ASTM E101-91

(Test Method)Test Method for Spectrographic Analysis of Aluminum and Aluminum Alloys by the Point-To-Plane Technique (Withdrawn 1996)

Test Method for Spectrographic Analysis of Aluminum and Aluminum Alloys by the Point-To-Plane Technique (Withdrawn 1996)

SCOPE

1.1 This test method covers the spectrographic analysis of aluminum and aluminum alloys for the following elements in the ranges indicated: Element Concentration Range, % Silicon 0.02 to 14.0 Copper 0.001 to 10.0 Magnesium 0.001 to 10.0 Zinc 0.03 to 8.0 Nickel 0.03 to 3.0 Iron 0.02 to 2.0 Manganese 0.005 to 2.0 Lead 0.03 to 0.7 Bismuth 0.03 to 0.7 Chromium 0.01 to 0.5 Titanium 0.01 to 0.5 Tin 0.01 to 0.5 Beryllium 0.0002 to 0.5 Calcium 0.0005 to 0.1 Sodium 0.0005 to 0.05

1.2 This test method is applicable primarily to the analysis of chill-cast disks, but it may be extended, with proper precautions, to the analysis of samples in other forms on which a flat surface for sparking can be machined. Standards and samples should be of similar composition and metallurgical state; when they are not, corrections must be applied to compensate for these effects.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

ASTM E101 ’71 9 0757510 0082274 7 I

AMERICAN SOCIETY FOR TESTING AND MATERIALS

#Tb Designation: E 101 - 91

1916 RaceSt Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

if not listed in the current combined index. will appear In the next edition.

Standard Test Method for

Spectrographic Analysis of Aluminum and Aluminum Alloys

by the Point-to-Plane Technique‘

This standard is issued under the fixed designation E 101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (i) indicates an editorial change since the last revision or reapproval.

1. Scope E 7 16 Practices for Sampling Aluminum and Aluminum

Alloys for Spectrochemical Analysis2

1.1 This test method covers the spectrographic analysis of

aluminum and aluminum alloys for the following elements

3. Terminology

in the ranges indicated:

3.1 Definitions-For definitions of terms used in this

Element Concentration Range, %

test method, refer to Terminology E 135.

