ASTM F1897-98

(Specification)Standard Specification for Leg Protection for Chain Saw Users

Standard Specification for Leg Protection for Chain Saw Users

SCOPE

1.1 This specification specified minimum requirements for the design, performance, testing, and certification of protective garments and protective devices designed to provide cut resistance protection to the legs of operators of power chain saws.

1.2 The object of this specification is to prescribe fit, function, and performance criteria for protective garments and protective devices that, when worn by chain saw operators, that are intended to reduce leg injuries caused by contact with a running power saw chain.

1.3 This standard is not intended to serve as a detailed manufacturing or purchasing specification, but can be referenced in purchase contracts to ensure that minimum performance requirements are met.

1.4 Controlled laboratory tests used to determine compliance with the performance requirements of this standard shall not be deemed as establishing performance levels for all situations to which chain saw operators may be exposed.

1.5 Mandatory requirements are indicated by the use of shall; recommendations and advisory information is indicated by use of should.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1897 – 98

Standard Specification for

Leg Protection for Chain Saw Users

This standard is issued under the fixed designation F 1897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification specifies minimum requirements for 3.1 Definitions:

the design, performance, testing, and certification of protective 3.1.1 approve, v—to be acceptable to the authority having

garments and protective devices designed to provide cut jurisdiction.

resistance protection to the legs of operators of power chain 3.1.2 authority having jurisdiction, n—the organization,

saws. office, or individual responsible for approving any equipment,

1.2 The objective of this specification is to prescribe fit, installation, or procedure.

function, and performance criteria for protective garments and 3.1.2.1 Discussion—The term authority having jurisdiction

protective devices that, when worn by chain saw operators, that is used in this document in a broad manner since jurisdictions

are intended to reduce leg injuries caused by contact with a and the responsibilities of approval agencies vary.

running power saw chain. 3.1.3 certification, n—a system whereby an organization

1.3 This standard is not intended to serve as a detailed determines that a manufacturer has demonstrated the ability to

manufacturing or purchasing specification, but can be refer- make a product that complies with the requirements of the

enced in purchase contracts to ensure that minimum perfor- specification, authorizes the manufacturer to use a label on

mance requirements are met. products that comply with the requirements of the specifica-

1.4 Controlled laboratory tests used to determine compli- tion, and conducts a follow-up to verify the methods the

ance with the performance requirements of this standard shall manufacturer uses to determine compliance with the require-

not be deemed as establishing performance levels for all ments of this specification.

situations to which chain saw operators may be exposed. 3.1.4 certification organization, n—an independent, third-

1.5 Mandatory requirements are indicated by the use of party organization that determines product compliance with the

shall; recommendations and advisory information is indicated requirements of the specification with a labeling and listing

by use of should. follow-up program.

3.1.5 chain saw, n—a portable power-operated tool used for

2. Referenced Documents

cutting wood that has cutters linked in a chain.

2.1 ASTM Standards: 3.1.6 chain speed, n—the velocity of synchronized move-

D 1776 Practice for Conditioning Textiles for Testing

ment of linked cutters around a guide bar and sprocket.

F 1414 Test Method for Measurement of Cut Resistance to 3.1.7 chain stop, n—for chain saw cut resistance, the

Chain Saw in Lower Body (Legs) Protective Clothing

resulting action when a material clogs (jams) the drive sprocket

2.2 AATCC Standards: or slows the speed sufficiently to prevent advancement of the

Test Method 96 - (1988) Dimensional Changes in Launder-

saw chain.

ing of Woven and Knitted Fabrics, except Wool 3.1.8 cut resistance, n—in textile testing for chain saws, the

Test Method 158 - (1985) Dimensional Changes on Dry

ability of a material, while in contact with the linked cutters, to

Cleaning in Perchloroethylene: Machine Method resist penetration of the cutters of a moving saw chain,

independent of either jamming or chain stop.

3.1.9 cut-through time, n—for chain saw cut resistance, the

This specification is under the jurisdiction of ASTM Committee F-23 on

time required for a running saw chain to affect complete

Protective Clothing and is under the direct responsibility of Subcommittee F23.20

breakthrough of a protective garment or protective device.

on Physical Properties.

