ASTM B449-93(2022)

(Specification)Standard Specification for Chromates on Aluminum

Standard Specification for Chromates on Aluminum

ABSTRACT

This specification covers the requirements relating to rinsed and non rinsed chromate conversion coatings on aluminum and aluminum alloys intended to give protection against corrosion and as a base for other coatings. Aluminum and aluminum alloys are chromate coated in order to retard corrosion; as a base for organic films including paints, plastics, and adhesives; and as a protective coating having a low electrical contact impedance. The materials are classified according to its coating thickness: Class 1; Class 2; Class 3; and Class 4. Chromate conversion coatings are normally applied by dipping: the coating may also be applied by inundation, spraying, roller coating, or by wipe-on techniques.

SCOPE

1.1 This specification covers the requirements relating to rinsed and nonrinsed chromate conversion coatings on aluminum and aluminum alloys intended to give protection against corrosion and as a base for other coatings. This edition of the specification has been coordinated with ISO/DIS 10546 and is technically equivalent.

1.2 Aluminum and aluminum alloys are chromate coated in order to retard corrosion; as a base for organic films including paints, plastics, and adhesives; and as a protective coating having a low electrical contact impedance.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B449 −93 (Reapproved 2022)

Standard Specification for

Chromates on Aluminum

This standard is issued under the fixed designation B449; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope B767 Guide for Determining Mass Per Unit Area of Elec-

trodeposited and Related Coatings by Gravimetric and

1.1 This specification covers the requirements relating to

Other Chemical Analysis Procedures

rinsed and nonrinsed chromate conversion coatings on alumi-

D1730 Practices for Preparation of Aluminum and

num and aluminum alloys intended to give protection against

Aluminum-Alloy Surfaces for Painting

corrosion and as a base for other coatings. This edition of the

D3359 Test Methods for Rating Adhesion by Tape Test

specification has been coordinated with ISO/DIS 10546 and is

2.2 ISO Standards:

technically equivalent.

ISO 2409 Paint and Varnishes—Cross-Cut Test

1.2 Aluminum and aluminum alloys are chromate coated in

ISO 3768 Metallic Coatings—Neutral Salt Spray Test (NSS

order to retard corrosion; as a base for organic films including

Test)

paints, plastics, and adhesives; and as a protective coating

ISO 3892 Conversion Coatings on Metallic Materials—

having a low electrical contact impedance.

Determination of Mass Per Unit Area—Gravimetric

1.3 The values stated in SI units are to be regarded as

Method

standard. No other units of measurement are included in this

ISO 4519 Electrodeposited Metallic Coatings and Related

standard.

Finishes—Sampling Procedures for Inspection by Attri-

butes

1.4 This standard does not purport to address all of the

ISO/DIS 10546 Chemical Conversion Coatings—Rinsed

safety concerns, if any, associated with its use. It is the

and Nonrinsed Chromate Conversion Coatings—On Alu-

responsibility of the user of this standard to establish appro-

minum and Aluminum Alloys

priate safety, health, and environmental practices and deter-

2.3 Federal Standard:

mine the applicability of regulatory limitations prior to use.

Fed. Std. No. 141 Paints, Varnish, Lacquer, and Related

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- Materials; Methods of Inspection

ization established in the Decision on Principles for the

2.4 Military Specification:

Development of International Standards, Guides and Recom-

MIL-DTL-5541 Chemical Films forAluminum andAlumi-

mendations issued by the World Trade Organization Technical

num Alloys

Barriers to Trade (TBT) Committee.

3. Terminology

2. Referenced Documents

3.1 Definitions:

3.1.1 nonrinsed—chromate coatings that are dried immedi-

2.1 ASTM Standards:

ately after the chromating step without receiving a water rinse.

B117 Practice for Operating Salt Spray (Fog) Apparatus

3.1.1.1 Discussion—This special type of coating is typically

B602 Guide for Attribute Sampling of Metallic and Inor-

used on long coils of aluminum sheet stock that receive an

ganic Coatings

immediate subsequent paint or adhesive coating.

NOTE 1—Nonrinsed chromate coatings are finding increased usage on

1 fabricated parts and castings.

This specification is under the jurisdiction of ASTM Committee B08 on

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

3.1.2 rinsed—chromate coatings that are rinsed in water

B08.07 on Conversion Coatings.

prior to drying.

Current edition approved Oct. 1, 2022. Published October 2022. Originally

approvedin1967.Lastpreviouseditionapprovedin2015asB449 – 93(2015).DOI:

10.1520/B0449-93R22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

the ASTM website. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B449 − 93 (2022)

3.1.2.1 Discussion—Thistypeofcoatingistypicallyapplied 6.2 Chromate conversion coatings are normally applied by

to extruded aluminum fabricated parts and castings. dipping: the coating may also be applied by inundation,

spraying, roller coating, or by wipe-on techniques. The appli-

4. Classification

cation method used should be taken from the operating

instructions for the chromating process employed. Chromating

4.1 Chromate finishes can be applied ranging in color from

solutions are usually acidic and may contain hexavalent

brown, thick coatings (Class 1) providing maximum corrosion

chromium salts together with other salts that may be varied to

protection to yellow, intermediate thickness coatings (Class 2)

affect the appearance and hardness of the film.The color of the

suitable as an organic film base or to colorless, thin coatings

film,and,therefore,thetypeofconversioncoating,dependson

(Class 3) suitable for low electrical contact resistance. The

the composition of the chromating solution, but it is also

yellow coatings vary from golden yellow to iridescent light

affected by the pH and temperature, the duration of the

yellow. Chromate-phosphate finishes (Class 4) can be applied

treatment, and the nature and surface condition of the alloy

ranging in color from green to iridescent light green.The Class

being treated.

