ASTM D4497-94(2004)

(Test Method)Standard Test Method for Determining the Open Time of Hot Melt Adhesives (Manual Method)

Standard Test Method for Determining the Open Time of Hot Melt Adhesives (Manual Method)

SCOPE

1.1 This test method covers the manual determination of the open-time range of hot-melt adhesives under the stated conditions.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4497 – 94 (Reapproved 2004)

Standard Test Method for

Determining the Open Time of Hot Melt Adhesives (Manual

Method)

This standard is issued under the fixed designation D 4497; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope using a heated film applicator on one surface. The bonded

specimens are examined later to determine the longest time

1.1 This test method covers the manual determination of the

period, between application of the adhesive to one surface and

open-time range of hot-melt adhesives under the stated condi-

mating with a second surface, which allows substantial bond-

tions.

ing.

1.2 The values stated in SI units are to be regarded as the

standard. The inch-pound units in parentheses are provided for

5. Significance and Use

information only.

5.1 This test method allows comparing the open time of

1.3 This standard does not purport to address all of the

several hot melt adhesives.

safety concerns, if any, associated with its use. It is the

5.2 This test method is not intended to provide the open-

responsibility of the user of this standard to establish appro-

time observed for a specific adhesive in a specific manufactur-

priate safety and health practices and determine the applica-

ing operation. This test method can be used to compare the

bility of regulatory limitations prior to use.

performance of adhesives which are represented to be identical

2. Referenced Documents or to rank the open-time of a group of hot melt adhesives.

2.1 ASTM Standards:

6. Apparatus

D 907 Terminology of Adhesives

6.1 Oven, which meets the precision required by the proce-

E 171 Specification for Standard Atmospheres for Condi-

dure, should be used to heat the adhesive sample and the

tioning and Testing Flexible Barrier Materials

applicator.

E 691 Practice for Conducting an Interlaboratory Study to

6.2 Film Applicator—Multiple clearance 0.125 to 1.25 mm

Determine the Precision of a Test Method

(5 to 50 mil) square P.G. and T. Number 2 Film Applicator

3. Terminology capable of providing an applied film of adhesive having a

nominal width of 50 mm (2 in.).

3.1 Definitions—Several terms in this test method are de-

6.3 Hand Thermometer, preferably metal, capable of mea-

fined in accordance with Terminology D 907.

suring the temperature of the hot-melt with an accuracy of

3.2 Definitions of Terms Specific to This Standard:

61°C (62°F).

3.2.1 open time, n—the time available between application

6.4 Primary Standard Substrate, 200 by 280 mm (8 by 11

of the adhesive to the first substrate and the mating of the

in.), NBS Standard Reference Material 1810 (Liner Board).

second substrate which still results in a minimum of 50 % fiber

Substrates are to be conditioned as described in Specification

tear when tested at ambient conditions.

E 171.

4. Summary of Test Method 6.5 Secondary Standard Substrate, 125 mm (5 in.) length in

the material direction cut to 19 mm (0.75 in.) wide, NBS

4.1 In this test method, open time is determined by bonding

Standard Reference Material 1810 (Liner Board).

together with the adhesive, pieces of standard paper at intervals

6.6 Glass Beakers (600 mL), for melting the adhesive.

of 5 s sequentially after the molten adhesive has been applied

6.7 Watchglass, to cover beaker.

6.8 Beakers, Tongs, and Protective gloves, for handling hot

vessels and applicators.

This test method is under the jurisdiction of ASTM Committee D14 on

6.9 Transparent Pressure Sensitive Tape.

Adhesives and is the direct responsibility of Subcommittee D14.50 on Hot Melts,

Pressure Sensitives, and Archival Adhesives.

Current edition approved Sept. 1, 2004. Published September 2004. Originally

approved in 1985. Last previous edition approved in 1999 as D 4497 – 94 (1999).