Current edition approved June 10, 1998. Published August 1998. 3.1.9.1 Discussion—When a cutthrough is effected, speed

Annual Book of ASTM Standards, Vol 07.01.

of the saw chain and time required must be measured.

Annual Book of ASTM Standards, Vol 11.03.

Available from American Association of Textile Chemists and Colorists, P. O.

Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1897–98

3.1.10 follow-up program, n—the sampling, inspection, 3.1.22 saw chain, n— closed loop of cutters linked together

tests, or other measures conducted by the certification organi- for use in a portable power-operated tool.

zation on a periodic basis to determine the continued compli-

4. Materials and Manufacture

ance of products that are being made by the manufacturer to the

requirements of the standard specification.

4.1 Protective garments and protective devices shall be

3.1.11 jamming, n—for chain saw cut resistance, the clog- constructed of materials that are sufficiently flexible to adapt to

the shape of the leg. Protective garments or protective devices

ging action manifested by a protective garment that can

produce a chain stop. should remain functional and effective throughout seasonal

climatic variations.

3.1.12 label, v—for protective clothing, to attach a symbol

4.2 Protective garments and protective devices shall be

or other identifying mark, the use of which has been authorized

constructed to be lightweight and flexible enough so as not to

by a certification organization.

severely restrict movement of the leg.

3.1.13 list, v—for protective clothing, to publish a register

4.3 Protective garments or protective devices shall be con-

of equipment or materials that has been verified by a certifi-

structed of materials that offer protection as stipulated in

cation organization as being acceptable and meeting the

Section 5 and that do not impede normal maneuverability or

requirements of standard specifications.

capability to perform the intended task. Protective garments or

3.1.13.1 Discussion—The means for identifying listed

protective devices should retain their shape and function when

equipment may vary for each organization concerned with

wet.

product evaluation, some of which do not recognize equipment

4.4 The workmanship in the production and assembly of the

as listed unless it is also labeled. The authority having

protective garment or protective device, and any associated

jurisdiction should utilize the system employed by the certifi-

clothing or restraining material, shall be such that the protec-

cation organization to identify a listed product.

tive pad is permanently attached to the protective clothing.

3.1.14 protective apron, n—for chain saw cut protection,an

4.5 Protective garments or protective devices shall be free

oversized protective device worn outside the trousers that is

of defects or imperfections that could detract from their

secured around the waist and may be secured around the legs

function or performance. All hardware on protective garments

(see protective chaps).

or protective devices should be free of rough spots, burrs, or

3.1.15 protective chaps, n—for chain saw cut protection,a

sharp edges.

protective device normally worn outside the trousers that is

secured around the legs and waist (see protective apron).

5. Areas of Protection

3.1.16 protective clothing, n—any material or combination

5.1 The means of maintaining the protective garment or

of materials used in an item of clothing for the purpose of

protective device in the intended position is considered part of

isolating parts of the body from a potential hazard.

the protective clothing. Protective garments or protective

3.1.16.1 Discussion—For this specification, the potential

devices shall have an adequate means to keep them securely

hazard is contact with a running chain saw.

fastened around the waist and legs.

3.1.17 protective device, n—for chain saw cut resistance,an

5.2 After pretreating in accordance with Section 6, protec-

article of personal protective equipment that augments other

tive garments and protective devices shall protect a minimum

equipment and is worn for the purpose of providing limited

area as described below:

