ASTM E2342/E2342M-10(2015)e1

(Test Method)Standard Test Method for Durability Testing of Duct Sealants

Standard Test Method for Durability Testing of Duct Sealants

SIGNIFICANCE AND USE

5.1 Residential duct systems are often field designed and assembled. There are many joints, often of dissimilar materials that require both mechanical connection and air sealing. Without this sealing, duct systems would be extremely leaky and hence inefficient. While some duct sealants are rated on their properties at the time of manufacture or during storage, none of these ratings adequately addresses the in-service lifetime. This test method has been developed to address this durability issue.

5.2 This standard applies to products which list duct sealing as one of their uses. This includes duct tape (cloth, metal foil, or plastic backed), mastics, and sprayed/aerosol sealants. It does not apply to caulks or plaster patches that are not intended to be permanent duct sealing methods.

5.3 The standard duct leak site is a collar to plenum connection for round duct that is 10 to 20 cm [4 to 8 in.] in diameter. This perpendicular connection was chosen because almost all residential duct systems have this type of connection and in field observations of duct systems, it is often this type of connection that has sealant failure.

SCOPE

1.1 This test method describes an accelerated aging test for evaluating the durability of duct sealants by exposure to temperatures and static pressures characteristic of residential duct systems.

1.2 This test method is intended to produce a relative measure of the durability of duct sealants. This standard does not measure durability under specific conditions of weather and building operation that might be experienced by an individual building and duct system. Instead it evaluates the sealant method under fixed conditions that do not include the manifold effects of installation practice.

1.3 This test method only addresses sealants not mechanical strength of the connections.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E2342/E2342M − 10 (Reapproved 2015)

Standard Test Method for

Durability Testing of Duct Sealants

ThisstandardisissuedunderthefixeddesignationE2342/E2342M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in 1.4 and units information was corrected editorially in February 2015.

INTRODUCTION

Duct leakage has been identified as a major source of energy loss in residential buildings. Most duct

leakage occurs at the connections to registers, plenums, or branches in the duct system. At each of

these connections a method of sealing the duct system is required. Typical sealing methods include

tapes or mastics applied around the joints in the system. Field examinations of duct systems have

typically shown that these seals tend to fail over extended periods of time.

The proposed method evaluates the durability of duct sealants by blowing heated air into test

sections, combined with a pressure difference between the test sections and their surroundings. The

temperatures and pressures were chosen to expose the test sections to typical conditions that are found

in residential duct systems. The duct leakage site geometry represents a leakage site commonly found

in duct systems. The test sections are constructed from standard duct fittings.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method describes an accelerated aging test for

bility of regulatory limitations prior to use. For specific hazard

evaluating the durability of duct sealants by exposure to

statements see Section 7.

temperatures and static pressures characteristic of residential

duct systems.

2. Referenced Documents

1.2 This test method is intended to produce a relative 2

2.1 ASTM Standards:

measure of the durability of duct sealants. This standard does

E631 Terminology of Building Constructions

notmeasuredurabilityunderspecificconditionsofweatherand

building operation that might be experienced by an individual

3. Terminology

building and duct system. Instead it evaluates the sealant

3.1 Terminology E631 defines much of the terminology

method under fixed conditions that do not include the manifold

used in this test method.

effects of installation practice.

3.2 Definitions of Terms Specific to This Standard:

1.3 This test method only addresses sealants not mechanical

3.2.1 air-leakage rate—the volume of air movement per

strength of the connections.

unit time across the duct wall.

1.4 The values stated in either SI units or inch-pound units

3.2.2 duct sealant—a method or material, or both, for

are to be regarded separately as standard. The values stated in

sealing leaks in forced air thermal distribution duct systems.

each system may not be exact equivalents; therefore, each

3.2.3 durability—the capability of maintaining the service-

system shall be used independently of the other. Combining

ability of a product, component, or assembly over a specified

values from the two systems may result in non-conformance

time.

with the standard.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 To evaluate sealant durability this test method uses a

standardized joint configuration with controlled temperature

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.41

on Air Leakage and Ventilation Performance. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2015. Published February 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2003. Last previous edition approved in 2010 as E2342 – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2342_E2342M-10R15E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E2342/E2342M − 10 (2015)

and pressure differences. These temperatures and pressures are 6. Apparatus

chosen to represent conditions found in residential duct sys-

6.1 The following is a general description of the required

tems. The test apparatus applies temperature and pressure

apparatus. Any arrangement of equipment using the same

conditions and measures how well the sealant performs over

principles and capable of performing the test procedure within

time.

the allowable tolerances is permitted.

