ASTM E290-14

(Test Method)Standard Test Methods for Bend Testing of Material for Ductility

Standard Test Methods for Bend Testing of Material for Ductility

SIGNIFICANCE AND USE

4.1 Bend tests for ductility provide a simple way to evaluate the quality of materials by their ability to resist cracking or other surface irregularities during one continuous bend. No reversal of the bend force shall be employed when conducting these tests.

4.2 The type of bend test used determines the location of the forces and constraints on the bent portion of the specimen, ranging from no direct contact to continuous contact.

4.3 The test can terminate at a given angle of bend over a specified radius or continue until the specimen legs are in contact. The bend angle can be measured while the specimen is under the bending force (usually when the semi-guided bend test is employed), or after removal of the force as when performing a free-bend test. Product requirements for the material being tested determine the method used.

4.4 Materials with an as-fabricated cross section of rectangular, round, hexagonal, or similar defined shape can be tested in full section to evaluate their bend properties by using the procedures outlined in these test methods, in which case relative width and thickness requirements do not apply.

SCOPE

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the specimen is bent, while in contact with a mandrel, through a specified angle or to a specified inside radius (r) of curvature, measured while under the bending force; a free-bend test in which the ends of the specimen are brought toward each other, but in which no transverse force is applied to the bend itself and there is no contact of the concave inside surface of the bend with other material; a bend and flatten test, in which a transverse force is applied to the bend such that the legs make contact with each other over the length of the specimen.

1.2 After bending, the convex surface of the bend is examined for evidence of a crack or surface irregularities. If the specimen fractures, the material has failed the test. When complete fracture does not occur, the criterion for failure is the number and size of cracks or surface irregularities visible to the unaided eye occurring on the convex surface of the specimen after bending, as specified by the product standard. Any cracks within one thickness of the edge of the specimen are not considered a bend test failure. Cracks occurring in the corners of the bent portion shall not be considered significant unless they exceed the size specified for corner cracks in the product standard.

1.3 The values stated in SI units are to be regarded as standard. Inch-pound values given in parentheses were used in establishing test parameters and are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E290 − 14

Standard Test Methods for

1

Bend Testing of Material for Ductility

This standard is issued under the fixed designation E290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods cover bend testing for ductility of

materials. Included in the procedures are four conditions of

2. Referenced Documents

constraint on the bent portion of the specimen; a guided-bend

2

2.1 ASTM Standards:

test using a mandrel or plunger of defined dimensions to force

E6 Terminology Relating to Methods of Mechanical Testing

themid-lengthofthespecimenbetweentwosupportsseparated

E8/E8M Test Methods for Tension Testing of Metallic Ma-

by a defined space; a semi-guided bend test in which the

terials

specimen is bent, while in contact with a mandrel, through a

E18 Test Methods for Rockwell Hardness of Metallic Ma-

specified angle or to a specified inside radius (r) of curvature,

terials

measured while under the bending force; a free-bend test in

E190 Test Method for Guided Bend Test for Ductility of

which the ends of the specimen are brought toward each other,

Welds

but in which no transverse force is applied to the bend itself

and there is no contact of the concave inside surface of the

3. Summary of Test Methods

bend with other material; a bend and flatten test, in which a

3.1 Four methods for ductility testing employing bending

transverse force is applied to the bend such that the legs make

are included in these test methods. Three methods have

contact with each other over the length of the specimen.

subgroups with specific procedures.

