ASTM G206-17(2021)e1

(Guide)Standard Guide for Measuring the Wear Volumes of Piston Ring Segments Run against Flat Coupons in Reciprocating Wear Tests

Standard Guide for Measuring the Wear Volumes of Piston Ring Segments Run against Flat Coupons in Reciprocating Wear Tests

SIGNIFICANCE AND USE

5.1 The practical life of an internal combustion engine is most often determined by monitoring its oil consumption. Excessive oil consumption is cause for engine repair or replacement and can be symptomatic of excessive wear of the piston ring or the cylinder bore or both. More wear-resistant materials of construction can extend engine life and reduce cost of operation. Although components made from more wear-resistant materials can be tested in actual operating engines, such tests tend to be expensive and time consuming, and they often lead to variable results because of the difficulty in controlling the operating environment. Although bench-scale tests do not simulate every aspect of a fired engine, they are used for cost-effective initial screening of candidate materials and lubricants. The test parameters for those tests are selected by the investigator, but the end result is a pair of worn specimens whose degree of wear needs to be accurately measured. The use of curved specimens, like segments of crowned piston rings, presents challenges for precise wear measurement. Weight loss or linear measurements of lengths and widths of wear scars may not provide sufficient accuracy to discriminate between small differences in wear. This guide is intended to address that problem.

SCOPE

1.1 This guide describes a profiling method for use accurately measuring the wear loss of compound-curved (crowned) piston ring specimens that run against flat counterfaces. It does not assume that the wear scars are ideally flat, as do some alternative measurement methods. Laboratory-scale wear tests have been used to evaluate the wear of materials, coatings, and surface treatments that are candidates for piston rings and cylinder liners in diesel engines or spark ignition engines. Various loads, temperatures, speeds, lubricants, and durations are used for such tests, but some of them use a curved piston ring segment as one sliding partner and a flat or curved specimen (simulating the cylinder liner) as its counterface. The goal of this guide is to provide more accurate wear measurements than alternative approaches involving weight loss or simply measuring the length and width of the wear marks.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: G206 − 17 (Reapproved 2021)

Standard Guide for

Measuring the Wear Volumes of Piston Ring Segments Run

against Flat Coupons in Reciprocating Wear Tests

This standard is issued under the fixed designation G206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in November 2021.

1. Scope G181 Test Method for Conducting Friction Tests of Piston

Ring and Cylinder Liner Materials Under Lubricated

1.1 This guide describes a profiling method for use accu-

Conditions

rately measuring the wear loss of compound-curved (crowned)

piston ring specimens that run against flat counterfaces. It does

3. Terminology

not assume that the wear scars are ideally flat, as do some

alternative measurement methods. Laboratory-scale wear tests 3.1 Definitions—See Terminology G40.

have been used to evaluate the wear of materials, coatings, and

3.2 Definitions of Terms Specific to This Standard:

surface treatments that are candidates for piston rings and

3.2.1 conformal contact, n—in friction and wear testing,

cylinder liners in diesel engines or spark ignition engines.

any macro-geometric specimen configuration in which the

Various loads, temperatures, speeds, lubricants, and durations

curvature of one contact surface matches that of the counter-

are used for such tests, but some of them use a curved piston

face.

ring segment as one sliding partner and a flat or curved

3.2.1.1 Discussion—Examples of conformal contact include

specimen (simulating the cylinder liner) as its counterface.The

a flat surface sliding on a flat surface and a ball rotating in a

goal of this guide is to provide more accurate wear measure-

socket that conforms to the shape of the ball.Apair of surfaces

ments than alternative approaches involving weight loss or

may begin a wear or friction test in a non-conformal contact

simply measuring the length and width of the wear marks.

configuration, but develop a conformal contact as a result of

1.2 This standard does not purport to address all of the wear.

safety concerns, if any, associated with its use. It is the

3.2.2 cylinder bore/cylinder liner, n—in an internal combus-

responsibility of the user of this standard to establish appro-

tion engine, the cylindrical cavity in which the piston moves.

priate safety, health, and environmental practices and deter-

3.2.2.1 Discussion—The terms cylinder bore and cylinder

mine the applicability of regulatory limitations prior to use.

liner are used interchangeably in the description of this guide.

