ASTM E1571-11(2016)e1

(Practice)Standard Practice for Electromagnetic Examination of Ferromagnetic Steel Wire Rope

Standard Practice for Electromagnetic Examination of Ferromagnetic Steel Wire Rope

SIGNIFICANCE AND USE

5.1 This practice outlines a procedure to standardize an instrument and to use the instrument to examine ferromagnetic wire rope products in which the magnetic flux and magnetic flux leakage methods are used. If properly applied, the magnetic flux method is capable of detecting the presence, location, and magnitude of metal loss from wear, broken wires, and corrosion, and the magnetic flux leakage method is capable of detecting the presence and location of flaws such as broken wires and corrosion pits.

5.2 The instrument's response to the rope's fabrication, installation, and in-service-induced flaws can be significantly different from the instrument's response to artificial flaws such as wire gaps or added wires. For this reason, it is preferable to detect and mark (using set-up standards that represent) real in-service-induced flaws whose characteristics will adversely affect the serviceability of the wire rope.

SCOPE

1.1 This practice covers the application and standardization of instruments that use the electromagnetic, the magnetic flux, and the magnetic flux leakage examination method to detect flaws and changes in metallic cross-sectional areas in ferromagnetic wire rope products.

1.1.1 This practice includes rope diameters up to 2.5 in. (63.5 mm). Larger diameters may be included, subject to agreement by the users of this practice.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1571 − 11 (Reapproved 2016)

Standard Practice for

Electromagnetic Examination of Ferromagnetic Steel Wire

Rope

This standard is issued under the fixed designation E1571; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Section 6.2 updated editorially in June 2016.

1. Scope NAS-410 Certification and Qualification of Nondestructive

Personnel (Quality Assurance Committee)

1.1 This practice covers the application and standardization

ISO 9712 Nondestructive Testing—Qualification and Certi-

of instruments that use the electromagnetic, the magnetic flux,

fication of NDT Personnel

and the magnetic flux leakage examination method to detect

flaws and changes in metallic cross-sectional areas in ferro-

3. Terminology

magnetic wire rope products.

1.1.1 This practice includes rope diameters up to 2.5 in. 3.1 Definitions—For definitions of terms used in this

(63.5 mm). Larger diameters may be included, subject to

practice, refer to Terminology E1316.

agreement by the users of this practice.

3.2 Definitions of Terms Specific to This Standard:

1.2 Units—The values stated in inch-pound units are to be

3.2.1 dual-function instrument—a wire rope NDT instru-

regarded as standard. The values given in parentheses are ment designed to detect and display changes of metallic

mathematical conversions to SI units are provided for infor-

cross-sectional area on one channel and local flaws on another

mation only and are not considered standard. channel of a dual-channel strip chart recorder or another

appropriate device.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.2 local flaw (LF)—a discontinuity in a rope, such as a

responsibility of the user of this standard to establish appro- broken or damaged wire, a corrosion pit on a wire, a groove

priate safety and health practices and determine the applica- worn into a wire, or any other physical condition that degrades

bility of regulatory limitations prior to use. the integrity of the rope in a localized manner.

3.2.3 loss of metallic cross-sectional area (LMA)—arelative

2. Referenced Documents

measure of the amount of material (mass) missing from a

2.1 ASTM Standards:

location along the wire rope and is measured by comparing a

E543 Specification for Agencies Performing Nondestructive

point with a reference point on the rope that represents

Testing

maximum metallic cross-sectional area, as measured with an

E1316 Terminology for Nondestructive Examinations

instrument.

2.2 Other Documents:

3.2.4 single-function instrument—a wire rope NDT instru-

ANSI/ASNT-CP-189 ASNT Standard for Qualification and

ment designed to detect and display either changes in metallic

Certification of Nondestructive Testing Personnel

cross-sectional area or local flaws, but not both, on a strip chart

SNT-TC-1A Recommended Practice for Personnel Qualifi-

recorder or another appropriate device.

cation and Certification in Nondestructive Testing

4. Summary of Practice

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

4.1 The principle of operation of a wire rope nondestructive

structive Testing and is the direct responsibility of Subcommittee E07.07 on

examination instrument is as follows:

Electromagnetic Method.

