ASTM C349-14

(Test Method)Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure)

Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars<brk/> (Using Portions of Prisms Broken in Flexure)

SIGNIFICANCE AND USE

3.1 This method provides a means of obtaining compressive strength values from the same specimens previously used for flexural strength determinations by Test Method C348. The compressive strength values are for reference purposes, and not as substitutes for values obtained by Test Method C109/C109M for cement acceptance.

SCOPE

1.1 This test method covers the determination of the compressive strength of hydraulic-cement mortars, using for the test specimens portions of prisms made and broken in flexure in accordance with Test Method C348.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 Values in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the Rules for Conversion and rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

(Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C349 −14

Standard Test Method for

Compressive Strength of Hydraulic-Cement Mortars

1

(Using Portions of Prisms Broken in Flexure)

This standard is issued under the fixed designation C349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Significance and Use

1.1 This test method covers the determination of the com- 3.1 This method provides a means of obtaining compressive

pressive strength of hydraulic-cement mortars, using for the strength values from the same specimens previously used for

test specimens portions of prisms made and broken in flexure flexural strength determinations by Test Method C348. The

in accordance with Test Method C348. compressivestrengthvaluesareforreferencepurposes,andnot

as substitutes for values obtained by Test Method C109/

1.2 The values stated in SI units are to be regarded as

C109M for cement acceptance.

standard. No other units of measurement are included in this

standard.

4. Apparatus

1.3 Values in SI units shall be obtained by measurement in

4.1 Bearing Plates—The bearing plates shall be ≥25 mm in

SI units or by appropriate conversion, using the Rules for

thicknessandshallbemadeofahardmetal.Thesurfacesofthe

Conversion and rounding given in Standard IEEE/ASTM SI

bearing plates that are placed in contact with the specimens

10, of measurements made in other units.

shall be 40.0 6 0.1-mm by 50.8-mm rectangles, with the

1.4 This standard does not purport to address all of the 50.8-mm dimension at right angles to the longitudinal axis of

safety concerns, if any, associated with its use. It is the the prism. The bearing plate surfaces in contact with the

responsibility of the user of this standard to establish appro- specimen shall have a Rockwell hardness of not less than 60

priate safety and health practices and determine the applica- HRC. These surfaces shall not depart from plane surfaces by

bility of regulatory limitations prior to use. (Warning—Fresh more than 0.01 mm when the plates are new and shall be

hydraulic cementitious mixtures are caustic and may cause maintained within a permissible variation of 0.03 mm.

2

chemical burns to skin and tissue upon prolonged exposure. )