5. Significance and Use

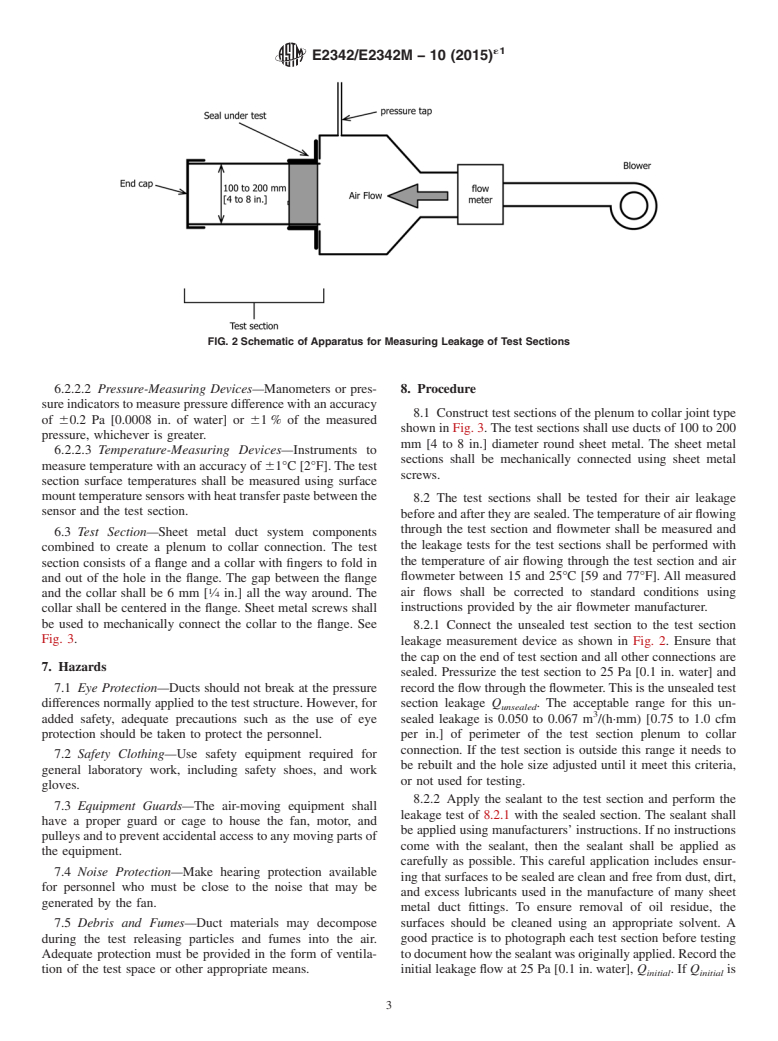

6.2 Major Components—There are two major components

5.1 Residential duct systems are often field designed and required to perform the testing: a test section leakage measure-

assembled. There are many joints, often of dissimilar materials ment device (Fig. 1) and a durability test apparatus (Fig. 2).

that require both mechanical connection and air sealing.

6.2.1 Test Section Leakage Measuring Device—Adevice for

Without this sealing, duct systems would be extremely leaky

measuring the leakage of individual test sections. This device

and hence inefficient. While some duct sealants are rated on

shall consist of a fan to blow air into the test section, a flow

their properties at the time of manufacture or during storage,

measurement device for measuring the flow rate in the test

none of these ratings adequately addresses the in-service

section, a pressure measuring device for measuring the pres-

lifetime. This test method has been developed to address this

sure difference between the inside and outside of the test

durability issue.

section, and a cap to seal the end of the test section. See Fig.

