ASTM E564-06(2012)

(Practice)Standard Practice for Static Load Test for Shear Resistance of Framed Walls for Buildings

Standard Practice for Static Load Test for Shear Resistance of Framed Walls for Buildings

SCOPE

1.1 This practice describes methods for evaluating the shear capacity of a typical section of a framed wall, supported on a rigid foundation and having load applied in the plane of the wall along the edge opposite the rigid support and in a direction parallel to it. The objective is to provide a determination of the shear stiffness and strength of any structural light-frame wall configuration to be used as a shear-wall on a rigid support.

1.2 Limitations—This practice is not intended to be used as a basis for classifying sheathing shear capacity or as an evaluation of combined flexure and shear resulting from the wall being loaded on a flexible foundation.

1.2.1 The effect of sheathing variations is assessed by holding all other variables constant. Permitted variations in framing configuration and boundary conditions, however, require accurate documentation of the test setup to validate across-study comparisons of sheathing contribution to wall shear capacity.Note 1—A wall tested on a flexible foundation is evaluated by comparing shear stiffness and strength results to those of an identical wall tested on a rigid foundation, following this practice. However, no methods are given for the measurement of wall bending displacements or assessment of stress distribution resulting from foundation flexure. Any extrapolation of wall racking behavior from the foundation conditions specified by this practice to flexible conditions shall be done with the support of a comparative test on a representative foundation.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E564 − 06 (Reapproved 2012)

Standard Practice for

Static Load Test for Shear Resistance of Framed Walls for

Buildings

This standard is issued under the fixed designation E564; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thispracticedescribesmethodsforevaluatingtheshear

capacity of a typical section of a framed wall, supported on a E4Practices for Force Verification of Testing Machines

E575Practice for Reporting Data from Structural Tests of

rigid foundation and having load applied in the plane of the

wallalongtheedgeoppositetherigidsupportandinadirection Building Constructions, Elements, Connections, and As-

semblies

parallel to it.The objective is to provide a determination of the

shear stiffness and strength of any structural light-frame wall E631Terminology of Building Constructions

configuration to be used as a shear-wall on a rigid support.

3. Terminology

1.2 Limitations—This practice is not intended to be used as

3.1 Defintions—For definitions of terms used in this

a basis for classifying sheathing shear capacity or as an

standard, see Terminology E631.

evaluation of combined flexure and shear resulting from the

wall being loaded on a flexible foundation. 3.2 Definitions of Terms Specific to This Standard:

1.2.1 The effect of sheathing variations is assessed by 3.2.1 racking—when applied to shear walls, refers to the

holding all other variables constant. Permitted variations in tendency for a wall frame to distort from rectangular to

framing configuration and boundary conditions, however, re- rhomboidundertheactionofanin-planeforceappliedparallel

quire accurate documentation of the test setup to validate to the wall length.

across-study comparisons of sheathing contribution to wall

3.2.2 shear wall—structural subassembly that acts as a

shear capacity.

cantilever/diaphragm to transfer horizontal building loads to

the foundation in the form of horizontal shear and an overturn-

NOTE 1—A wall tested on a flexible foundation is evaluated by

comparing shear stiffness and strength results to those of an identical wall ing moment.

testedonarigidfoundation,followingthispractice.However,nomethods

3.2.3 uplift—the vertical displacement measured at the

are given for the measurement of wall bending displacements or assess-

loaded end stud with respect to the test apparatus.

