ASTM E3061-17

(Test Method)Standard Test Method for Analysis of Aluminum and Aluminum Alloys by Inductively Coupled Plasma Atomic Emission Spectrometry (Performance Based Method)

Standard Test Method for Analysis of Aluminum and Aluminum Alloys by Inductively Coupled Plasma Atomic Emission Spectrometry (Performance Based Method)

SIGNIFICANCE AND USE

5.1 This test method for the analysis of aluminum and aluminum alloys is primarily intended to test material for compliance with The Aluminum Association Inc.5 registered composition limits or other specified composition limits for aluminum and aluminum alloys.

5.2 It is assumed that all who use this test method will be trained analysts capable of performing common laboratory procedures skillfully and safely, and that the work will be performed in a properly equipped laboratory.

5.3 This is a performance-based test method that relies more on the demonstrated quality of the test result than on strict adherence to specific procedural steps. It is expected that laboratories using this test method will prepare their own work instructions. These work instructions should include detailed operating instructions for the specific laboratory, the specific reference materials employed, and performance acceptance criteria.

SCOPE

1.1 This test method describes the inductively coupled plasma atomic emission spectrometric analysis of aluminum and aluminum alloys for the following elements:

Elements

Application Range, %

Minimum

Maximum

Si

0.02

16.8

Fe

0.02

3.06

Cu

0.005

7.0

Mn

0.003

1.41

Mg

0.006

8.2

Cr

0.004

0.52

Ni

0.004

2.71

Zn

0.02

9.65

Ti

0.009

0.20

Ag

0.003

0.4

As

0.005

0.012

B

0.009

0.027

Ba

0.002

0.03

Be

0.002

0.11

Bi

0.01

0.59

Ca

0.003

0.048

Cd

0.002

0.055

Co

0.002

0.034

Ga

0.01

0.019

Li

0.001

2.48

Mo

0.02

0.15

Na

0.008

0.026

P

0.01

0.025

Pb

0.009

0.51

Sb

0.01

0.28

Sc

0.01

0.065

Sn

0.008

6.28

Sr

0.0008

0.028

Ti

0.005

0.20

Tl

0.009

0.13

V

0.01

0.12

Zr

0.004

0.25

1.2 This test method has only been interlaboratory tested for the elements and ranges specified. It may be possible to extend this test method to other elements or different composition ranges if method validation, which includes evaluation of method sensitivity and precision and bias (as described in Section 14), is performed. Additionally, the validation study must evaluate the acceptability of sample preparation methodology using reference materials and/or spike recoveries. The user should carefully evaluate the validation data against the laboratory’s data quality objectives. Method validation of scope extensions is also a requirement of ISO/IEC 17025.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Safety hazard statements are given in Section 10 and specific warning statements are given in Sections 15, 17, 18, 19, 20 and 21.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3061 − 17

Standard Test Method for

Analysis of Aluminum and Aluminum Alloys by Inductively

Coupled Plasma Atomic Emission Spectrometry

1

(Performance Based Method)

This standard is issued under the fixed designation E3061; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Section 14), is performed. Additionally, the validation study

must evaluate the acceptability of sample preparation method-

1.1 This test method describes the inductively coupled

ology using reference materials and/or spike recoveries. The

plasma atomic emission spectrometric analysis of aluminum

user should carefully evaluate the validation data against the

and aluminum alloys for the following elements:

laboratory’s data quality objectives. Method validation of

Application Range, %

Elements

scope extensions is also a requirement of ISO/IEC 17025.

Minimum Maximum

Si 0.02 16.8

1.3 The values stated in SI units are to be regarded as

Fe 0.02 3.06

standard. No other units of measurement are included in this

Cu 0.005 7.0

Mn 0.003 1.41

standard.

Mg 0.006 8.2

1.4 This standard does not purport to address all of the

Cr 0.004 0.52

Ni 0.004 2.71

safety concerns, if any, associated with its use. It is the

Zn 0.02 9.65

responsibility of the user of this standard to establish appro-

Ti 0.009 0.20

priate safety and health practices and determine the applica-

Ag 0.003 0.4

As 0.005 0.012

bility of regulatory limitations prior to use. Safety hazard

B 0.009 0.027

statements are given in Section 10 and specific warning

Ba 0.002 0.03

statements are given in Sections 15, 17, 18, 19, 20 and 21.

