ASTM E147-61(1996)

(Specification)Standard Specification for Apparatus For Microdetermination Of Nitrogen By Kjeldahl Method

Standard Specification for Apparatus For Microdetermination Of Nitrogen By Kjeldahl Method

SCOPE

1.1 This specification covers digestion and distillation apparatus used for the microdetermination of nitrogen by the Kjeldahl method, and modifications thereof at atmospheric pressure.

Note 1—This specification is based on those originally developed by the Committee on Microchemical Apparatus, Division of Analytical Chemistry, American Chemical Society.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 147 – 61 (Reapproved 1996)

Standard Specification for

Apparatus For Microdetermination Of Nitrogen By Kjeldahl

Method

This standard is issued under the fixed designation E 147; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Digestion Flasks

1. Scope

Capacity, mL Figure Use

1.1 This specification covers digestion and distillation ap-

10 1 with digests of 1 mL or less

paratus used for the microdetermination of nitrogen by the

30 2 with digests of 1 to 4 mL

Kjeldahl method, and modifications thereof at atmospheric

30 (Soltys) 3 with digests of 1 to 4 mL when

pressure.

danger of spattering is

great.

NOTE 1—This specification is based on those originally developed by

the Committee on Microchemical Apparatus, Division of Analytical

Chemistry, American Chemical Society.

support, and a fume duct. The rack shall be supplied with a heat

deflector mounted under the burners to prevent overheating of

2. Referenced Documents

the bench top.

2.1 ASTM Standards:

5.1.1 Heaters—The source of heat may be either electric or

E 124 Specification for Weighing and Drying Apparatus for

gas. In operation, each heater shall supply sufficient heat to a

Microchemical Analysis

30-mL flask to cause 15 mL of water at 25°C to come to a

rolling boil in not less than 2 or more than 3 min. A device shall

3. Tolerances

be provided for regulating the amount of heat supplied to the

3.1 The following commercial length tolerance shall be

flask so that these conditions can be met. The amount of heat

adhered to, unless otherwise specified:

supplied to the flasks also shall be so adjustable that low-

Up to 10 mm 61mm

temperature digestions are possible. Switches and controls

10 to 100 mm 62mm

100 to 200 mm 63mm

200 mm 64mm

4. Digestion Flasks

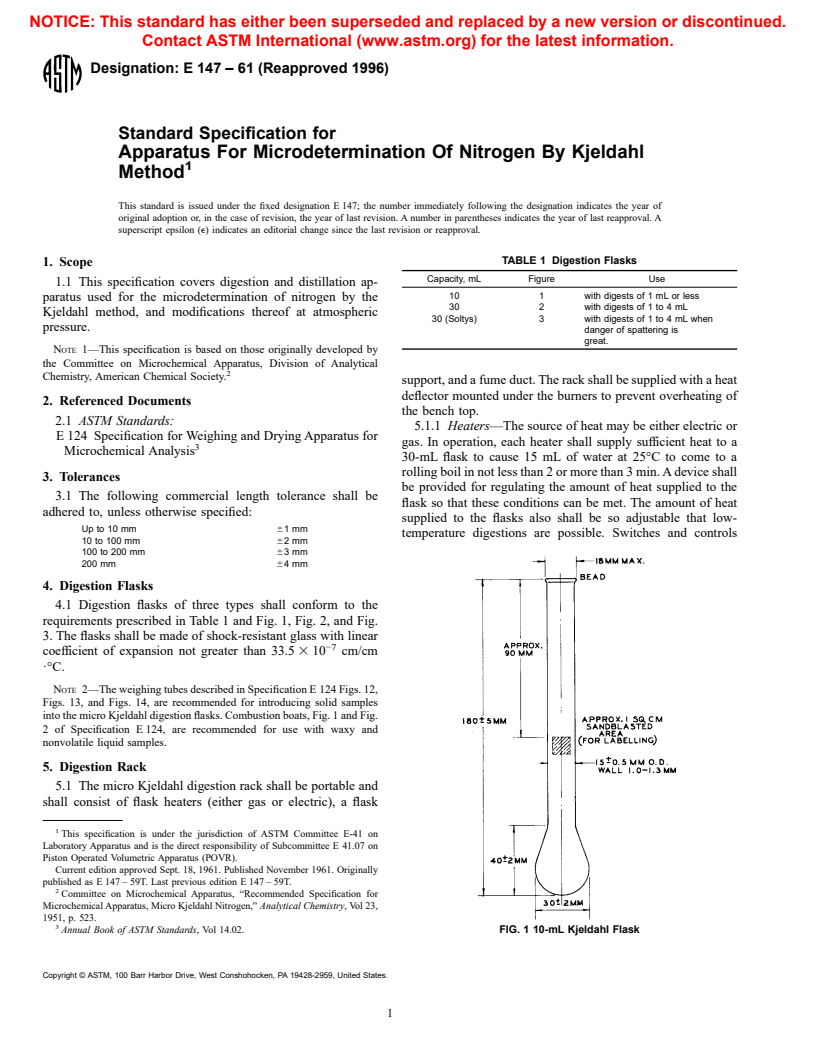

4.1 Digestion flasks of three types shall conform to the

requirements prescribed in Table 1 and Fig. 1, Fig. 2, and Fig.

