ASTM A966/A966M-08

(Test Method)Standard Practice for Magnetic Particle Examination of Steel Forgings Using Alternating Current

Standard Practice for Magnetic Particle Examination of Steel Forgings Using Alternating Current

SIGNIFICANCE AND USE

For ferromagnetic materials, magnetic particle examination is widely specified for the detection of surface and near-surface flaws such as cracks, laps, seams, and linearly oriented nonmetallic inclusions. Such examinations are included as mandatory requirements in some forging standards such as Specifications A 508/A 508M and A 963/A 963M.

Use of alternating current as the power source for magnetic particle examination imposes a significant restriction on the detection of subsurface indications, so that the procedure is essentially limited to the finding of flaws that are open to the surface. Attention therefore is drawn to the need to have the component in the finish-machined condition before conducting the magnetic particle examination.

The presence of residual magnetic fields in a component may be undesirable, and an advantage of the use of an AC power source for magnetic particle examination is that an acceptable level of demagnetization can be readily achieved.

SCOPE

1.1 This practice covers a procedure for the magnetic particle examination of steel forgings using alternating current as the power source. The procedure will produce consistent results upon which acceptance standards can be based. This practice does not contain acceptance limits or recommended quality levels.

1.2 Only alternating 50–60 cycle current shall be used as the electric power source for any of the magnetizing methods.

1.3 When subsurface indications are sought in forgings, then dc magnetization in accordance with Practice A 275/A 275M should be used.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Unless the order specifies the applicable “M” specification designation [SI units], the inch-pound units shall be used.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A966/A966M–08

Standard Practice for

Magnetic Particle Examination of Steel Forgings Using

1

Alternating Current

This standard is issued under the fixed designationA966/A966M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A963/A963M SpecificationforDeepDrawingSteel(DDS),

3

Sheet, Carbon, Cold-Rolled

1.1 This practice covers a procedure for the magnetic

2.2 Other Document:

particle examination of steel forgings using alternating current

Practice No. SNT-TC-1A, Supplement B—Magnetic Par-

as the power source. The procedure will produce consistent

4

ticle Method

results upon which acceptance standards can be based. This

practice does not contain acceptance limits or recommended

3. Terminology

quality levels.

3.1 Definitions:

1.2 Onlyalternating50–60cyclecurrentshallbeusedasthe

3.1.1 (ac) magnetic particle method of examination, n—a

electric power source for any of the magnetizing methods.

method for detecting discontinuities on the surface in suitably

1.3 When subsurface indications are sought in forgings,

magnetized materials, which employs finely divided magnetic

then dc magnetization in accordance with Practice A275/

particles that tend to congregate in regions of leakage fields.

A275M should be used.

3.1.2 indication, n—the visual magnetic particle buildup

1.4 The values stated in either inch-pound units or SI units

resulting from leakage fields in the magnetic field.

are to be regarded separately as standard. Within the text, the

3.1.3 linear indication, n—an indication in which the length

SI units are shown in brackets. The values stated in each

is at least three times the width. The minimum length of

system are not exact equivalents; therefore each system shall

1

indications to be considered linear shall be ⁄16 in. [1.5 mm].

be used independently of the other. Combining values from the

3.1.4 magnetic flux, n—the product of the magnetic induc-

two systems may result in nonconformance with the specifi-

tion and the area of a surface (or cross section) when the

cation. Unless the order specifies the applicable “M” specifi-

magnetic induction is uniformly distributed and normal to the

cation designation [SI units], the inch-pound units shall be

plane of the surface.

used.