Be 0.002 0.11

Bi 0.01 0.59

Ca 0.003 0.048

2. Referenced Documents

Cd 0.002 0.055

2

Co 0.002 0.034 2.1 ASTM Standards:

Ga 0.01 0.019

B985 Practice for Sampling Aluminum Ingots, Billets, Cast-

Li 0.001 2.48

ings and Finished or Semi-Finished Wrought Aluminum

Mo 0.02 0.15

Na 0.008 0.026 Products for Compositional Analysis

P 0.01 0.025

D1193 Specification for Reagent Water

Pb 0.009 0.51

E34 Test Methods for Chemical Analysis of Aluminum and

Sb 0.01 0.28

Sc 0.01 0.065 Aluminum-Base Alloys

Sn 0.008 6.28

E50 Practices for Apparatus, Reagents, and Safety Consid-

Sr 0.0008 0.028

erations for Chemical Analysis of Metals, Ores, and

Ti 0.005 0.20

Tl 0.009 0.13

Related Materials

V 0.01 0.12

E135 Terminology Relating to Analytical Chemistry for

Zr 0.004 0.25

Metals, Ores, and Related Materials

1.2 This test method has only been interlaboratory tested for

E177 Practice for Use of the Terms Precision and Bias in

the elements and ranges specified. It may be possible to extend

ASTM Test Methods

this test method to other elements or different composition

E406 Practice for Using Controlled Atmospheres in Spec-

ranges if method validation, which includes evaluation of

trochemical Analysis

method sensitivity and precision and bias (as described in

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1

This test method is under the jurisdiction of ASTM Committee E01 on

2

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of Subcommittee E01.04 on Aluminum and Magnesium. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Jan. 15, 2017. Published March 2017. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E3061–17 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3061 − 17

E716 Practices for Sampling and Sample Preparation of operating instructions for the specific laboratory, the specific

Aluminum and Aluminum Alloys for Determination of reference materials employed, and performance acceptance

Chemical Composition by Spark Atomic Emission Spec- criteria.

trometry

6. Interferences

E1329 Practice for Verification and Use of Control Charts in

Spectrochemical Analysis

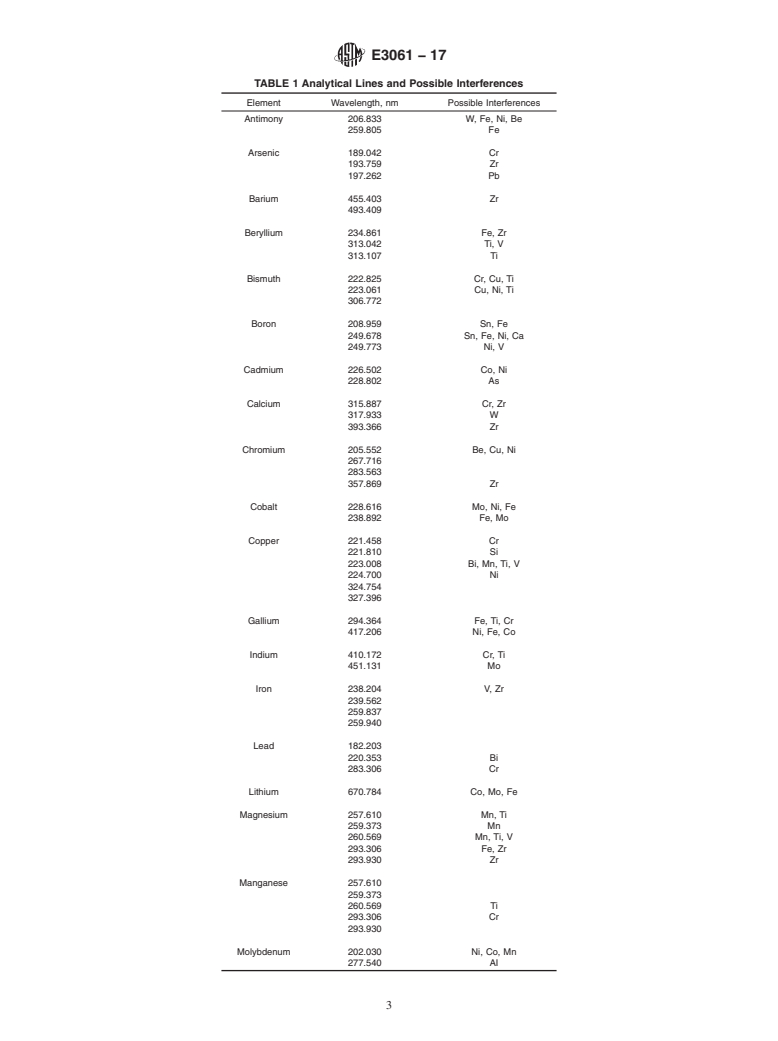

6.1 The effect of potential spectral overlap interferences and

E1452 Practice for Preparation of Calibration Solutions for

background will vary based on the wavelengths selected,

Spectrophotometric and for Spectroscopic Atomic Analy-

instrument design, and may vary from instrument to instrument

3

sis (Withdrawn 2005)

of the same design. Variation of excitation cond

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.