Current edition approved June 1, 2016. Published June 2016. Originally

approved in 1993. Last previous edition approved in 2011 as E1571 – 11. DOI:

10.1520/E1571-11R16E01.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from International Organization for Standardization (ISO), ISO

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1571 − 11 (2016)

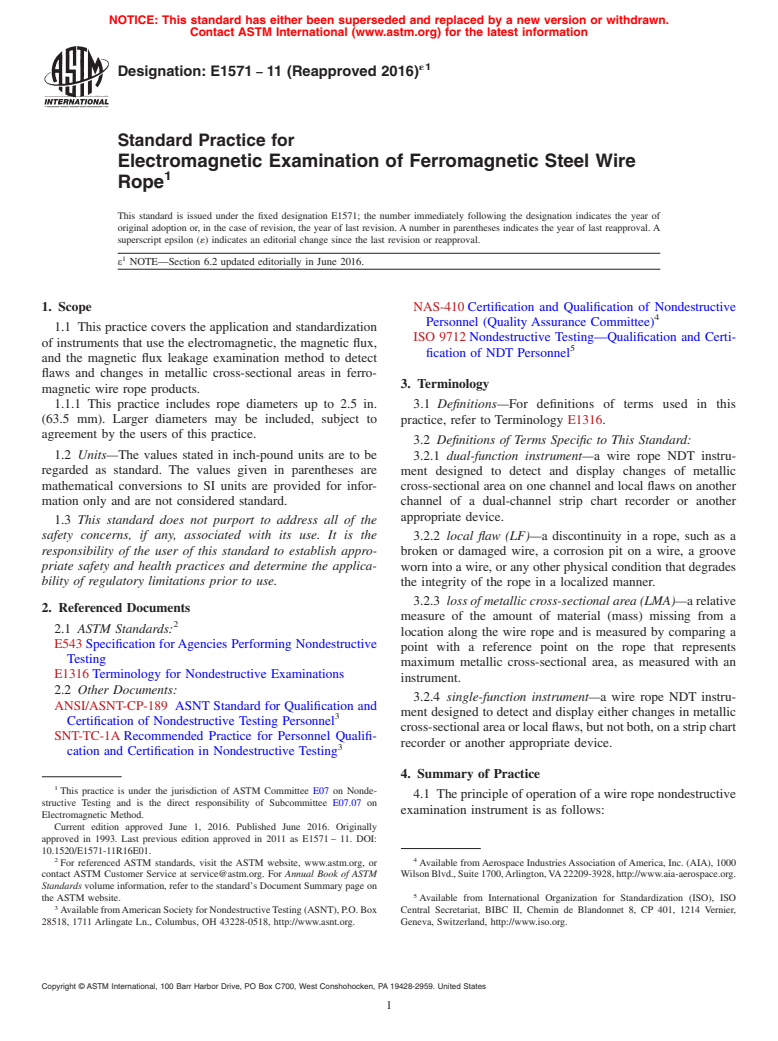

4.1.1 Direct Current and Permanent Magnet (Magnetic and magnitude of metal loss from wear, broken wires, and

Flux) Instruments—Direct current (dc) and permanent magnet corrosion, and the magnetic flux leakage method is capable of

instruments (Figs. 1 and 2) supply a constant flux that detecting the presence and location of flaws such as broken

magnetizesalengthofropeasitpassesthroughthesensorhead wires and corrosion pits.

(magnetizing circuit). The total axial magnetic flux in the rope

5.2 The instrument’s response to the rope’s fabrication,

can be measured either by Hall effect sensors, an encircling

installation, and in-service-induced flaws can be significantly

(sense) coil, or by any other appropriate device that can

different from the instrument’s response to artificial flaws such

measure absolute magnetic fields or variations in a steady

as wire gaps or added wires. For this reason, it is preferable to

magnetic field. The signal from the sensors is electronically

detect and mark (using set-up standards that represent) real

processed, and the output voltage is proportional to the volume

in-service-induced flaws whose characteristics will adversely

of steel or the change in metallic cross-sectional area, within

affect the serviceability of the wire rope.

the region of influence of the magnetizing circuit. This type of

instrument measures changes in metallic cross-sectional area.

