ASTM B135-08a

(Specification)Standard Specification for Seamless Brass Tube

Standard Specification for Seamless Brass Tube

ABSTRACT

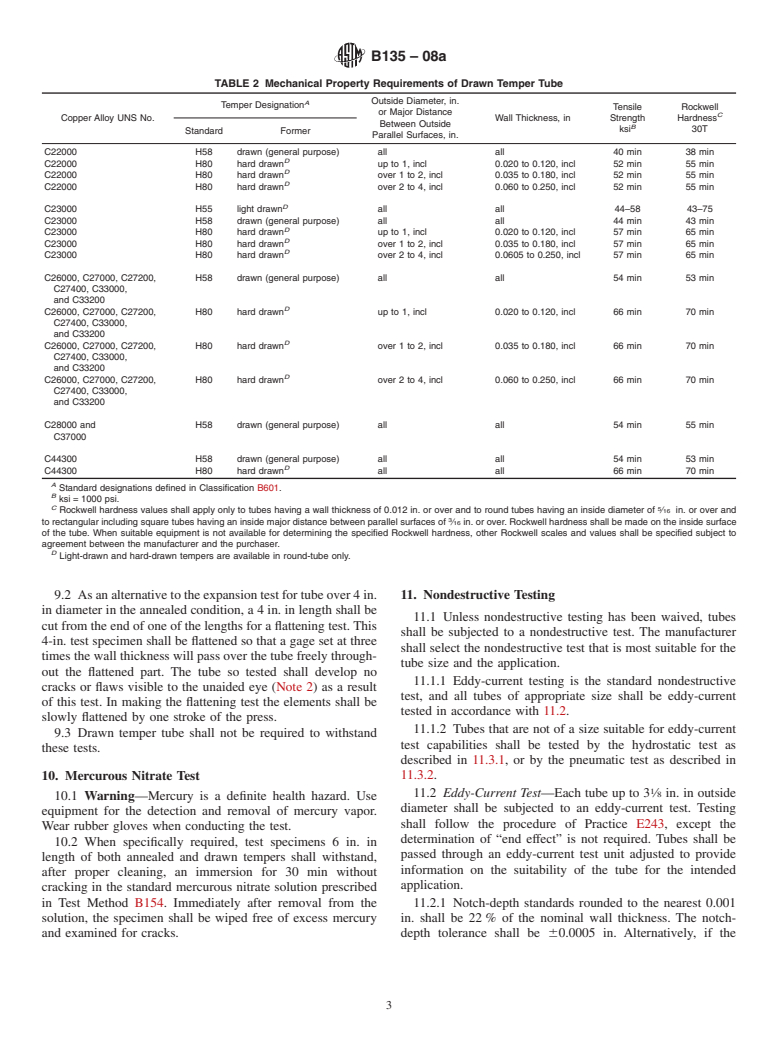

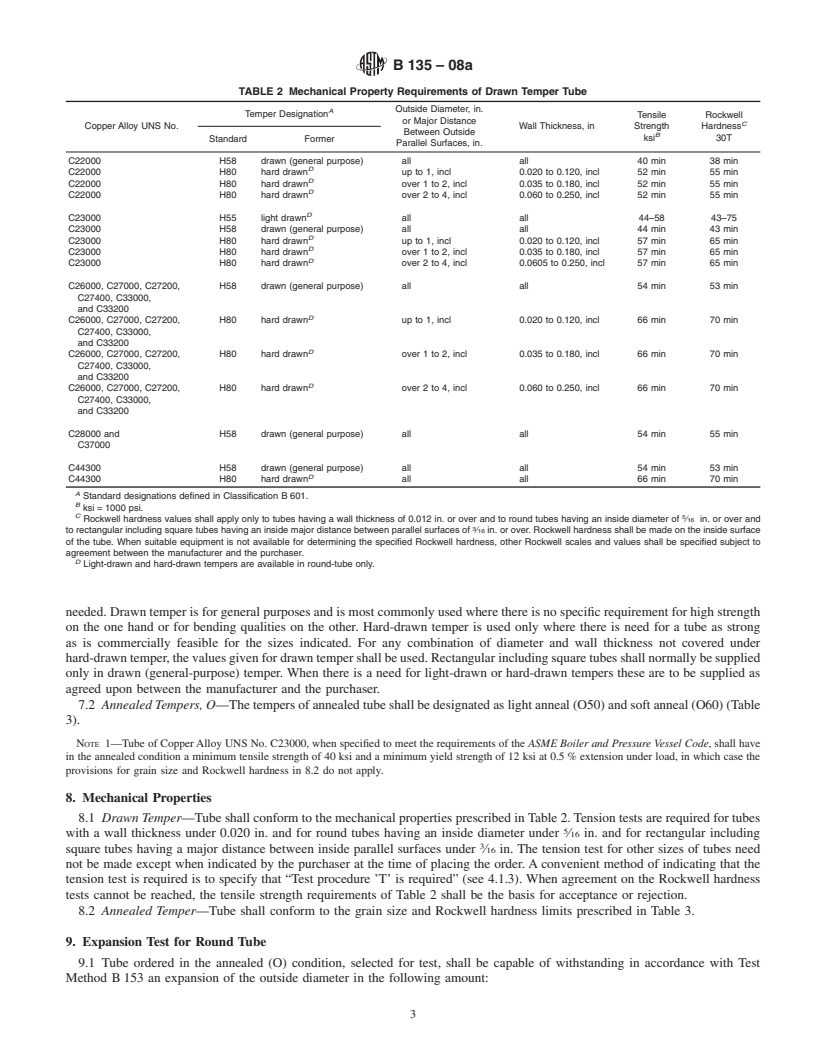

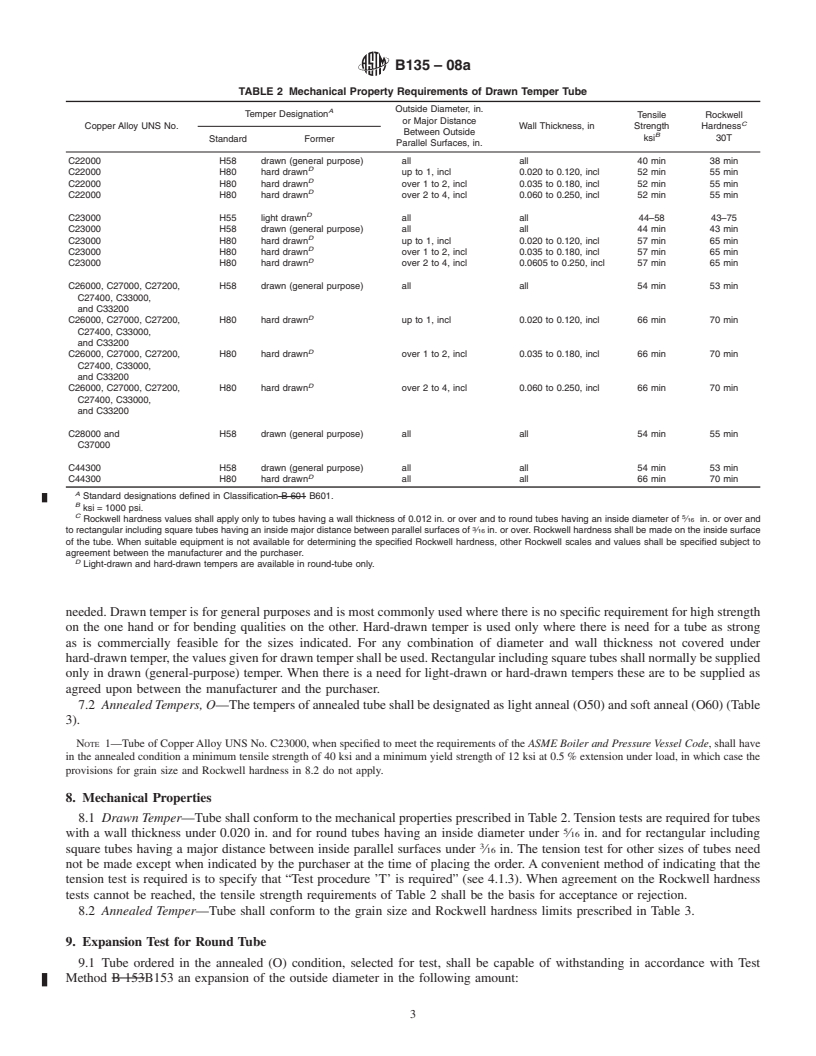

This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. The tempers of drawn tube shall be designated as light-drawn, drawn, and hard-drawn. Light-drawn temper shall be used only when a tube of some stiffness but yet capable of being bent is needed. Drawn temper, which is most commonly used where there is no specific requirement for high strength on the one hand, shall be utilized for general purposes and or for bending qualities on the other. Hard-drawn temper shall be used only where there is need for a tube as strong as is commercially feasible for the sizes indicated. For any