mentofstressdistributionresultingfromfoundationflexure.Anyextrapo-

lation of wall racking behavior from the foundation conditions specified

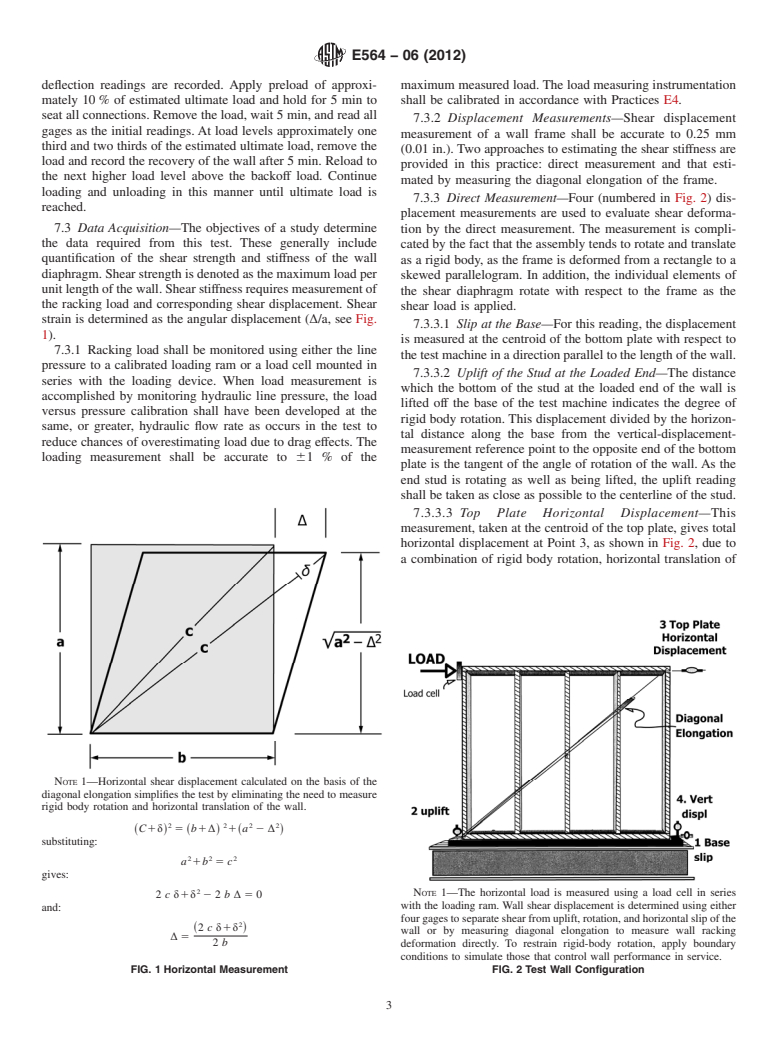

3.3 Symbols:

by this practice to flexible conditions shall be done with the support of a

3.3.1 a—height of cantilevered shear wall, in metres (feet).

comparative test on a representative foundation.

3.3.2 b—length of cantilevered shear wall, in metres (feet).

1.3 The values stated in SI units are to be regarded as

2 2

3.3.3 C—initial length of the diagonal =a 1b , in metres

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa- (feet).

tion only and are not considered standard.

3.3.4 δ—diagonal elongation, in millimetres (inches).

1.4 This standard does not purport to address all of the

3.3.5 ∆—totalhorizontaldisplacementofthetopofthewall

safety concerns, if any, associated with its use. It is the

measured with respect to the test apparatus, in millimetres

responsibility of the user of this standard to establish appro-

(inches). This value includes effects due to panel rotation,

priate safety and health practices and determine the applica-

translation, and shear.

bility of regulatory limitations prior to use.

3.3.6 G'—global shear stiffness of the assembly, includes

rotation and translational displacements as well as diaphragm

shear displacement.

This practice is under the jurisdiction of ASTM Committee E06 on Perfor-

mance of Buildings and is the direct responsibility of Subcommittee E06.11 on

Horizontal andVertical Structures/Structural Performance of Completed Structures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2012. Published October 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1976. Last previous edition approved in 2006 as E564–06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0564-06R12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E564 − 06 (2012)

3.3.7 G' —internalshearstiffnessoftheassembly,includes or roof members that will be used in the actual building

int

only the shear displacement of the wall in calculation. construction. When required to minimize distortion,

reinforcement, such as a strong-back attached along the length

3.3.8 P—concentrated load applied at the top edge of the

of the top plate or a steel bearing plate attached to the end of

wallattheselectedreferencedisplacement,innewtons(pound-

the top plate shall be installed. The wall test assembly shall be

force).

laterally supported along its top with rollers or equivalent

3.3.9 P —highest load level held long enough to record

u

meanssoastorestrictassemblydisplacementoutsidetheplane

gage measurements, in newtons (pound-force).

of loading. Lateral support rigidity shall not exceed that

3.3.10 S —ultimate shear strength of the assembly, in new-

u provided in the actual building construction.

tons per metre (pounds per foot).