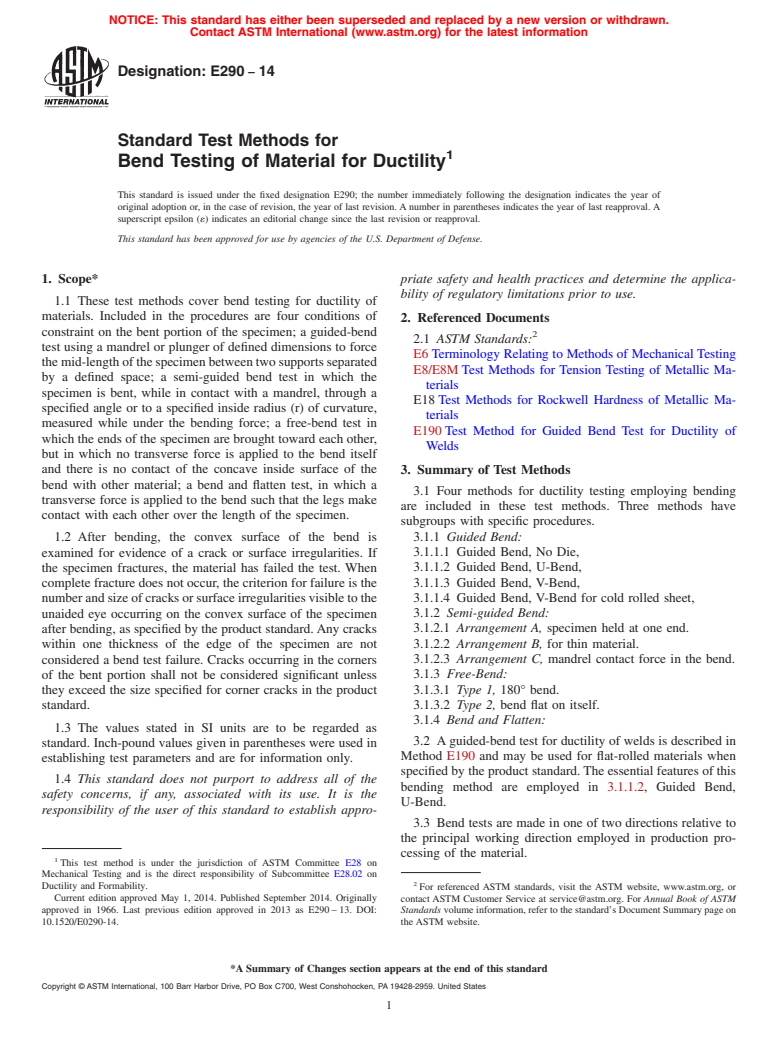

1.2 After bending, the convex surface of the bend is 3.1.1 Guided Bend:

examined for evidence of a crack or surface irregularities. If 3.1.1.1 Guided Bend, No Die,

3.1.1.2 Guided Bend, U-Bend,

the specimen fractures, the material has failed the test. When

complete fracture does not occur, the criterion for failure is the 3.1.1.3 Guided Bend, V-Bend,

3.1.1.4 Guided Bend, V-Bend for cold rolled sheet,

numberandsizeofcracksorsurfaceirregularitiesvisibletothe

unaided eye occurring on the convex surface of the specimen 3.1.2 Semi-guided Bend:

3.1.2.1 Arrangement A, specimen held at one end.

after bending, as specified by the product standard.Any cracks

within one thickness of the edge of the specimen are not 3.1.2.2 Arrangement B, for thin material.

3.1.2.3 Arrangement C, mandrel contact force in the bend.

considered a bend test failure. Cracks occurring in the corners

of the bent portion shall not be considered significant unless 3.1.3 Free-Bend:

3.1.3.1 Type 1, 180° bend.

they exceed the size specified for corner cracks in the product

standard. 3.1.3.2 Type 2, bend flat on itself.