combination of diameter and wall thickness not covered under hard-drawn temper, the values given for drawn temper shall be used. Expansion test shall be performed on the rounded tube and shall show no cracking or rupture visible to the unaided eye. Both annealed and drawn tempers shall withstand, after proper cleaning, an immersion in standard mercurous nitrate solution for a certain amount of time without cracking. Materials shall then be removed from the solution and shall be wiped free of excess mercury and shall then be examined for cracks. The specimen shall undergo the eddy-current testing which is the standard nondestructive test. The specimen shall undergo the pneumatic test which subjects the tube to an internal air pressure making sure that it must not show evidence of leakage. The test method used shall provide for easy visual detection of any leakage, such as by immersion of the tube under water or by the pressure differential method. Annealed tube shall be either bright annealed or acid cleaned after final annealing operations.

SCOPE

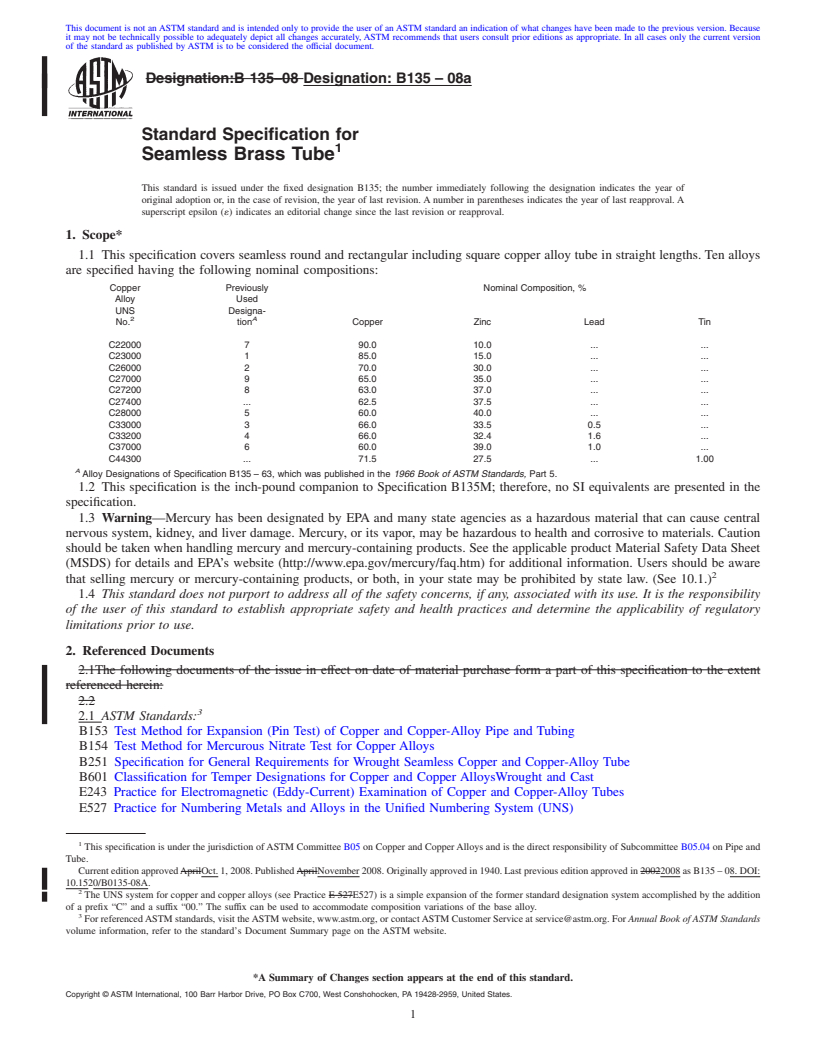

1.1 This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. Ten alloys are specified having the following nominal compositions:

CopperPreviously Nominal Composition, % AlloyUsed UNSDesigna- No. tionACopper ZincLeadTin C22000790.010.0 ...... C23000185.015.0 ...... C26000270.030.0 ...... C27000965.035.0 ...... C27200863.037.0 ...... C27400...62.537.5 ...... C28000560.040.0 ...... C33000366.033.5 0.5... C33200466.032.4 1.6... C37000660.039.0 1.0... C44300...71.527.5 ...1.00

A Alloy Designations of Specification B 135 – 63, which was published in the 1966 Book of ASTM Standards, Part 5.

