ASTM E1251-04

(Test Method)Test Method for Analysis of Aluminum and Aluminum Alloys by Atomic Emission Spectrometry

Test Method for Analysis of Aluminum and Aluminum Alloys by Atomic Emission Spectrometry

SCOPE

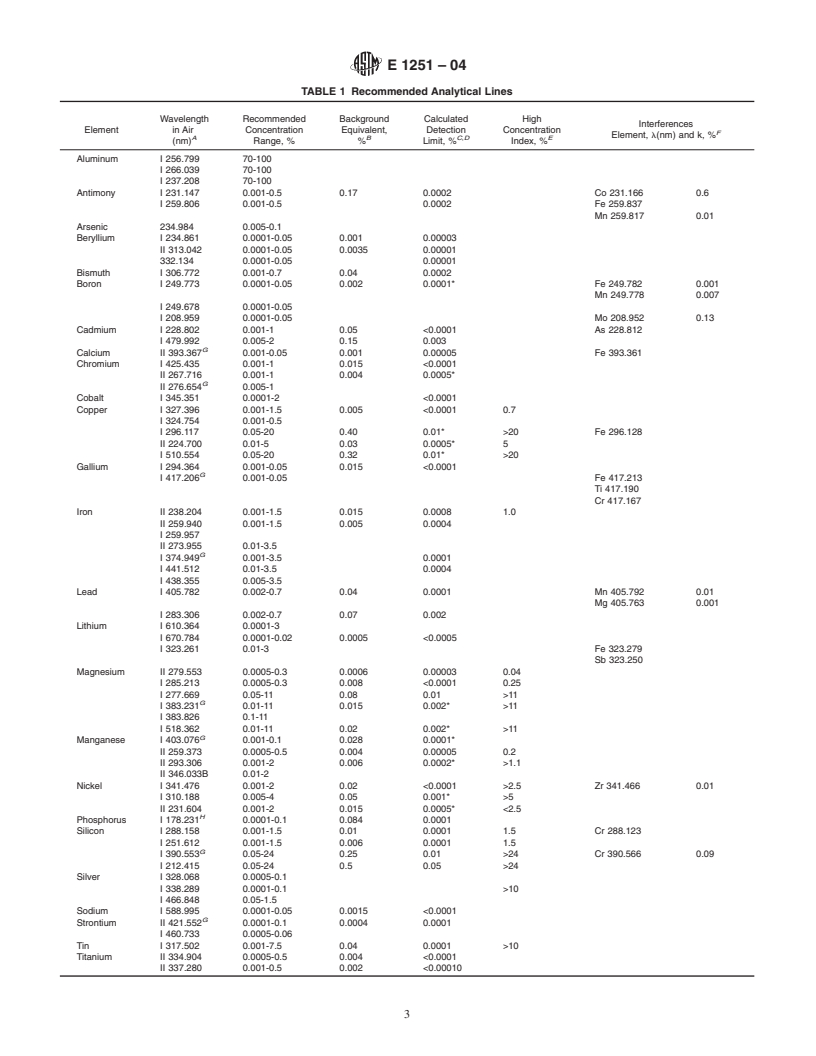

1.1 This test method describes the analysis of aluminum and its alloys by atomic emission spectrometry. The aluminum specimen to be analyzed may be in the form of a chill cast disk, casting, foil, sheet, plate, extrusion or some other wrought form or shape. The elements covered in the scope of this method are listed in the table below.ElementTested Concentration Range(Wt %)Beryllium0.0004 to 0.24Bismuth0.03 to 0.6Boron0.0006 to 0.009Calcium0.0002 to -Chromium0.001 to 0.23Cobalt0.4 to -Copper0.001 to 5.5Gallium0.02 to -Iron0.2 to 0.5Lead0.04 to 0.6Lithium0.0003 to 2.1Magnesium0.03 to 5.4Manganese0.001 to 1.2Nickel0.005 to 2.6Phosphorus0.003 to 0.003Silicon0.07 to 4.0Sodium0.003 to 0.02Strontium0.003 to -Tin0.03 to -Titanium0.001 to 0.12Vanadium0.002 to 0.022Zinc0.002 to 5.7Zirconium0.001 to 0.12Note 1—The conncentration ranges given in the above scope were established through cooperative testing (ILS) of selected reference materials. The range shown for each element does not demonstrate the actual usable analytical range for that element. The usable analytical range may be extended higher or lower based on individual instrument capability, spectral characteristics of the specific element wavelength being used and the availability of appropriate reference materials.