Silicon

0.02 to 14.0

0.001 to 10.0

Copper

4. Summary of Test Method

Magnesium

0.001 to 10.0

Zinc 0.03 to 8.0

4.1 A flat sample surface is excited by a controlled spark

Nickel 0.03 to 3.0

discharge using the point-to-plane technique. The spectra are

Iron 0.02 to 2.0

Mangan es e 0.005 to 2.0 photographed on a calibrated emulsion and the intensity

Lead 0.03 to 0.7

ratios of selected pairs of analytical lines and internal

Bismuth 0.03 to 0.7

standard lines are determined photometrically. Concentra-

Chromium

0.01 to 0.5

tions of the elements are read from analytical curves relating

Titanium 0.01 to 0.5

Tin

0.01 to 0.5

log intensity ratio to c~ncentration.~

Beryllium 0.0002 to 0.5

Calcium

0.0005 to O. 1

5. Apparatus

Sodium 0.0005 to 0.05

5.1 Sample Preparation Equipment:

1.2 This test method is applicable primarily to the analysis

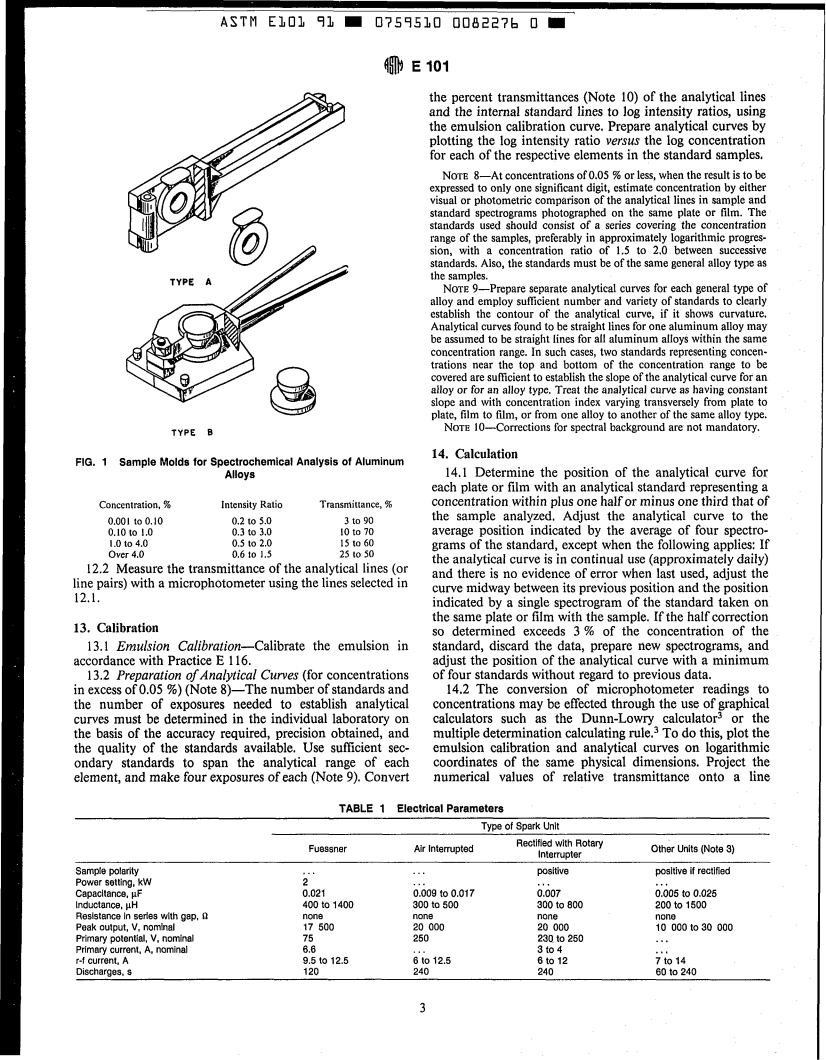

5.1.1 Sample Molds-Refer to Practices E 7 16.

of chill-cast disks, but it may be extended, with proper

5.1.2 Lathe-Refer to Practices E 7 16.

precautions, to the analysis of samples in other forms on

5.2 Electrode Critter, for shaping electrodes to the config-

which a flat surface for sparking can be machined. Standards

uration described in 6.1.

and samples should be of similar composition and metallur-

5.3 Excitation Source, providing a controlled spark with

gical state; when they are not, corrections must be applied to

the parameters described in Section 10.

compensate for these effects.

5.4 Excitation Stand, a Petrey stand to accommodate a

1.3 This standard does not purport to address all of the

flat disk electrode in opposition to a graphite counter

safety problems, if any, associated with its use. It is the

electrode. The lower support has a spring clip for holding the

user ofthis standard to establish appro-

responsibility of the

graphite rod vertically. The upper electrode supports the

priate safety and health practices and determine the applica-

sample. The top surface of this support is in a horizontal or

bility of regulatory limitations prior to use.

slightly inclined position, so arranged that an extension of

the plane of this surface passes through the top of the

2. Referenced Documents

condensing lens and the center of the spark column is on the

2.1 ASTM Standards: optical axis.

E 11 5 Practice for Photographic Processing in Optical 5.5 Spectrograph-Almost any of the commercial instru-

Emission Spectrographic Analysis2 ments offered for metallurgical work may be applied to this

E 116 Practice for Photographic Photometry in Spectro- method. Of the prism instruments, the large quartz Littrow

chemical Analysis2 or Wadsworth types are preferred, although the medium

E 130 Practice for Designation of Shapes and Sizes of Cornu type is acceptable. Grating spectrographs having a

Graphite Electrodes2 1.5-m focal length for 960 grooves/mm grating, a 2-m focal

E 135 Terminology Relating to Analytical Atomic Spec-

length for a 600 grooves/mm grating, or a 3-m focal length

troscopy2 for a 600 grooves/mm grating are sätisfactory.

E 409 Practice for Description and Performance of the

5.6 Microphotometer, conforming to the requirements of

Microphotometer2

Practice E 409.

This test method is under the jurisdiction of ASTM Committee E-I on

3 This test method is based largely on the following material:

Analytical Chemistry of Metals, Ores and Related Materials and is the direct Churchill, J. R., Selec[ed Topics in Modern Itisrrirrnentnl Analysis, edited by

responsibility of Subcommittee E01 .O4 on Aluminum and Magnesium.

David F. Boltz, Prentice-Hall, Inc., Chapter 5, 1952, pp. 160-235.

Current edition approved Sept. 15, 1991. Originally published as E IO1 - 53 T. Churchill, J. R., “Techniques of Quantitative Spectrographic Analysis,” Iridirs-

Last previous edition E 101 - 67 (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.