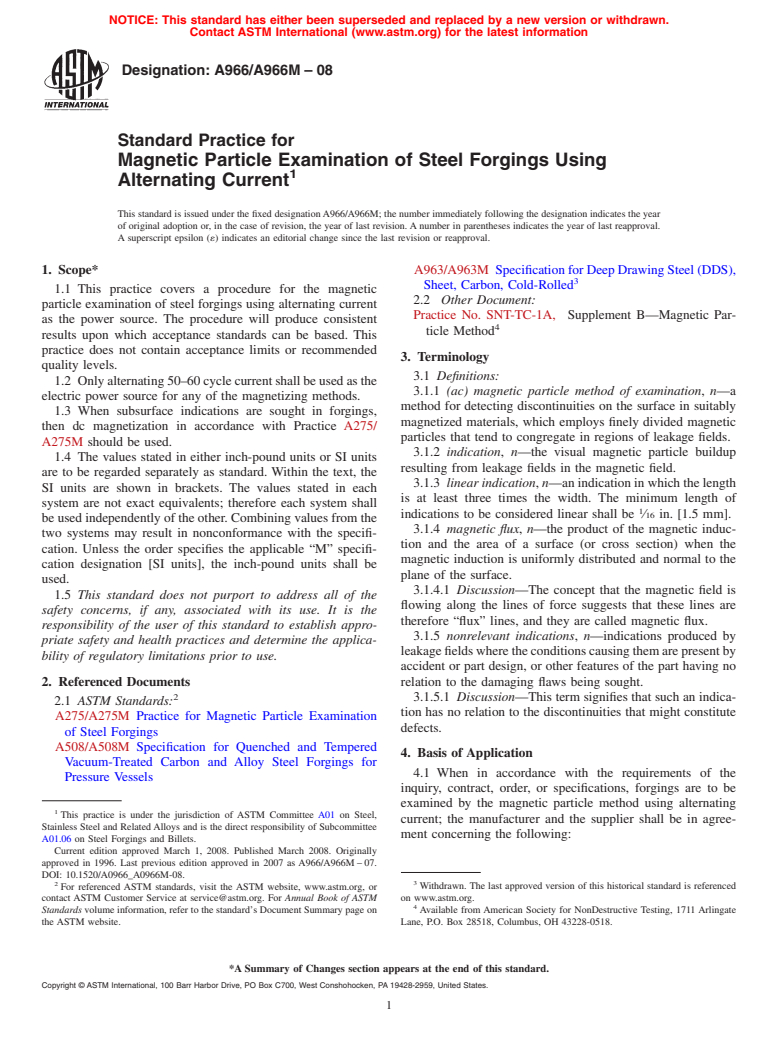

3.1.4.1 Discussion—The concept that the magnetic field is

1.5 This standard does not purport to address all of the

flowing along the lines of force suggests that these lines are

safety concerns, if any, associated with its use. It is the

therefore “flux” lines, and they are called magnetic flux.

responsibility of the user of this standard to establish appro-

3.1.5 nonrelevant indications, n—indications produced by

priate safety and health practices and determine the applica-

leakagefieldswheretheconditionscausingthemarepresentby

bility of regulatory limitations prior to use.

accident or part design, or other features of the part having no

2. Referenced Documents relation to the damaging flaws being sought.

2

3.1.5.1 Discussion—This term signifies that such an indica-

2.1 ASTM Standards:

tion has no relation to the discontinuities that might constitute

A275/A275M Practice for Magnetic Particle Examination

defects.

of Steel Forgings

A508/A508M Specification for Quenched and Tempered

4. Basis of Application

Vacuum-Treated Carbon and Alloy Steel Forgings for

4.1 When in accordance with the requirements of the

Pressure Vessels

inquiry, contract, order, or specifications, forgings are to be

examined by the magnetic particle method using alternating

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

current; the manufacturer and the supplier shall be in agree-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

ment concerning the following:

A01.06 on Steel Forgings and Billets.

Current edition approved March 1, 2008. Published March 2008. Originally

approved in 1996. Last previous edition approved in 2007 as A966/A966M – 07.

DOI: 10.1520/A0966_A0966M-08.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Withdrawn. The last approved version of this historical standard is referenced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM on www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for NonDestructive Testing, 1711 Arlingate

the ASTM website. Lane, P.O. Box 28518, Columbus, OH 43228-0518.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 966/A 966M–07 Designation:A 966/A 966M–08

Standard Practice for

Magnetic Particle Examination of Steel Forgings Using

1

Alternating Current

This standard is issued under the fixed designationA966/A966M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers a procedure for the magnetic particle examination of steel forgings using alternating current as the

power source.The procedure will produce consistent results upon which acceptance standards can be based.This practice does not

contain acceptance limits or recommended quality levels.

1.2Only alternating 50–60 cycle current shall be used as the electric power source for any of the magnetizing methods. The

ability to detect subsurface discontinuities is very limited when using an alternating power source, and therefore the test surfaces

should be in the final thermally treated and finish machined condition.

