ASTM A254-97(2002)

(Specification)Standard Specification for Copper-Brazed Steel Tubing

Standard Specification for Copper-Brazed Steel Tubing

SCOPE

1.1 This specification covers double-wall, copper-brazed steel tubing suitable for general engineering uses, particularly in the automotive, refrigeration, and stove industries for fuel lines, brake lines, oil lines, heating and cooling units, and the like.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 254 – 97 (Reapproved 2002)

Standard Specification for

Copper-Brazed Steel Tubing

This standard is issued under the fixed designation A 254; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers double-wall, copper-brazed

steel tubing suitable for general engineering uses, particularly

in the automotive, refrigeration, and stove industries for fuel

lines, brake lines, oil lines, heating and cooling units, and the

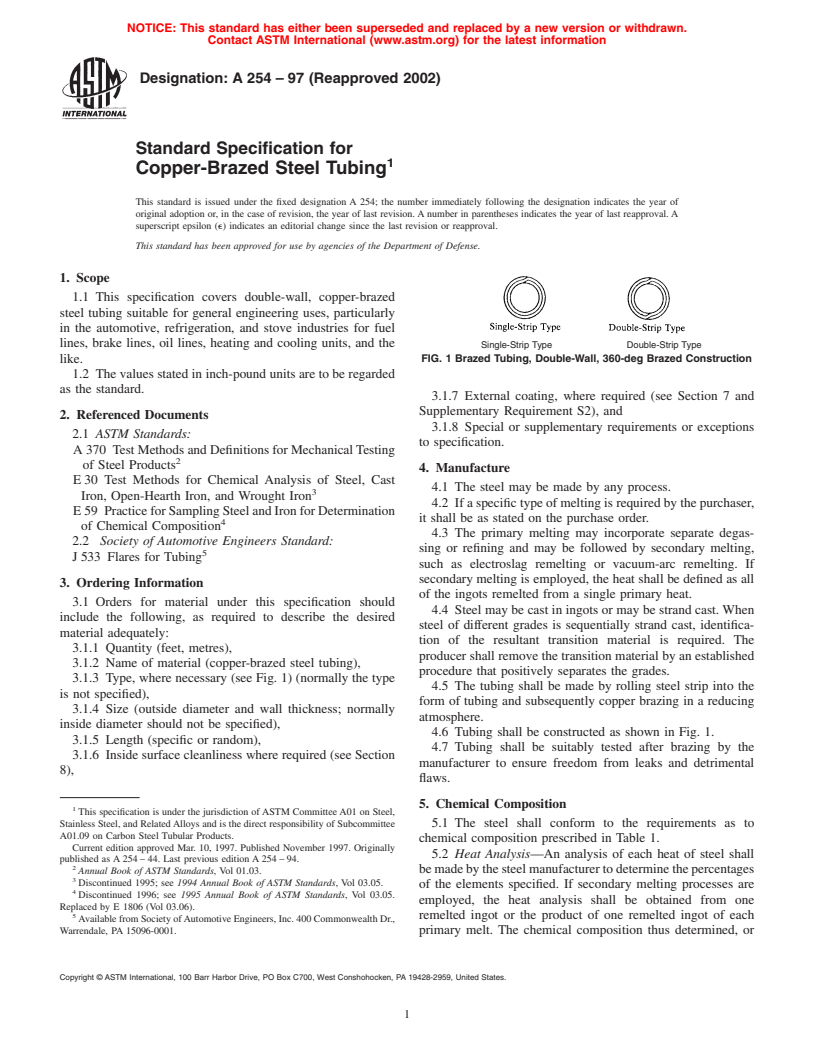

Single-Strip Type Double-Strip Type

like. FIG. 1 Brazed Tubing, Double-Wall, 360-deg Brazed Construction

1.2 The values stated in inch-pound units are to be regarded

as the standard.

3.1.7 External coating, where required (see Section 7 and

Supplementary Requirement S2), and

2. Referenced Documents

3.1.8 Special or supplementary requirements or exceptions

2.1 ASTM Standards:

to specification.

A370 TestMethodsandDefinitionsforMechanicalTesting

of Steel Products

4. Manufacture

E30 Test Methods for Chemical Analysis of Steel, Cast

4.1 The steel may be made by any process.

Iron, Open-Hearth Iron, and Wrought Iron

4.2 Ifaspecifictypeofmeltingisrequiredbythepurchaser,

E59 PracticeforSamplingSteelandIronforDetermination

it shall be as stated on the purchase order.

of Chemical Composition

4.3 The primary melting may incorporate separate degas-

2.2 Society of Automotive Engineers Standard:

sing or refining and may be followed by secondary melting,

J533 Flares for Tubing

such as electroslag remelting or vacuum-arc remelting. If

secondary melting is employed, the heat shall be defined as all

3. Ordering Information

of the ingots remelted from a single primary heat.

3.1 Orders for material under this specification should

4.4 Steel may be cast in ingots or may be strand cast.When

include the following, as required to describe the desired

steel of different grades is sequentially strand cast, identifica-

material adequately:

tion of the resultant transition material is required. The

3.1.1 Quantity (feet, metres),

producer shall remove the transition material by an established

3.1.2 Name of material (copper-brazed steel tubing),

procedure that positively separates the grades.

