ASTM D4745-97

(Specification)Standard Specification for Filled Compounds of Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

Standard Specification for Filled Compounds of Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

SCOPE

1.1 This specification covers polytetrafluoroethylene (PTFE) filled molding compounds made with virgin PTFE resins defined in Specification D 4894, except Types I, IV, V, and VI.

Note 1—This specification can be used as a model for other PTFE compounds having particulate fillers that can survive the sintering temperatures of PTFE as can those listed in this specification. This specification is restricted to virgin PTFE for technical reasons. Recycled material cannot be processed successfully.

Note 2—The properties measured on commercially fabricated parts may differ from the listed values for samples prepared by the procedures given in this specification, depending on part geometry and processing parameters.

Note 3—There is no ISO equivalent to this specification.

1.2 The values stated in SI units are to be regarded as standard.

1.3 The following statement applies to the test method portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 9.5 and Note 4 for a specific warning statement.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4745 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Filled Compounds of Polytetrafluoroethylene (PTFE)

Molding and Extrusion Materials

This standard is issued under the fixed designation D 4745; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 1895 Test Methods for Apparent Density, Bulk Factor,

and Pourability of Plastic Materials

1.1 This specification covers polytetrafluoroethylene

D 1898 Practice for Sampling of Plastics

(PTFE) filled molding compounds made with virgin PTFE

D 3892 Practice for Packaging/Packing of Plastics

resins defined in Specification D 4894, except Types I, IV, V,

D 4894 Specification for Polytetrafluoroethylene (PTFE)

and VI.

Granular Molding and Extrusion Materials

NOTE 1—This specification can be used as a model for other PTFE

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

compounds having particulate fillers that can survive the sintering

poses

temperatures of PTFE as can those listed in this specification. This

E 380 Practice for the Use of the International System of

specification is restricted to virgin PTFE for technical reasons. Recycled

Units (SI)

material cannot be processed successfully.

NOTE 2—The properties measured on commercially fabricated parts E 691 Practice for Conducting an Interlaboratory Study to

may differ from the listed values for samples prepared by the procedures

Determine the Precision of a Test Method

given in this specification, depending on part geometry and processing

parameters.

3. Terminology

NOTE 3—There is no ISO equivalent to this specification.

3.1 Definitions—The terminology given in Terminology

1.2 The values stated in SI units as detailed in Practice

D 883 is applicable to this specification unless otherwise

E 380 are to be regarded as the standard and the practices of

specified.

E380 incorporated herein.

3.2 Definitions of Terms Specific to This Standard:

1.3 The following statement applies to the test method

3.2.1 bulk density, n—the mass in kilograms per cubic

portion, Section 12, of this specification: This standard does

metre of resin compound measured under the conditions of the

not purport to address all of the safety concerns, if any,

test.

associated with its use. It is the responsibility of the user of this

3.2.2 density, n—the mass per unit volume in air in milli-

standard to establish appropriate safety and health practices

grams per cubic metre (grams per cubic centimetre) of the

and determine the applicability of regulatory limitations prior

material at a temperature of 23 6 2°C (73.4 6 4°F).

to use. See 9.5 and Note 4 for a specific warning statement.

3.2.3 filled compound, n—blend of PTFE resin as the matrix

and particulate fillers, generally glass, other inorganic, metal-

2. Referenced Documents

lic, or polymeric materials that withstand the sintering tem-

2.1 ASTM Standards:

perature of PTFE (327 to 380°C).

D 618 Practice for Conditioning Plastics and Electrical

3.2.4 free-flow resins (pelletized), n—generally made by

Insulating Materials for Testing

treatment of finely divided resins to produce free-flowing

D 638 Test Method for Tensile Properties of Plastics

agglomerates.

D 792 Test Methods for Specific Gravity (Relative Density)

3.2.5 lot, n—one continuous production run or a uniform

and Density of Plastics by Displacement

blend of two or more production runs of the compound.

D 883 Terminology Relating to Plastics

3.2.6 pigmented compound, n—a compound in which a

D 1600 Terminology for Abbreviated Terms Relating to

pigment is added for colorant purposes only.

Plastics

3.2.7 standard flow resins (nonpelletized), n—finely divided

resin with an average particle size less than 100 μm.

