ASTM D6662-22

(Specification)Standard Specification for Polyolefin-Based Plastic Lumber Decking Boards

Standard Specification for Polyolefin-Based Plastic Lumber Decking Boards

ABSTRACT

This specification covers polyolefin-based plastic lumber products for use as exterior residential decking boards. Plastic lumber products are currently made predominantly with recycled polyolefin plastics (in particular high-density polyethylene) where the products are more or less non-homogenous in the cross-section. However, this specification is also potentially applicable to similar manufactured plastic products made from other plastic and plastic composite materials that have non-homogenous cross-sections. Performance requirements to which the products should adhere to are flexural properties (allowable flexural stress, and effective modulus of elasticity and adjustment for creep), dimensional stability during thermal expansion, weatherability (surface appearance and flexural property changes, and hygrothermal cycling), fire properties, and slip resistance. Also detailed here is a procedure to calculate recommended span lengths for spacing of support joists.

SCOPE

1.1 This specification covers polyolefin-based plastic lumber products for use as exterior residential decking boards.

1.2 Plastic lumber products are currently made predominantly with recycled polyolefin plastics (in particular high-density polyethylene) where the products are more or less non-homogenous in the cross-section. However, this specification is also potentially applicable to similar manufactured plastic products made from other plastic and plastic composite materials that have non-homogenous cross-sections.

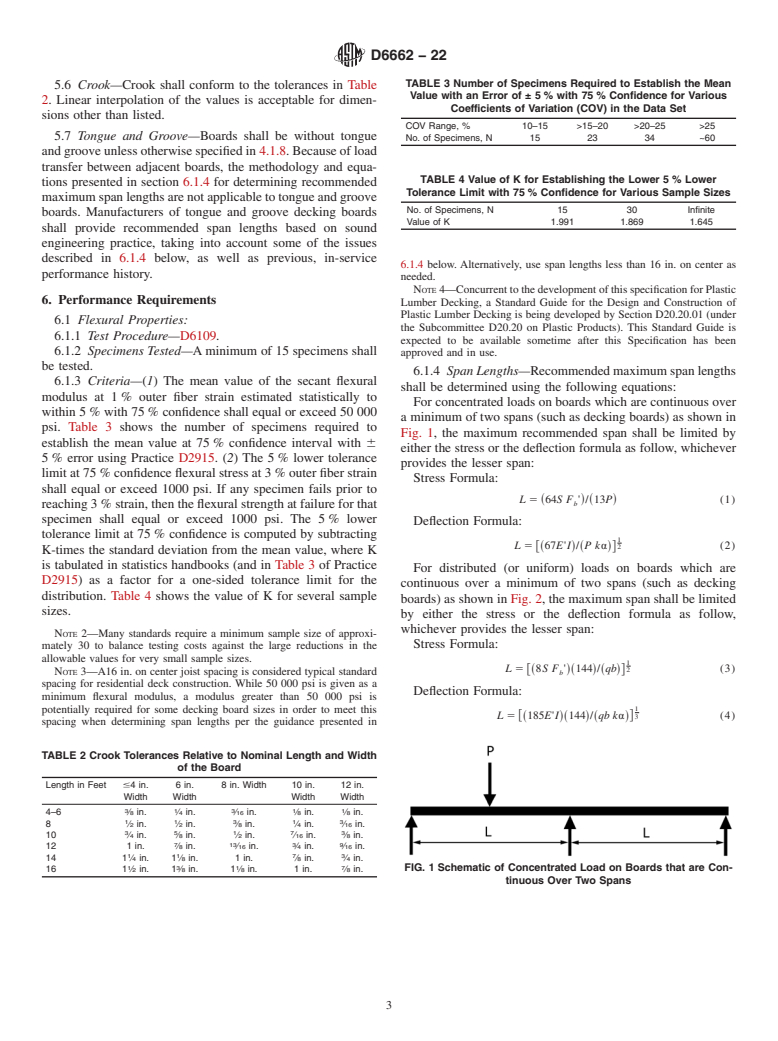

1.3 This specification details a procedure to calculate recommended span lengths for spacing of support joists. This procedure was developed using experimental data from a typical unreinforced plastic lumber made predominantly from recycled high-density polyethylene. The methodology to develop span lengths for other types and compositions of plastic lumber is detailed in Appendix X1 of this standard.

1.4 The values are stated in inch-pound units, as these are currently the most common units used by the construction industry. Equivalent SI units are indicated in parentheses. However, the units stated for irradiance exposure in the weatherability section (6.3) are in SI units as these are the units commonly used for testing of this type.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no similar or equivalent ISO Standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6662 −22

Standard Specification for

1

Polyolefin-Based Plastic Lumber Decking Boards

This standard is issued under the fixed designation D6662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This specification covers polyolefin-based plastic lum- 2.1 The following documents of the issue in effect on the

dateofmaterialpurchaseformapartofthisspecificationtothe

ber products for use as exterior residential decking boards.

extent referenced herein:

1.2 Plastic lumber products are currently made predomi-

2

2.2 ASTM Standards:

nantly with recycled polyolefin plastics (in particular high-

D883Terminology Relating to Plastics

density polyethylene) where the products are more or less

D2565Practice for Xenon-Arc Exposure of Plastics In-

non-homogenous in the cross-section. However, this specifica-

tended for Outdoor Applications

tion is also potentially applicable to similar manufactured

D2898 Practice for Accelerated Weathering of Fire-

plastic products made from other plastic and plastic composite

Retardant-Treated Wood for Fire Testing

materials that have non-homogenous cross-sections.

