ASTM F1045-07(2013)

(Specification)Standard Performance Specification for Ice Hockey Helmets

Standard Performance Specification for Ice Hockey Helmets

SCOPE

1.1 This performance specification2 covers performance requirements for ice hockey helmets.

1.2 The intent of this performance specification is to reduce the risk of injury to the head without compromising the form and appeal of the game.

1.3 This performance specification covers: (1) performance tests for shock absorption properties of the complete helmet and strength and elongation of the chin strap and its attachment; and (2) requirements for area of coverage and penetration.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 The following precautionary caveat pertains only to the test methods portion, Section 12, of this performance specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1045 −07(Reapproved 2013) An American National Standard

Standard Performance Specification for

Ice Hockey Helmets

This standard is issued under the fixed designation F1045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Ice hockey is a contact sport with intrinsic hazards. The use of protective equipment will not

eliminateallinjuriesbutshouldsubstantiallyreducetheseverityandfrequencyofinjury.Participation

in the sport of ice hockey by a player implies acceptance of some risk of injury. The goal is to

minimize this risk.

Thisperformancespecificationforheadprotectiveequipmenthasbeenpreparedafterconsideration

of head protection relative to the following principle risks: high-mass, low-velocity impact (various

playing situations), and fit. This performance specification may be modified as other risks are

identified.

Performance requirements were determined after consideration of state-of-the-art of helmet design

and manufacture and the demands of the sport.

1. Scope 2. Referenced Documents

1.1 This performance specification covers performance

2.1 ASTM Standards:

requirements for ice hockey helmets.

F513Specification for Eye and Face Protective Equipment

for Hockey Players

1.2 The intent of this performance specification is to reduce

F2220Specification for Headforms

the risk of injury to the head without compromising the form

and appeal of the game.

3. Terminology

1.3 This performance specification covers: (1) performance

3.1 Definitions of Terms Specific to This Standard:

tests for shock absorption properties of the complete helmet

3.1.1 retention system:

and strength and elongation of the chin strap and its attach-

3.1.1.1 chin strap—the chin strap, including a cup that

ment; and (2) requirements for area of coverage and penetra-

tion. covers the chin (see Fig. 1), is affixed to both sides of the

helmet and secures the helmet to the head when a Type I or

1.4 The values stated in SI units are to be regarded as

Type II full face protector is not worn with the helmet.

standard. The values given in parentheses are for information

3.1.1.2 neck strap—theneckstrapthatsecuresthehelmetto

only.

theheadisaffixedonbothsidesofthehelmetandpassesunder

1.5 The following precautionary caveat pertains only to the

the lower jaw in close proximity to the jaw and the neck.

test methods portion, Section 12, of this performance specifi-

Where the helmet is worn with a Type I or Type II full face

cation:This standard does not purport to address all of the

protector,theneckstrapservesastheattachmentofthehelmet

safety concerns, if any, associated with its use. It is the

to the head.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- NOTE 1—For a description of the Type I or Type II face protector, see

the Types of Protectors Section in Safety Specification F513.

bility of regulatory limitations prior to use.

3.1.2 crown—apointinthemedianplanethatisequalchord

lengths from the anterior and posterior intersections of the

median and reference planes.

This performance specification is under the jurisdiction of ASTM Committee

F08 on Sports Equipment, Playing Surfaces, and Facilitiesand is the direct

responsibility of Subcommittee F08.15 on Ice Hockey.

Current edition approved Dec. 1, 2013. Published February 2014. Originally

approved in 1988. Last previous edition approved in 2007 as F1045–07. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/F1045-07R13. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Thisperformancespecificationissubjecttorevisionasindicatedbysubsequent Standards volume information, refer to the standard’s Document Summary page on

injury statistics and subject to review at least every five years. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1045−07 (2013)

FIG. 1 Chin Strap (Includes a Chin Cup)

3.1.3 drop height—the vertical distance between the lowest

point (impact point) of the elevated helmet and the apex of the

impact surface.