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Film Applicator No. 2 is available from Precision Gage and Tool Company, 28

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Volkenand Street, Dayton, OH 45410.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

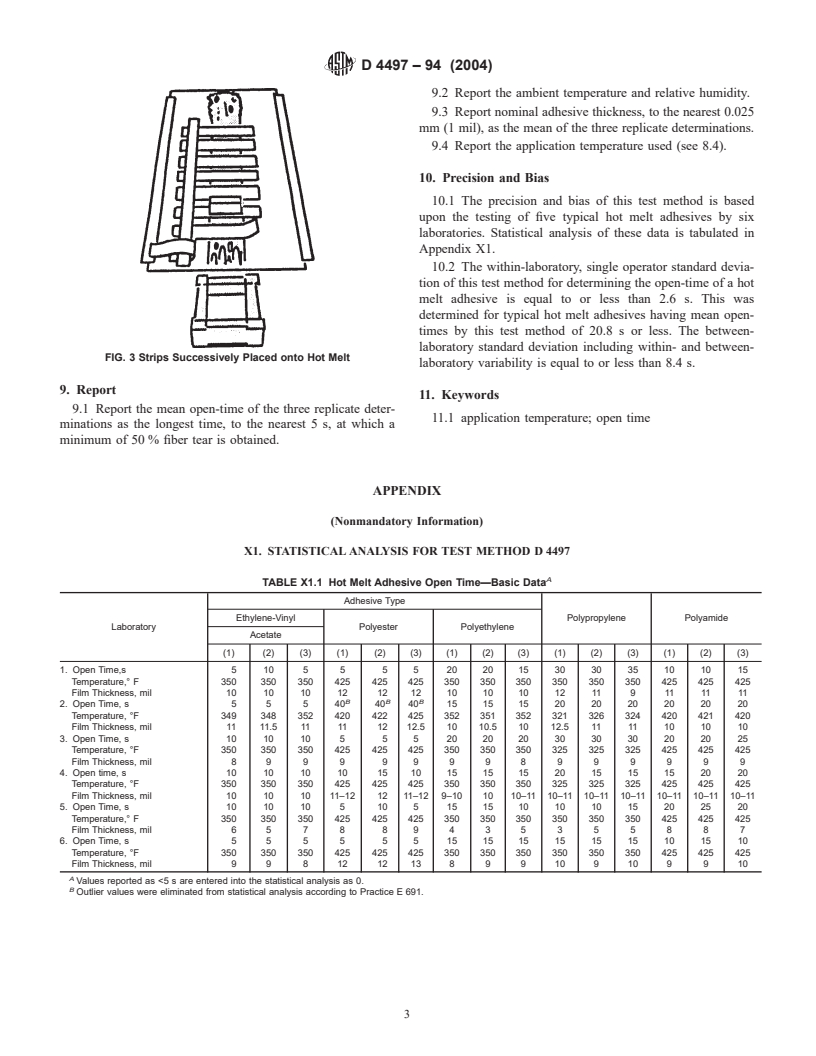

D 4497 – 94 (2004)

6.10 Stop Watch or Other Timer, graduated to at least 0.5 s.

6.11 Weighted Rectangular Block, having at least one

smooth and flat wood face, 50 by 12.5 mm (2 by 0.5 in.)

weighing 100 g (3.5 oz), the mass being uniformly distributed.

6.12 Micrometer or Thickness Gage, capable of measuring

to the nearest 0.025 mm (1 mil).

7. Sampling

7.1 The test sample should be representative of the adhesive

being tested.

8. Procedure

8.1 Add 300 6 10 g of the adhesive to the 600-mL glass

beaker and cover with a watch glass. Place the beaker

containing the adhesive into the oven and heat until at the

application temperature recommended by the manufacturer.