6. Basis of Application

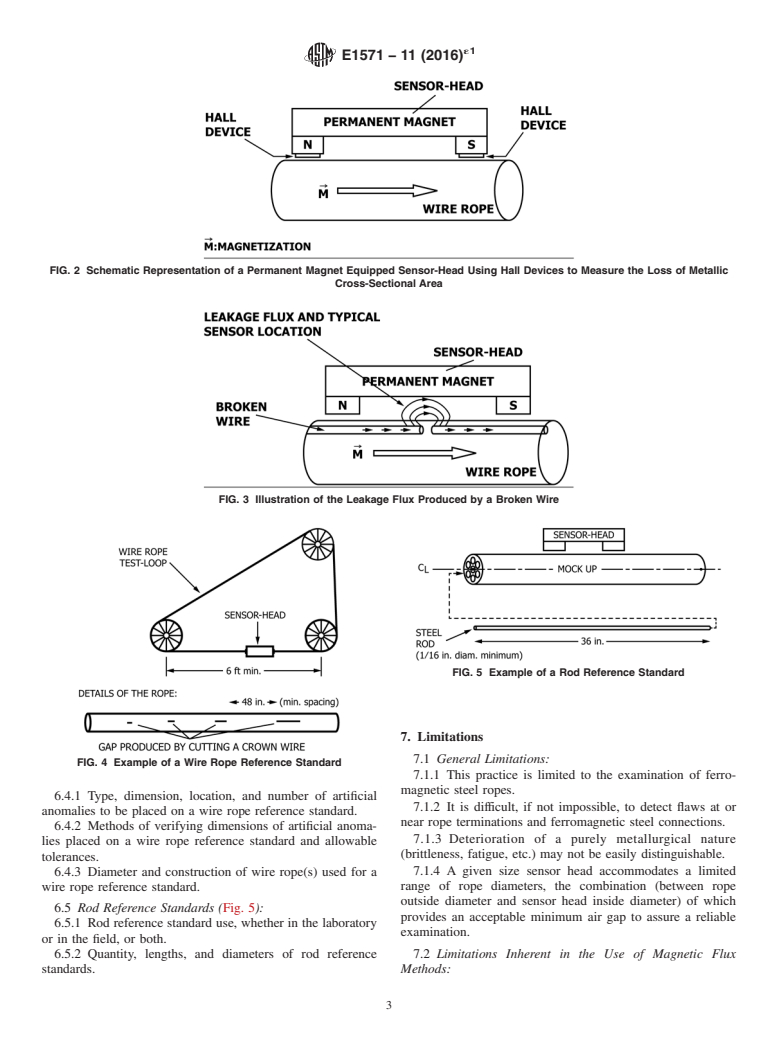

4.1.2 Magnetic Flux Leakage Instrument—A direct current

6.1 The following items require agreement by the users of

or permanent magnet instrument (Fig. 3) is used to supply a

this practice and should be included in the rope examination

constant flux that magnetizes a length of rope as it passes

contract:

through the sensor head (magnetizing circuit). The magnetic

flux leakage created by a discontinuity in the rope, such as a 6.1.1 Acceptance criteria.

broken wire, can be detected with a differential sensor, such as 6.1.2 Determination of LMA, or the display of LFs, or both.

a Hall effect sensor, sensor coils, or by any other appropriate

6.1.3 Extent of rope examination (that is, full length that

device. The signal from the sensor is electronically processed

may require several setups or partial length with one setup).

and recorded.This type of instrument measures LFs.While the

6.1.4 Standardization method to be used: wire rope refer-

information is not quantitative as to the exact nature and

ence standard, rod reference standards, or a combination

magnitude of the causal flaws, valuable conclusions can be

thereof.

drawn as to the presence of broken wires, internal corrosion,

6.1.5 Maximum time interval between equipment standard-

and fretting of wires in the rope.”

izations.

4.2 The examination is conducted using one or more tech-

6.2 Personnel Qualification—If specified in the contractual

niques discussed in 4.1. Loss of metallic cross-sectional area

agreement, personnel performing examinations in accordance

can be determined by using an instrument operating according

with this test method shall be qualified in accordance with a

to the principle discussed in 4.1.1. Broken wires and internal

nationally or internationally recognized NDT personnel quali-

(orexternal)corrosioncanbedetectedbyusingamagneticflux

fication practice or standard such as ANSI/ASNT CP-189,

leakage instrument as described in 4.1.2. The examination

SNT-TC-1A, NAS-410, ISO 9712, or a similar document and

procedure must conform to Section 9. One instrument may

certified by the employer or certifying agency as applicable.

incorporate both magnetic flux and magnetic flux leakage

The practice or standard used and its applicable revision shall

principles.

be specified in the contractual agreement between the using

parties.