1.2 This specification is the inch-pound companion to Specification B 135M; therefore, no SI equivalents are presented in the specification.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law. (See 10.1.)

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B135 – 08a

Standard Specification for

1

Seamless Brass Tube

This standard is issued under the fixed designation B135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This specification covers seamless round and rectangu-

bility of regulatory limitations prior to use.

lar including square copper alloy tube in straight lengths. Ten

alloys are specified having the following nominal composi-

2. Referenced Documents

tions:

3

2.1 ASTM Standards:

Copper Previously Nominal Composition, %

B153 Test Method for Expansion (Pin Test) of Copper and

Alloy Used

UNS Designa-

Copper-Alloy Pipe and Tubing

2 A

No. tion Copper Zinc Lead Tin

B154 Test Method for Mercurous Nitrate Test for Copper

Alloys

C22000 7 90.0 10.0 . .

C23000 1 85.0 15.0 . .

B251 Specification for General Requirements for Wrought

C26000 2 70.0 30.0 . .

Seamless Copper and Copper-Alloy Tube

C27000 9 65.0 35.0 . .

B601 Classification for Temper Designations for Copper

C27200 8 63.0 37.0 . .

C27400 . 62.5 37.5 . .

and Copper Alloys—Wrought and Cast

C28000 5 60.0 40.0 . .

E243 Practice for Electromagnetic (Eddy-Current) Exami-

C33000 3 66.0 33.5 0.5 .

nation of Copper and Copper-Alloy Tubes

C33200 4 66.0 32.4 1.6 .

C37000 6 60.0 39.0 1.0 .

E527 Practice for Numbering Metals and Alloys in the

C44300 . 71.5 27.5 . 1.00

Unified Numbering System (UNS)

A

Alloy Designations of Specification B135 – 63, which was published in the

1966 Book of ASTM Standards, Part 5.

3. Terminology

1.2 This specification is the inch-pound companion to

3.1 Definitions of Terms Specific to This Standard:

Specification B135M; therefore, no SI equivalents are pre-

3.1.1 capable of—the test need not be performed by the

sented in the specification.

producer of the material. However, if subsequent testing by the

1.3 Warning—Mercury has been designated by EPA and

purchaser establishes that the material does not meet these

many state agencies as a hazardous material that can cause

requirements, the material shall be subject to rejection.

central nervous system, kidney, and liver damage. Mercury, or

its vapor, may be hazardous to health and corrosive to

4. Ordering Information

materials. Caution should be taken when handling mercury and

4.1 Orders for material under the specification shall include

mercury-containing products. See the applicable product Ma-

the following information:

terial Safety Data Sheet (MSDS) for details and EPA’s website

4.1.1 Alloy (Section 1),

(http://www.epa.gov/mercury/faq.htm) for additional informa-

4.1.2 Temper (Section 7),

tion. Users should be aware that selling mercury or mercury-

4.1.3 Whether tension tests are required (for drawn tempers

containingproducts,orboth,inyourstatemaybeprohibitedby

2 only (see 8.1)),

state law. (See 10.1.)

4.1.4 Dimensions: diameter or distance between parallel

1.4 This standard does not purport to address all of the

surfaces and wall thickness (see 11.2 and 11.3),

safety concerns, if any, associated with its use. It is the

4.1.5 Length (see 12.4),

4.1.6 Mercurous nitrate test, if required (Section 10),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper 4.1.7 Total length of each size,

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

4.1.8 Hydrostatic pressure test, when specified, and

and Tube.

4.1.9 Pneumatic test, when specified.

Current edition approved Oct. 1, 2008. Published November 2008. Originally

approved in 1940. Last previous edition approved in 2008 as B135 – 08. DOI:

10.1520/B0135-08A.

