ASTM D6109-97e1

(Test Method)Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastic Lumber

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastic Lumber

SCOPE

1.1 These test methods cover the determination of flexural properties of plastic lumber with rectangular or square cross-sections. The test specimens are whole "as manufactured" pieces without any altering or machining of surfaces beyond cutting to length. As such, this is a test method for evaluating the properties of plastic lumber as a product and not a material property test method. Flexural strength cannot be determined for those products that do not break or that do not fail in the extreme outer fiber.

1.2 Test Method A— designed principally for products in the flat or "plank" position.

1.3 Test Method B— designed principally for those materials in the edgewise or "joist" position.

1.4 Plastic lumber is currently made predominately with recycled plastics where the product is non-homogeneous in the cross-section. However, this test method would also be applicable to similar manufactured plastic products made from virgin resins or other plastic composite materials.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulator limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

Designation:D 6109–97

Standard Test Methods for

Flexural Properties of Unreinforced and Reinforced Plastic

Lumber

This standard is issued under the fixed designation D 6109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorially corrected 1.1 in April 2002.

1. Scope D 883 Terminology Relating to Plastics

D 4000 Classification System for Specifying Plastic Mate-

1.1 These test methods cover the determination of flexural

rials

properties of plastic lumber with rectangular or square cross-

D5033 GuidefortheDevelopmentofStandardsRelatingto

sections. The test specimens are whole “as manufactured”

the Proper Use of Recycled Plastics

pieces without any altering or machining of surfaces beyond

D 5947 Test Methods for Physical Dimensions of Solid

cutting to length. As such, this is a test method for evaluating

Plastics Specimens

the properties of plastic lumber as a product and not a material

E4 Practices for Force Verification of Testing Machines

property test method. Flexural strength cannot be determined

for those products that do not break or that do not fail in the

3. Terminology

extreme outer fiber.

3.1 Definitions: Definitions of terms applying to these test

1.2 Test Method A—designedprincipallyforproductsinthe

methods appear in Terminology D883D 883 and Guide

flat or “plank” position.

D5033D 5033.

1.3 Test Method B—designedprincipallyforthosematerials

3.1.1 plastic lumber, n—a manufactured product composed

in the edgewise or “joist” position.

ofmorethan50weightpercentresin,andinwhichtheproduct

1.4 Plastic lumber is currently made predominately with

generally is rectangular in cross-section and typically supplied

recycledplasticswheretheproductisnon-homogeneousinthe

in board and dimensional lumber sizes, may be filled or

cross-section. However, this test method would also be appli-

unfilled, and may be composed of single or multiple resin

cable to similar manufactured plastic products made from

blends.

virgin resins or other plastic composite materials.

3.1.2 plastic shape, n—a manufactured product composed

1.5 Thevaluesstatedininch–poundunitsaretoberegarded

ofmorethan50weightpercentresin,andinwhichtheproduct

as the standard. The values given in parentheses are for

generally is not rectangular in cross-section, may be filled or

information only.

unfilled, and may be composed of single or multiple resin

1.6 This standard does not purport to address all of the

blends.

safety concerns, if any, associated with its use. It is the

3.1.3 resin, n—solid or pseudosolid organic material often

responsibility of the user of this standard to establish appro-

of high molecular weight, that exhibits a tendency to flow

priate safety and health practices and determine the applica-

when subjected to stress, usually has a softening or melting

bility of regulator limitations prior to use.

range, and usually fractures conchoidally. (See Terminology

NOTE 1—There is no similar or equivalent ISO standard.

D883D 883.)

3.1.3.1 Discussion—In a broad sense, the term is used to

2. Referenced Documents

designate any polymer that is a basic material for plastics.

2.1 ASTM Standards:

D 198 Methods of Static Tests of Lumber in Structural 4. Summary of Test Method

Sizes

4.1 A specimen of rectangular cross section is tested in

D 618 Practice for Conditioning Plastics for Testing

flexure as a beam as follows:

4.1.1 The bar rests on two supports and is loaded at two

points(bymeansoftwoloadingnoses),eachanequaldistance

These test methods are under the jurisdiction of ASTM Committee D-20 on

Plastics and are the direct responsibility of Subcommittee D20.20 on Plastic

Products (Section D20.20.01).