2. For these test section leakage measurements, the air flow

5.2 This standard applies to products which list duct sealing

measuring device shall have an accuracy of 60.085 m /h [0.05

as one of their uses. This includes duct tape (cloth, metal foil,

or plastic backed), mastics, and sprayed/aerosol sealants. It cfm] or 61 % of the measured flow, whichever is greater.

does not apply to caulks or plaster patches that are not intended

6.2.2 Durability Test Apparatus—A device for blowing hot

to be permanent duct sealing methods.

air through one or more test sections. This device is comprised

of the following components.

5.3 The standard duct leak site is a collar to plenum

connection for round duct that is 10 to 20 cm [4 to 8 in.] in 6.2.2.1 Air-Moving Equipment—A fan that is capable of

moving air through the test sections. The fan must be selected

diameter. This perpendicular connection was chosen because

almost all residential duct systems have this type of connection to provide the required flow rates and pressure differences. In

and in field observations of duct systems, it is often this type of addition, the fan must be selected to be capable of operating at

connection that has sealant failure. the hot conditions existing in the test apparatus.

FIG. 1 Schematic of Durability Apparatus

´1

E2342/E2342M − 10 (2015)

FIG. 2 Schematic of Apparatus for Measuring Leakage of Test Sections

6.2.2.2 Pressure-Measuring Devices—Manometers or pres- 8. Procedure

sure indicators to measure pressure difference with an accuracy

8.1 Construct test sections of the plenum to collar joint type

of 60.2 Pa [0.0008 in. of water] or 61 % of the measured

shown in Fig. 3. The test sections shall use ducts of 100 to 200

pressure, whichever is greater.

mm [4 to 8 in.] diameter round sheet metal. The sheet metal

6.2.2.3 Temperature-Measuring Devices—Instruments to

sections shall be mechanically connected using sheet metal

measure temperature with an accuracy of 61°C [2°F]. The test

screws.

section surface temperatures shall be measured using surface

mounttemperaturesensorswithheattransferpastebetweenthe

8.2 The test sections shall be tested for their air leakage

sensor and the test section.

before and after they are sealed.The temperature of air flowing

through the test section and flowmeter shall be measured and

6.3 Test Section—Sheet metal duct system components

the leakage tests for the test sections shall be performed with

combined to create a plenum to collar connection. The test

the temperature of air flowing through the test section and air

section consists of a flange and a collar with fingers to fold in

flowmeter between 15 and 25°C [59 and 77°F]. All measured

and out of the hole in the flange. The gap between the flange

air flows shall be corrected to standard conditions using

and the collar shall be 6 mm [ ⁄4 in.] all the way around. The

instructions provided by the air flowmeter manufacturer.

collar shall be centered in the flange. Sheet metal screws shall

be used to mechanically connect the collar to the flange. See

8.2.1 C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E2342 − 10 E2342/E2342M − 10 (Reapproved 2015)

Standard Test Method for

Durability Testing of Duct Sealants

This standard is issued under the fixed designation E2342;E2342/E2342M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in 1.4 and units information was corrected editorially in February 2015.

INTRODUCTION

Duct leakage has been identified as a major source of energy loss in residential buildings. Most duct

leakage occurs at the connections to registers, plenums, or branches in the duct system. At each of

these connections a method of sealing the duct system is required. Typical sealing methods include

tapes or mastics applied around the joints in the system. Field examinations of duct systems have

typically shown that these seals tend to fail over extended periods of time.

The proposed method evaluates the durability of duct sealants by blowing heated air into test

sections, combined with a pressure difference between the test sections and their surroundings. The

temperatures and pressures were chosen to expose the test sections to typical conditions that are found

in residential duct systems. The duct leakage site geometry represents a leakage site commonly found

in duct systems. The test sections are constructed from standard duct fittings.

1. Scope

1.1 This test method describes an accelerated aging test for evaluating the durability of duct sealants by exposure to

temperatures and static pressures characteristic of residential duct systems.