protection from injury due to contact with a moving power saw

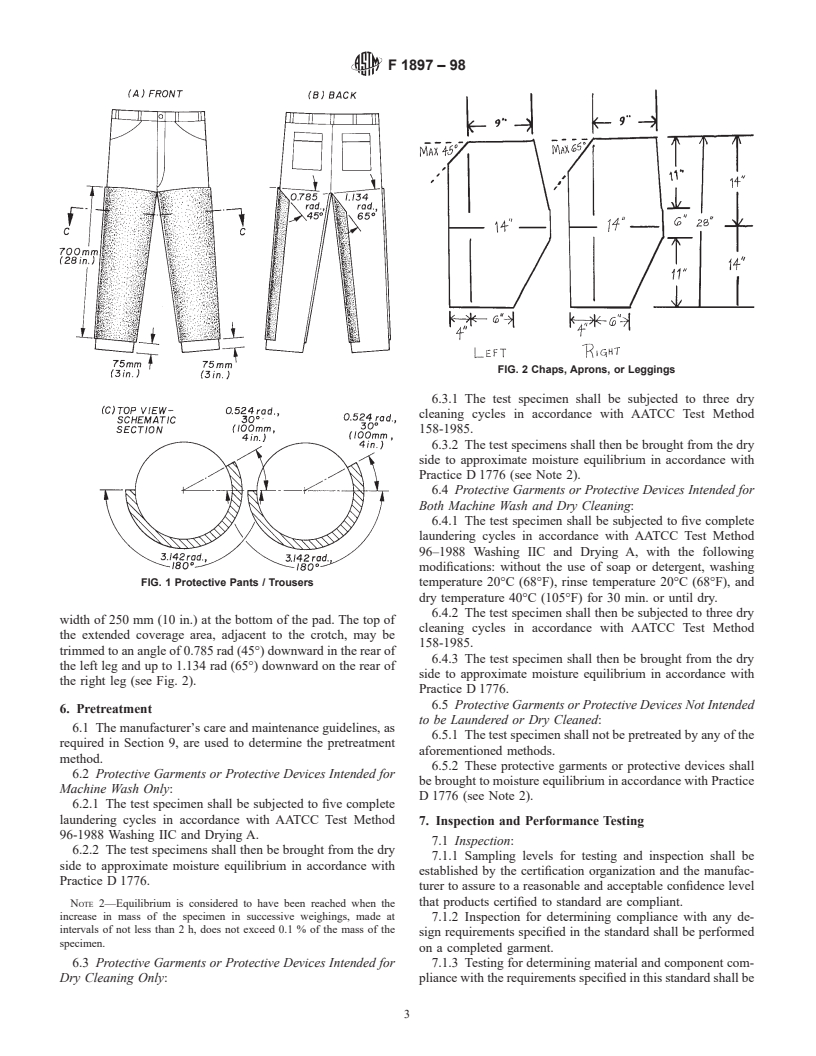

5.2.1 Pants/Trousers:

chain (see protective garment).

5.2.1.1 The protective pad shall have a minimum length of

3.1.17.1 Discussion—Examples of protective devices for

700 mm (28 in.) and extend from the crotch to a point no more

leg protection include protective aprons and protective chaps. than 75 mm (3 in.) above the bottom of the pant leg.

3.1.18 protective garment, n—for chain saw cut protection,

NOTE 1—Should the inseam length be less than 700 mm (28 in.), then

an article of personal protective equipment that is worn for the

the pad may extend above the crotch.

purpose of providing limited protection from injury due to

5.2.1.2 The protective pad shall cover at least 3.142 rad

contact with a moving power saw chain. (See protective

(180°) across the frontal arc of each leg plus an additional

device.)

0.524 rad (30°) or 100 mm (4 in.) on the left side of both legs.

3.1.18.1 Discussion—Examples of protective garments for

The top of the extended coverage area, adjacent to the crotch,

leg protection include protective leggings and protective pants.

may be trimmed to an angle, not to exceed 0.785 rad (45°)

3.1.19 protective legging, n—for chain saw cut resistance,a

downwards in the back of the left leg, and at an angle not to

protective garment with independent legs normally worn

exceed 1.134 rad (65°) in the back of the right leg. The

outside the trousers.

protective pad should overlap the boot top by at least 50 mm (2

3.1.20 protective pad, n—for chain saw cut protection,a

in.) as worn on the user (see Fig. 1a, 1b, and 1c).

protective material permanently attached into or onto the

5.2.2 Chaps, Aprons, or Leggings:

protective garment or protective device, designed to reduce leg

5.2.2.1 The protective pad shall have a minimum length of

injuries in the event of contact with a moving power saw chain.

