ASTM C1624-05(2015)

(Test Method)Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing

Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing

SIGNIFICANCE AND USE

5.1 This test is intended to assess the mechanical integrity, failure modes, and practical adhesion strength of a specific hard ceramic coating on a given metal or ceramic substrate. The test method does not measure the fundamental “adhesion strength” of the bond between the coating and the substrate. Rather, the test method gives a quantitative engineering measurement of the practical (extrinsic) adhesion strength and damage resistance of the coating-substrate system as a function of applied normal force. The adhesion strength and damage modes depend on the complex interaction of the coating/substrate properties (hardness, fracture strength, modulus of elasticity, damage mechanisms, microstructure, flaw population, surface roughness, and so forth) and the test parameters (stylus properties and geometry, loading rate, displacement rate, and so forth).

5.2 The quantitative coating adhesion scratch test is a simple, practical, and rapid test. However, reliable and reproducible test results require careful control of the test system configuration and testing parameters, detailed analysis of the coating damage features, and appropriate characterization of the properties and morphology of the coating and the substrate of the test specimens.

5.3 The coating adhesion test has direct application across the full range of coating development, engineering, and production efforts. Measurements of the damage mechanisms in a coating as a function of applied normal forces are useful to understand material-process-property relations; quantify and qualify the mechanical response of coating-substrate systems; assess coating durability; measure production quality; and support failure analysis.

5.4 This test method is applicable to a wide range of hard ceramic coating compositions—carbides, nitrides, oxides, diamond, and diamond like carbon—applied by physical vapor deposition, chemical vapor deposition, and direct oxidation methods to metal and ceramic substrates.

Note 2: U...

SCOPE

1.1 This test method covers the determination of the practical adhesion strength and mechanical failure modes of hard (Vickers Hardness HV = 5 GPa or higher), thin (≤30 μm) ceramic coatings on metal and ceramic substrates at ambient temperatures. These ceramic coatings are commonly used for wear/abrasion resistance, oxidation protection, and functional (optical, magnetic, electronic, biological) performance improvement.

