ASTM B737-90(2000)

(Specification)Standard Specification for Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

Standard Specification for Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

SCOPE

1.1 This specification covers hot- or cold-worked hafnium rod and wire, or both.

1.2 This specification contains two material grades, one specifically for nuclear applications (Grade R1) and one for commercial applications for alloying (Grade R3).

1.3 The products covered include the following:

1.3.1 Rod 3/8 to 1.0 in. (9.5 to 25.4 mm) in diameter.

1.3.2 Wire less than 3/8 in. (9.5 mm) in diameter.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.5 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 737 – 90 (Reapproved 2000)

Standard Specification for

Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

This standard is issued under the fixed designation B 737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.2 Name of material,

4.1.3 Form (rod, wire),

1.1 This specification covers hot- or cold-worked hafnium

4.1.4 Metallurgical condition (Section 6),

rod and wire, or both.

4.1.5 Finish (Section 12),

1.2 This specification contains two material grades, one

4.1.6 Applicable dimensions (diameter and length),

specifically for nuclear applications (Grade R1) and one for

4.1.7 Grade (Table 1), and

commercial applications for alloying (Grade R3).

4.1.8 ASTM designation and year of issue.

1.3 The products covered include the following:

1.3.1 Rod ⁄8to 1.0 in. (9.5 to 25.4 mm) in diameter.

NOTE 1—A typical ordering description is as follows: 500 lb hafnium

1.3.2 Wire less than ⁄8 in. (9.5 mm) in diameter. rod, annealed; mechanically descaled and pickled; 0.375 in. diameter by 6

in. minimum random lengths; Grade R1; ASTM Specification B 737.

1.4 The values stated in inch-pound units are to be regarded

as the standard. The SI units given in parentheses are for

4.2 In addition to the data specified in 4.1, the following

information only.

options and points of agreement between the manufacturer and

1.5 This standard does not purport to address all of the

the purchaser shall be specified on the purchase order if

safety concerns, if any, associated with its use. It is the

required:

responsibility of the user of this standard to establish appro-

4.2.1 Mechanical test temperature (see 8.1),

priate safety and health practices and determine the applica-

4.2.2 Tolerances (Section 10),

bility of regulatory limitations prior to use.

4.2.3 Workmanship standards (Section 13),

4.2.4 Special tests (Section 11),

2. Referenced Documents

4.2.5 Inspection (Section 16),

2.1 ASTM Standards:

4.2.6 Zirconium analysis requirements (Table 1), and

E 8 Test Methods for Tension Testing of Metallic Materials

4.2.7 The isotopic hafnium composition and its analysis, if

E 21 Test Methods for Elevated Temperature Tension Tests

required, shall be mutually agreed upon by the purchaser and

of Metallic Materials

producer.

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications 5. Materials and Manufacture

5.1 Material covered by this specification shall be made by

3. Terminology

conventional hot and cold working procedures, from ingots

3.1 Definitions of Terms Specific to This Standard:

produced by vacuum melting in electron beam or consumable

3.1.1 lot—a lot shall consist of all material of the same mill

arc furnaces, or both, of a type conventionally used for reactive

size, shape, and condition produced from the same ingot by the

metals.

same reduction schedule and the same final heat treating

6. Metallurgical Condition

conditions.

6.1 All grades furnished under this specification shall be in

4. Ordering Information

the recrystallization annealed condition unless otherwise speci-

4.1 Purchase orders for material under this specification

fied.

shall include the following information as required to ad-

7. Chemical Composition

equately describe the desired material:

