ASTM A987/A987M-09(2014)

(Practice)Standard Practice for Measuring Shape Characteristics of Tin Mill Products

Standard Practice for Measuring Shape Characteristics of Tin Mill Products

SIGNIFICANCE AND USE

4.1 The definitions and procedures for measuring shape characteristics of tin mill products are provided so that purchasers and suppliers have common measuring procedures and definitions of shape characteristics. These procedures provide definitions and measuring techniques of shape characteristics. The intention of these definitions and measuring practices is not to provide a dimensional specification for shape characteristics, but rather common procedure(s) for quantifying shape anomalies.

SCOPE

1.1 Shape is a significant quality characteristic for tin mill products. Plate-shape is affected by mill process factors plus the temper, thickness and width of the material supplied. It is the purpose of this practice to define accurately the different plate shape characteristics and to describe the practice(s) most commonly used to measure particular characteristics.

1.2 Quantitative limits are not addressed and should be established on an individual producer and user basis, where appropriate.

1.3 The values stated in either in-pound or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A987/A987M − 09 (Reapproved 2014)

Standard Practice for

Measuring Shape Characteristics of Tin Mill Products

This standard is issued under the fixed designationA987/A987M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A626/A626M Specification for Tin Mill Products, Electro-

lytic Tin Plate, Double Reduced

1.1 Shape is a significant quality characteristic for tin mill

A650/A650M Specification for Tin Mill Products, Black

products. Plate-shape is affected by mill process factors plus

Plate, Double Reduced

the temper, thickness and width of the material supplied. It is

A657/A657M Specification for Tin Mill Products, Black

the purpose of this practice to define accurately the different

Plate Electrolytic Chromium-Coated, Single and Double

plate shape characteristics and to describe the practice(s) most

Reduced

commonly used to measure particular characteristics.

1.2 Quantitative limits are not addressed and should be

3. Classification

established on an individual producer and user basis, where

appropriate. 3.1 The substrate shall conform to all the requirements of

the appropriate specifications as follows: Specifications A623,

1.3 The values stated in either in-pound or SI units are to be

A623M, A599/A599M, A624/A624M, A625/A625M, A626/

regarded as standard. Within the text, the SI units are shown in

A626M, A650/A650M, and A657/A657M.

brackets. The values stated in each system must be used

independently of the other. Combining values from the two

4. Significance and Use

systems may result in nonconformance with this specification.

4.1 The definitions and procedures for measuring shape

1.4 This standard does not purport to address the safety

characteristics of tin mill products are provided so that pur-

concerns, if any, associated with its use. It is the responsibility

chasers and suppliers have common measuring procedures and

of the user of this standard to establish appropriate safety and

definitions of shape characteristics. These procedures provide

health practices and to determine the applicability of regula-

definitions and measuring techniques of shape characteristics.

tory limitations prior to use.

The intention of these definitions and measuring practices is

2. Referenced Documents

not to provide a dimensional specification for shape

characteristics, but rather common procedure(s) for quantify-

2.1 ASTM Standards:

ing shape anomalies.

A599/A599M Specification for Tin Mill Products, Electro-

lytic Tin-Coated, Cold-Rolled Sheet

5. Interferences

A623 Specification for Tin Mill Products, General Require-

ments

5.1 Measurementofshapeoftenhasbeensubjective,atbest.

A623M Specification for Tin Mill Products, General Re-

Successful measurement of various shape anomalies on quan-

quirements [Metric]

titative terms requires recognition of several factors that can

A624/A624M Specification for Tin Mill Products, Electro-

interfere with accurate measurements.

lytic Tin Plate, Single Reduced

5.1.1 Flat surfaces are required. Measurement of several

A625/A625M Specification for Tin Mill Products, Black

anomalies require laying of the sample on a flat surface. A

Plate, Single-Reduced

machined flat surface is recommended. Laying a sample on a

floor may introduce error due to areas on a floor that are not

flat.

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.1.2 Several anomalies are measured by hanging the sheet.

A01.20 on Tin Mill Products.