3. The flasks shall be made of shock-resistant glass with linear

−7

coefficient of expansion not greater than 33.5 3 10 cm/cm

·°C.

NOTE 2—The weighing tubes described in Specification E 124 Figs. 12,

Figs. 13, and Figs. 14, are recommended for introducing solid samples

into the micro Kjeldahl digestion flasks. Combustion boats, Fig. 1 and Fig.

2 of Specification E 124, are recommended for use with waxy and

nonvolatile liquid samples.

5. Digestion Rack

5.1 The micro Kjeldahl digestion rack shall be portable and

shall consist of flask heaters (either gas or electric), a flask

This specification is under the jurisdiction of ASTM Committee E-41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E 41.07 on

Piston Operated Volumetric Apparatus (POVR).

Current edition approved Sept. 18, 1961. Published November 1961. Originally

published as E 147 – 59T. Last previous edition E 147 – 59T.

Committee on Microchemical Apparatus, “Recommended Specification for

Microchemical Apparatus, Micro Kjeldahl Nitrogen,” Analytical Chemistry, Vol 23,

1951, p. 523.

Annual Book of ASTM Standards, Vol 14.02. FIG. 1 10-mL Kjeldahl Flask

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 147

shall be conveniently located and shall remain cool enough to

handle even after long periods of operation.

NOTE 3—Boiling chips shall be added when testing the heaters to

minimize superheating, and the burners and rack shall be at equilibrium

temperature.

5.1.2 Flask Support—The support on which the bulbs of the

flasks rest shall shield the necks of the flasks from excessive

heating during digestion and shall be provided with circular

openings not exceeding 26 mm in diameter, centered over each

heater.

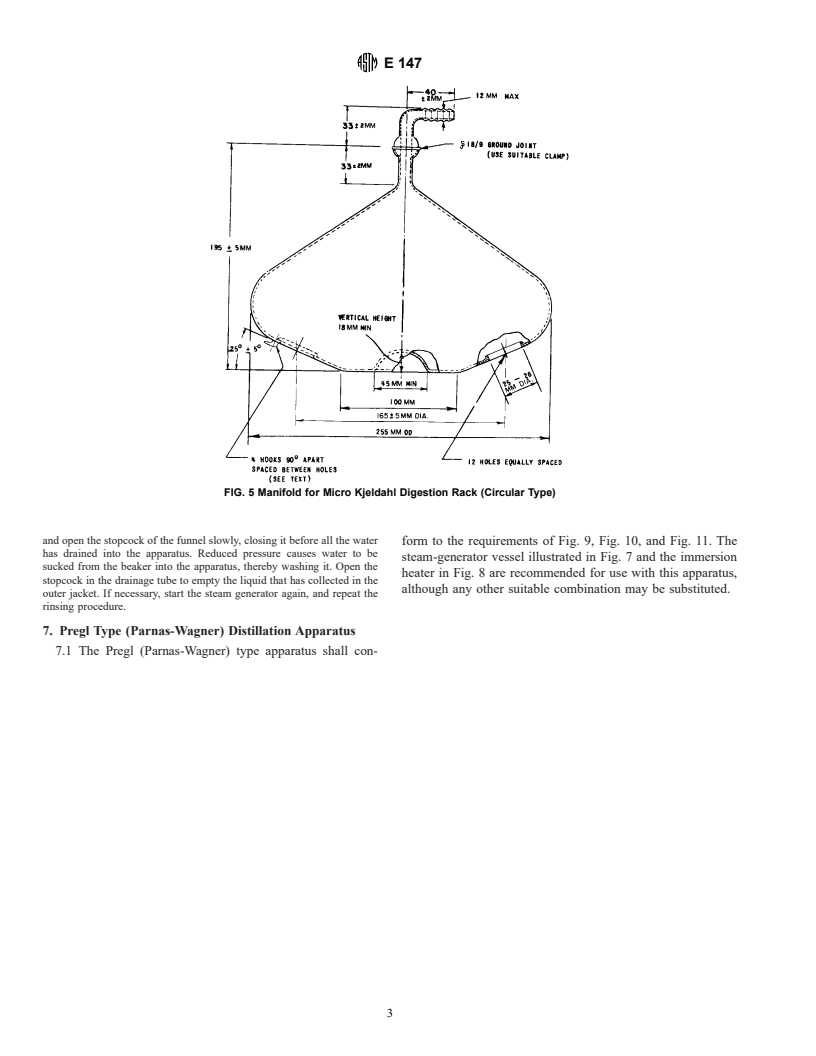

5.1.3 Fume Duct—The fume duct shall provide means for

adequately removing the fumes evolved during the digestion

and shall support the necks of the flasks at an angle greater than

35° to the horizontal. Fume ducts meeting these specifications

are shown in Fig. 4 and Fig. 5. The fume duct illustrated in Fig.

4 is supported and held in place by suitable clamps mounted at

either end of the digestion rack. The fume duct in Fig. 5 rests

upon a circular support plate and is held in place by springs

from the plate to the four glass hooks. The concav

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.