3.1.3 Type, where necessary (see Fig. 1) (normally the type

4.5 The tubing shall be made by rolling steel strip into the

is not specified),

form of tubing and subsequently copper brazing in a reducing

3.1.4 Size (outside diameter and wall thickness; normally

atmosphere.

inside diameter should not be specified),

4.6 Tubing shall be constructed as shown in Fig. 1.

3.1.5 Length (specific or random),

4.7 Tubing shall be suitably tested after brazing by the

3.1.6 Inside surface cleanliness where required (see Section

manufacturer to ensure freedom from leaks and detrimental

8),

flaws.

5. Chemical Composition

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

5.1 The steel shall conform to the requirements as to

A01.09 on Carbon Steel Tubular Products.

chemical composition prescribed in Table 1.

Current edition approved Mar. 10, 1997. Published November 1997. Originally

5.2 Heat Analysis—An analysis of each heat of steel shall

published as A254–44. Last previous edition A254–94.

bemadebythesteelmanufacturertodeterminethepercentages

Annual Book of ASTM Standards, Vol 01.03.

Discontinued 1995; see 1994 Annual Book of ASTM Standards, Vol 03.05.

of the elements specified. If secondary melting processes are

Discontinued 1996; see 1995 Annual Book of ASTM Standards, Vol 03.05.

employed, the heat analysis shall be obtained from one

Replaced by E 1806 (Vol 03.06).

remelted ingot or the product of one remelted ingot of each

AvailablefromSocietyofAutomotiveEngineers,Inc.400CommonwealthDr.,

Warrendale, PA 15096-0001. primary melt. The chemical composition thus determined, or

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 254 – 97 (2002)

TABLE 1 Chemical Requirements

cracking or otherwise showing flaws. (Prior to the expansion

Element Composition, % test, tubing shall be cut off square, edge crowned, and

deburred. It shall be held firmly and squarely in the die, and

Carbon 0.05 to 0.15

Manganese 0.27 to 0.63

punch must be guided on the axis of the tubing.)

Phosphorus, max 0.035

6.4 BendTest—Thefinishedtubingshallstandbendingona

Sulfur, max 0.035

centerline radius equal to three times the tubing outside

diameter without kinking, cracking, or developing other flaws

where proper bending fixtures are used.

that determined from a product analysis made by the tubular

6.5 Pressure Proof Tests—Each tube shall be capable of

product manufacturer shall conform to the requirements speci-

withstanding, without bursting or leaking, either of the follow-

fied.

ing proof tests:

5.3 Product Analysis—Tubing of this quality is commonly

6.5.1 An internal hydrostatic pressure sufficient to subject

produced in rimmed or capped steel which is characterized by

the material to a minimum fiber stress of 16 000 psi (110

a lack of uniformity in its chemical composition. For this

MPa). Hydrostatic pressure shall be determined by the follow-

reason, rejection for product analysis is not appropriate unless

ing formula:

misapplication is clearly indicated.

P 52St/D

5.4 Methods of Analysis—Methods described in Test Meth-

ods E30 shall be used for referee purposes. Due allowance

where:

shall be made for the presence of copper brazing metal.

P = hydrostatic pressure, psi (or MPa),

5.5 Samples for Product Analysis—Except for spectro-

S = allowable fiber stress, 16 000 psi (110 MPa),

graphic analysis, samples shall be taken in accordance with

t = actual wall thickness of tubing, in. (or mm), and

Practice E59.

D = actual outside diameter of tubing, in. (or mm).

6. Mechanical Requirements

6.5.2 An underwater air pressure between 225 and 250 psi

6.1 Tension Test—Tensile properties of tubing as manufac-

(1.55 and 1.73 MPa).

tured(priortocoldworking)shallconformtotherequirements

specified in Table 2.

7. Coating

6.1.1 The specimens and tension tests required shall be

7.1 Tubing may be furnished with a copper coating on the

made in accordance with Test Methods and DefinitionsA370.

inside and outside surfaces, at the option of the manufacturer.

6.1.2 Specimens shall be tested at room temperature.

6.1.3 Test specimens shall be taken from the ends of

8. Inside Surface Cleanliness

finished tubes prior to upsetting, swaging, expanding, or other

8.1 When inside surface cleanliness is specified by the

forming operations, or being cut to length. They shall be

purchaser, tubing for certain uses, such as refrigeration con-

smooth on the ends and free from burrs and flaws.

densers, shall conform to the following requirement for inter-

6.1.4 If any test specimen shows flaws or defective machin-

nal cleanliness:

ing, it may be discarded and another specimen substituted.

8.1.1 When a length of tubing is washed internally with

6.1.5 The yield strength shall be determined as that corre-

redistilled chloroform or redistilled 1,1,1-trichloroethane, the

sponding to a permanent offset of 0.2% of the gage length of

residue remaining upon evaporation of the solvent shall not

the specimen, or a total extension of 0.5% of the gage length

−4 2 2

exceed 1.25 3 10 g/in. (0.194 g/m ) of internal surface. To

under load.

perform the test, pour 100 mL of solvent through the tubing

6.1.6 If the percentage of elongation of any test specimen is

and collect.The total length of tubing tested should not be less

lessthanthatspecifiedandanypartofthefractureismorethan

than40ft(12m),althoughthistotallengthmaybeobtainedby

⁄4 in. (19.0 mm) from the center of the gage length, as

washing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.