepa- described.

ration, experimental design, or report preparation).

5. Apparatus

1.2 The values stated in inch-pound units are to be regarded

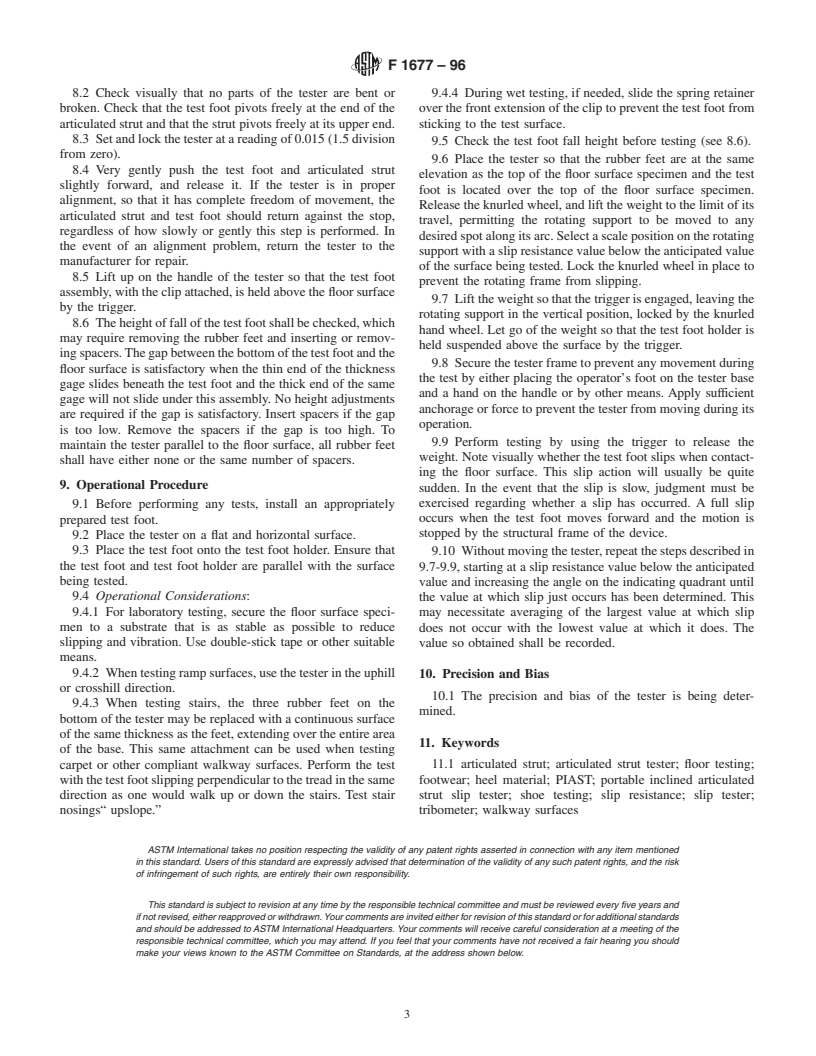

as the standard. The values given in parentheses are for 5.1 Portable Inclined Articulated Strut Tribometer—See

Fig. 1.

information only.

1.3 This standard does not purport to address all of the 5.2 Main Frame—A ⁄4-in. (1.9-cm) thick aluminum plate

having a piece of skid-resistant surfacing on the front end of it.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- Either operators foot can be placed in this area to help hold the

tester in place during use.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5.3 Handle—Atubular assembly extending upward near the

center of the main frame. This can be used to lift and carry the

2. Referenced Documents

tester and also to hold the tester in place during use.

2.1 ASTM Standards: 5.4 Indicating Quadrant—With the skid-resistant foot pad

F 1646 Terminology Relating to Safety and Traction for to the left when facing the tester, the indicating quadrant is on

Footwear the front edge of the tester and is graduated in terms of slip

resistance.