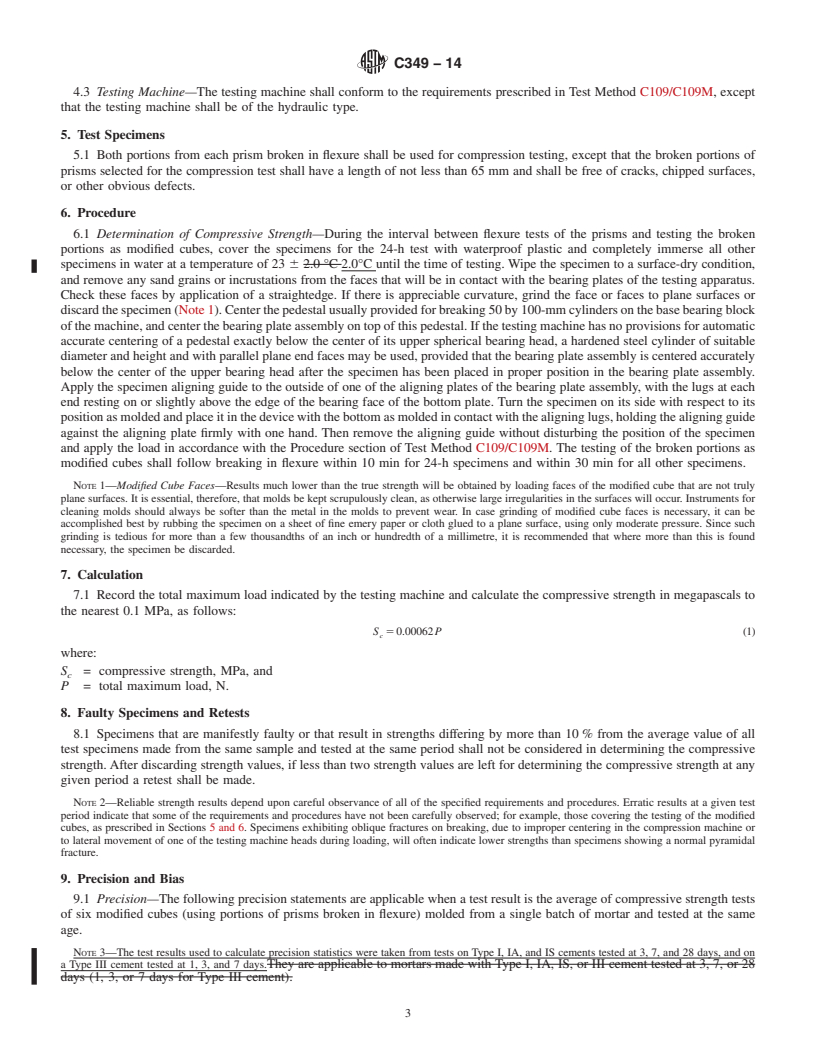

4.2 Device for Aligning Bearing Plates—Adevice for align-

ing the bearing plates to ensure the proper location of the upper

2. Referenced Documents

plate with reference to the lower plate is shown in Fig. 1.Ifthe

3

2.1 ASTM Standards:

upper bearing plate does not have free movement within the

C109/C109M Test Method for Compressive Strength of

aligning plates, these shall be separated from the bottom plate

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

by insertion of 0.05-mm shims on each side of the bottom

Specimens)

bearingplate,andthetwo6-mmpinsintheupperbearingplate

C348 Test Method for Flexural Strength of Hydraulic-

filed down just sufficiently to permit free up and down

Cement Mortars

movement in the slots at the top of the aligning plates.

C670 Practice for Preparing Precision and Bias Statements

4.3 Testing Machine—The testing machine shall conform to

for Test Methods for Construction Materials

the requirements prescribed in Test Method C109/C109M,

IEEE/ASTM SI 10 Standard for Use of the International

except that the testing machine shall be of the hydraulic type.

System of Units (SI): The Modern Metric System

5. Test Specimens

1

5.1 Bothportionsfromeachprismbrokeninflexureshallbe

This test method is under the jurisdiction ofASTM Committee C01 on Cement

and is the direct responsibility of Subcommittee C01.27 on Strength.

usedforcompressiontesting,exceptthatthebrokenportionsof

Current edition approved Dec. 1, 2014. Published January 2015. Originally

prisms selected for the compression test shall have a length of

approved in 1954. Last previous edition approved in 2008 as C349 – 08. DOI:

not less than 65 mm and shall be free of cracks, chipped

10.1520/C0349-14.

2

See the section on Safety, Manual of Cement Testing, Annual Book of ASTM surfaces, or other obvious defects.

Standards, Vol 04.01.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Procedure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Determination of Compressive Strength—During the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. interval between flexure tests of the prisms and testing the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C349 − 08 C349 − 14

Standard Test Method for

Compressive Strength of Hydraulic-Cement Mortars

1

(Using Portions of Prisms Broken in Flexure)

This standard is issued under the fixed designation C349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the compressive strength of hydraulic-cement mortars, using for the test

specimens portions of prisms made and broken in flexure in accordance with Test Method C348.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 Values in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the Rules for Conversion

and rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

2

tissue upon prolonged exposure. )

2. Referenced Documents

3

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C348 Test Method for Flexural Strength of Hydraulic-Cement Mortars

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI): The Modern Metric System

3. Significance and Use

3.1 This method provides a means of obtaining compressive strength values from the same specimens previously used for

flexural strength determinations by Test Method C348. The compressive strength values are for reference purposes, and not as

substitutes for values obtained by Test Method C109/C109M for cement acceptance.

4. Apparatus

4.1 Bearing Plates—The bearing plates shall be not less than 25 ≥25 mm in thickness and shall be made of a hard metal. The

surfaces of the bearing plates that are placed in contact with the specimens shall be 40.0 6 0.1-mm by 50.8-mm rectangles, with

the 50.8-mm dimension at right angles to the longitudinal axis of the prism. The bearing plate surfaces in contact with the specimen

shall have a Rockwell hardness of not less than 60 HRC. These surfaces shall not depart from plane surfaces by more than 0.01

mm when the plates are new and shall be maintained within a permissible variation of 0.03 mm.

4.2 Device for Aligning Bearing Plates—A device for aligning the bearing plates to ensure the proper location of the upper plate

with reference to the lower plate is shown in Fig. 1. If the upper bearing plate does not have free movement within the aligning

plates, these shall be separated from the bottom plate by insertion of 0.05-mm shims on each side of the bottom bearing plate, and

the two 6-mm pins in the upper bearing plate filed down just sufficiently to permit free up and down movement in the slots at the

top of the aligning plates.

1

This test method is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.27 on Strength.

Current edition approved Dec. 1, 2008Dec. 1, 2014. Published January 2009January 2015. Originally approved in 1954. Last previous edition approved in 20022008 as

C349 – 02.C349 – 08. DOI: 10.1520/C0349-08.10.1520/C0349-14.

2

See the section on Safety, Manual of Cement Testing, Annual Book of ASTM Standards, Vol 04.01.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C349 − 14

FIG. 1 Bearing Plates and Bearing Plate Aligning Device for Testing 40 by 40 by 160-mm Mortar Prisms as Modified Cubes

2

---------------------- Page:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.