5. Significance and Use

6.3 Qualification of Nondestructive Agencies—If specified

5.1 This practice outlines a procedure to standardize an

in the contractual agreement, NDT agencies shall be qualified

instrument and to use the instrument to examine ferromagnetic

and evaluated as described in E543. The applicable edition of

wire rope products in which the magnetic flux and magnetic

E543 shall be specified in the contractual agreement.

flux leakage methods are used. If properly applied, the mag-

neticfluxmethodiscapableofdetectingthepresence,location,

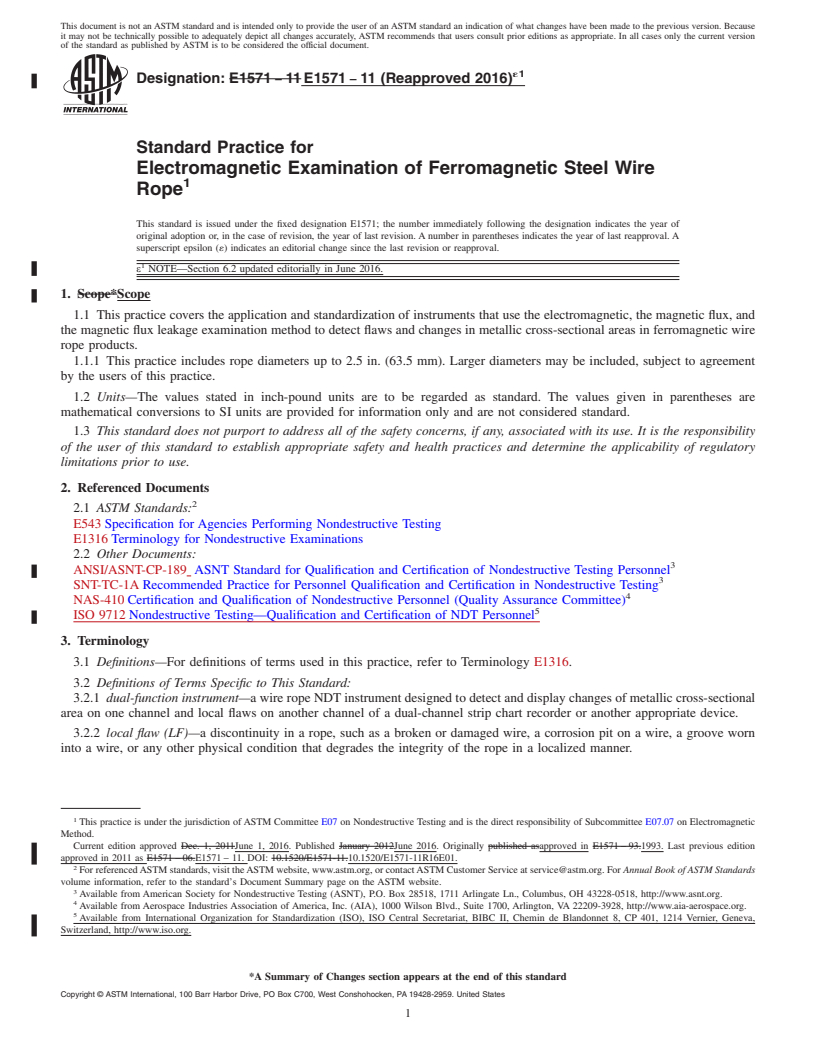

6.4 Wire Rope Reference Standard (Fig. 4):

FIG. 1 Schematic Representation of a Permanent Magnet Equipped Sensor-Head Using a Sense Coil to Measure the Loss of Metallic

Cross-Sectional Area

´1

E1571 − 11 (2016)

FIG. 2 Schematic Representation of a Permanent Magnet Equipped Sensor-Head Using Hall Devices to Measure the Loss of Metallic

