ASTM A31-00

(Specification)Standard Specification for Steel Rivets and Bars for Rivets, Pressure Vessels

Standard Specification for Steel Rivets and Bars for Rivets, Pressure Vessels

SCOPE

1.1 This specification covers steel rivets for use in boilers and pressure vessels and steel bars for use in the manufacture of rivets.

1.2 Two grades are covered:

1.2.1 Grade A -Bars having a yield point of 23 000 psi (160 MPa) minimum with no controls on carbon content.

1.2.2 Grade B -Bars having a yield point of 29 000 psi (200 MPa) minimum with carbon 0.28% maximum.

1.2.3 Rivets are manufactured from the applicable bar grade.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 31 – 00

Standard Specification for

1

Steel Rivets and Bars for Rivets, Pressure Vessels

This standard is issued under the fixed designation A 31; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

7

1. Scope * B18.24.1 Part Identifying Number (PIN) Code System

2

1.1 This specification covers steel rivets for use in boilers

3. Ordering Information

and pressure vessels and steel bars for use in the manufacture

3.1 Orders for rivets and bars under this specification shall

of rivets.

include:

1.2 Two grades are covered:

3.1.1 ASTM designation and date of issue,

1.2.1 Grade A—Bars having a yield point of 23 000 psi

3.1.2 Quantity—Number of pieces for rivets and weight for

(160 MPa) minimum with no controls on carbon content.

bars,

1.2.2 Grade B—Bars having a yield point of 29 000 psi

3.1.3 Name of product and grade (A or B),

(200 MPa) minimum with carbon 0.28 % maximum.

3.1.4 Size (diameter and length),

1.2.3 Rivets are manufactured from the applicable bar

3.1.5 Rivet head type,

grade.

3.1.6 If inspection at point of manufacture is required,

1.3 The values stated in inch-pound units are to be regarded

3.1.7 Certification, if required (Section 14), and

as the standard. The values given in parentheses are for

3.1.8 Additional testing or special requirements, if required.

information only.

3.1.9 For establishment of a part identifying system, see

2. Referenced Documents ASME B18.24.1.

2.1 ASTM Standards:

NOTE 1—A typical ordering description is: ASTM A 31 – 82, 10 000

1

A 29/A29M Specification for Steel Bars, Carbon and Alloy, pieces, steel rivets Grade A, ⁄2 by 2 in., button head, test reports required.

Hot-Wrought and Cold-Finished, General Requirements

3 4. Materials and Manufacture

for

A 370 Test Methods and Definitions for Mechanical Testing 4.1 The steel shall be made by any of the following

4

processes: open-hearth, electric-furnace, or basic-oxygen.

of Steel Products

A 751 Test Methods, Practices, and Terminology for 4.2 Rivets shall be manufactured from rivet bars conform-

4

ing to the applicable grade ordered.

Chemical Analysis of Steel Products

F 1470 Guide for Fastener Sampling for Specified Mechani- 4.3 Rivets shall be manufactured by hot- or cold-heading.

5

4.4 Bars shall be furnished as rolled and not pickled, blast

cal Properties and Performance Inspection

2.2 ANSI/ASME Standards: cleaned, or oiled. At producer’s option, bars may be cleaned for

7

inspection or cold drawn.

B18.1.1 Small Solid Rivets ⁄16 Inch Nominal Diameter and

6

Smaller

5. Chemical Composition

1

B18.1.2 Large Rivets ⁄2 Inch Nominal Diameter and

6

5.1 The steel shall conform to chemical composition pre-

Larger

scribed in Table 1.

5.2 Heat Analysis—An analysis of each heat of steel shall

be made by the bar manufacturer to determine for Grades A and

B the percentages of carbon, manganese, phosphorus, and

1

This specification is under the jurisdiction of ASTM Committee F16 on

sulfur. This analysis shall be made from a test ingot taken

Fasteners and is the direct responsibility of Subcommittee F 16.02 on Steel Bolts,

during the pouring of the heat. The chemical composition thus

Nuts, Rivets, and Washers.

determined shall be reported to the purchaser or his represen-

Current edition approved May 10, 2000. Published July 2000. Originally

published as A 31 – 01. Last previous edition A 31 – 95.

tative and shall conform to the requirements for heat analysis

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

in accordance with Table 1.

cation SA-31 in Section II of that Code.