Hanging by holding the sample with a hand can introduce error

Current edition approved Oct. 1, 2014. Published November 2014. Originally

from pressures exerted by fingers. A mechanical single device

approved in 1998. Last previous edition approved in 2009 as A987 - 09. DOI:

10.1520/A0987_A0987M-09R14. clamp to help hold these samples is recommended.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.3 Stepblock gauges or tapered gauges should be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

checked regularly with a calibrated hand micrometer. Wear or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. dirt build up could affect accuracy.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A987/A987M − 09 (2014)

5.1.4 Computer-basedshapemeasuringinstrumentsmustbe 7.2.1 Definition—These buckles are continuous deviations

clean and the sensors must be in good condition. The sheet from a recognized flat surface occurring usually in narrow

sample must be damage free. width areas parallel to the rolling direction other than at the

sheet edges.

6. Apparatus

7.2.2 Measuring Practices:

7.2.2.1 Asheet sample of approximately 3 ft [0.9 m] by coil

6.1 Appropriate tools to measure shape anomalies are de-

width is placed on a flat table. Push material diagonally along

scribed along with drawings (attached) as required.

the sample to within 4 in. [10 cm] of the selected corner and

6.1.1 Flat Surfaces— Accurate measurements of shape

measure the vertical uplift using a tapered gauge or a stepblock

anomalies require a flat surface, machined flat preferred.

gauge.

6.1.2 Machined Stepblock Gauge—See Fig. 1, typically,

7.2.2.2 Shear through the center line of the shape anomaly

steps are in ⁄16-in. increments.

and measure as an edge wave using a tapered gauge or a

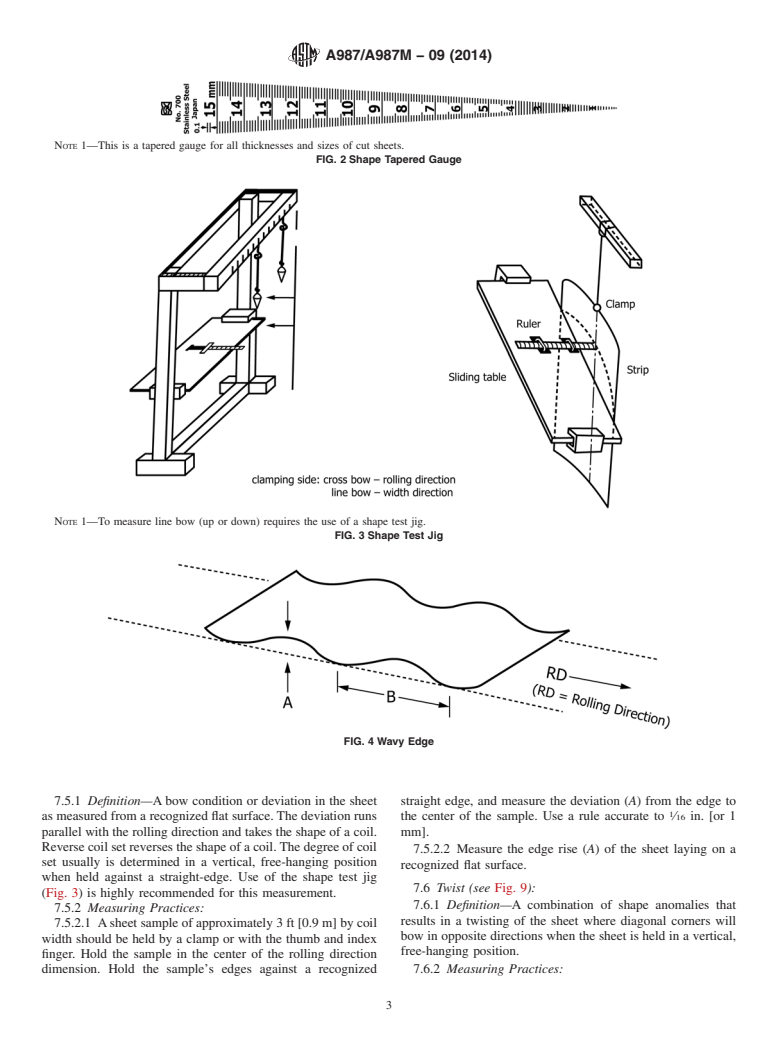

6.1.3 Tapered Gauge— See Fig. 2.

stepblock gauge.

6.1.4 Standard Ruler or Tape Measure.

7.2.2.3 Measure using a computer-based shape measuring

6.1.5 Hand Micrometer.

instrument or other instrument of appropriate design.