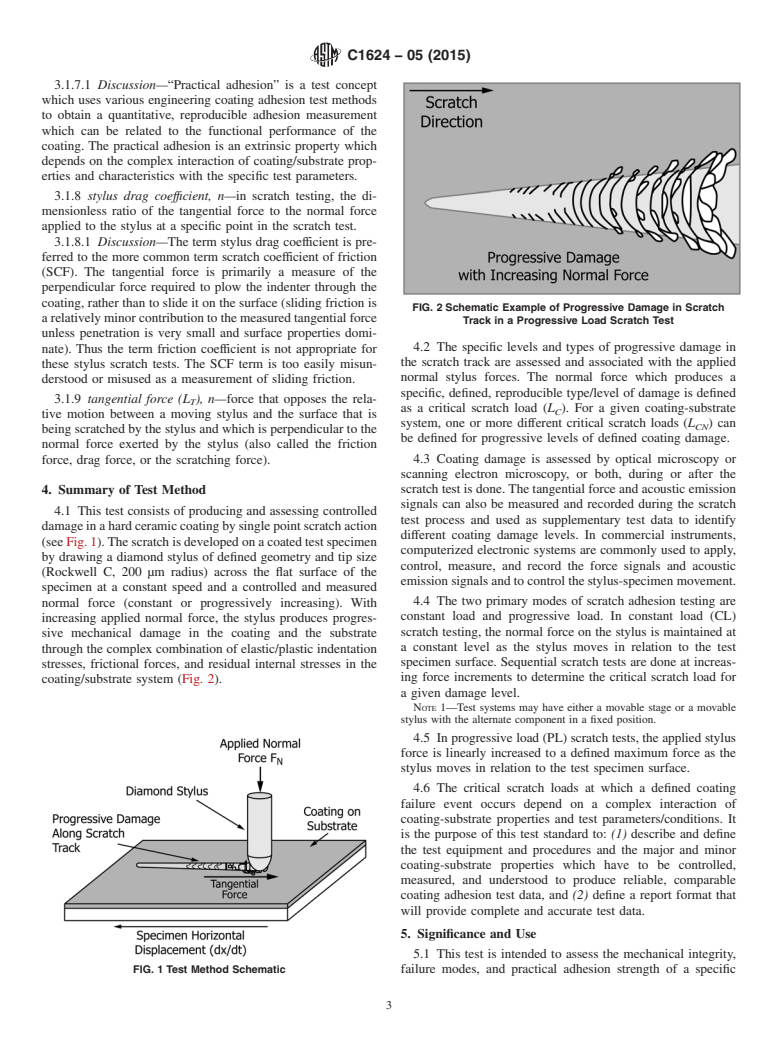

1.2 In the test method, a diamond stylus of defined geometry (Rockwell C, a conical diamond indenter with an included angle of 120° and a spherical tip radius of 200 μm) is drawn across the flat surface of a coated test specimen at a constant speed and a defined normal force (constant or progressively increasing) for a defined distance. The damage along the scratch track is microscopically assessed as a function of the applied force. Specific levels of progressive damage are associated with increasing normal stylus forces. The force level(s) which produce a specific type/level of damage in the coating are defined as a critical scratch load(s). The test method also describes the use of tangential force and acoustic emission signals as secondary test data to identify different coating damage levels.

1.3 Applicability to Coatings—This test method is applicable to a wide range of hard ceramic coating compositions: carbides, nitrides, oxides, diamond, and diamond-like carbon on ceramic and metal substrates. The test method, as defined with the 200 μm radius diamond stylus, is commonly used for coating thicknesses in the range of 0.1 to 30 μm. Test specimens generally have a planar surface for testing, but cylinder geometries can also be tested with an appropriate fixture.

1.4 Principal Limitations:

1.4.1 The test method does not measure the fundamental adhesion strength of the bond between the coating and the substrate. Rather, the test method gives an engineering measurement of the practical (extr...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1624 − 05 (Reapproved 2015)

Standard Test Method for

Adhesion Strength and Mechanical Failure Modes of

Ceramic Coatings by Quantitative Single Point Scratch

1

Testing

This standard is issued under the fixed designation C1624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.1 The test method does not measure the fundamental

adhesion strength of the bond between the coating and the

1.1 This test method covers the determination of the prac-

substrate. Rather, the test method gives an engineering mea-

tical adhesion strength and mechanical failure modes of hard

surement of the practical (extrinsic) adhesion strength of a

(Vickers Hardness HV = 5 GPa or higher), thin (≤30 µm)

coating-substrate system, which depends on the complex

ceramic coatings on metal and ceramic substrates at ambient

interaction of the test parameters (stylus properties and

temperatures. These ceramic coatings are commonly used for

geometry,loadingrate,displacementrate,andsoforth)andthe

wear/abrasion resistance, oxidation protection, and functional

coating/substrateproperties(hardness,fracturestrength,modu-

(optical, magnetic, electronic, biological) performance im-

lus of elasticity, damage mechanisms, microstructure, flaw

provement.

population, surface roughness, and so forth).

1.2 Inthetestmethod,adiamondstylusofdefinedgeometry

1.4.2 The defined test method is not directly applicable to

(Rockwell C, a conical diamond indenter with an included

metal or polymeric coatings which fail in a ductile, plastic

angle of 120° and a spherical tip radius of 200 µm) is drawn

manner, because plastic deformation mechanisms are very

across the flat surface of a coated test specimen at a constant

different than the brittle damage modes and features observed

speed and a defined normal force (constant or progressively

inhardceramiccoatings.Thetestmethodmaybeapplicableto

increasing) for a defined distance. The damage along the

hard metal coatings which fail in a brittle mode with appro-

scratch track is microscopically assessed as a function of the

priate changes in test parameters and damage analysis proce-

applied force. Specific levels of progressive damage are

dures and criteria.

associated with increasing normal stylus forces. The force

1.4.3 The test method, as defined with the Rockwell C

level(s) which produce a specific type/level of damage in the

diamond stylus and specific normal force and rate parameters,

coatingaredefinedasacriticalscratchload(s).Thetestmethod

isnotrecommendedforverythin(<0.1µm)orthickercoatings

alsodescribestheuseoftangentialforceandacousticemission

(>30 µm). Such coatings may require different stylus

signals as secondary test data to identify different coating

geometries, loading rates, and ranges of applied normal force

damage levels.

for usable, accurate, repeatable results.