4 coatings comply with the requirements of MIL-DTL-5541.

6.3 These coatings receive a final water rinse. If the coating

4.2 Finishers can seldom guarantee to supply exact shades

is meant to be a basis for additional coatings, the detail shall be

ofcolorwithchromateconversioncoatings.Ifitisnecessaryto

subject to a rinse in deionized water with a conductivity less

have exact shades of color, it is possible to dye chromate

2 than 100t µS/cm. If hot water is used as the final rinse after the

coatings having a coating mass greater than 0.4 g/m to obtain

chromating process, it is essential that the time of rinsing

a wide range of colors, but they can only be expected to give

should be kept as short as possible in order to prevent the

an order of added corrosion resistance similar to that provided

dissolution of the hexavalent chromium. The drying of the

by the undyed coatings. It should be noted that color and color

coating shall be carried out at a temperature not exceeding

uniformity will vary somewhat between one alloy and another

60°Ctopreventcrackingduetodehydration,whichcausesloss

and from a polished surface to an etched surface. Iridescence

of adhesion and performance of the chromate coating.

and variations in color density from one area of the surface to

6.4 Any additional subsequent treatments depend upon the

another are normal and shall not be considered a sign of poor

purpose for which the chromated parts are intended.

quality.

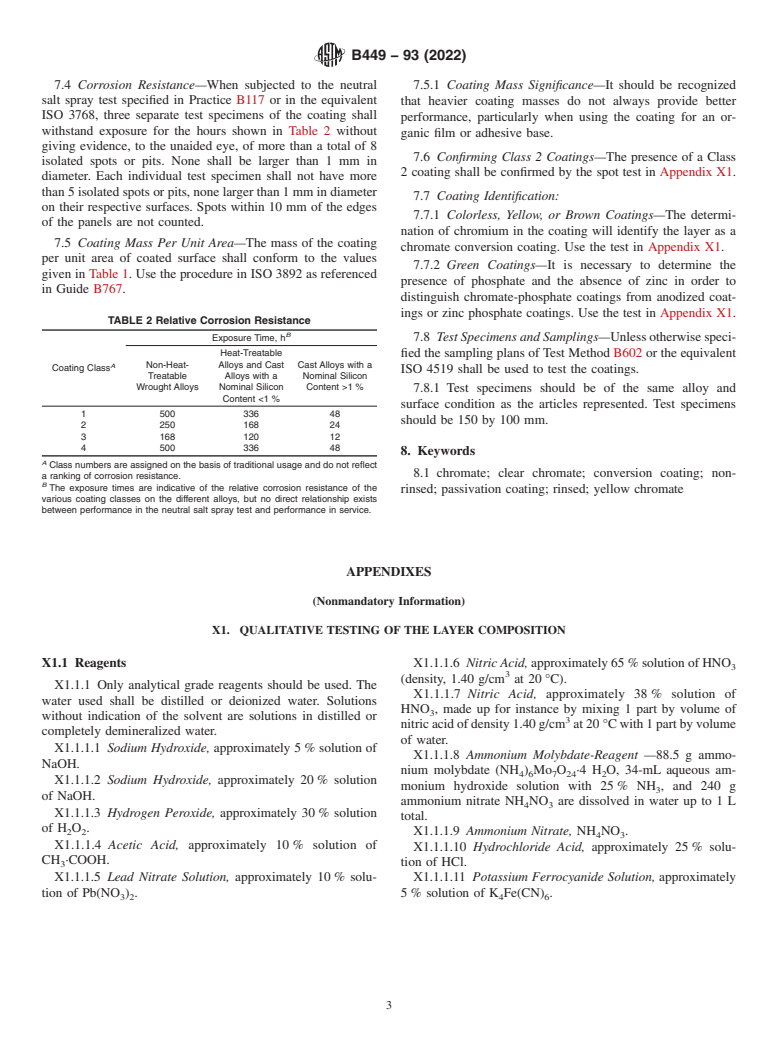

4.3 The finishes are divided into four classes; their most 7. Coating Requirements

important characteristics are listed in Table 1.

7.1 General—Chromate conversion coatings harden with

agebygradualdehydration.Theyshould,therefore,behandled

5. Surfaces Preparation

carefully for the first 24 h after treatment, and any tests

5.1 The surfaces of the parts to be chromated must be clean (including corrosion tests) shall be deferred until the expiration

andfreeofanyoxidation,scale,orsoilssuchasmetalturnings, of that period. The green chromate-phosphate coatings usually

grinding dust, oil, grease, lubricants, hand-sweat, or any other continue to improve in corrosion resistance after initial forma-

contaminationdetrimentaltothechromatingprocess.Theparts

tion. They achieve their maximum corrosion resistance after 1

must therefore, as far as necessary, be cleaned before chromat- to 2 months at room temperature. It is not required to store

ing and if necessary be pickled. Fig. X2.1 shows the various

parts for this purpose.

processing step options.

7.2 Electrical Resistance—Colorless, light yellow, or light

green iridescent chromate layers of low mass per unit area

6. Methods of Application of Chromate Coatings

increase the electrical resistance between an electrical contact

6.1 Metallic material other than aluminum should not be and the aluminum to a very small extent. When measured at

treated with the parts to be chromated. 9-V and a 2-Acurrent the resistance should be less than 0.1Ω.

Highly colored brown, yellow, or green coatings show a

marked increase in electrical contact resistance with increasing

mass per unit area of the chromate layer and may reach

TABLE 1 Classification of Chromate Coatings

resistances of 10 000Ω or more.

Coating Mass per

A

Class Appearance Corrosion Protection

2 7.3 Adhesion—The coatings shall be adherent and non-

Unit Area, g/m

powdery. There are no p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.