3.3 Abbreviations—Abbreviations are in accordance with

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved April 10, 1997. Published April 1998. Originally Annual Book of ASTM Standards, Vol 08.02.

published as D 4745 – 91. Last previous edition D 4745 – 91. Annual Book of ASTM Standards, Vol 08.03.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

D 4745

Terminology D 1600. PTFE is the acronym for polytetrafluo- 6. Requirements

roethylene.

6.1 The PTFE compounds covered by this specification

shall be uniform (filler and resin particles evenly distributed)

4. Classification

and shall contain no foreign material.

4.1 This specification covers the following two types of

6.2 The PTFE compounds shall conform to the require-

PTFE compounds

ments prescribed in Tables 1-3 when tested by the procedures

4.1.1 Type I—Nonpelletized material, for general-purpose

specified herein. Table 1 and Table 3 list requirements for Type

compression molding.

I. Table 2 and Table 3 reference requirements for Type II.

4.1.2 Type II—Pelletized or free-flowing material, for mold-

6.3 Other PTFE compounds are commercially available, but

ing, automatic molding, or ram extrusion.

are not described in this specification.

4.2 Thirteen grades of each type distinguished by the nature

of the filler(s) are listed in Tables 1-3.

7. Sampling

4.3 A one-line system may be used to specify materials

7.1 Sample the resin in accordance with the Sections cov-

covered by this specification. The system uses predefined cells

ering General Sampling Procedures in Practice D 1898. Ad-

to refer to specific aspects of this specification, as the following

equate statistical sampling prior to packaging shall be consid-

illustrates:

ered an acceptable alternative.

Specification

7.2 The producer shall take (and test) sufficient within-lot

Standard Number : Type : Grade : Class : Special

samples to ensure adequate in-process quality control and

Block : : : : Notes

:: : : :

continuing conformance to the property requirements of this

Example: Specification II 2

specification.

D4745–97

8. Number of Tests

4.3.1 For this example, the line callout would be Specifica-

tion D 4745 – 97, II 2, and would specify a pelletized or 8.1 Routine lot inspection tests shall consist of those carried

free-flowing filled composition of polytetrafluoroethylene that out to determine the requirements specified in Table 1 or Table

has all of the properties listed for that type, and grade in the 3 depending on type. Periodic tests shall include using all the

appropriate specified properties, tables, or both, in the specifi- tests to determine the requirements in Table 3, depending on

cation identified. A comma is used as the separator between the type.

standard number and the type. Separators are not needed 8.2 The requirements listed in Tables 1-3, as they apply, are

between the type, grade, and class. A provision for special sufficient to establish conformity of a material to this specifi-

notes is included so that other information can be provided cation. When the number of test specimens is not stated in the

when required. An example would be in Specification test method, single determinations may be made. If more than

D 3295 – 81a where dimensions and tolerances are specified single determinations are made on specimens from separate

for each AWG size within type and class. When special notes portions of the same sample, the results shall be averaged. The

are used, they should be preceded by a comma. single or average result shall conform to the requirements

prescribed in this specification.

5. Ordering Information

5.1 The filled compounds of PTFE may be ordered using the

9. Test Specimens

type, (see 4.1) and the grade (see reference Table 1 and Table

9.1 Test specimens shall be cut from billets molded in

3), or they may be ordered using the designation of the

accordance with the following procedures. An acceptable

suppliers.

alternate procedure for molding the test plaque is described in

Specification D 4894.

See the ASTM Form and Style Manual, available from ASTM Headquarters.

9.2 Test Billets:

TABLE 1 TFE Compounds, Type I, Standard Flow (Nonpelletized)

Molded Parts (Molded and Sintered)