4.1.1 Quantity (weight or number of pieces),

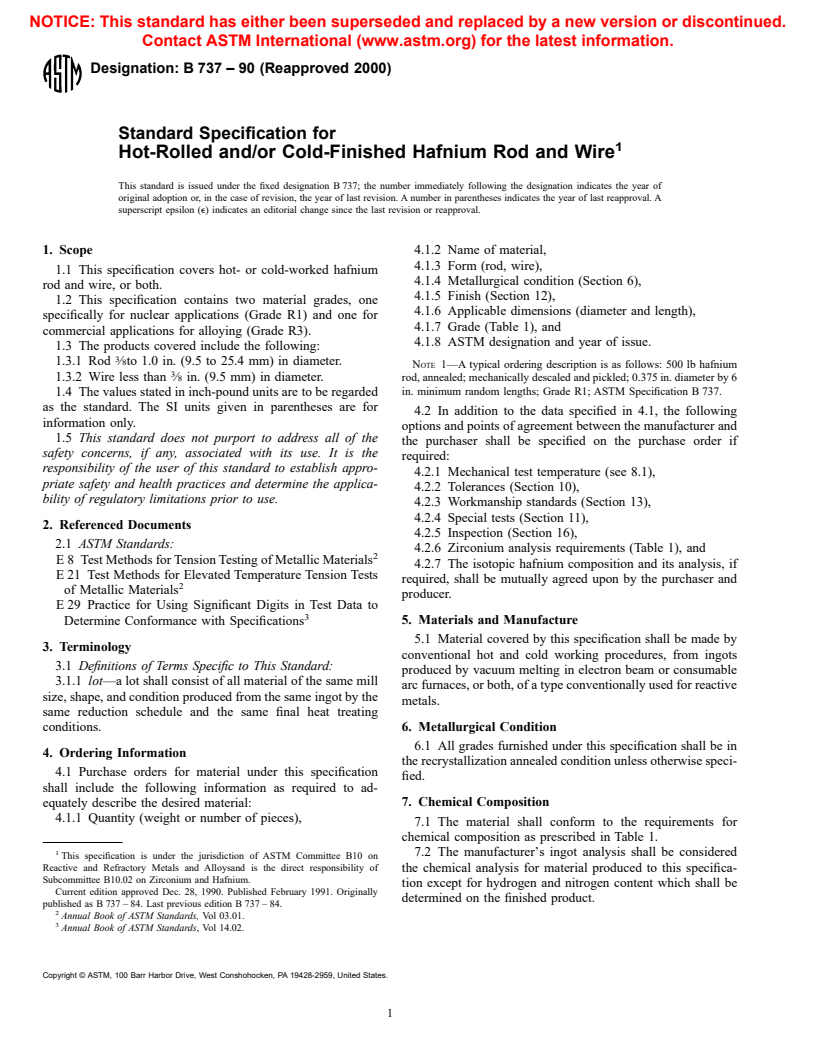

7.1 The material shall conform to the requirements for

chemical composition as prescribed in Table 1.

7.2 The manufacturer’s ingot analysis shall be considered

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloysand is the direct responsibility of the chemical analysis for material produced to this specifica-

Subcommittee B10.02 on Zirconium and Hafnium.

tion except for hydrogen and nitrogen content which shall be

Current edition approved Dec. 28, 1990. Published February 1991. Originally

determined on the finished product.

published as B 737 – 84. Last previous edition B 737 – 84.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 737

TABLE 1 Chemical Requirements

9.2 Grade R1—Coupons shall exhibit a weight gain of not

Composition, Weight % more than 10 mg/dm .

Alloying 9.3 Grade R3—Test for information only, if required by

Nuclear Grade

Grade

Element purchase order.