1.3When subsurface indications are sought in forgings, then dc magnetization in accordance with Test Method A275/A275M

1.2 Only alternating 50–60 cycle current shall be used as the electric power source for any of the magnetizing methods.

1.3 When subsurface indications are sought in forgings, then dc magnetization in accordance with Practice A 275/A 275M

should be used.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification. Unless

the order specifies the applicable “M” specification designation [SI units], the inch-pound units shall be used.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A 275/A 275MPractice for Numbering Metals and Alloys in the Unified Numbering System (UNS) Practice for Magnetic

Particle Examination of Steel Forgings

A 508/A 508M Specification for Quenched and Tempered Vacuum-Treated Carbon and Alloy Steel Forgings for Pressure

Vessels

3

A 963/A 963M Specification for Deep Drawing Steel (DDS), Sheet, Carbon, Cold-Rolled

2.2 Other Document:

4

Practice No. SNT-TC-1A, Supplement B—Magnetic Particle Method

3. Terminology

3.1 Definitions:

3.1.1 (ac) magnetic particle method of examination, n—a method for detecting discontinuities on the surface in suitably

magnetized materials, which employs finely divided magnetic particles that tend to congregate in regions of leakage fields.

3.1.2 indication, n—the visual magnetic particle buildup resulting from leakage fields in the magnetic field.

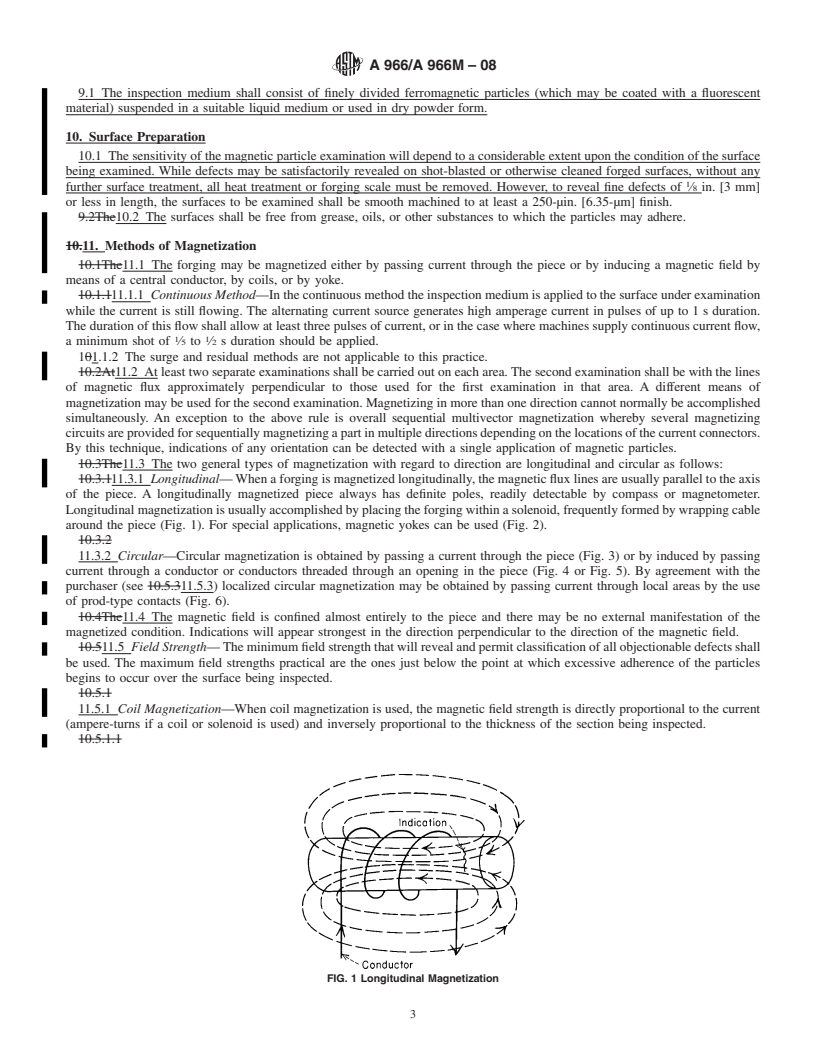

3.1.3 linear indication, n—anindicationinwhichthelengthisatleastthreetimesthewidth.Theminimumlengthofindications

1

to be considered linear shall be ⁄16 in. [1.5 mm].

3.1.4 magnetic flux, n—the product of the magnetic induction and the area of a surface (or cross section) when the magnetic

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved May 1, 2007. Published June 2007. Originally approved in 1996. Last previous edition approved in 2006 as A966/A966M–96 (2006).

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1996. Last previous edition approved in 2007 as A 966/A 966M – 07.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn.

4

Available from American Society for NonDestructive Testing, 1711 Arlingate Lane, P.O. Box 28518, Columbus, OH 43228-0518.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 -----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.