3. Terminology

3.1 Definitions—For definitions of terms, refer to Terminol-

The portable inclined articulated strut slip tester (PIAST or Mark II) was

ogy F 1646.

developed by Dr. Robert Brungraber of Bucknell University, Lewisburg, PA. The

Mark II is covered by a patent held by Slip-Test and is available from P.O. Box 387,

Spring Lake, NJ 07762. It has been found suitable for this use. Interested parties are

This test method is under the jurisdiction ofASTM Committee F-13 on Safety invited to submit information regarding the identification of acceptable alternatives

and Traction for Footwear and is the direct responsibility of Subcommittee F13.10 to this patented item to the Committee on Standards,ASTM Headquarters, 100 Barr

on Traction. Harbor Drive, West Conshohocken, PA 19428-2959. Your comments will receive

Current edition approved Feb. 10, 1996. Published May 1996. careful consideration at a meeting of the responsible technical committee, which

Annual Book of ASTM Standards, Vol 15.07. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1677–96

pivoted to the test foot holder on the bottom of the tester. This

articulated strut indicates the occurrence of slip by permitting

the test foot holder/clip assembly to slide forward.

5.9 TestFootHolder—Anassemblycomposedofaluminum

or stainless steel, with a thin piece of stainless steel riveted

loosely to it to permit a modest amount of lateral articulation of

the test foot. The bottom of the test foot holder has magnetic

tape attached to it. The magnetic tape serves to hold the test

foot in place.

2 2

5.10 Test Foot Clip—The test foot is 3 in. (7.62 cm ) light

gage mild steel. This clip is retained against the magnetic tape

on the bottom of the test foot holder. The test foot material is

affixed to the clip by means of double-stick tape or contact

cement.

5.11 Spring Steel Retainer, made of light gage steel.

5.12 Thickness Gage—A special thickness gage used to

check the height of the bottom of the test foot, in the set

position, above the floor surface. The thin end of this gage is

1 1

⁄8-in. (3.17-mm) thick. The thick end of this gage is ⁄4-in.

(6.34-mm) thick.

5.13 Spacers—If height adjustments are required, spacers

shall be inserted or removed between the tester bottom and the

rubber feet.

5.14 Rubber Feet—Three rubber feet are connected by

removable machine screws to the underside of the tester.

5.15 Test Foot Material—Aspecimen of sole, heel, or other

material.

6. Test Foot and Test Surface

6.1 Test Foot:

6.1.1 The test foot is prepared by fastening a sample,

2 2

typically 3 by 3 in. (76.2 by 76.2 mm ), of the test foot

FIG. 1 Portable Inclineable Articulated Strut Slip Tester

material, appropriate side exposed, using a suitable adhesive,

such as double-stick tape.

5.5 Rotating Support—A 1 ⁄4-in. (3.18-cm) thick aluminum

6.1.2 The test foot is placed on the test foot holder, where it

piecepivotedtothemainframebyapairofpinsnearthecenter

is held in place by magnetic attraction. If needed, the spring

of the main frame. This support is able to rotate from a vertical

steel retainer can be pushed onto the test foot’s vertical

position to an angle from vertical of slightly more than 45°.

extension to fasten the test foot positively to the test foot

The angled position of this support is controlled by either of

holder.

two methods: (1) a knurled hand wheel that tightens against the

6.2 Test Surface—The floor surface specimens shall not be

indicating quadrant and (2) a rubber pad that engages a control

less than 4 by 4 in. (10.16 by 10.16 cm) and should be

quadrant that has the cross section of a V belt pulley and is

surrounded by enough material of similar thickness or placed

attached near the rear of the frame. The rubber pad is

in a suitable fixture so that the tribometer feet will be at the

disengaged from the control quadrant, permitting free rotation

same elevation as the top of the specimen. The test foot

of the rotating support by lifting the 10-lb (4.5-kg) weight to

material shall fit within the area of the test surface.

the end of its travel.

5.6 Weight—A 10-lb (4.5-kg) weight of cast iron, incorpo- 7. Reagents and Materials

rating a handle that is used to operate the tester and that can

7.1 Double-Stick Tape.

also be used to lift and carry the tester. Extending from the

bottom of this weight are three ⁄2-in. (1.27-mm) round 8. Tribometer Operation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.