Cross-Sectional Area

FIG. 3 Illustration of the Leakage Flux Produced by a Broken Wire

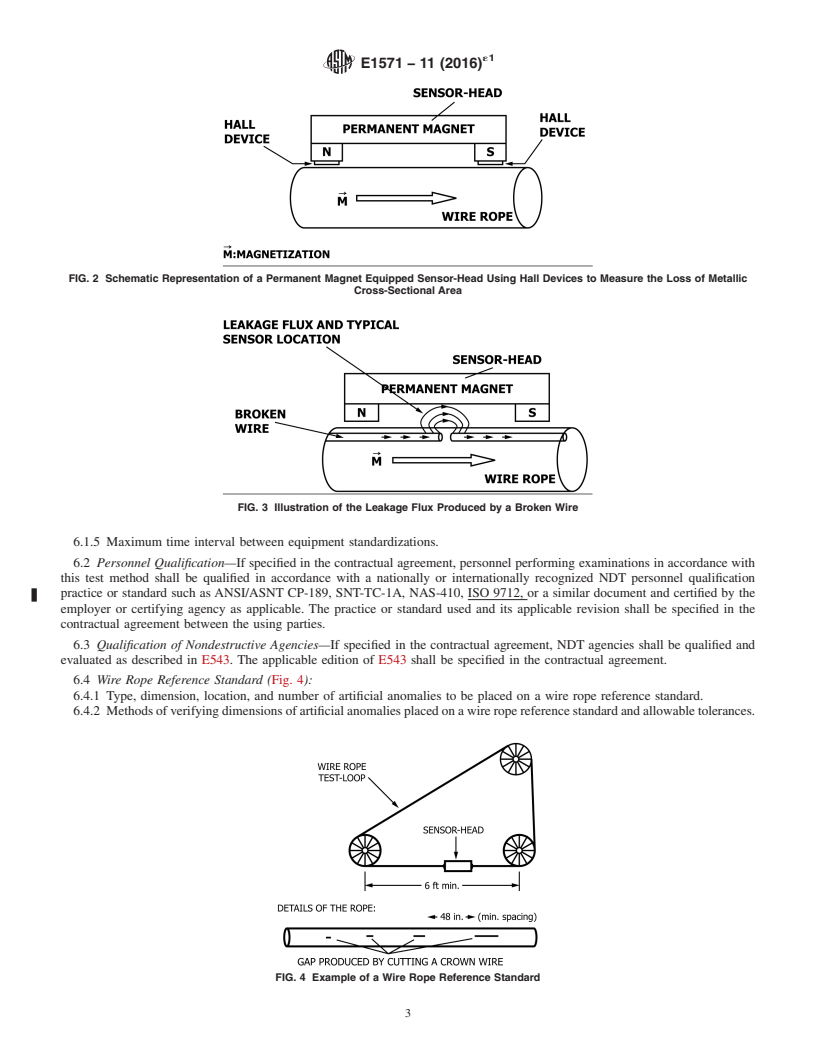

FIG. 5 Example of a Rod Reference Standard

7. Limitations

7.1 General Limitations:

FIG. 4 Example of a Wire Rope Reference Standard

7.1.1 This practice is limited to the examination of ferro-

magnetic steel ropes.

6.4.1 Type, dimension, location, and number of artificial

7.1.2 It is difficult, if not impossible, to detect flaws at or

anomalies to be placed on a wire rope reference standard.

near rope terminations and ferromagnetic steel connections.

6.4.2 Methods of verifying dimensions of artificial anoma-

7.1.3 Deterioration of a purely metallurgical nature

lies placed on a wire rope reference standard and allowable

(brittleness, fatigue, etc.) may not be easily distinguishable.

tolerances.

7.1.4 A given size sensor head accommodates a limited

6.4.3 Diameter and construction of wire rope(s) used for a

range of rope diameters, the combination (between rope

wire rope reference standard.

outside diameter and sensor head inside diameter) of which

6.5 Rod Reference Standards (Fig. 5):

provides an acceptable minimum air gap to assure a reliable

6.5.1 Rod reference standard use, whether in the laboratory

examination.

or in the field, or both.

6.5.2 Quantity, lengths, and diameters of rod reference 7.2 Limitations Inherent in the Use of Magnetic Flux

standards. Methods:

´1

E1571 − 11 (2016)

7.2.1 Instruments designed to measure changes in metallic 9.2.1 The rope may need to be demagnetized before an

cross-sectional area are capable of showing changes relative to examination. If a magnetic flux or a magnetic flux leakage

that point on the rope where the instrument was standardized. instrument is used, it may be necessary to repeat the examina-

7.2.2 The sensitivity of these methods may decrease with tion to homogenize the magnetization of the rope.

the depth of the flaw from the surface of the rope and with

9.2.2 The sensor head must be approximately centered

decreasing gaps between the ends of the broken wires.

around the wire rope.

9.2.3 The instrument must be adjusted in accordance with a

7.3 Limitations Inherent in the Use of the Magnetic Flux

procedure. The sensitivity setting should be verified prior to

Leakage Method:

starting the examination by inserting a ferromagnetic steel rod

7.3.1 It may be impossible to discern relatively small-

or wire of known cross-sectional area. This standardization

diameter broken wires, broken wires with small gaps, or

signal should be permanently recorded for future reference.

individual broken wires within closely-spaced multiple breaks.