Raw Resin

Density, min, SPG, max,

Type Grade Bulk Density, Tensile Strength

3 3 Elongation, min,

g/cm g/cm

min, g/L

%

min, MPa min, psi

1 15 % glass fiber 400 2.150 2.25 19.6 2840 250

2 25 % glass fiber 425 2.150 2.250 15.7 2270 200

3 35 % glass fiber 450 2.200 2.300 10.3 1500 150

4 5 % glass fiber and 5 % MoS 350 2.150 2.300 20.7 3000 250

5 15 % glass fiber and 5 % MoS 375 2.150 2.300 17.2 2500 200

6 10 % graphite 350 2.100 2.220 17.9 2600 225

7 15 % graphite 300 2.100 2.200 16.6 2400 100

8 25 % carbon and graphite 350 1.950 2.100 11.0 1600 80

9 32 % carbon and graphite 325 1.900 2.100 6.9 1000 50

10 40 % bronze 500 2.900 3.200 17.2 2500 175

11 60 % bronze 650 3.800 4.000 13.8 2000 140

12 55 % bronze and 5 % MoS 700 3.500 4.000 10.3 1500 80

13 50 % stainless steel 500 3.200 3.600 17.2 2500 150

D 4745

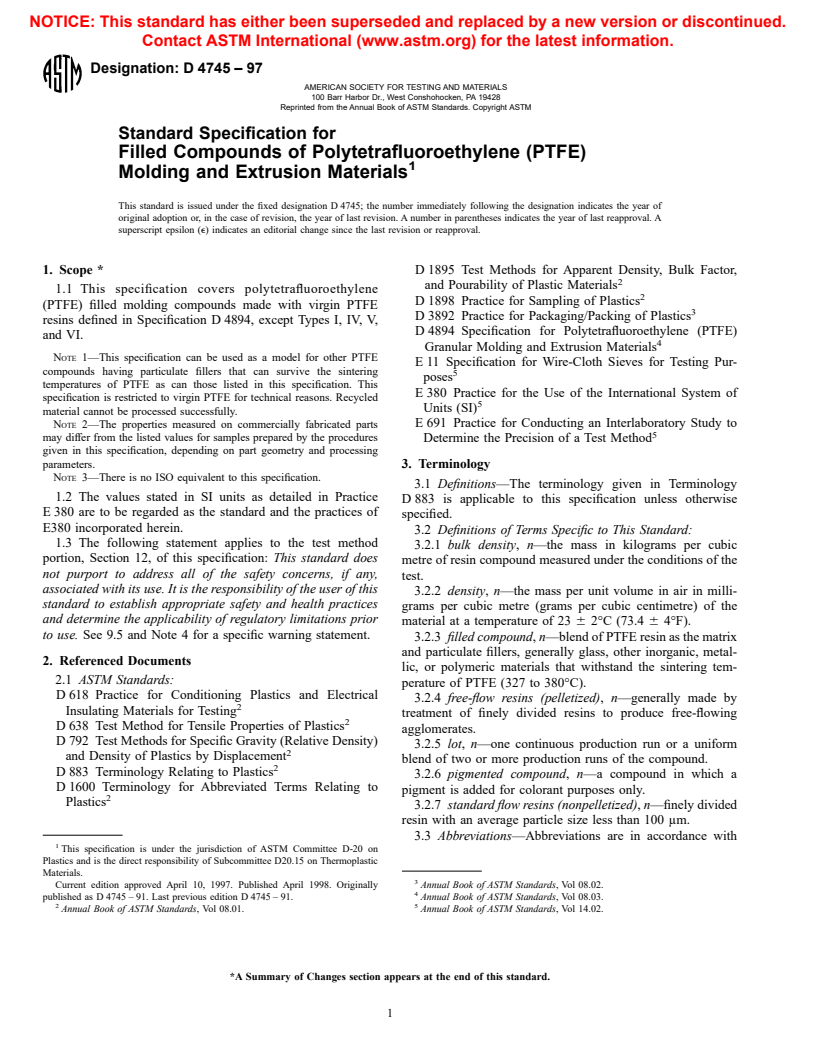

TABLE 2 TFE Compounds, Type II, Free-Flow (Pelletized)

Molded Parts (Molded and Sintered)