Current edition approved July 10, 1997. Published February 1998. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 08.03.

3 6

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

D 6109–97

from the adjacent support point. The distance between the loading nose in contact with the specimen shall be sufficiently

loadingnoses(thatis,theloadspan)isone-thirdofthesupport large to prevent contact of the specimen with the sides of the

span (see Fig. 1). noses (see Fig. 2).

4.1.2 The specimen is deflected until rupture occurs in the

NOTE 2—Test data have shown that the loading noses and support

outer fibers or until a maximum outer fiber strain of 3% is

dimensions can influence the flexural modulus values. Dimensions of

reached, whichever occurs first.

loading noses and supports must be specified in the test report.

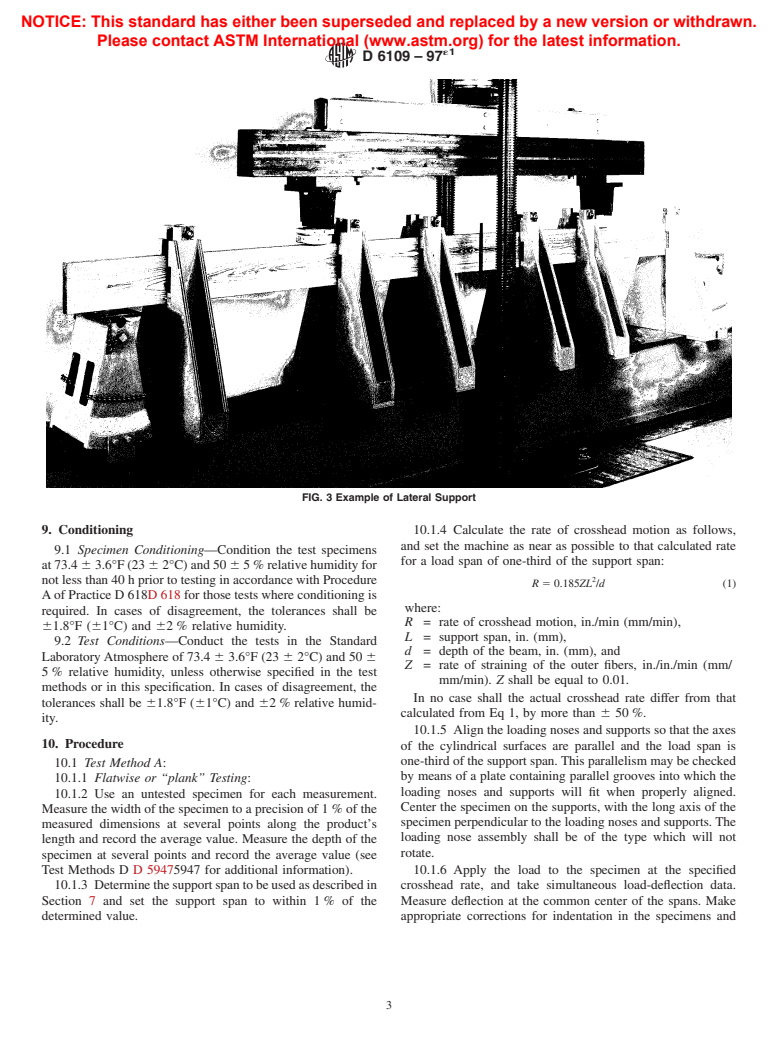

6.3 Lateral Supports—Specimens tested in the edgewise or

5. Significance and Use

“joist” position having a depth-to-width ratio greater than two

5.1 Flexural properties determined by this test method are

aresubjecttolateralinstabilityduringloading,especiallyifthe

especiallyusefulforresearchanddevelopment,qualitycontrol,

specimen breaks. For safety, lateral supports are needed while

acceptance or rejection under specifications, and special pur-

testing such specimens. Lateral support apparatus shall be

poses.

provided at least at points located about half-way between the

5.2 For many materials, there may be a specification that

reactionandtheloadpoint.Additionalsupportsmaybeusedas

requires the use of this test method, but with some procedural

required. Each support shall allow vertical movement without

modifications that take precedence when adhering to the

frictional restraint but shall restrict lateral deflection (See Fig.

specification. It is therefore advisable to refer to that material

3). Test Method D198D 198 provides further examples of

specification before using these test methods. Table 1 in

lateral support apparatus.