3.1.4 Bend and Flatten:

1.3 The values stated in SI units are to be regarded as

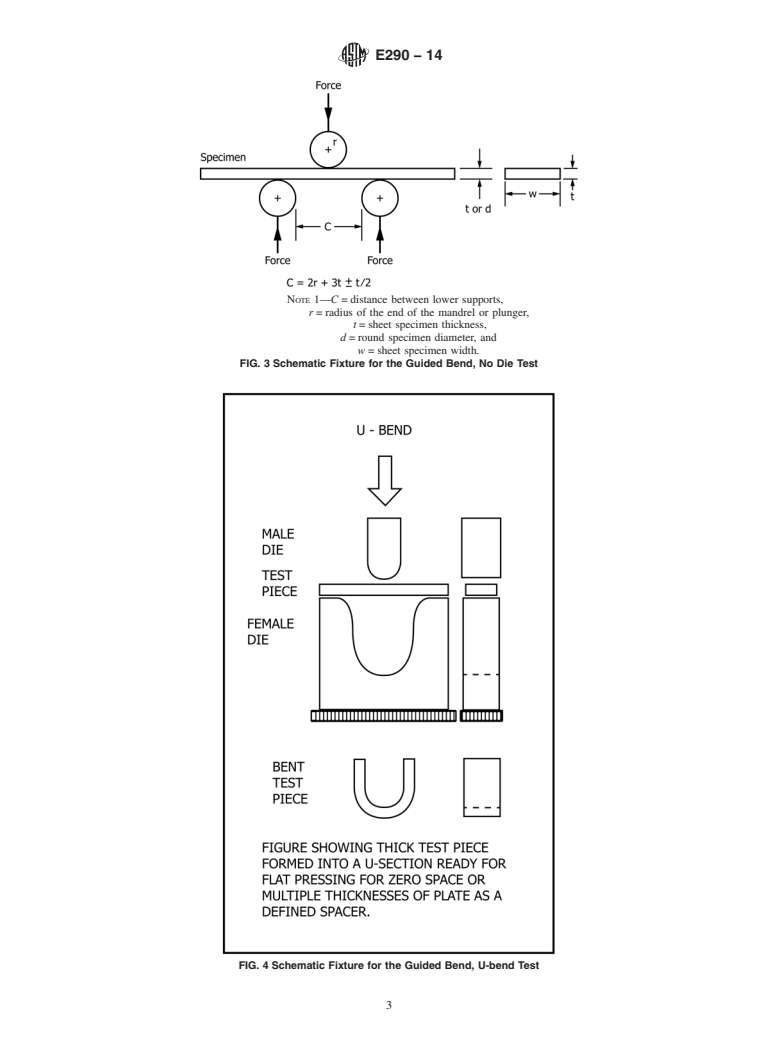

3.2 Aguided-bend test for ductility of welds is described in

standard. Inch-pound values given in parentheses were used in

Method E190 and may be used for flat-rolled materials when

establishing test parameters and are for information only.

specified by the product standard. The essential features of this

1.4 This standard does not purport to address all of the

bending method are employed in 3.1.1.2, Guided Bend,

safety concerns, if any, associated with its use. It is the

U-Bend.