6.1.6 Shape Test Jig—Fig. 3, or other shape test jigs of

appropriate design.

7.3 Full Center (see Fig. 6):

6.1.7 Light-Weight Straight-Edge.

7.3.1 Definition—Any overall deviation of a sheet from a

6.1.8 Computer-based Shape Measuring Instruments are

recognized flat surface occurring over a major portion of the

designed for flatness measurements on samples of cold rolled

sheet width parallel to the rolling direction other than at the

sheet products or tin mill products.

sheet edges.

7.3.2 Measuring Practices:

7. Procedure

7.3.2.1 Asheet sample of approximately 3 ft [0.9 m] by coil

width is placed on a flat table. Push material diagonally along

Definitions and Measuring Practices of Shape Anomalies

the sample until the maximum lift occurs at the selected corner

7.1 Wavy Edge (See Fig. 4):

and measure the vertical uplift using a tapered gauge or a

7.1.1 Definition—A series of rolling direction edge devia-

stepblock gauge, or a standard ruler.

tions from a recognized flat surface. When a sample is placed

7.3.2.2 Shear through the center line of the shape anomaly

on a recognized flat table, wavy edges will appear as undula-

and measure as an edge wave using a tapered gauge or a

tions along the edge, having the height (A) and a measurable

stepblock gauge.

cycle (B). This defect can be quantified using the “I” unit (see

7.3.2.3 Measure using a computer-based shape measuring

Section 8) or steepness calculations.

instrument or other instrument of appropriate design.

7.1.2 Measuring Practices:

Fig. 7):

7.4 Edge Lift (see

7.1.2.1 Asample of approximately 3 ft [0.9 m] in length by

7.4.1 Definition—Any deviation of one sheet edge other

coil width is placed on a flat table. Measure the height (A)at

than a wavy edge. This edge lift is parallel to the rolling

the peak point of each wave from the recognized flat surface

direction and rises when placed on a recognized flat surface.

with a tapered gauge or a stepblock gauge. Also measure the

7.4.2 Measuring Practice— A sheet sample of approxi-

cycle length (B) from peak to peak of each wave with a ruler

or tape measure. mately 3 ft [0.9 m] by coil width is placed on a flat table. Push

material diagonally along the sheet until the maximum lift

7.1.2.2 Measure using a computer-based shape measuring

instrument or other instrument of appropriate design. occurs at the selected edge and measure the vertical distance

(A)withataperedgauge,astepblockgauge,orastandardruler.

7.2 Ridge Buckle, Quarter Buckle, Center Buckle (see Fig.

5): 7.5 Coil Set and Reverse Coil Set (see Fig. 8):

NOTE 1—This is a stepblock gauge for all thicknesses and sizes of cut sheets.

NOTE 2—Dimensions given are approximate overall dimensions.

FIG. 1 Shape

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A987/A987M − 09 A987/A987M − 09 (Reapproved 2014)

Standard Practice for

Measuring Shape Characteristics of Tin Mill Products

This standard is issued under the fixed designation A987/A987M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Shape is a significant quality characteristic for tin mill products. Plate-shape is affected by mill process factors plus the

temper, thickness and width of the material supplied. It is the purpose of this practice to define accurately the different plate shape

characteristics and to describe the practice(s) most commonly used to measure particular characteristics.

1.2 Quantitative limits are not addressed and should be established on an individual producer and user basis, where appropriate.

1.3 The values stated in either in-pound or SI units are to be regarded as standard. Within the text, the SI units are shown in

brackets. The values stated in each system must be used independently of the other. Combining values from the two systems may

result in nonconformance with this specification.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A599/A599M Specification for Tin Mill Products, Electrolytic Tin-Coated, Cold-Rolled Sheet

A623 Specification for Tin Mill Products, General Requirements

A623M Specification for Tin Mill Products, General Requirements [Metric]

A624/A624M Specification for Tin Mill Products, Electrolytic Tin Plate, Single Reduced

A625/A625M Specification for Tin Mill Products, Black Plate, Single-Reduced

A626/A626M Specification for Tin Mill Products, Electrolytic Tin Plate, Double Reduced

A650/A650M Specification for Tin Mill Products, Black Plate, Double Reduced

A657/A657M Specification for Tin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double Reduced

3. Classification

3.1 The substrate shall conform to all the requirements of the appropriate specifications as follows: Specifications A623,

A623M, A599/A599M, A624/A624M, A625/A625M, A626/A626M, A650/A650M, and A657/A657M.