3.1.4 g—the dimensionless ratio of the acceleration of the

headform during impact to the acceleration due to gravity.

3.1.4.1 g —the maximum value of g encountered during

max

impact.

3.1.5 helmet—the complete product, including the shell,

liner,chinstrap,includingthecuporneckstrap,andassociated

attachment hardware, assembled with components supplied by

the manufacturer. The helmet is intended to protect the

wearer’s head while participating in ice hockey.

3.1.6 helmet position index (HPI)—the vertical distance

from the brow of the helmet to the basic plane, when the

helmet is placed on a reference headform. The manufacturer

shallspecifythesizeoftheheadformandtheverticaldistance.

3.1.7 liner—the material inside the shell for the purpose of

shock absorption or comfortable fit, or both.

FIG. 3 Test Headform—Basic, Reference, and Misadgittal Planes

3.1.8 Reference Planes:

3.1.8.1 basic plane—an anatomical plane that includes the

superiorrimoftheexternalauditorymeatus(upperedgeofthe

external openings of the ear) and the inferior margin of the

3.1.8.2 coronal plane—an anatomical plane perpendicular

orbit (the lowest point of the floor of the eye socket). The

to both the basic and midsagittal planes and passing through

headforms are marked with the basic plane (see Figs. 2 and 3).

the superior rims of the right and left auditory meatuses. The

transverse plane corresponds to the coronal plane (see Figs. 2

and 3).

3.1.8.3 midsagittal plane—an anatomical plane perpendicu-

lar to the basic plane and containing the midpoint of the line

connecting the notches of the right and left inferior orbital

ridgesandthemidpointofthelineconnectingthesuperiorrims

of the right and left external auditory meatus.The longitudinal

plane corresponds to the midsagittal plane (see Figs. 2 and 3).