responsibility of the user of this standard to establish appro-

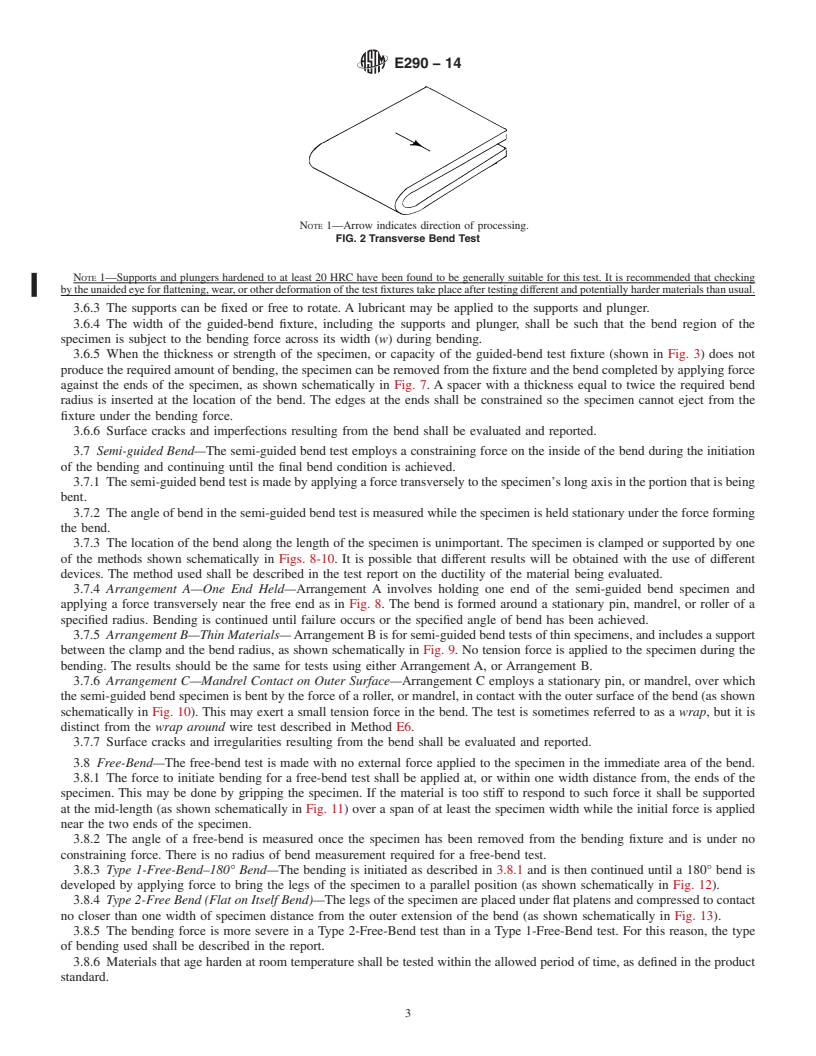

3.3 Bend tests are made in one of two directions relative to

the principal working direction employed in production pro-

cessing of the material.

1

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

2

Ductility and Formability. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2014. Published September 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1966. Last previous edition approved in 2013 as E290 – 13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0290-14. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E290 − 14

3.3.1 Longitudinal tests use a specimen with its long dimen-

sion aligned with the processing direction

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E290 − 13 E290 − 14

Standard Test Methods for

1

Bend Testing of Material for Ductility

This standard is issued under the fixed designation E290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint

on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length

of the specimen between two supports separated by a defined space; a semi-guided bend test in which the specimen is bent, while

in contact with a mandrel, through a specified angle or to a specified inside radius (r) of curvature, measured while under the

bending force; a free-bend test in which the ends of the specimen are brought toward each other, but in which no transverse force

is applied to the bend itself and there is no contact of the concave inside surface of the bend with other material; a bend and flatten

test, in which a transverse force is applied to the bend such that the legs make contact with each other over the length of the

specimen.

1.2 After bending, the convex surface of the bend is examined for evidence of a crack or surface irregularities. If the specimen

fractures, the material has failed the test. When complete fracture does not occur, the criterion for failure is the number and size

of cracks or surface irregularities visible to the unaided eye occurring on the convex surface of the specimen after bending, as

specified by the product standard. Any cracks within one thickness of the edge of the specimen are not considered a bend test

failure. Cracks occurring in the corners of the bent portion shall not be considered significant unless they exceed the size specified

for corner cracks in the product standard.

1.3 The values stated in SI units are to be regarded as standard. Inch-pound values given in parentheses were used in

establishing test parameters and are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E190 Test Method for Guided Bend Test for Ductility of Welds

3. Summary of Test Methods

3.1 Four methods for ductility testing employing bending are included in these test methods. Three methods have subgroups

with specific procedures.

3.1.1 Guided Bend:

3.1.1.1 Guided Bend, No Die,

3.1.1.2 Guided Bend, U-Bend,

3.1.1.3 Guided Bend, V-Bend,

3.1.1.4 Guided Bend, V-Bend for cold rolled sheet,

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on Ductility and

Formability.

Current edition approved April 1, 2013May 1, 2014. Published May 2013September 2014. Originally approved in 1966. Last previous edition approved in 20092013 as

E290 – 09.E290 – 13. DOI: 10.1520/E0290-13.10.1520/E0290-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E290 − 14

3.1.2 Semi-guided Bend:

3.1.2.1 Arrangement A, specimen held at one end.

3.1.2.2 Arrangement B, for thin material.

3.1.2.3 Arrangement C, mandrel contact force in the bend.

3.1.3 Free-Bend:

3.1.3.1 Type 1, 180° bend.

3.1.3.2 Type 2, bend flat on itself.

3.1.4 Bend and Flatten:

3.2 A guided-bend test for ductility of welds is described in Method E190 and may be used for flat-rolled materials when

specified by the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.