Raw Resin

SPG, max,

Type Grade Bulk Density, Density, min, g/cm Tensile Strength

Elongation, min,

g/cm

min, g/L

%

min, MPa min, psi

1 15 % glass fiber 625 2.150 2.25 17.2 2500 200

2 25 % glass fiber 625 2.150 2.250 12.4 1800 180

3 35 % glass fiber 650 2.200 2.300 8.3 1200 100

4 5 % glass fiber and 5 % MoS 575 2.150 2.300 17.2 2500 220

5 15 % glass fiber and 5 % MoS 600 2.150 2.300 13.8 2000 180

6 10 % graphite 600 2.100 2.220 13.8 2000 180

7 15 % graphite 550 2.100 2.200 10.3 1500 100

8 25 % carbon and graphite 500 1.950 2.100 8.3 1200 20

9 32 % carbon and graphite 500 1.900 2.100 6.9 1000 20

10 40 % bronze 750 2.900 3.200 13.8 2000 100

11 60 % bronze 900 3.800 4.000 10.3 1500 100

12 55 % bronze and 5 % MoS 900 3.500 4.000 6.9 1000 50

13 50 % stainless steel 850 3.200 3.600 13.8 2000 100

TABLE 3 Required Filler Content

9.2.3 Assemble the mold. Add the resin to the mold, taking

Mass, % Tolerance,6 ,% care not to fill within 13 mm (0.5 in.) of the top of the cavity.

Insert the top plug and apply hand pressure, making certain that

10to3 1

2 4 to 25 2

the pusher is centered in the mold. Place the mold in a

3 26to60 3

hydraulic press and remove the support ring or spacers. Do not

4 61to75 5

allow the two end plugs to bottom on the mold shell. Apply an

initial load to the mold of 3.45 MPa (500 psi) 6 10 % and hold

for 1 to 2 min. Increase the loading smoothly to the final

9.2.1 Prior to molding, screen the material through a

preforming pressure in 3 to 5 min. Use 35 MPa (5100 psi) for

2.0-mm hand sieve.