It may be impossible to discern broken wires from wires with 9.2.4 The wire rope must be examined by moving the head,

corrosion pits. or the rope, at a relatively uniform speed. Relevant signal(s)

7.3.2 Because deterioration of a purely metallurgical nature must be recorded on suitable media, such as on a strip chart

may not be easily distinguishable, more frequent examinations recorder, on a tape recorder, or on computer file(s), for the

may be necessary after broken wires are detected to determine

purpose of both present and future replay/analysis.

when the rope should be retired, based on percent rate of

9.2.5 Thefollowinginformationshallberecordedasexami-

increase of broken wires.

nation data for analysis:

9.2.5.1 Date of examination,

8. Apparatus

9.2.5.2 Examination number,

8.1 The equipment used shall be specifically designed to

9.2.5.3 Customer identification,

examine ferromagnetic wire rope products.

9.2.5.4 Rope identification (use, location, reel and rope

8.1.1 The energizing unit within the sensor head shall

number, etc.),

consist of permanent magnets or dc solenoid coils configured

9.2.5.5 Rope diameter and construction,

to allow application to the rope at the location of service.

8.1.2 The energizing unit shall be capable of magnetically

9.2.5.6 Instrument serial number,

saturating the range (size and construction) of ropes for which

9.2.5.7 Instrument standardization settings,

it was designed.

9.2.5.8 Strip chart recorder settings,

8.1.3 The sensor head, containing the energizing and detect-

9.2.5.9 Strip chart speed,

ing units, and other components, should be designed to

9.2.5.10 Location of sensor head with respect to a well-

accommodate different rope diameters. The rope should be

defined reference point along the rope, both at the beginning of

approximately centered in the sensor head.

the examination and when commencing a second set-up run,

8.1.4 The instrument should have connectors, or other

9.2.5.11 Direction of rope or sensor head travel,

means, for transmitting output signals to strip chart recorders,

9.2.5.12 Total length of rope examined, and

data recorders, or a multifunction computer interface. The

instrument may also contain meters, bar indicators, or other 9.2.5.13 Examination speed.

display devices, necessary for instrument setup,

9.2.6 To assure repeatability of the examination results, two

standardization, and examination.

or more operational passes are required.

8.1.5 The instrument should have an examination distance

9.2.7 When more than one setup is required to examine the

and rope speed output indicating the current examination

full working length of the rope, the sensor head should be

distance traveled and rope speed or, whenever applicable, have

positioned to maintain the same magnetic polarity with respect

a proportional drive chart control that synchronizes the chart

to the rope for all se

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1571 − 11 E1571 − 11 (Reapproved 2016)

Standard Practice for

Electromagnetic Examination of Ferromagnetic Steel Wire

Rope

This standard is issued under the fixed designation E1571; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Section 6.2 updated editorially in June 2016.

1. Scope*Scope

1.1 This practice covers the application and standardization of instruments that use the electromagnetic, the magnetic flux, and

the magnetic flux leakage examination method to detect flaws and changes in metallic cross-sectional areas in ferromagnetic wire

rope products.

1.1.1 This practice includes rope diameters up to 2.5 in. (63.5 mm). Larger diameters may be included, subject to agreement

by the users of this practice.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1316 Terminology for Nondestructive Examinations

2.2 Other Documents:

ANSI/ASNT-CP-189 ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel

SNT-TC-1A Recommended Practice for Personnel Qualification and Certification in Nondestructive Testing

NAS-410 Certification and Qualification of Nondestructive Personnel (Quality Assurance Committee)

ISO 9712 Nondestructive Testing—Qualification and Certification of NDT Personnel

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, refer to Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 dual-function instrument—a wire rope NDT instrument designed to detect and display changes of metallic cross-sectional

area on one channel and local flaws on another channel of a dual-channel strip chart recorder or another appropriate device.

3.2.2 local flaw (LF)—a discontinuity in a rope, such as a broken or damaged wire, a corrosion pit on a wire, a groove worn

into a wire, or any other physical condition that degrades the integrity of the rope in a localized manner.

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.07 on Electromagnetic

Method.

Current edition approved Dec. 1, 2011June 1, 2016. Published January 2012June 2016. Originally published asapproved in E1571 – 93.1993. Last previous edition

approved in 2011 as E1571 – 06.E1571 – 11. DOI: 10.1520/E1571-11.10.1520/E1571-11R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Available from Aerospace Industries Association of America, Inc. (AIA), 1000 Wilson Blvd., Suite 1700, Arlington, VA 22209-3928, http://www.aia-aerospace.org.