D2915Practice for Sampling and Data-Analysis for Struc-

1.3 This specification details a procedure to calculate rec-

tural Wood and Wood-Based Products

ommended span lengths for spacing of support joists. This

D4329Practice for Fluorescent Ultraviolet (UV) Lamp Ap-

procedure was developed using experimental data from a

paratus Exposure of Plastics

typical unreinforced plastic lumber made predominantly from

D5033GuideforDevelopmentofASTMStandardsRelating

recycled high-density polyethylene. The methodology to de-

to Recycling and Use of Recycled Plastics (Withdrawn

velop span lengths for other types and compositions of plastic 3

2007)

lumber is detailed in Appendix X1 of this standard.

D6109TestMethodsforFlexuralPropertiesofUnreinforced

1.4 The values are stated in inch-pound units, as these are and Reinforced Plastic Lumber and Related Products

currently the most common units used by the construction D6112Test Methods for Compressive and Flexural Creep

industry. Equivalent SI units are indicated in parentheses. and Creep-Rupture of Plastic Lumber and Shapes

However, the units stated for irradiance exposure in the D6341Test Method for Determination of the Linear Coef-

ficient of Thermal Expansion of Plastic Lumber and

weatherabilitysection(6.3)areinSIunitsasthesearetheunits

commonly used for testing of this type. Plastic Lumber Shapes Between –30 and 140°F (–34.4

and 60°C)

1.5 This standard does not purport to address all of the

E84Test Method for Surface Burning Characteristics of

safety concerns, if any, associated with its use. It is the

Building Materials

responsibility of the user of this standard to establish appro-

E108Test Methods for Fire Tests of Roof Coverings

priate safety, health, and environmental practices and deter-

G151PracticeforExposingNonmetallicMaterialsinAccel-

mine the applicability of regulatory limitations prior to use.

erated Test Devices that Use Laboratory Light Sources

NOTE 1—There is no similar or equivalent ISO Standard.

G154Practice for Operating Fluorescent Ultraviolet (UV)

Lamp Apparatus for Exposure of Nonmetallic Materials

1.6 This international standard was developed in accor-

G155PracticeforOperatingXenonArcLampApparatusfor

dance with internationally recognized principles on standard-

Exposure of Materials

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1 Definitions:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction of ASTM Committee D20 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

PlasticsandisthedirectresponsibilityofSubcommitteeD20.20onPlasticLumber. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2022. Published April 2022. Originally the ASTM website.

3

approved in 2001. Last previous edition approved in 2017 as D6662-17. DOI: The last approved version of this historical standard is referenced on

10.1520/D6662-22. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6662 − 17 D6662 − 22

Standard Specification for

1

Polyolefin-Based Plastic Lumber Decking Boards

This standard is issued under the fixed designation D6662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers polyolefin-based plastic lumber products for use as exterior residential decking boards.

1.2 Plastic lumber products are currently made predominantly with recycled polyolefin plastics (in particular high-density

polyethylene) where the products are more or less non-homogenous in the cross-section. However, this specification is also

potentially applicable to similar manufactured plastic products made from other plastic and plastic composite materials that have

non-homogenous cross-sections.

1.3 This specification details a procedure to calculate recommended span lengths for spacing of support joists. This procedure was

developed using experimental data from a typical unreinforced plastic lumber made predominantly from recycled high-density

polyethylene. The methodology to develop span lengths for other types and compositions of plastic lumber is detailed in Appendix

X1 of this standard.

1.4 The values are stated in inch-pound units, as these are currently the most common units used by the construction industry.

Equivalent SI units are indicated in parentheses. However, the units stated for irradiance exposure in the weatherability section

(6.3) are in SI units as these are the units commonly used for testing of this type.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no similar or equivalent ISO Standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.20 on Plastic Lumber.

Current edition approved March 1, 2017April 1, 2022. Published March 2017April 2022. Originally approved in 2001. Last previous edition approved in 20132017 as

D6662 - 13.D6662 - 17. DOI: 10.1520/D6662-17.10.1520/D6662-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6662 − 22

D883 Terminology Relating to Plastics

D2565 Practice for Xenon-Arc Exposure of Plastics Intended for Outdoor Applications

D2898 Practice for Accelerated Weathering of Fire-Retardant-Treated Wood for Fire Testing

D2915 Practice for Sampling and Data-Analysis for Structural Wood and Wood-Based Products

D4329 Practice for Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of Plastics

3

D5033 Guide for Development of ASTM Standards Relating to Recycling and Use of Recycled Plastics (Withdrawn 2007)

D6109 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastic Lumber and Related Products

D6112 Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

D6341 Test Method for Determination of the Linear Coefficient of Thermal Expansion of Plastic Lumber and Plastic Lumber

Shapes Between –30 and 140°F (–34.4 and 60°C)

E84 Test Method for Surface Burning Characteristics of Building Materials

E108 Test Methods for Fire Tests of Roof Coverings

G151 Practice for Exposing Nonmetallic Ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.