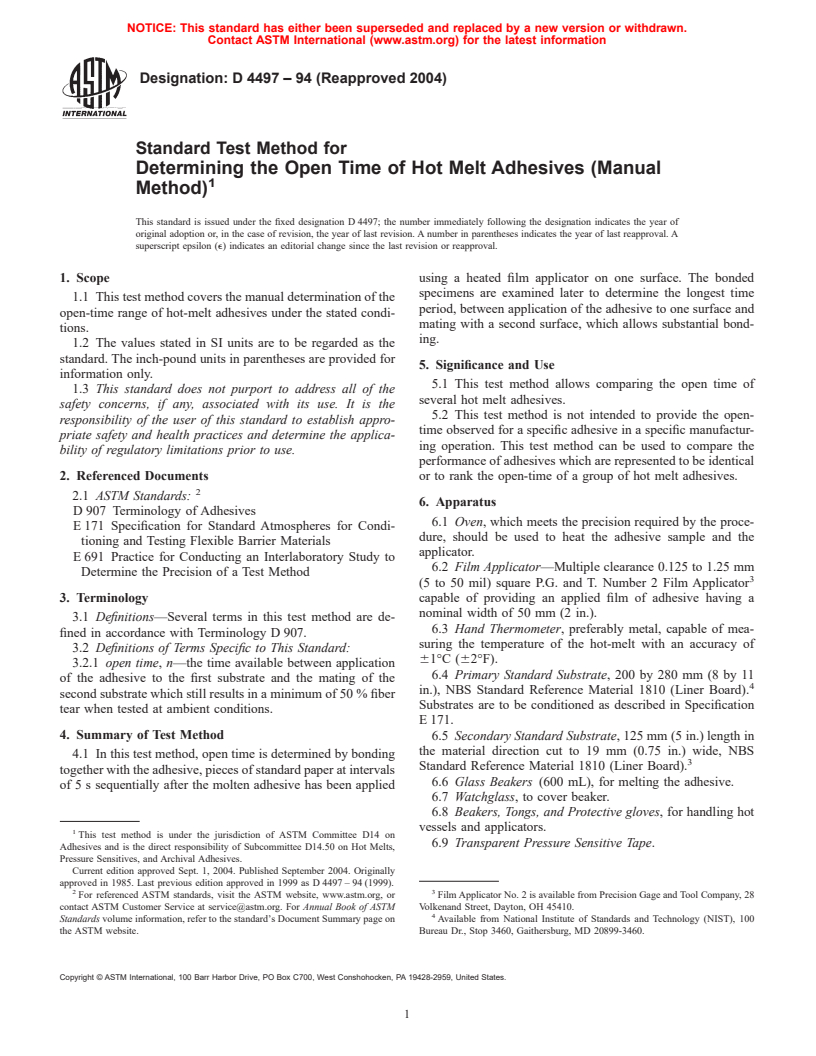

FIG. 2 Strips Drawn Back to Allow Hot Melt Application

8.2 Concurrently heat the film applicator in the same oven

to condition it to the sample temperature as in 8.1.

0.5 mm (20 mil) gap should face down and be near the top end

8.3 Perform testing in a relatively draft-free room. While the

of the primary substrate.

sample is melting, prepare the substrates for testing as shown

8.6 Fill the applicator reservoir to approximately a ⁄4-in.

in Figs. 1 and 2.

level with conditioned hot adhesive.

8.3.1 Tape the long sides of a piece of primary standard

8.7 Move the applicator and the contained molten adhesive

substrate (see 6.4), minimum sheet size 100 by 280 mm (4 by

with one smooth motion over the length of the paper taking

11 in.), to a flat smooth surface of low thermal conductivity,

approximately2sto complete the drawdown.

specifically to a larger piece of chipboard (such as from the

back of a tablet). Then tape the chipboard to an underlying NOTE 1—Approximately2sis satisfactory. The purpose is to standard-

ize on a reasonable rate and eliminate an excessively fast or slow

surface.

drawdown which will affect the results.

8.3.2 Place the strips of the secondary standard substrate

NOTE 2—Trial applications should be made to determine the proper

(see 6.5) across the width of the primary substrate, as shown in

applicator gap to lay down a specified film thickness. Normally, a gap of

Fig. 1, leaving approximately 6 mm ( ⁄4 in.) between the strips.

0.50 mm (20 mil) will lay down a film of 0.25 mm (10 mil). Variations in

The top strip should be approximately 75 mm (3 in.) below the

applied film thickness will occur because of differences in the hot flow

top edge of the primary substrate. Using pressure sensitive properties of the adhesive.

tape, attach one end of the strips to the primary substrate. Fold

8.8 Immediately after the film has been drawn down, start

the unattached end of each strip back over the attached end

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.