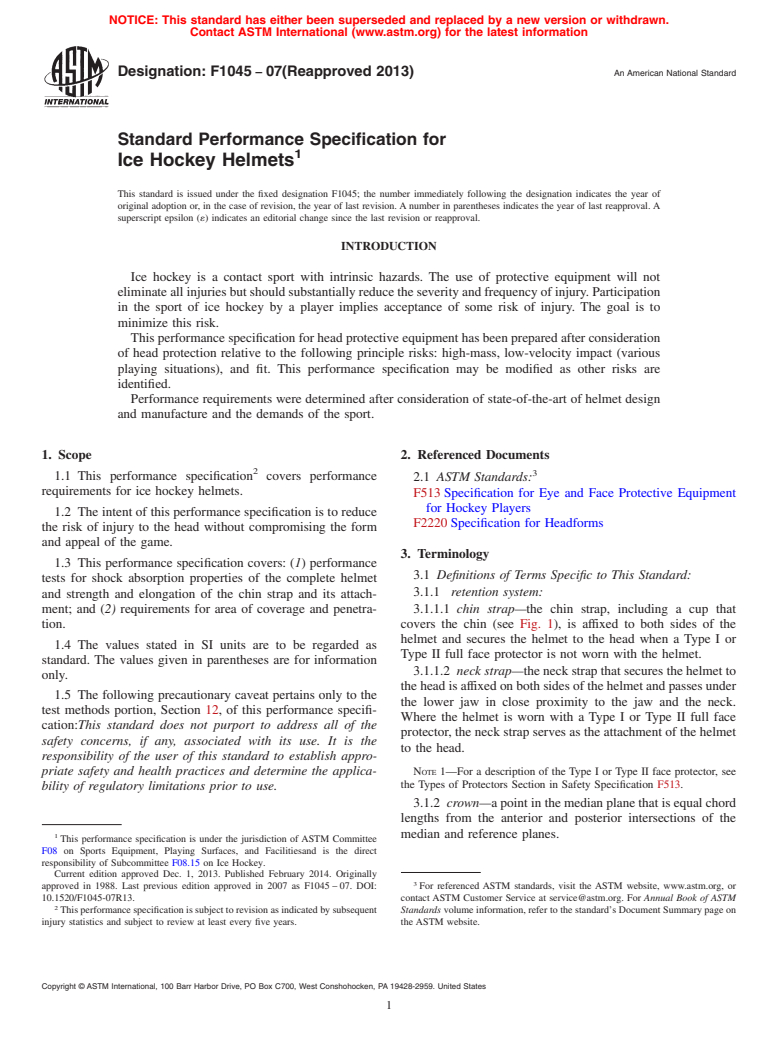

3.1.8.4 reference plane—a plane marked on the headforms

ataspecifieddistanceaboveandparalleltothebasicplane(see

Fig. 4).

3.1.9 shell—therigidoutermaterialthatgivesthehelmetits

form.

4. General Requirements

4.1 Materials:

4.1.1 All materials used in the fabrication of helmets shall

be known to be suitable for the intended application. For

example, shell materials shall remain strong, semirigid, and

firm,andshallnotpermanentlydistortduringanexposureofat

least4htoanytemperatureintherangefrom−27to32°C,nor

shall the material be significantly affected by exposure to

ultraviolet radiation, water, dirt, or vibration. All materials

shall be rot-resistant. In addition, paints, glues, and finishes

used in manufacture shall be compatible with the helmet shell

FIG. 2 Anatomical Planes and shock absorption system materials.

F1045−07 (2013)

correspond to the physical dimensions defined in Specification

F2220 as sizes A, E, J, or M. If a helmet size range, as

identified by the manufacturer’s instructions, is capable of

fitting two different headforms, the larger headform shall be

used.