1.3 This international standard was developed in accor-

Cylinder liners are most commonly used in heavy-duty engines

dance with internationally recognized principles on standard-

that are intended to be rebuilt. They are sleeves, generally of a

ization established in the Decision on Principles for the

cast iron, that are surrounded on their outer surface by coolant

Development of International Standards, Guides and Recom-

for better heat transfer, and meant to be replaced when

mendations issued by the World Trade Organization Technical

excessively worn. A cylinder bore is either machined directly

Barriers to Trade (TBT) Committee.

into an engine block or is added as a sleeve (typically of iron)

into a block of another material (typically aluminum). The

2. Referenced Documents

material of the cylinder bore, therefore, may or may not be the

2.1 ASTM Standards:

same material as the engine block and the inside surface of the

G40 Terminology Relating to Wear and Erosion

bore may or may not have additional surface treatment.

4. Summary of Guide

This guide is under the jurisdiction of ASTM Committee G02 on Wear and

Erosion and is the direct responsibility of Subcommittee G02.40 on Non-Abrasive

4.1 A reciprocating wear testing apparatus is used to simu-

Wear.

late the back-and-forth motion of a piston ring within a

Current edition approved Nov. 1, 2021. Published November 2021. Originally

cylinder bore in the presence of a heated lubricant. Depending

approved in 2011. Last previous edition approved in 2017 as G206 – 17. DOI:

ɛ1

10.1520/G0206-17R21 .

on the duration and severity of the imposed test conditions,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

some degree of wear is generally produced on one or both

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

members of the sliding pair. Mathematical models of the wear

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. scar geometry on both the piston ring and cylinder liner

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

G206 − 17 (2021)