1.2 This test method is suitable primarily for the analysis of chill cast disks as defined in Practices E 716. Other forms may be analyzed, provided that: (1) they are sufficiently massive to prevent undue heating, (2) they allow machining to provide a clean, flat surface, which creates a seal between the specimen and the spark stand, and (3) reference materials of a similar metallurgical condition and chemical composition are available.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety and health statements are given in Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1251–04

Standard Test Method for

Analysis of Aluminum and Aluminum Alloys by Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation E 1251; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope prevent undue heating, (2) they allow machining to provide a

clean, flat surface, which creates a seal between the specimen

1.1 Thistestmethoddescribestheanalysisofaluminumand

and the spark stand, and (3) reference materials of a similar

its alloys by atomic emission spectrometry. The aluminum

metallurgical condition and chemical composition are avail-

specimentobeanalyzedmaybeintheformofachillcastdisk,

able.

casting,foil,sheet,plate,extrusionorsomeotherwroughtform

1.3 This standard does not purport to address all of the

or shape. The elements covered in the scope of this method are

safety concerns, if any, associated with its use. It is the

listed in the table below.

responsibility of the user of this standard to establish appro-

Tested Concentration Range

Element

priate safety and health practices and determine the applica-

(Wt %)

Beryllium 0.0004 to 0.24

bility of regulatory limitations prior to use. Specific safety and

Bismuth 0.03 to 0.6

health statements are given in Section 10.

Boron 0.0006 to 0.009

Calcium 0.0002 to –

2. Referenced Documents

Chromium 0.001 to 0.23

Cobalt 0.4 to –

2

2.1 ASTM Standards:

Copper 0.001 to 5.5

E 135 Terminology Relating to Analytical Chemistry for

Gallium 0.02 to –

Iron 0.2 to 0.5

Metals, Ores, and Related Materials

Lead 0.04 to 0.6

E 158 Practice for Fundamental Calculations to Convert

Lithium 0.0003 to 2.1

Intensities into Concentrations in Optical Emission Spec-

Magnesium 0.03 to 5.4

Manganese 0.001 to 1.2

trochemical Analysis

Nickel 0.005 to 2.6

E 172 Practice for Describing and Specifying the Excitation

Phosphorus 0.003 to 0.003

3

Source in Emission Spectrochemical Analysis

Silicon 0.07 to 4.0

Sodium 0.003 to 0.02

E 305 Practice for Establishing and Controlling Spectro-

Strontium 0.003 to –

chemical Analytical Curves

Tin 0.03to–

E 406 Practice for Using Controlled Atmospheres in Spec-

Titanium 0.001 to 0.12

Vanadium 0.002 to 0.022

trochemical Analysis

Zinc 0.002 to 5.7

E 691 Practice for Conducting an Interlaboratory Study to

Zirconium 0.001 to 0.12

Determine the Precision of a Test Method

NOTE 1—The concentration ranges given in the above scope were

E 716 Practices for Sampling Aluminum and Aluminum

established through cooperative testing (ILS) of selected reference mate-

Alloys for Spectrochemical Analysis

rials. The range shown for each element does not demonstrate the actual

E 826 Practice for Testing Homogeneity of Materials for

usable analytical range for that element. The usable analytical range may

be extended higher or lower based on individual instrument capability, Development of Reference Materials

spectral characteristics of the specific element wavelength being used and

E 876 Practice for Use of Statistics in the Evaluation of

the availability of appropriate reference materials.

Spectrometric Data

E 1329 Practice for Verification and Use of Control Charts

1.2 This test method is suitable primarily for the analysis of

in Spectrochemical Analysis

chill cast disks as defined in Practices E 716. Other forms may

be analyzed, provided that: (1) they are sufficiently massive to

1 2

This test method is under the jurisdiction of ASTM Committee E01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee E01.04 on Aluminum and Magnesium. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2004. Published August 2004. Originally the ASTM website.

3

approved in 1988. Last previous edition approved in 1999 as E 1251 – 94 (1999). Discontinued—See 2000 Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1251–04

E 1507 Guide for Describing and Specifying the Spectrom- inter-element effects. Like the method above, specific alloy

eter of an Optical Emission Direct Reading Instrument calibrants may be used to apply a slope and/or intercept

correction to the observed readings.

3. Terminology

4.2.3 The third method, alloy calibration, employs calibra-

3.1 Definitions—For definitions of terms used in this Stan-

tion c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.