Classification D4000D 4000 lists the ASTM materials stan-

dards that currently exist.

7. Test Specimens

5.3 Flexural properties may vary with specimen depth,

7.1 The specimens shall be full size as manufactured, then

temperature, atmospheric conditions, and the difference in rate

cut to length for testing. The original outside surfaces shall be

of straining specified in Test Methods A and B.

unaltered. The support span to depth ratio shall be nominally

16:1.

6. Apparatus

7.2 For Test Method A, flatwise or “plank” tests, the depth

6.1 Testing Machine—A properly calibrated testing ma-

ofthespecimenshallbethethickness,orsmallerdimension,of

chine that is capable of operation at a constant rate of motion

the material. For Test Method B, edgewise or “joist” tests the

of the movable head and has the accuracy of 61%of

widthbecomesthesmallerdimensionanddepththelarger.For

maximum load expected to be measured. It shall be equipped

all tests, the support span shall be 16 (tolerance +4 and −2)

with a deflection measuring device. The stiffness of the testing

times the depth of the beam. The specimen shall be long

machine shall be such that the total elastic deformation of the

enough to allow for overhanging on each end of at least 10%

system does not exceed1%ofthe total deflection of the test

of the support span. Overhang shall be sufficient to prevent the

specimen during testing, or appropriate corrections shall be

specimen from slipping through the supports.

made. The load indication mechanism shall be essentially free

frominertiallagatthecrossheadrateused.Theaccuracyofthe

8. Number of Test Specimens

testing machine shall be verified in accordance with Practice

8.1 Five specimens shall be tested for each sample.

E4E4.

6.2 Loading Noses and Supports—The loading noses and

supports shall have cylindrical surfaces. In order to avoid

excessive indentation, of the failure due to stress concentration

directly under the loading noses, the radius or noses and

supports shall be at least 0.5 in. (12.7 mm) for all specimens.

If significant indentation or compressive failure occurs or is

observed at the point where the loading noses contact the

specimen, then the radius of the loading noses should be

increased up to 1.5 times the specimen depth. The arc of the

NOTE 1—(A) = minimum radius = 12.7 mm; (B) = maximum radius =

1.5 times the specimen depth.

FIG. 2 Four Point Loading and Support Noses at Minimum and

FIG. 1 Loading Diagram Maximum Radius

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

D 6109–97

FIG. 3 Example of Lateral Support

9. Conditioning 10.1.4 Calculate the rate of crosshead motion as follows,

and set the machine as near as possible to that calculated rate

9.1 Specimen Conditioning—Condition the test specimens

for a load span of one-third of the support span:

at73.4 63.6°F(23 62°C)and50 65%relativehumidityfor

notlessthan40hpriortotestinginaccordancewithProcedure

R 50.185ZL /d (1)

AofPracticeD618D618forthosetestswhereconditioningis

where:

required. In cases of disagreement, the tolerances shall be

R = rate of crosshead motion, in./min (mm/min),

61.8°F (61°C) and 62% relative humidity.

L = support span, in. (mm),

9.2 Test Conditions—Conduct the tests in the Standard

d = depth of the beam, in. (mm), and

LaboratoryAtmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6

Z = rate of straining of the outer fibers, in./in./min (mm/

5% relative humidity, unless otherwise specified in the test

mm/min). Z shall be equal to 0.01.

methods or in this specification. In cases of disagreement, the

In no case shall the actual crosshead rate differ from that

tolerances shall be 61.8°F (61°C) and 62% relative humid-

calculated from Eq 1, by more than 6 50%.

ity.

