ASTM B1023-22

(Test Method)Standard Test Method for Abrasion Resistance of Hard Anodic Coatings by a Taber-Type Abraser

Standard Test Method for Abrasion Resistance of Hard Anodic Coatings by a Taber-Type Abraser

SIGNIFICANCE AND USE

5.1 Hard anodic oxidation coatings are often used to obtain improved resistance to abrasion, and have been used in such applications as valves, sliding parts, hinge mechanisms, cams, gears, swivel joints, pistons, insulation plates, blast shields, etc.

5.2 This abrasion resistance test method may be useful for acceptance testing of a hard anodic coating, and it can be used to evaluate the effects of processing variables such as substrate preparation before coating, surface texture, coating technique variables, and post coating treatments.

5.3 Results may be used for process control, comparative ranking, or to correlate with end-use performance. The resistance of material surfaces to abrasion, as measured on a testing machine in the laboratory, is generally only one of several factors contributing to wear performance as experienced in the actual use of the material. Other factors may need to be considered in any calculation of predicted life from specific abrasion data.

5.4 The properties and characteristics of hard anodic oxidation coatings are significantly affected by both the alloy and the method of production.

Note 2: Hard anodizing will usually result in a dimensional increase on each surface equal to about 50 % of the coating thickness. Normal thickness for wear applications tends to be 40 µm to 60 µm; however the thickness of anodized coatings often ranges between 8 µm to 150 µm.

5.5 The resistance of hard anodic coatings to abrasion may be affected by factors including test conditions, type of abradant, pressure between the specimen and abradant, composition of the alloy, thickness of the coating, and the conditions of anodizing or sealing, or both.

Note 3: The resistance to abrasion is generally measured on unsealed anodic oxidation coatings. While corrosion resistance is often increased by sealing the coating, it has been observed that sealing or dyeing can reduce the resistance to abrasion by over 50 %.

5.6 The outer surface of the anod...

SCOPE

1.1 This test method quantifies the abrasion resistance of electrolytically formed hard anodic oxidation coatings on a plane, rigid surface of aluminum or aluminum alloy.