Available from International Organization for Standardization (ISO), ISO Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1571 − 11 (2016)

3.2.3 loss of metallic cross-sectional area (LMA)—a relative measure of the amount of material (mass) missing from a location

along the wire rope and is measured by comparing a point with a reference point on the rope that represents maximum metallic

cross-sectional area, as measured with an instrument.

3.2.4 single-function instrument—a wire rope NDT instrument designed to detect and display either changes in metallic

cross-sectional area or local flaws, but not both, on a strip chart recorder or another appropriate device.

4. Summary of Practice

4.1 The principle of operation of a wire rope nondestructive examination instrument is as follows:

4.1.1 Direct Current and Permanent Magnet (Magnetic Flux) Instruments—Direct current (dc) and permanent magnet

instruments (Figs. 1 and 2) supply a constant flux that magnetizes a length of rope as it passes through the sensor head (magnetizing

circuit). The total axial magnetic flux in the rope can be measured either by Hall effect sensors, an encircling (sense) coil, or by

any other appropriate device that can measure absolute magnetic fields or variations in a steady magnetic field. The signal from

the sensors is electronically processed, and the output voltage is proportional to the volume of steel or the change in metallic

cross-sectional area, within the region of influence of the magnetizing circuit. This type of instrument measures changes in metallic

cross-sectional area.

4.1.2 Magnetic Flux Leakage Instrument—A direct current or permanent magnet instrument (Fig. 3) is used to supply a constant

flux that magnetizes a length of rope as it passes through the sensor head (magnetizing circuit). The magnetic flux leakage created

by a discontinuity in the rope, such as a broken wire, can be detected with a differential sensor, such as a Hall effect sensor, sensor

coils, or by any other appropriate device. The signal from the sensor is electronically processed and recorded. This type of

instrument measures LFs. While the information is not quantitative as to the exact nature and magnitude of the causal flaws,

valuable conclusions can be drawn as to the presence of broken wires, internal corrosion, and fretting of wires in the rope.”

4.2 The examination is conducted using one or more techniques discussed in 4.1. Loss of metallic cross-sectional area can be

determined by using an instrument operating according to the principle discussed in 4.1.1. Broken wires and internal (or external)

corrosion can be detected by using a magnetic flux leakage instrument as described in 4.1.2. The examination procedure must

conform to Section 9. One instrument may incorporate both magnetic flux and magnetic flux leakage principles.

5. Significance and Use

5.1 This practice outlines a procedure to standardize an instrument and to use the instrument to examine ferromagnetic wire rope

products in which the magnetic flux and magnetic flux leakage methods are used. If properly applied, the magnetic flux method

is capable of detecting the presence, location, and magnitude of metal loss from wear, broken wires, and corrosion, and the

magnetic flux leakage method is capable of detecting the presence and location of flaws such as broken wires and corrosion pits.

5.2 The instrument’s response to the rope’s fabrication, installation, and in-service-induced flaws can be significantly different

from the instrument’s response to artificial flaws such as wire gaps or added wires. For this reason, it is preferable to detect and

mark (using set-up standards that represent) real in-service-induced flaws whose characteristics will adversely affect the

serviceability of the wire rope.

6. Basis of Application

6.1 The following items require agreement by the users of this practice and should be included in the rope examination contract:

6.1.1 Acceptance criteria.

6.1.2 Determination of LMA, or the display of LFs, or both.

6.1.3 Extent of rope examination (that is, full length that may require several setups or partial length with one setup).

6.1.4 Standardization method to be used: wire rope reference standard, rod reference standards, or a combination thereof.

FIG. 1 Schematic Representation of a Permanent Magnet Equipped Sensor-Head Using a Sense Coil to Measure the Loss of Metallic

Cross-Sectional Area

´1

E1571 − 11 (2016)

FIG. 2 Schematic Representation of a Permanent Magnet Equipped Sensor-Head Using Hall Devices to Measure the Loss of Metallic

Cross-Sectional Area

FIG. 3 Illustration of the Leakage Flux Produced by a Broken Wire

6.1.5 Maximum time interval between equipment standardizations.

6.2 Personnel Qualification—If specified in the contractual agreement, personnel performing examinations in accordance with

this test method shall be qualified in accordance with a nationally or internationally recognized NDT personnel qualification

practice or standard such as ANSI/ASNT CP-189, SNT-TC-1A, NAS-410, ISO 9712, or a similar document and certified by the

employer or certifying agency as applicable. The practice or standard used and its applicable revision shall be specified in the

contractual agreement between the using parties.