6.5 Wall Size—Test wall size will vary with the study

objectives. Tests conducted to assess the structural perfor-

4. Significance and Use

mance of actual building construction shall have dimensions

4.1 This practice is used to determine static load capacity

commensurate with those of the shear walls being simulated.

and deflection of framed wall sections.This practice is used to

6.6 Curing and Conditioning—For framed wall construc-

establish a load deflection curve. It is used to evaluate various

tions containing elements whose structural performance is a

framed systems representative of those intended for use in

function of age, curing conditions, moisture content, or

actual building constructions.

temperature, the wall test assembly shall be conditioned prior

to the test in accordance with the appropriate voluntary

5. Summary of Practice

consensus standards, manufacturer specifications, or industry

5.1 The shear strength and stiffness of a wall assembly and

curing practices for the various products used, or as needed to

its connections are determined by forcing a racking deforma-

meet the intent of the test. Care shall be taken to ensure that

tion.Thisisaccomplishedbyanchoringthebottomedgeofthe

curing and conditioning are representative of that expected in

wall assembly and applying a force to the top edge oriented

the actual building construction and that all elements of the

perpendicular to the wall height dimension and parallel to the

wall test assembly at the time of the test are approximately at

wall length dimension.Wall distortion is restricted to the plane

the equilibrium conditions expected in service.

oftheunstressedwall.Theforcesrequiredtorackthewalland

the corresponding displacements at each load interval are 6.7 Environmental Effect—When required to evaluate wall

measured. assemblyperformanceforsimulatedenvironmentalconditions,

preconditioned specimens shall be tested in an environmental

6. Wall Test Assembly chamber.

6.1 General—A wall assembly consists of frame elements

7. Procedure

including any diagonal bracing members or other

reinforcements, sheathing elements, and connections.The wall

7.1 Number of Tests—Test a minimum of two wall assem-

assemblytestedinaccordancewiththispracticeshallrepresent

blies to determine the shear capacity of a given construction.

the minimum acceptable stiffness using the targeted frame and

For unsymmetrical shear walls, run the second test with the

sheathing materials.

specimen orientation reversed with respect to the direction of

theloadapplicationusedinthefirsttest.Ifthestrengthorshear

6.2 Connections—The performance of the wall test assem-

stiffness of the second test is not within 15% of the results of

bly is influenced by the type and spacing of framing

the first test, test a third wall assembly with the wall oriented

connections, sheathing-to-frame connections and the wall as-

in the same manner as the weaker of the two test values. The

sembly anchorage connection to the test fixture, floor, or

strength and stiffness values reported shall be the average of

foundation.

the two weakest specimen values if three or more tests are

6.2.1 Allconnectionsusedinthetestshallberepresentative

performed.

of those used in the actual building construction.

6.2.2 Connector size and location on the frame shall corre-

7.2 Loading Procedure:

spond to specifications.

7.2.1 General—Racking loads shall be applied parallel to

6.3 Frame Requirements—The frame is an integral part of

and at the top of the wall, in the central plane of the frame,

the wall test assembly. The test wall shall consist of the same

using a hydraulic jack or similar loading device capable of

number,size,andgradeofframingmembersasareintendedto

maintainingaconstantdisplacementrateforcontinuousloadto

be used in service.

failure or holding a static load in the case of incremental

loading. Loads shall be applied at a constant rate of displace-

6.4 Test Setup—Provisions shall be made to resist rigid-

ment to reach the target limit (that is, limiting displacement of

bodyrotationintheplaneofthewallwherethisreflectstheuse

ultimate load) in no less than 5 min.

of the assembly in actual building constructions. This shall be

7.2.2 Gravity loads, when required, shall be applied along

done by application of relevant gravity or other loadings

the top of the wall in a manner consistent with floor or roof

simultaneously with the racking loads. The bottom of the

frame loading.

assembly shall be attached to the test base with anchorage

connections simulating those that will be used in service. Load 7.2.3 Static Load Test—Maintain the duration of load

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.