4. Significance and Use

4.1 The definitions and procedures for measuring shape characteristics of tin mill products are provided so that purchasers and

suppliers have common measuring procedures and definitions of shape characteristics. These procedures provide definitions and

measuring techniques of shape characteristics. The intention of these definitions and measuring practices is not to provide a

dimensional specification for shape characteristics, but rather common procedure(s) for quantifying shape anomalies.

5. Interferences

5.1 Measurement of shape often has been subjective, at best. Successful measurement of various shape anomalies on

quantitative terms requires recognition of several factors that can interfere with accurate measurements.

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.20

on Tin Mill Products.

Current edition approved May 1, 2009Oct. 1, 2014. Published June 2009November 2014. Originally approved in 1998. Last previous edition approved in 20072009 as

A987 - 07.A987 - 09. DOI: 10.1520/A0987_A0987M-09.10.1520/A0987_A0987M-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A987/A987M − 09 (2014)

5.1.1 Flat surfaces are required. Measurement of several anomalies require laying of the sample on a flat surface. A machined

flat surface is recommended. Laying a sample on a floor may introduce error due to areas on a floor that are not flat.

5.1.2 Several anomalies are measured by hanging the sheet. Hanging by holding the sample with a hand can introduce error

from pressures exerted by fingers. A mechanical single device clamp to help hold these samples is recommended.

5.1.3 Stepblock gauges or tapered gauges should be checked regularly with a calibrated hand micrometer. Wear or dirt build up

could affect accuracy.

5.1.4 Computer-based shape measuring instruments must be clean and the sensors must be in good condition. The sheet sample

must be damage free.

6. Apparatus

6.1 Appropriate tools to measure shape anomalies are described along with drawings (attached) as required.

6.1.1 Flat Surfaces— Accurate measurements of shape anomalies require a flat surface, machined flat preferred.

6.1.2 Machined Stepblock Gauge—See Fig. 1, typically, steps are in ⁄16-in. increments.

6.1.3 Tapered Gauge— See Fig. 2.

6.1.4 Standard Ruler or Tape Measure.

6.1.5 Hand Micrometer.

6.1.6 Shape Test Jig—Fig. 3, or other shape test jigs of appropriate design.

6.1.7 Light-Weight Straight-Edge.

6.1.8 Computer-based Shape Measuring Instruments are designed for flatness measurements on samples of cold rolled sheet

products or tin mill products.

7. Procedure

Definitions and Measuring Practices of Shape Anomalies

7.1 Wavy Edge (See Fig. 4):

7.1.1 Definition—A series of rolling direction edge deviations from a recognized flat surface. When a sample is placed on a

recognized flat table, wavy edges will appear as undulations along the edge, having the height (A) and a measurable cycle (B). This

defect can be quantified using the “I” unit (see Section 8) or steepness calculations.

7.1.2 Measuring Practices:

7.1.2.1 A sample of approximately 3 ft [0.9 m] in length by coil width is placed on a flat table. Measure the height (A) at the

peak point of each wave from the recognized flat surface with a tapered gauge or a stepblock gauge. Also measure the cycle length

(B) from peak to peak of each wave with a ruler or tape measure.

7.1.2.2 Measure using a computer-based shape measuring instrument or other instrument of appropriate design.

7.2 Ridge Buckle, Quarter Buckle, Center Buckle (see Fig. 5):

7.2.1 Definition—These buckles are continuous deviations from a recognized flat surface occurring usually in narrow width

areas parallel to the rolling direction other than at the sheet edges.

7.2.2 Measuring Practices:

7.2.2.1 A sheet sample of approximately 3 ft [0.9 m] by coil width is placed on a flat table. Push material diagonally along the

sample to within 4 in. [10 cm] of the selected corner and measure the vertical uplift using a tapered gauge or a stepblock gauge.

7.2.2.2 Shear through the center line of the shape anomaly and measure as an edge wave using a tapered gauge or a stepblock

gauge.