6.3 Qualification of Nondestructive Agencies—If specified in the contractual agreement, NDT agencies shall be qualified and

evaluated as described in E543. The applicable edition of E543 shall be specified in the contractual agreement.

6.4 Wire Rope Reference Standard (Fig. 4):

6.4.1 Type, dimension, location, and number of artificial anomalies to be placed on a wire rope reference standard.

6.4.2 Methods of verifying dimensions of artificial anomalies placed on a wire rope reference standard and allowable tolerances.

FIG. 4 Example of a Wire Rope Reference Standard

´1

E1571 − 11 (2016)

6.4.3 Diameter and construction of wire rope(s) used for a wire rope reference standard.

6.5 Rod Reference Standards (Fig. 5):

6.5.1 Rod reference standard use, whether in the laboratory or in the field, or both.

6.5.2 Quantity, lengths, and diameters of rod reference standards.

7. Limitations

7.1 General Limitations:

7.1.1 This practice is limited to the examination of ferromagnetic steel ropes.

7.1.2 It is difficult, if not impossible, to detect flaws at or near rope terminations and ferromagnetic steel connections.

7.1.3 Deterioration of a purely metallurgical nature (brittleness, fatigue, etc.) may not be easily distinguishable.

7.1.4 A given size sensor head accommodates a limited range of rope diameters, the combination (between rope outside

diameter and sensor head inside diameter) of which provides an acceptable minimum air gap to assure a reliable examination.

7.2 Limitations Inherent in the Use of Magnetic Flux Methods:

7.2.1 Instruments designed to measure changes in metallic cross-sectional area are capable of showing changes relative to that

point on the rope where the instrument was standardized.

7.2.2 The sensitivity of these methods may decrease with the depth of the flaw from the surface of the rope and with decreasing

gaps between the ends of the broken wires.

7.3 Limitations Inherent in the Use of the Magnetic Flux Leakage Method:

7.3.1 It may be impossible to discern relatively small-diameter broken wires, broken wires with small gaps, or individual broken

wires within closely-spaced multiple breaks. It may be impossible to discern broken wires from wires with corrosion pits.

7.3.2 Because deterioration of a purely metallurgical nature may not be easily distinguishable, more frequent examinations may

be necessary after broken wires are detected to determine when the rope should be retired, based on percent rate of increase of

broken wires.

8. Apparatus

8.1 The equipment used shall be specifically designed to examine ferromagnetic wire rope products.

8.1.1 The energizing unit within the sensor head shall consist of permanent magnets or dc solenoid coils configured to allow

application to the rope at the location of service.

8.1.2 The energizing unit shall be capable of magnetically saturating the range (size and construction) of ropes for which it was

designed.

8.1.3 The sensor head, containing the energizing and detecting units, and other components, should be designed to

accommodate different rope diameters. The rope should be approximately centered in the sensor head.

8.1.4 The instrument should have connectors, or other means, for transmitting output signals to strip chart recorders, data

recorders, or a multifunction computer interface. The instrument may also contain meters, bar indicators, or other display devices,

necessary for instrument setup, standardization, and examination.

8.1.5 The instrument should have an examination distance and rope speed output indicating the current examination distance

traveled and rope speed or, whenever applicable, have a proportional drive chart control that synchronizes the chart speed with the

rope speed.

8.2 Auxiliary Equipment The examination results shall be recorded on a permanent basis by eithereither:

8.2.1 a strip chart recorder,

8.2.2 and/or by an other another type of data recorderrecorder, or

8.2.3 and/or by a multifunctional computer interface.interface, or combinations thereof.

9. Examination Procedure

9.1 The electronic system shall have a pre-examination standardization procedure.

FIG. 5 Example of a Rod Reference Standard

´1

E1571 − 11 (2016)

9.2 The wire rope shall be examined for LFs or LMA, or both, as specified in the agreement by the users of this practice. The

users may select the instrument that best suits the intended purpose of the examination. The examination should be conducted as

follows:

9.2.1 The rope may need to be demagnetized before an examination. If a magnetic flux or a magnetic flux leakage instrument

is used, it may be necessary to repeat the examination to homogenize the magnetization of the rope.

9.2.2 The sensor head must be approximately centered around the wire rope.

9.2.3 The instrument must be adjusted in accordance with a procedure. The sensitivity setting should be verified prior to starting

the examination by inserting a ferromagnetic steel rod or wire of known cross-sectional area. This standardization signal should

be permanently recorded for future reference.

9.2.4 The wire rope must be examined by moving the head, or the rope, at a relatively uniform speed. Rele

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.