1.2 This test method is intended to produce a relative measure of the durability of duct sealants. This standard does not measure

durability under specific conditions of weather and building operation that might be experienced by an individual building and duct

system. Instead it evaluates the sealant method under fixed conditions that do not include the manifold effects of installation

practice.

1.3 This test method only addresses sealants not mechanical strength of the connections.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements see Section 7.

2. Referenced Documents

2.1 ASTM Standards:

E631 Terminology of Building Constructions

3. Terminology

3.1 Terminology E631 defines much of the terminology used in this test method.

3.2 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.41 on Air Leakage

and Ventilation Performance.

Current edition approved March 1, 2010Jan. 1, 2015. Published April 2010February 2015. Originally approved in 2003. Last previous edition approved in 20032010 as

E2342 – 03.E2342 – 10. DOI: 10.1520/E2342-10.10.1520/E2342_E2342M-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E2342/E2342M − 10 (2015)

3.2.1 air-leakage rate—the volume of air movement per unit time across the duct wall.

3.2.2 duct sealant—a method or material, or both, for sealing leaks in forced air thermal distribution duct systems.

3.2.3 durability—the capability of maintaining the serviceability of a product, component, or assembly over a specified time.

4. Summary of Test Method

4.1 To evaluate sealant durability this test method uses a standardized joint configuration with controlled temperature and

pressure differences. These temperatures and pressures are chosen to represent conditions found in residential duct systems. The

test apparatus applies temperature and pressure conditions and measures how well the sealant performs over time.

5. Significance and Use

5.1 Residential duct systems are often field designed and assembled. There are many joints, often of dissimilar materials that

require both mechanical connection and air sealing. Without this sealing, duct systems would be extremely leaky and hence

inefficient. While some duct sealants are rated on their properties at the time of manufacture or during storage, none of these ratings

adequately addresses the in-service lifetime. This test method has been developed to address this durability issue.

5.2 This standard applies to products which list duct sealing as one of their uses. This includes duct tape (cloth, metal foil, or

plastic backed), mastics, and sprayed/aerosol sealants. It does not apply to caulks or plaster patches that are not intended to be

permanent duct sealing methods.

5.3 The standard duct leak site is a collar to plenum connection for round duct that is 10 to 20 cm (4[4 to 8 in.)in.] in diameter.

This perpendicular connection was chosen because almost all residential duct systems have this type of connection and in field

observations of duct systems, it is often this type of connection that has sealant failure.

6. Apparatus

6.1 The following is a general description of the required apparatus. Any arrangement of equipment using the same principles

and capable of performing the test procedure within the allowable tolerances is permitted.