3

Annual Book of ASTM Standards, Vol 01.05.

4

Annual Book of ASTM Standards, Vol 01.03.

5

Annual Book of ASTM Standards, Vol 01.08.

6 7

Available from American National Standards Institute, 11 W. 42nd St., 13th Fl., Available from American Society of Mechanical Engineers, Three Park

New York, NY 10036. Avenue, New York, NY 10016–5990.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A31

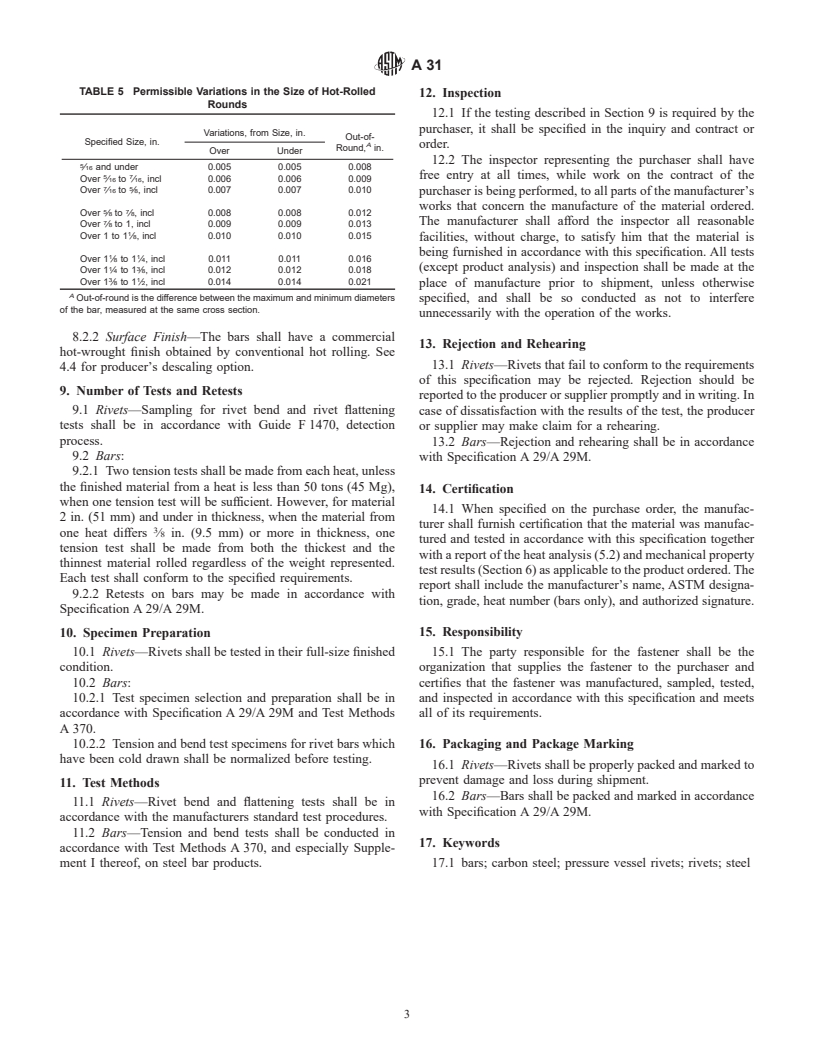

TABLE 1 Chemical Requirements TABLE 2 Bend Requirements, Rivets

Grade A Grade B Ratio of Bend Diameter to Diameter of

Diameter of

River Shank

Heat Product Heat Product

Rivet Shank, in.

Analysis Analysis Analysis Analysis Grade A Grade B

3

Carbon, max, % . . . . . . 0.28 0.31 ⁄4 and under flat 1

3 1

Manganese, % 0.30–0.60 0.27–0.63 0.30–0.80 0.27–0.83 Over ⁄4 flat 1 ⁄2

Phosphorus, max, % 0.040 0.048 0.040 0.048

Sulfur, max, % 0.050 0.058 0.050 0.058

5.3 Product

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.