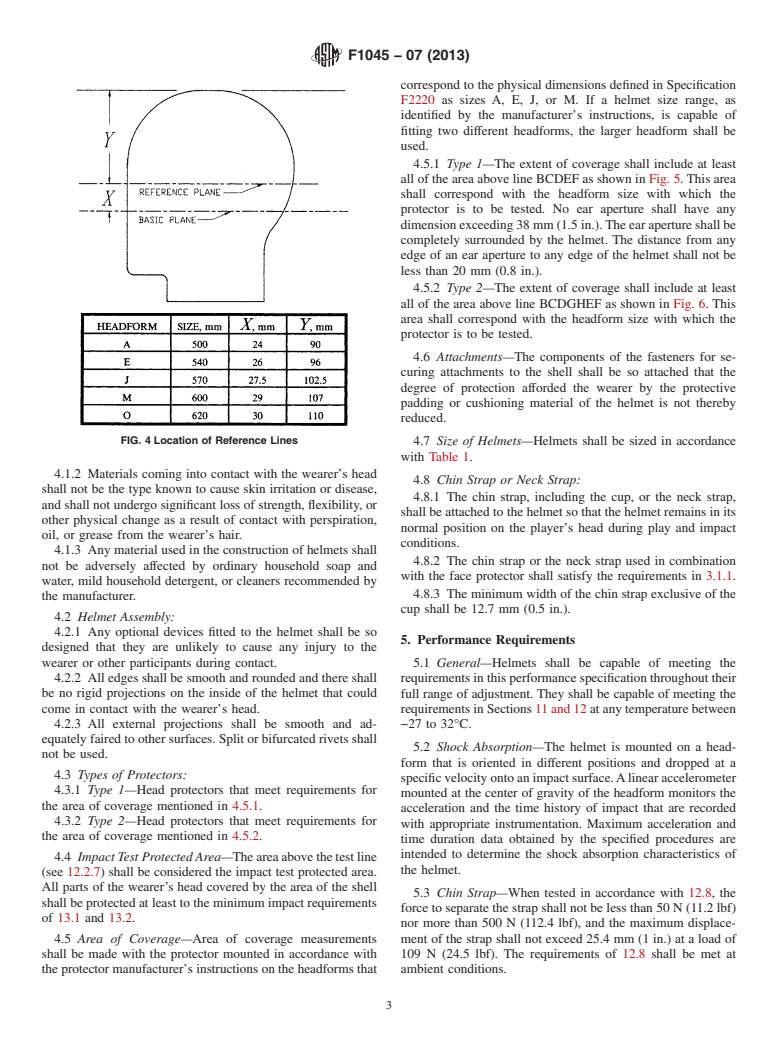

4.5.1 Type 1—The extent of coverage shall include at least

alloftheareaabovelineBCDEFasshowninFig.5.Thisarea

shall correspond with the headform size with which the

protector is to be tested. No ear aperture shall have any

dimensionexceeding38mm(1.5in.).Theearapertureshallbe

completely surrounded by the helmet. The distance from any

edge of an ear aperture to any edge of the helmet shall not be

less than 20 mm (0.8 in.).

4.5.2 Type 2—The extent of coverage shall include at least

all of the area above line BCDGHEF as shown in Fig. 6. This

area shall correspond with the headform size with which the

protector is to be tested.

4.6 Attachments—The components of the fasteners for se-

curing attachments to the shell shall be so attached that the

degree of protection afforded the wearer by the protective

padding or cushioning material of the helmet is not thereby

reduced.

FIG. 4Location of Reference Lines

4.7 Size of Helmets—Helmets shall be sized in accordance

with Table 1.

4.1.2 Materials coming into contact with the wearer’s head

4.8 Chin Strap or Neck Strap:

shall not be the type known to cause skin irritation or disease,

4.8.1 The chin strap, including the cup, or the neck strap,

and shall not undergo significant loss of strength, flexibility, or

shallbeattachedtothehelmetsothatthehelmetremainsinits

other physical change as a result of contact with perspiration,

normal position on the player’s head during play and impact

oil, or grease from the wearer’s hair.

conditions.

4.1.3 Any material used in the construction of helmets shall

4.8.2 The chin strap or the neck strap used in combination

not be adversely affected by ordinary household soap and

with the face protector shall satisfy the requirements in 3.1.1.

water, mild household detergent, or cleaners recommended by

4.8.3 The minimum width of the chin strap exclusive of the

the manufacturer.

cup shall be 12.7 mm (0.5 in.).

4.2 Helmet Assembly:

4.2.1 Any optional devices fitted to the helmet shall be so

5. Performance Requirements

designed that they are unlikely to cause any injury to the

wearer or other participants during contact. 5.1 General—Helmets shall be capable of meeting the

4.2.2 All edges shall be smooth and rounded and there shall requirementsinthisperformancespecificationthroughouttheir

be no rigid projections on the inside of the helmet that could full range of adjustment. They shall be capable of meeting the

come in contact with the wearer’s head. requirementsinSections11and12atanytemperaturebetween

4.2.3 All external projections shall be smooth and ad- −27 to 32°C.

equatelyfairedtoothersurfaces.Splitorbifurcatedrivetsshall

5.2 Shock Absorption—The helmet is mounted on a head-

not be used.

form that is oriented in different positions and dropped at a

4.3 Types of Protectors:

specificvelocityontoanimpactsurface.Alinearaccelerometer

4.3.1 Type 1—Head protectors that meet requirements for

mounted at the center of gravity of the headform monitors the

the area of coverage mentioned in 4.5.1.

acceleration and the time history of impact that are recorded

4.3.2 Type 2—Head protectors that meet requirements for

with appropriate instrumentation. Maximum acceleration and

the area of coverage mentioned in 4.5.2.

time duration data obtained by the specified procedures are

intended to determine the shock absorption characteristics of

4.4 Impact Test ProtectedArea—Theareaabovethetestline

the helmet.

(see 12.2.7) shall be considered the impact test protected area.