1.4.4 The values stated in SI units are to be regarded as

1.3 Applicability to Coatings—This test method is appli-

cable to a wide range of hard ceramic coating compositions: standard. No other units of measurement are included in this

standard. Test data values in SI units (newtons (N) for force

carbides, nitrides, oxides, diamond, and diamond-like carbon

on ceramic and metal substrates. The test method, as defined andmillimetres(mm)fordisplacement)aretobeconsideredas

standard and are in accordance with IEEE/ASTM SI10.

with the 200 µm radius diamond stylus, is commonly used for

coating thicknesses in the range of 0.1 to 30 µm. Test 1.4.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

specimens generally have a planar surface for testing, but

cylinder geometries can also be tested with an appropriate responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

fixture.

bility of regulatory limitations prior to use.

1.4 Principal Limitations:

1.5 Organization—The test method is organized into the

following sections:

1

Section

This test method is under the jurisdiction of ASTM Committee C28 on

Scope 1

Advanced Ceramics and is the direct responsibility of Subcommittee C28.04 on

Purpose and Description 1.1

Applications.

Applicability 1.3

Current edition approved Jan. 1, 2015. Published April 2015. Originally

Principal Limitations 1.4

approved in 2005. Last previous edition approved in 2010 as C1624–05(2010).

Organization 1.5

DOI: 10.1520/C1624-05R15.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1624 − 05 (Reapproved 2010) C1624 − 05 (Reapproved 2015)

Standard Test Method for

Adhesion Strength and Mechanical Failure Modes of

Ceramic Coatings by Quantitative Single Point Scratch

1

Testing

This standard is issued under the fixed designation C1624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the practical adhesion strength and mechanical failure modes of hard (Vickers

Hardness HV = 5 GPa or higher), thin (≤30 μm) ceramic coatings on metal and ceramic substrates at ambient temperatures. These

ceramic coatings are commonly used for wear/abrasion resistance, oxidation protection, and functional (optical, magnetic,

electronic, biological) performance improvement.

1.2 In the test method, a diamond stylus of defined geometry (Rockwell C, a conical diamond indenter with an included angle

of 120° and a spherical tip radius of 200 μm) is drawn across the flat surface of a coated test specimen at a constant speed and

a defined normal force (constant or progressively increasing) for a defined distance. The damage along the scratch track is

microscopically assessed as a function of the applied force. Specific levels of progressive damage are associated with increasing

normal stylus forces. The force level(s) which produce a specific type/level of damage in the coating are defined as a critical scratch

load(s). The test method also describes the use of tangential force and acoustic emission signals as secondary test data to identify

different coating damage levels.

1.3 Applicability to Coatings—This test method is applicable to a wide range of hard ceramic coating compositions: carbides,

nitrides, oxides, diamond, and diamond-like carbon on ceramic and metal substrates. The test method, as defined with the 200 μm

radius diamond stylus, is commonly used for coating thicknesses in the range of 0.1 to 30 μm. Test specimens generally have a

planar surface for testing, but cylinder geometries can also be tested with an appropriate fixture.

1.4 Principal Limitations:

1.4.1 The test method does not measure the fundamental adhesion strength of the bond between the coating and the substrate.

Rather, the test method gives an engineering measurement of the practical (extrinsic) adhesion strength of a coating-substrate

system, which depends on the complex interaction of the test parameters (stylus properties and geometry, loading rate,

displacement rate, and so forth) and the coating/substrate properties (hardness, fracture strength, modulus of elasticity, damage

mechanisms, microstructure, flaw population, surface roughness, and so forth).

1.4.2 The defined test method is not directly applicable to metal or polymeric coatings which fail in a ductile, plastic manner,

because plastic deformation mechanisms are very different than the brittle damage modes and features observed in hard ceramic

coatings. The test method may be applicable to hard metal coatings which fail in a brittle mode with appropriate changes in test

parameters and damage analysis procedures and criteria.

1.4.3 The test method, as defined with the Rockwell C diamond stylus and specific normal force and rate parameters, is not

recommended for very thin (<0.1 μm) or thicker coatings (>30 μm). Such coatings may require different stylus geometries, loading

rates, and ranges of applied normal force for usable, accurate, repeatable results.

1.4.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Test data values in SI units (newtons (N) for force and millimetres (mm) for displacement) are to be considered as standard and

are in accordance with IEEE/ASTM SI 10.

1.4.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 Organization—The test method is organized into the following sections:

1

This test method is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.04 on Applications.

Current edition approved Dec. 1, 2010Jan. 1, 2015. Published January 2011Apr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.