10.1.5 Aligntheloadingnosesandsupportssothattheaxes

10. Procedure

of the cylindrical surfaces are parallel and the load span is

one-thirdofthesupportspan.Thisparallelismmaybechecked

10.1 Test Method A:

by means of a plate containing parallel grooves into which the

10.1.1 Flatwise or “plank” Testing:

loading noses and supports will fit when properly aligned.

10.1.2 Use an untested specimen for each measurement.

Center the specimen on the supports, with the long axis of the

Measurethewidthofthespecimentoaprecisionof1%ofthe

specimen perpendicular to the loading noses and supports.The

measured dimensions at several points along the product’s

loading nose assembly shall be of the type which will not

length and record the average value. Measure the depth of the

rotate.

specimen at several points and record the average value (see

Test Methods D D 59475947 for additional information). 10.1.6 Apply the load to the specimen at the specified

10.1.3 Determinethesupportspantobeusedasdescribedin crosshead rate, and take simultaneous load-deflection data.

Section 7 and set the support span to within 1% of the Measure deflection at the common center of the spans. Make

determined value. appropriate corrections for indentation in the specimens and

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

´1

D 6109–97

deflections in the weighing system of the machine. Stress-

d = depth of beam, in. (mm).

strain curves may be plotted to determine the flexural yield

NOTE 6—Eq 3 applies strictly to materials for which the stress is

strength, modulus of elasticity and secant modulus at 1%

linearly proportional to the strain up to the point of rupture and for which

strain.

the strains are small. Since this is not always the case, a slight error will

10.1.7 If no break has occurred in a specimen by the time

be introduced in the use of this equation. The equation will, however, be

the maximum strain in the outer fibers has reached 0.03 in./in.

valid for comparison data and specification values up to the maximum

(mm/mm), discontinue the test (see Note 3 and Note 4). The fiberstrainof3%forspecimenstestedbytheprocedurehereindescribed.

NOTE 7—The above calculation is not valid if the specimen is slipping

deflection at which this strain occurs may be calculated by

excessively between the supports.

letting r equal 0.03 in./in./min (mm/mm/min) as follows for a

load span of one-third of the support span:

11.2 Flexural Strength (Modulus of Rupture)—The flexural

strengthisequaltothemaximumstressintheouterfibersatthe

D 50.21 rL /d (2)

moment of break. It is calculated in accordance with Eq 3 by

where:

letting P equal the load at the moment of break. If the material

D = midspan deflection, in. (mm),

does not break, this part of the test is not applicable. In this

r = strain, in./in./min (mm/mm/min), and

case, it is suggested that yield strength, if applicable, be

d = depth of the beam, in. (mm).

calculated and that the corresponding strain be reported also.

11.3 Flexural Yield Strength—Some materials that do not

NOTE 3—For some materials the increase in strain rate provided under

break at outer fiber strains up to 3 % may give load-deflection

Test Method B may induce the specimen to yield or rupture, or both,

within the required 3% strain limit. curves that show a point Y, at which the load does not increase

NOTE 4—If the product does not fracture at 3% strain, these test

with an increase in deflection. In such cases, the flexural yield

methods do not reveal product strength.

strength may be calculated in accordance with Eq 3 by letting

P equal the load at point Y.

10.2 Test Method B:

11.4 Stress at a Given Strain—The maximum fiber stress at

10.2.1 Edgewise or “Joist” Testing:

any given strain may be calculated in accordance with Eq 3 by

10.2.2 Specimens that have a depth-to-width ratio of two or

letting P equal the load read from the load-deflection curve at

greater will have some additional considerations when testing

the deflection corresponding to the desired strain.

in the edgewise position.

11.5 Maximum Strain—The maximum strain in the outer

10.2.3 Follow procedures of Test Method A, except that Z,

fibers also occurs at the midspan, and it may be calculated as

the rate of strain of the outer fibers, shall nominally be in the

follows for a load span of one-third of the support span:

range of 0.002 and 0.003 in./in./min (mm/mm/min).

10.2.4 Lateral Supports—Specimens tested in the edgewise 2

r 54.70Dd/L (4)

or “joist” position having a depth-to-width ratio gr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.