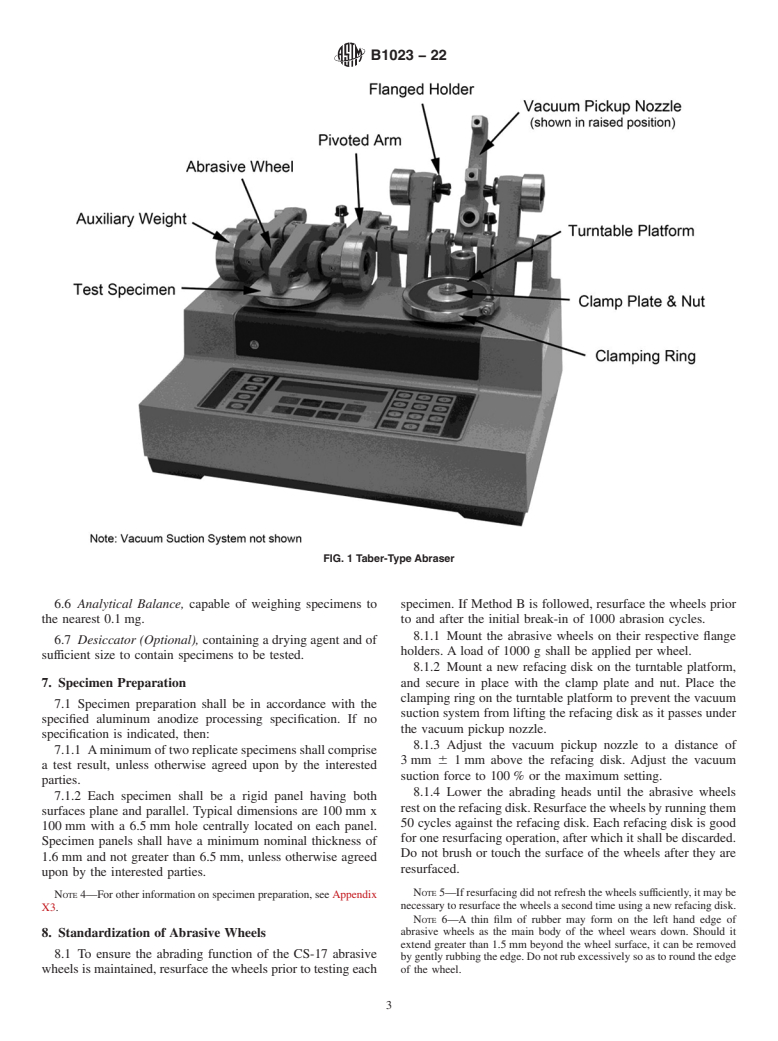

1.2 This test uses a Taber-type abraser,2 which generates a combination of rolling and rubbing to cause wear to the coating surface. Wear is quantified as cumulative mass loss or loss in mass per thousand cycles of abrasion.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1: The procedure described in Method A is similar to MIL-PRF-8625 (paragraph 4.5.5) and SAE AMS 2469 (paragraph 3.3.4). The procedure described in Method B includes a break-in period of 1000 cycles and is similar to ISO 10074 Annex B. When no procedure is specified, Method A shall be the default procedure. Although the procedures described in this method may be similar, they are not equivalent to Specification B893 or Test Method D4060.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B1023 − 22

Standard Test Method for

Abrasion Resistance of Hard Anodic Coatings by a Taber-

1

Type Abraser

This standard is issued under the fixed designation B1023; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B893 Specification for Hard-Coat Anodizing of Magnesium

for Engineering Applications

1.1 This test method quantifies the abrasion resistance of

D4060 Test Method for Abrasion Resistance of Organic

electrolytically formed hard anodic oxidation coatings on a

Coatings by the Taber Abraser

plane, rigid surface of aluminum or aluminum alloy.

E177 Practice for Use of the Terms Precision and Bias in

2

1.2 This test uses a Taber-type abraser, which generates a

ASTM Test Methods

combinationofrollingandrubbingtocauseweartothecoating

E691 Practice for Conducting an Interlaboratory Study to

surface. Wear is quantified as cumulative mass loss or loss in

Determine the Precision of a Test Method

mass per thousand cycles of abrasion.

G195 Guide for Conducting Wear Tests Using a Rotary

Platform Abraser

1.3 Units—The values stated in SI units are to be regarded

4

as standard. No other units of measurement are included in this

2.2 ISO Standard:

standard.

ISO 10074 Specification for Hard Anodic Oxidation Coat-

ings on Aluminium and Its Alloys

NOTE 1—The procedure described in MethodAis similar to MIL-PRF-

5

2.3 SAE Standard:

8625 (paragraph 4.5.5) and SAE AMS 2469 (paragraph 3.3.4). The

procedure described in Method B includes a break-in period of 1000

SAE AMS 2469 Hard Anodic Coating Treatment of Alumi-

cycles and is similar to ISO 10074 Annex B. When no procedure is

num andAluminumAlloys – Processing and Performance

specified, Method A shall be the default procedure. Although the proce-

Requirements

dures described in this method may be similar, they are not equivalent to

6

Specification B893 or Test Method D4060. 2.4 Other Standard:

MIL-PRF-8625 Anodic Coatings for Aluminum and Alumi-

1.4 This standard does not purport to address all of the

num Alloys

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

1.5 This international standard was developed in accor- 3.1.1 For definitions of terms used in this test method, refer

dance with internationally recognized principles on standard-

to Terminology B374.

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 abraser, n—a wear testing instrument that is designed

mendations issued by the World Trade Organization Technical

to determine the resistance of surfaces to composite rolling and

Barriers to Trade (TBT) Committee.

rubbing action, also referred to as an abrader.

2. Referenced Documents 3.2.2 abrasion cycle, n—in abrasion testing, one or more

movements of the abradant across a material surface, or the

3

2.1 ASTM Standards:

material surface across the abradant, that permits a return to its

B374 Terminology Relating to Electroplating

starting position; in the case of a Taber-type abraser test

method, it consists of one complete rotation of the specimen

1

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

turntable platform.

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

Test Methods.

Current edition approved Aug. 1, 2022. Published September 2022. DOI:

4

10.1520/B1023-22. Available from International Organization for Standardization (ISO), ISO

2

Taber is a registered trademark of Taber Industries. Central Secretariat, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Switzerland, https://www.iso.org.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

Standards volume information, refer to the standard’s Document Summary page on PA 15096, http://www.sae.org.

6

the ASTM website. Available from IHS Markit, https://global.ihs.com/.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1023 − 22

3.2.3 resurface, v—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.