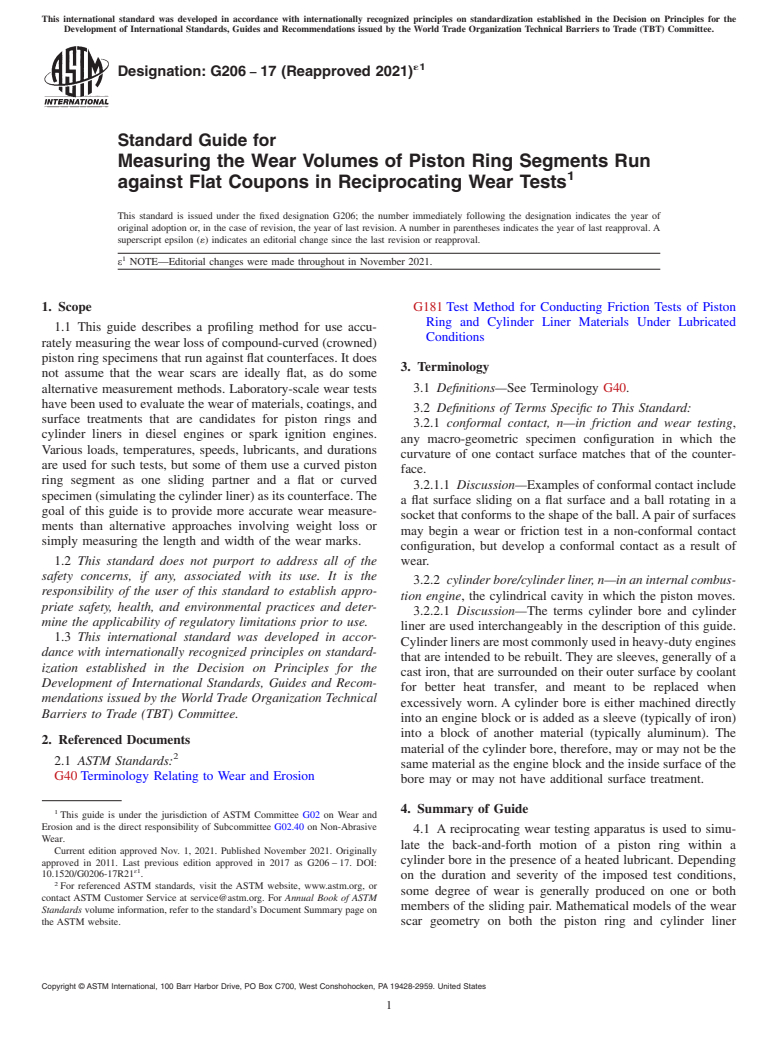

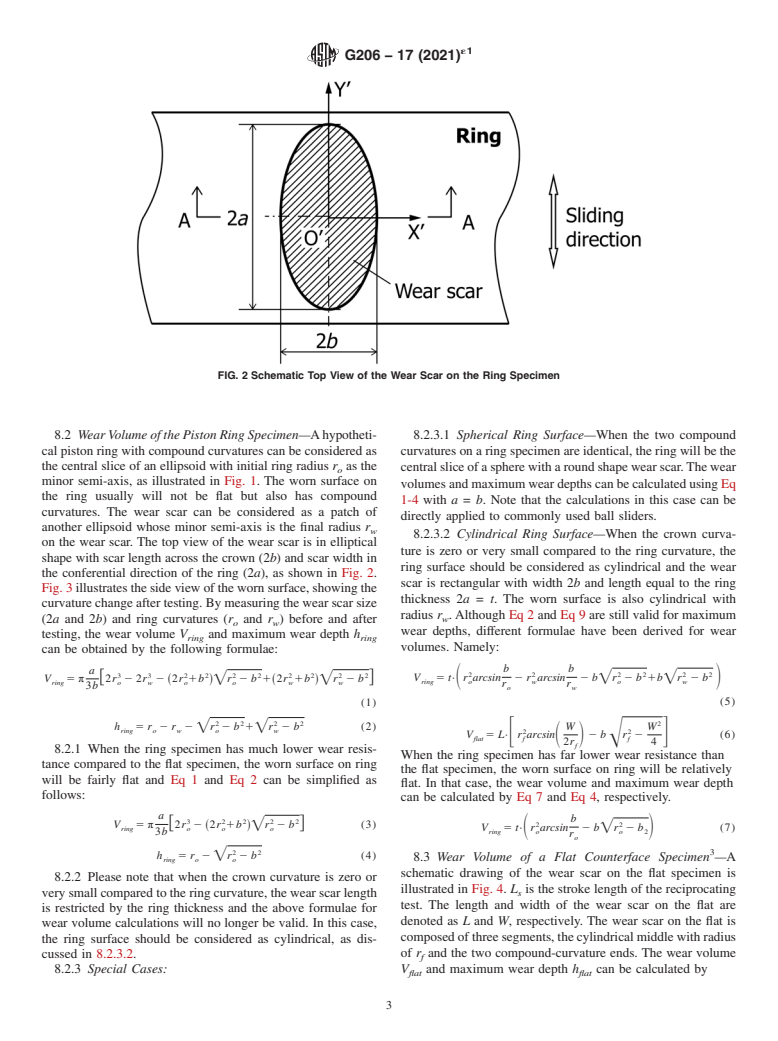

FIG. 1 Schematic Drawing of the Ring

surfaces allow the degree of wear to be quantified in terms of and cleaning specimens afterward. No specific solvents are

volumelost.Thecontactgeometryforsuchtests,inthecontext recommended here, except that they should not chemically

of ring-on-liner frictional behavior, is exemplified in Test attackthetestedsurfaces,norleavearesidualfilmorstainafter

Method G181. That method uses pre-worn-in surfaces, and cleaning.

therefore it differs from the present case in which wear loss is

7. Apparatus and Specimen Preparation

based on measurements of initial and final profiles of the test

specimens.

7.1 Description of the Test Apparatus—Any dimensional

metrology instrument that is capable of measuring the length,

5. Significance and Use

width, and depths of the subject wear scars, and the curvatures

5.1 The practical life of an internal combustion engine is

of the regions that surround and contain them, may be used.

most often determined by monitoring its oil consumption.

These include stylus-type profiling instruments, optical or

Excessive oil consumption is cause for engine repair or

laser-based interferometric instruments, and the like. It is the

replacement and can be symptomatic of excessive wear of the

responsibility of the user to ensure that the dimensional

piston ring or the cylinder bore or both. More wear-resistant

measurement apparatus used has been correctly calibrated.

materialsofconstructioncanextendenginelifeandreducecost

7.1.1 Specimen Preparation—The test specimens shall be

of operation. Although components made from more wear-

solvent cleaned and free from debris or other measurement-

resistant materials can be tested in actual operating engines,

complicating artifacts.

such tests tend to be expensive and time consuming, and they

7.1.2 Specimen Fixturing—A suitable fixture shall be used

often lead to variable results because of the difficulty in

to clamp the specimens in the proper orientation for profiling

controlling the operating environment. Although bench-scale

and dimensional measu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.