All parts of the wearer’s head covered by the area of the shell

5.3 Chin Strap—When tested in accordance with 12.8, the

shallbeprotectedatleasttotheminimumimpactrequirements

forcetoseparatethestrapshallnotbelessthan50N(11.2lbf)

of 13.1 and 13.2.

nor more than 500 N (112.4 lbf), and the maximum displace-

4.5 Area of Coverage—Area of coverage measurements ment of the strap shall not exceed 25.4 mm (1 in.) at a load of

shall be made with the protector mounted in accordance with 109 N (24.5 lbf). The requirements of 12.8 shall be met at

theprotectormanufacturer’sinstructionsontheheadformsthat ambient conditions.

F1045−07 (2013)

NOTE 1—A-Reference plane, B-Coronal plane

FIG. 5Type 1–Area of Coverage

5.4 Penetration Resistance Test Requirements—It shall not 6.1.2.2 System Accuracy—The impact recording system

be possible to touch the test headform with the curved end of shall be capable of measuring shocks of up to 500 g peak

the test stick blade within the required area of coverage, acceleration with an accuracy of 65%.

excluding the ear opening. 6.1.2.3 Impact Recording—The impact shall be recorded on

single- or dual-trace storage oscilloscope with 0.1-mVto 20-V

6. Apparatus

deflectionfactor,1to5-mssweepspeed-division,and500-kHz

bandwidth.

6.1 Shock Absorption Test—The apparatus for the shock

6.1.2.4 Test Headforms—Test headforms that correspond to

absorption test shall consist of the following:

thephysicaldimensionsdefinedinSpecificationF2220assizes

6.1.1 Guide Assembly—The headform shall be attached to

A,E,J,andM.Theweightofthedropassembly,includingthe

the free fall drop assembly carriage by an adjustable mounting

headform, shall be in accordance with 12.4 unless otherwise

that will allow impacts to be delivered to any prescribed point

specified in the individual performance specifications.The test

onthehelmet(seeFig.7).Thecarriageshallbefreetoslideon

headformsshallincludesurfacemarkingscorrespondingtothe

vertical guides. If wires are used, they must be placed under at

basic, coronal, midsagittal, and reference planes (see Figs. 2

least 845.2 N (190 lbf) tension (see 12.4 for guide assembly

and 3).

specifications and allowable weight of drop assembly).

6.1.2.5 Reference Headforms—Measuring headforms con-

6.1.2 Recording Equipment—Therecordingequipmentshall

toured in the same configuration as the test headforms sizesA,

meet the following criteria:

E, J, and M, as defined in Specification F2220. The reference

6.1.2.1 Acceleration Transducer—The linear accelerometer

headformsshallincludesurfacemarkingscorrespondingtothe

is mounted at the center of gravity of the combined test

basic, coronal, midsagittal, and reference planes (see Figs.

headformandcarriageassemblywiththesensitiveaxisaligned

2-4).

to within 5° of the vertical when the helmet and headform are

in the impact position. This transducer shall be capable of

withstandingashockof1000 gwithoutdamageandshallhave

Equivalent instrumentation capable of recording, displaying, and providing a

afrequencyresponse(variation 61.5%)overtherangefrom5

permanent record of the generated accelerometer shock signal will meet this

to 900 Hz. requirement.

F1045−07 (2013)

NOTE 1—A-Reference plane, B-Coronal plane

NOTE 2—Dimension Y and Z are taken and must cover between the reference and the basic plane.

NOTE 3—A-Headform does not have Type 2 coverage.

FIG. 6Type 2–Area of Coverage

TABLE 1 Hat Sizes and Head Fittings

5 Durometer ShoreAHardness impact surface. The base shall

consist of a rigid slab weighing at least 136.1 kg (300 lb). The

NOTE 1—These are U.S. and Canadian hat sizes.

top surface of this base may be used as the flat metal anvil if

Circumference of Head

Hat Size

it is faced with a steel plate with minimum thickness of 25.4

in. mm

2 2

mm (1 in.) and minimum top surface area of 0.09 m (1 ft ). If

6 19 483

1 3

a detachable flat metal anvil is used it must have a top s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.