compounds containing 15 % by weight or less filler and 70

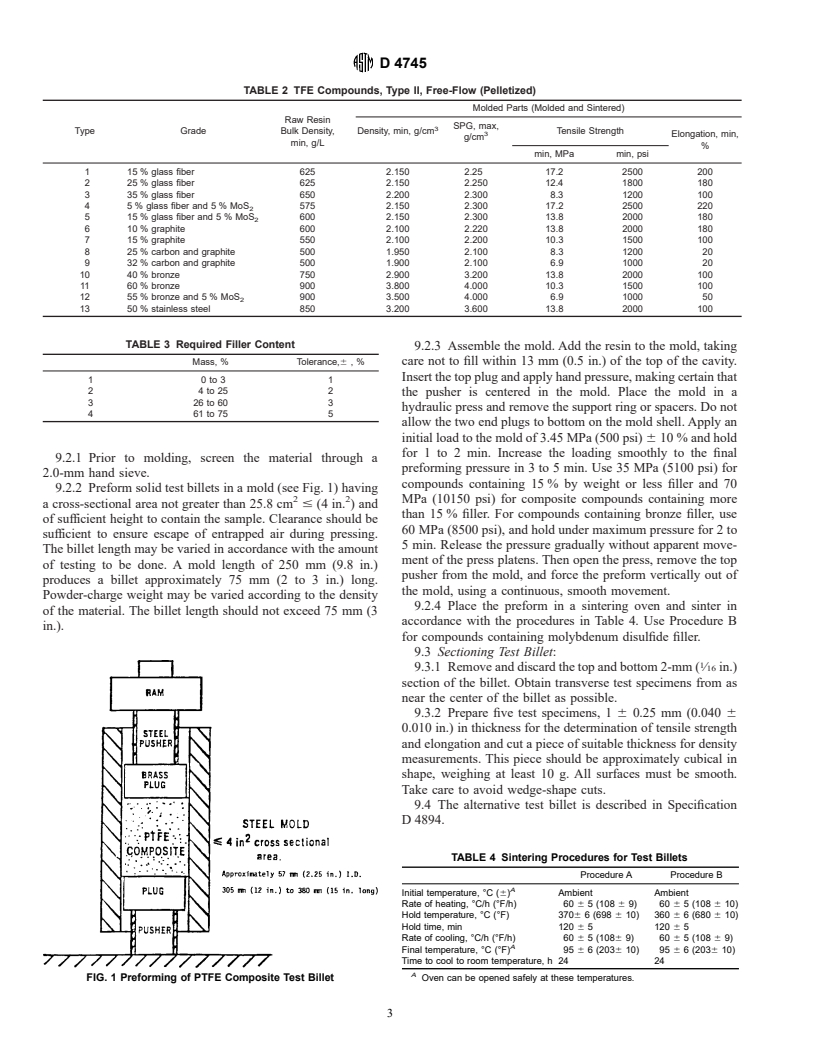

9.2.2 Preform solid test billets in a mold (see Fig. 1) having

2 2

MPa (10150 psi) for composite compounds containing more

a cross-sectional area not greater than 25.8 cm # (4 in. ) and

than 15 % filler. For compounds containing bronze filler, use

of sufficient height to contain the sample. Clearance should be

60 MPa (8500 psi), and hold under maximum pressure for 2 to

sufficient to ensure escape of entrapped air during pressing.

5 min. Release the pressure gradually without apparent move-

The billet length may be varied in accordance with the amount

ment of the press platens. Then open the press, remove the top

of testing to be done. A mold length of 250 mm (9.8 in.)

pusher from the mold, and force the preform vertically out of

produces a billet approximately 75 mm (2 to 3 in.) long.

the mold, using a continuous, smooth movement.

Powder-charge weight may be varied according to the density

9.2.4 Place the preform in a sintering oven and sinter in

of the material. The billet length should not exceed 75 mm (3

accordance with the procedures in Table 4. Use Procedure B

in.).

for compounds containing molybdenum disulfide filler.

9.3 Sectioning Test Billet:

9.3.1 Remove and discard the top and bottom 2-mm ( ⁄16 in.)

section of the billet. Obtain transverse test specimens from as

near the center of the billet as possible.

9.3.2 Prepare five test specimens, 1 6 0.25 mm (0.040 6

0.010 in.) in thickness for the determination of tensile strength

and elongation and cut a piece of suitable thickness for density

measurements. This piece should be approximately cubical in

shape, weighing at least 10 g. All surfaces must be smooth.

Take care to avoid wedge-shape cuts.

9.4 The alternative test billet is described in Specification

D 4894.

TABLE 4 Sintering Procedures for Test Billets

Procedure A Procedure B

A

Initial temperature, °C (6) Ambient Ambient

Rate of heating, °C/h (°F/h) 60 6 5 (108 6 9) 60 6 5 (108 6 10)

Hold temperature, °C (°F) 3706 6 (698 6 10) 360 6 6 (680 6 10)

Hold time, min 120 6 5 120 6 5

Rate of cooling, °C/h (°F/h) 60 6 5 (1086 9) 60 6 5 (108 6 9)

A

Final temperature, °C (°F) 95 6 6 (2036 10) 95 6 6 (2036 10)

Time to cool to room temperature, h 24 24

A

FIG. 1 Preforming of PTFE Composite Test Billet Oven can be opened safely at these temperatures.

D 4745

9.5 Safety Warning—At normal processing temperatures,

F 5 grams per liter of the filler.

PTFE liberates vapors that may be harmful. Provide adequate

U 5 grams per liter of the unfilled PTFE.

ventilation in areas where PTFE compounds are exposed to

E 5 equivalent filler content (% by volume).

elevated temperatures. Avoid contaminating smoking materials

12.1.6 The percent by volume of filler in a finished piece is

with PTFE compounds.

lower than that in the powder compounds due to the increase in

volume of PTFE that results from the change in crystalline

10. Conditioning Test Specimens

content that occurs during sintering.

10.1 For density and tensile properties the test specimens

12.2 Filler Content (Alternate Method):

shall be conditioned in accordance with Procedure A of

12.2.1 Scope—This burn-out procedure for filler content

Practice D 618 for a period of at least 4 h prior to test.

may be used as alternate to the split tube furnace method of

12.1. The procedure shall be carried out in an inert atmosphere,

11. Test Conditions

especially when fillers that react with PTFE and oxygen in the

11.1 Tests shall be conducted at 25 6 2°C (77 6 3.6°F)

air are present. This reaction produces volatile products that

instead of the standard laboratory temperature of 23 6 2°C

cause incorrect results.

(73.4 6 3.6°F) unless otherwise specified in the test methods

12.2.2 Equipment—Thermogravimetric a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.