700 mm (28 in.) and extend from the crotch to a point 25 mm

3.1.21 protective pant, n—for chain saw cut resistance,a (1 in.) above the bottom of the carrier garment.

trouser-style protective garment in which the protective mate- 5.2.2.2 The protective pad shall have a minimum width of

rial is permanently attached to the garment. 350 mm (14 in.) at the midpoint of the pad and a minimum

F1897–98

FIG. 2 Chaps, Aprons, or Leggings

6.3.1 The test specimen shall be subjected to three dry

cleaning cycles in accordance with AATCC Test Method

158-1985.

6.3.2 The test specimens shall then be brought from the dry

side to approximate moisture equilibrium in accordance with

Practice D 1776 (see Note 2).

6.4 Protective Garments or Protective Devices Intended for

Both Machine Wash and Dry Cleaning:

6.4.1 The test specimen shall be subjected to five complete

laundering cycles in accordance with AATCC Test Method

96–1988 Washing IIC and Drying A, with the following

modifications: without the use of soap or detergent, washing

FIG. 1 Protective Pants / Trousers temperature 20°C (68°F), rinse temperature 20°C (68°F), and

dry temperature 40°C (105°F) for 30 min. or until dry.

6.4.2 The test specimen shall then be subjected to three dry

width of 250 mm (10 in.) at the bottom of the pad. The top of

cleaning cycles in accordance with AATCC Test Method

the extended coverage area, adjacent to the crotch, may be

158-1985.

trimmed to an angle of 0.785 rad (45°) downward in the rear of

6.4.3 The test specimen shall then be brought from the dry

the left leg and up to 1.134 rad (65°) downward on the rear of

side to approximate moisture equilibrium in accordance with

the right leg (see Fig. 2).

Practice D 1776.

6.5 Protective Garments or Protective Devices Not Intended

6. Pretreatment

to be Laundered or Dry Cleaned:

6.1 The manufacturer’s care and maintenance guidelines, as

6.5.1 The test specimen shall not be pretreated by any of the

required in Section 9, are used to determine the pretreatment

aforementioned methods.

method.

6.5.2 These protective garments or protective devices shall

6.2 Protective Garments or Protective Devices Intended for

be brought to moisture equilibrium in accordance with Practice

Machine Wash Only:

D 1776 (see Note 2).

6.2.1 The test specimen shall be subjected to five complete

laundering cycles in accordance with AATCC Test Method

7. Inspection and Performance Testing

96-1988 Washing IIC and Drying A.

7.1 Inspection:

6.2.2 The test specimens shall then be brought from the dry

7.1.1 Sampling levels for testing and inspection shall be

side to approximate moisture equilibrium in accordance with

established by the certification organization and the manufac-

Practice D 1776.

turer to assure to a reasonable and acceptable confidence level

that products certified to standard are compliant.

NOTE 2—Equilibrium is considered to have been reached when the

increase in mass of the specimen in successive weighings, made at 7.1.2 Inspection for determining compliance with any de-

intervals of not less than 2 h, does not exceed 0.1 % of the mass of the

sign requirements specified in the standard shall be performed

specimen.

on a completed garment.

6.3 Protective Garments or Protective Devices Intended for 7.1.3 Testing for determining material and component com-

Dry Cleaning Only: pliance with the requirements specified in this standard shall be

F1897–98

performed on samples that are no better than components used tests, a program for calibration of all instruments, and proce-

in the actual construction of the protective clothing. The dures to ensure proper control of all testing. These procedures

certification organization shall also be permitted to use sample shall include the use of laboratory manuals, data sheets,

materials cut from representative protective clothing as defined documented calibration and calibration routines, performance

by this standard. verification, proficiency testing, and staff qualification and

7.2 Performance Testing: training programs.

7.2.1 Performance Requirement —After pretreating the 8.2.4.1 Investigative procedures are important elements of

samples as described in Section 6, the test specimens shall be an effective and meaningful product safety certification pro-

tested in accordance with Test Method F 1414. With the gram. A preliminary review should be carried out on product

running saw chain moving at a minimum initial speed of 13 submitted to the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.