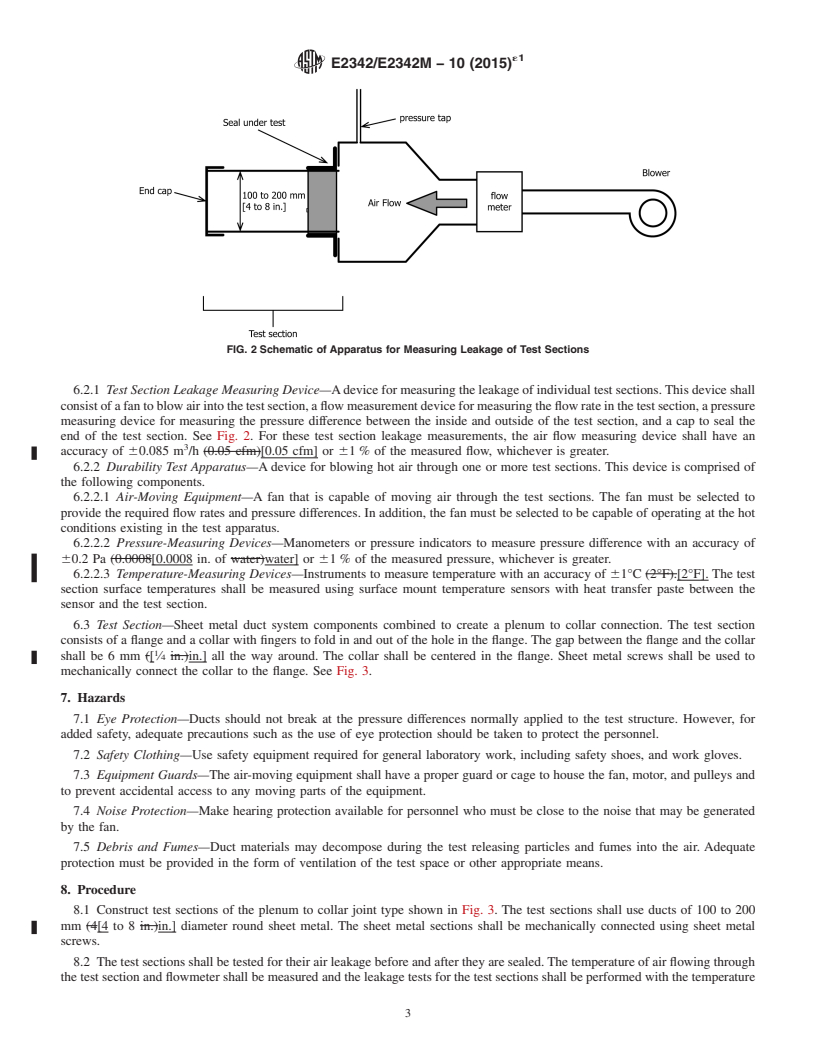

6.2 Major Components—There are two major components required to perform the testing: a test section leakage measurement

device (Fig. 1) and a durability test apparatus (Fig. 2).

FIG. 1 Schematic of Durability Apparatus

´1

E2342/E2342M − 10 (2015)

FIG. 2 Schematic of Apparatus for Measuring Leakage of Test Sections

6.2.1 Test Section Leakage Measuring Device—A device for measuring the leakage of individual test sections. This device shall

consist of a fan to blow air into the test section, a flow measurement device for measuring the flow rate in the test section, a pressure

measuring device for measuring the pressure difference between the inside and outside of the test section, and a cap to seal the

end of the test section. See Fig. 2. For these test section leakage measurements, the air flow measuring device shall have an

accuracy of 60.085 m /h (0.05 cfm)[0.05 cfm] or 61 % of the measured flow, whichever is greater.

6.2.2 Durability Test Apparatus—A device for blowing hot air through one or more test sections. This device is comprised of

the following components.

6.2.2.1 Air-Moving Equipment—A fan that is capable of moving air through the test sections. The fan must be selected to

provide the required flow rates and pressure differences. In addition, the fan must be selected to be capable of operating at the hot

conditions existing in the test apparatus.

6.2.2.2 Pressure-Measuring Devices—Manometers or pressure indicators to measure pressure difference with an accuracy of

60.2 Pa (0.0008[0.0008 in. of water)water] or 61 % of the measured pressure, whichever is greater.

6.2.2.3 Temperature-Measuring Devices—Instruments to measure temperature with an accuracy of 61°C (2°F).[2°F]. The test

section surface temperatures shall be measured using surface mount temperature sensors with heat transfer paste between the

sensor and the test section.

6.3 Test Section—Sheet metal duct system components combined to create a plenum to collar connection. The test section

consists of a flange and a collar with fingers to fold in and out of the hole in the flange. The gap between the flange and the collar

shall be 6 mm ([ ⁄4 in.)in.] all the way around. The collar shall be centered in the flange. Sheet metal screws shall be used to

mechanically connect the collar to the flange. See Fig. 3.

7. Hazards

7.1 Eye Protection—Ducts should not break at the pressure differences normally applied to the test structure. However, for

added safety, adequate precautions such as the use of eye protection should be taken to protect the personnel.

7.2 Safety Clothing—Use safety equipment required for general laboratory work, including safety shoes, and work gloves.

7.3 Equipment Guards—The air-moving equipment shall have a proper guard or cage to house the fan, motor, and pulleys and

to prevent accidental access to any moving parts of the equipment.

7.4 Noise Protection—Make hearing protection available for personnel who must be close to the noi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.