Grade R1 Grade R3

10. Permissible Variations in Dimensions

Aluminum 0.010 0.050

Carbon 0.015 0.025

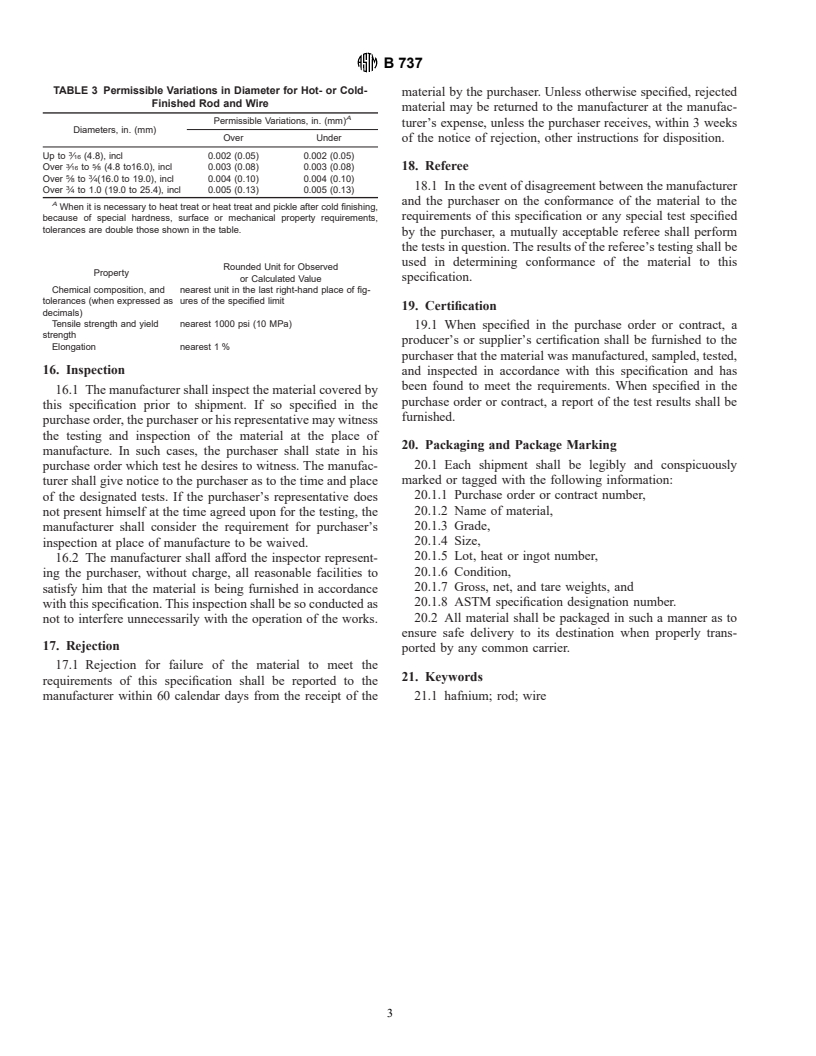

10.1 Rod and wire shall conform to the dimensional require-

Chromium 0.010 0.050

Copper 0.010 .

ments for the specified product as prescribed in Tables 3-5.

Hydrogen 0.0025 0.0050

Iron 0.050 0.0750

11. Special Tests

Molybdenum 0.0020 .

Nickel 0.0050 .

11.1 Additional tests may be specified in the purchase order.

Niobium 0.010 .

The test method and standards shall be agreed upon in advance

Nitrogen 0.010 0.0150

Oxygen 0.040 0.130

between manufacturer and purchaser.

Silicon 0.010 0.050

Tantalum 0.020 .

12. Finish

Tin 0.0050 .

Titanium 0.010 0.050

12.1 Rods shall be furnished with one of the following

Tungsten 0.0150 0.0150

Uranium 0.0010 . surface finishes as designated in the purchase order:

Vanadium 0.0050 .

12.1.1 Mechanically descaled and pickled,

AA

Zirconium

Hafnium balance balance

12.1.2 Centerless ground and pickled, or

A

Zirconium shall be reported. Acceptable levels shall be established by mutual

12.1.3 Centerless ground, pickled, and oxidized.

agreement between purchaser and producer.

12.2 Wire shall be furnished with one of the following

surface finishes as designated in the purchase order:

7.3 Analysis shall be made using the manufacturer’s stan-

dard methods. In the event of disagreement as to the chemical 12.2.1 Conditioned and pickled, or

composition of the metal, methods of chemical analysis for

12.2.2 Conditioned, pickled, and oxidized.

reference purposes shall be determined by a mutually accept-

able laboratory.

13. Workmanship

7.4 Sampling for chemical composition shall consist of

13.1 Cracks, seams, slivers, blisters, burrs, and other inju-

samples taken at top, middle, and bottom of the ingot. Samples

rious imperfections shall not exceed standards of acceptability

for hydrogen and nitrogen shall be taken as two random

agreed upon by the manufacturer and the purchaser.

samples from each lot at final size.

14. Number of Test and Retests

8. Mechanical Properties

8.1 Grade R1 in rod form shall conform to the requirements

14.1 Two random samples shall be taken from each lot.

prescribed in Table 2 for room temperature mechanical prop-

14.2 If any sample or specimen exhibits obvious contami-

erties. Elevated temperature properties shall be used to deter-

nation, improper preparation, or flaws disqualifying it as a

mine compliance only when specified in the purchase order

representative sample, it shall be discarded and a new sample

(see Test Methods E 21).

or specimen substituted.

8.2 The yield strength shall be determined by the offset

14.3 If the results of any test lot are not in conformance with

(0.2 %) method as prescribed in Test Methods E 8.

the requirements of this specification, the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.