2 3

The UNS system for copper and copper alloys (see Practice E527) is a simple For referenced ASTM standards, visit the ASTM website, www.astm.org, or

expansion of the former standard designation system accomplished by the addition contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate Standards volume information, refer to the standard’s Document Summary page on

composition variations of the base alloy. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B135 – 08a

5. General Requirements these are to be supplied as agreed upon between the manufac-

turer and the purchaser.

5.1 Material furnished under this spec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B135–08 Designation: B 135 – 08a

Standard Specification for

1

Seamless Brass Tube

This standard is issued under the fixed designation B 135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. Ten alloys

are specified having the following nominal compositions:

Copper Previously Nominal Composition, %

Alloy Used

UNS Designa-

2 A

No. tion Copper Zinc Lead Tin

C22000 7 90.0 10.0 . .

C23000 1 85.0 15.0 . .

C26000 2 70.0 30.0 . .

C27000 9 65.0 35.0 . .

C27200 8 63.0 37.0 . .

C27400 . 62.5 37.5 . .

C28000 5 60.0 40.0 . .

C33000 3 66.0 33.5 0.5 .

C33200 4 66.0 32.4 1.6 .

C37000 6 60.0 39.0 1.0 .

C44300 . 71.5 27.5 . 1.00

A

Alloy Designations of Specification B 135 – 63, which was published in the 1966 Book of ASTM Standards, Part 5.

1.2 This specification is the inch-pound companion to Specification B 135M; therefore, no SI equivalents are presented in the

specification.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

2

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law. (See 10.1.)

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2

3

2.1 ASTM Standards:

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B 154 Test Method for Mercurous Nitrate Test for Copper Alloys

B 251 Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

B 601 Classification for Temper Designations for Copper and Copper AlloysWrought and Cast

E 243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E 527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved AprilOct. 1, 2008. Published AprilNovember 2008. Originally approved in 1940. Last previous edition approved in 20022008 as B 135 – 028.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 135 – 08a

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 capable of—the test need not be performed by the producer of the material. However, if subsequent testing by the

purchaser establishes that the material does not meet these requirements, the material shall be subject to rejection.

4. Ordering Information

4.1 Orders for material under the specification shall include the following information:

4.1.1 Alloy (Section 1),

4.1.2 Temper (Section 7),

4.1.3 Whether tension tests are required (for drawn tempers only (see 8.1)),

4.1.4

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 135–08 Designation: B135 – 08a

Standard Specification for

1

Seamless Brass Tube

This standard is issued under the fixed designation B135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. Ten alloys

are specified having the following nominal compositions:

Copper Previously Nominal Composition, %

Alloy Used

UNS Designa-

2 A

No. tion Copper Zinc Lead Tin

C22000 7 90.0 10.0 . .

C23000 1 85.0 15.0 . .

C26000 2 70.0 30.0 . .

C27000 9 65.0 35.0 . .

C27200 8 63.0 37.0 . .

C27400 . 62.5 37.5 . .

C28000 5 60.0 40.0 . .

C33000 3 66.0 33.5 0.5 .

C33200 4 66.0 32.4 1.6 .

C37000 6 60.0 39.0 1.0 .

C44300 . 71.5 27.5 . 1.00

A

Alloy Designations of Specification B135 – 63, which was published in the 1966 Book of ASTM Standards, Part 5.

1.2 This specification is the inch-pound companion to Specification B135M; therefore, no SI equivalents are presented in the

specification.

1.3 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

2

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law. (See 10.1.)

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2

3

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B251 Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

B601 Classification for Temper Designations for Copper and Copper AlloysWrought and Cast

E243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approvedAprilOct. 1, 2008. PublishedAprilNovember 2008. Originally approved in 1940. Last previous edition approved in 20022008 as B135 – 08. DOI:

10.1520/B0135-08A.

2

The UNS system for copper and copper alloys (see Practice E 527E527) is a simple expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B135 – 08a

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 capable of—the test need not be performed by the producer of the material. However, if subsequent testing by the

purchaser establishes that the material does not meet these requirements, the material shall be subject to rejection.

4. Ordering Information

4.1 Orders for material under the specification shall include the following information:

4.1.1 Alloy (Section 1),

4.1.2 Temper (Section 7),

4.1.3 Whether tension tests are required (for drawn tempers only (se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.