7.2.2.3 Measure using a computer-based shape measuring instrument or other instrument of appropriate design.

7.3 Full Center (see Fig. 6):

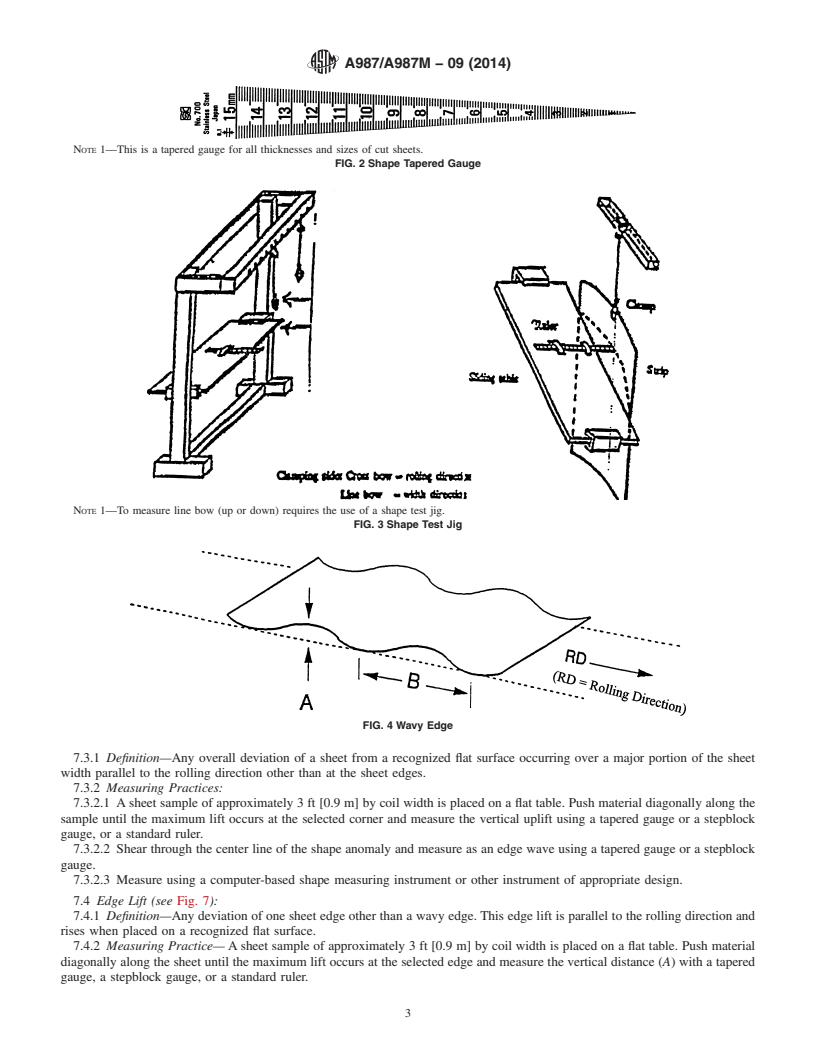

NOTE 1—This is a stepblock gauge for all thicknesses and sizes of cut sheets.

NOTE 2—Dimensions given are approximate overall dimensions.

FIG. 1 Shape Stepblock Gauge

A987/A987M − 09 (2014)

NOTE 1—This is a tapered gauge for all thicknesses and sizes of cut sheets.

FIG. 2 Shape Tapered Gauge

NOTE 1—To measure line bow (up or down) requires the use of a shape test jig.

FIG. 3 Shape Test Jig

FIG. 4 Wavy Edge

7.3.1 Definition—Any overall deviation of a sheet from a recognized flat surface occurring over a major portion of the sheet

width parallel to the rolling direction other than at the sheet edges.

7.3.2 Measuring Practices:

7.3.2.1 A sheet sample of approximately 3 ft [0.9 m] by coil width is placed on a flat table. Push material diagonally along the

sample until the maximum lift occurs at the selected corner and measure the vertical uplift using a tapered gauge or a stepblock

gauge, or a standard ruler.

7.3.2.2 Shear through the center line of the shape anomaly and measure as an edge wave using a tapered gauge or a stepblock

gauge.

7.3.2.3 Measure using a computer-based shape measuring instrument or other instrument of appropriate design.

7.4 Edge Lift (see Fig. 7):

7.4.1 Definition—Any deviation of one sheet edge other than a wavy edge. This edge lift is parallel to the rolling direction and

rises when placed on a recognized flat surface.

7.4.2 Measuring Practice— A sheet sample of approximately 3 ft [0.9 m] by coi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.