ASTM C636-04

(Practice)Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and Lay-In Panels

Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and Lay-In Panels

SCOPE

1.1 This practice covers the installation of suspension systems for acoustical tile and lay-in panels. It is applicable to contractors whose services are utilized for installing acoustical ceilings and to other trades if their activities are responsible for interference with ceiling components or performance as defined in this recommended practice.

1.2 While the practices described in this document have equal application to rated fire-resistive suspension systems, additional requirements may have been imposed to obtain the fire endurance classification of particular floor-ceiling or roof-ceiling assemblies. These details should be obtained from the manufacturers.

1.3 Similarly, additional detailing may be necessary to meet sound attenuation requirements when ceiling plenums extend over contiguous rooms. These, too, should be obtained from the manufacturer of the acoustical material employed.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 While many of the practices described in this practice have application to the installation of metal suspension systems in exterior environments, the specific design of exterior ceiling installations requires the review and approval of the architect or engineer, or both, who are responsible for the construction of the building or modifications to an existing building. While recommendations from the manufacturer should be solicited, it remains the final responsibility of the architect/engineer to ensure proper application of the materials in question.

This standard does not purport to address of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C636–04

Standard Practice for

Installation of Metal Ceiling Suspension Systems for

1

Acoustical Tile and Lay-In Panels

This standard is issued under the fixed designation C 636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Installation of Components

1.1 This practice covers the installation of suspension sys- 2.1 Hangers:

tems for acoustical tile and lay-in panels. It is applicable to 2.1.1 Where acoustical ceilings are suspended from a struc-

contractors whose services are utilized for installing acoustical ture of wood construction, attach hangers with suitable me-

ceilings and to other trades if their activities are responsible for chanical devices either to the bottom edge of the wood joists or

interference with ceiling components or performance as de- to the vertical face of the wood joists near the bottom edge.

fined in this recommended practice. Holding power tests certified by the manufacturer must be

1.2 While the practices described in this document have available on request for bottom edge attachment devices.

equal application to rated fire-resistive suspension systems, 2.1.2 Where acoustical ceilings are suspended from a struc-

additional requirements may have been imposed to obtain the ture of concrete construction, mount hangers using cast-in-

fire endurance classification of particular floor-ceiling or roof- place hanger wires, hanger inserts, or other hanger attachment

ceiling assemblies. These details should be obtained from the devices whose suitability has been demonstrated by standard

manufacturers. construction practice or by certified test data.

1.3 Similarly, additional detailing may be necessary to meet 2.1.3 Space hangers for carrying channels or main runners 4

sound attenuation requirements when ceiling plenums extend ft 0 in. (1.2 m) on centers. If local situations allow greater

over contiguous rooms. These, too, should be obtained from center distances between hangers, reduce the load-carrying

the manufacturer of the acoustical material employed. capacity of the ceiling suspension system commensurate with

1.4 The values stated in inch-pound units are to be regarded the actual center-to-center hanger distances used. If local

as the standard. The values given in parentheses are for situations allow lesser center distances between hangers, in-

information only. crease the load-carrying capacity of the ceiling suspension

1.5 While many of the practices described in this practice system commensurate with the actual center-to-center hanger

haveapplicationtotheinstallationofmetalsuspensionsystems distances used.

in exterior environments, the specific design of exterior ceiling 2.1.4 Each suspension wire shall not hang more than one in

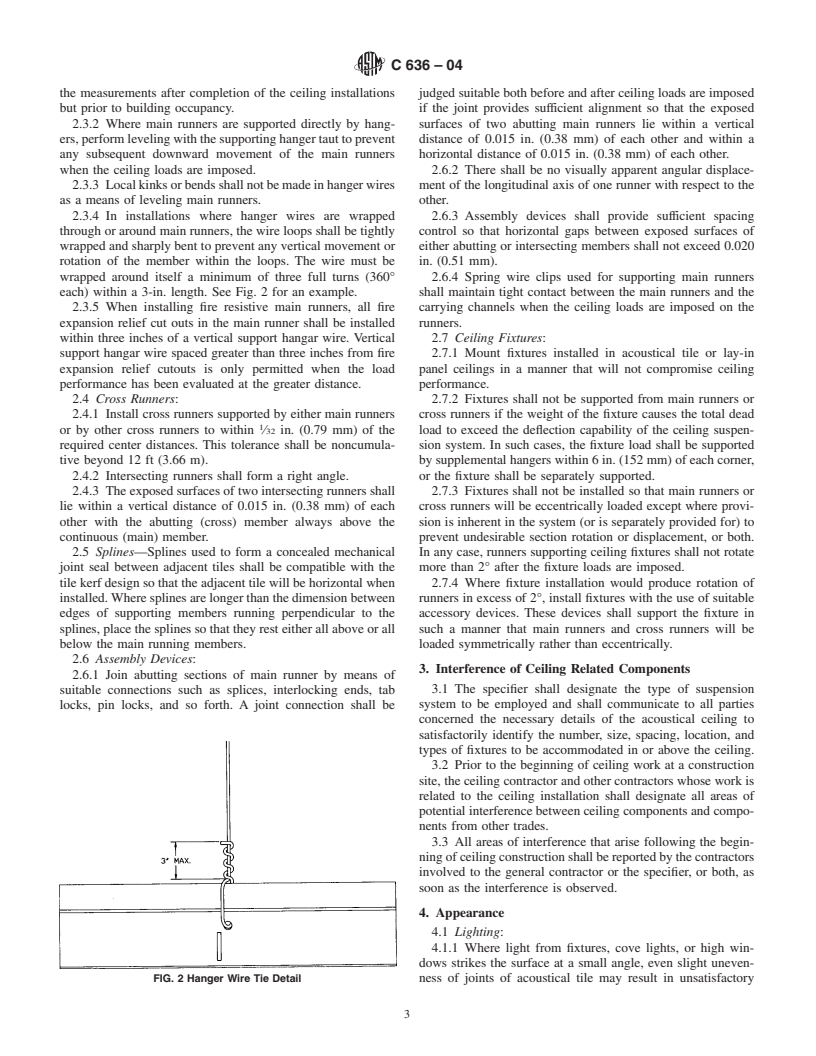

installations requires the review and approval of the architect six out of plumb unless a countersloping wire or horizontal

or engineer, or both, who are responsible for the construction bracing is provided. See Fig. 1 for allowable countersloping

of the building or modifications to an existing building. While methods. Suspension wires should not press against ducts or

recommendations from the manufacturer should be solicited, it pipes.

remains the final responsibility of the architect/engineer to 2.1.5 Hangers formed from galvanized sheet metal stock

ensure proper application of the materials in question. shall be suitable for suspending carrying channels or main

1.6 This standard does not purport to address of the safety runners from an existing structure provided that the hangers do

concerns, if any, associated with its use. It is the responsibility not yield, twist, or undergo other objectionable movement.

of the user of this standard to establish appropriate safety and 2.1.6 Wire hangers for suspending carrying channels or

health practices and determine the applicability of regulatory main runners from an existing structure shall be prepared from

limitations prior to use. a minimum of No. 12-gage (2.05-mm) galvanized, soft-

annealed, mild steel wire.

2.1.7 In some installations hanger wires are secured to

1

This practice is under the jurisdiction of ASTM Committee E33 on Environ-

special attachment devices that support the carrying channels

mental Acoustics and is the direct responsibility of Subcommittee E33.04 on

or main runners. Such attachment devices shall have certified

Application of Acoustical Materials and Systems.

load test data from an independent test laboratory and shall be

Current edition approved April 1, 2004. Published May 2004.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.