ASTM F2592-16

(Test Method)Standard Test Method for Measuring the Force-Displacement of a Membrane Switch (Withdrawn 2023)

Standard Test Method for Measuring the Force-Displacement of a Membrane Switch (Withdrawn 2023)

SIGNIFICANCE AND USE

3.1 The force and displacement values when converted to a slope are useful in quantifying the differences in tactile response among membrane switches.

3.2 Specified resistance is useful to manufacturers and users when designing membrane switch interface circuitry.

3.3 Actuation force and contact force are useful to manufacturers and users in determining the suitability, reference and aesthetics of a membrane switch in a given application.

3.4 The tendency of a switch to make or break electrical contact at unexpected moments during closure or release can be a sign of a poor design. The degree of teasing can range from a simple annoyance to a failure of critical control process.

3.5 The amount of switch sensitivity or teasing can also be a result of poor surface conductivity that will prevent an electrical event even when switch poles are in partial contact.

SCOPE

1.1 This test method covers the measurement of force displacement characteristics of a membrane switch.

1.1.1 This test method replaces Test Method F1570 (Tactile Ratio). Tactile Actuating Slope Angle and Tactile Recovery Slope Angle better represent the characterization of tactile sensation, previously called “Tactile Ratio” in Test Method F1570.

1.1.2 This test method replaces Test Method F1682 (Travel).

1.1.3 This test method replaces Test Method F1597 (Actuation and Contact Force).

1.1.4 This test method replaces Test Method F1997 (Switch Sensitivity).

1.2 Force displacement hysterisis loop curve can be used in the determination of Actuation Force, Displacement, Contact Force, Return Force, and Tactile Actuating Slope Angle and Tactile Recovery Slope Angle.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the measurement of force displacement characteristics of a membrane switch.

Formerly under the jurisdiction of Committee F01 on Electronics, this specification was withdrawn in November 2023. This standard is being withdrawn without replacement because Committee F01 was disbanded.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2592 − 16

Standard Test Method for

1

Measuring the Force-Displacement of a Membrane Switch

This standard is issued under the fixed designation F2592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.6 contact displacement (Tc)—the displacement at con-

tact closure.

1.1 This test method covers the measurement of force

displacement characteristics of a membrane switch. 2.1.7 contact force (Fc)—the force at contact closure.

1.1.1 This test method replaces Test Method F1570 (Tactile

2.1.8 displacement—measured distance of movement when

Ratio). Tactile Actuating Slope Angle and Tactile Recovery

membrane is depressed.

Slope Angle better represent the characterization of tactile

2.1.8.1 Discussion—Displacement is sometimes referred to

sensation, previously called “Tactile Ratio” in Test Method

as “switch travel.”

F1570.

2.1.9 Fmax—an applied force, maximum force measured

1.1.2 This test method replaces Test Method F1682

prior to or including point (Fmin) (see Fig. 1).

(Travel).

2.1.9.1 Discussion—Sometimes referred to as Actuation

1.1.3 This test method replaces Test Method F1597 (Actua-

Force.

tion and Contact Force).

1.1.4 This test method replacesTest Method F1997 (Switch 2.1.10 Fmin—an applied force, minimum force seen be-

Sensitivity).

tween Fmax and point at which probe movement ceases.

2.1.10.1 Discussion—Fmax can equal Fmin.

1.2 Force displacement hysterisis loop curve can be used in

the determination of Actuation Force, Displacement, Contact

2.1.11 force-displacement hysteresis curve—relationship

Force, Return Force, and Tactile Actuating Slope Angle and

between force applied and displacement of a membrane switch

Tactile Recovery Slope Angle.

in terms of the actuation and return (recovery).

2.1.11.1 Discussion—Usually expressed as a line graph;

1.3 This standard does not purport to address all of the

sometimes referred to as Force-Travel curve (see Fig. 1).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2.1.12 force factor – make (Ffactor)—mathematical expres-

priate safety and health practices and determine the applica-

sion for the change in force between Fmax and Fmin (see Eq

bility of regulatory limitations prior to use.

7.1.1).

2.1.12.1 Discussion—Ffactor = 0 for non-tactile switch.

2. Terminology

2.1.13 force factor – break (Frfactor)—mathematical ex-

2.1 Definitions:

pression for the change in force between Frmax and Frmin

2.1.1 break displacement (Tb)—the displacement at contact

(see Eq 7.1.2).

break.

2.1.13.1 Discussion—Frfactor = 0 for non-tactile switch.

2.1.2 break force (Fb)—the force at contact break.

2.1.14 membrane switch—a momentary switching device in

2.1.3 circuit resistance—electrical resistance as measured

which at least one contact is on, or made of, a flexible

between two test points whose internal contacts, when held

substrate.

closed, complete a circuit.

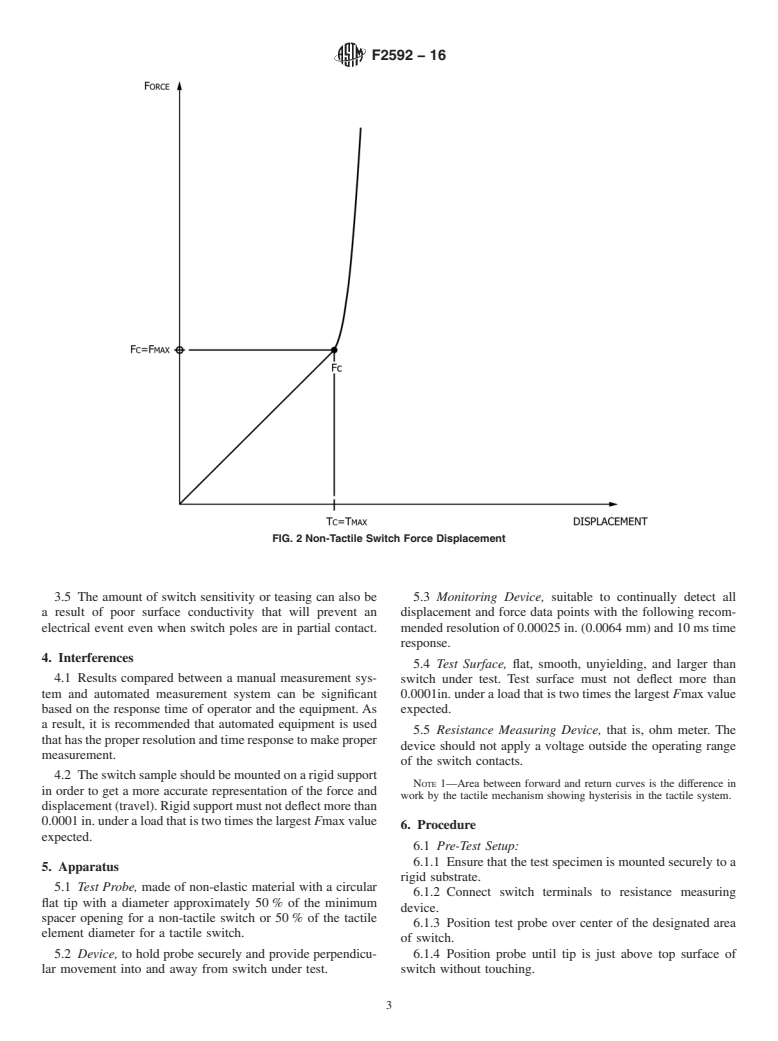

2.1.15 non-tactile switch—switch that does not have a

2.1.4 closure (make)—the event at which a specified resis-

tactile response and therefore has a response slope equal to

tance is achieved.

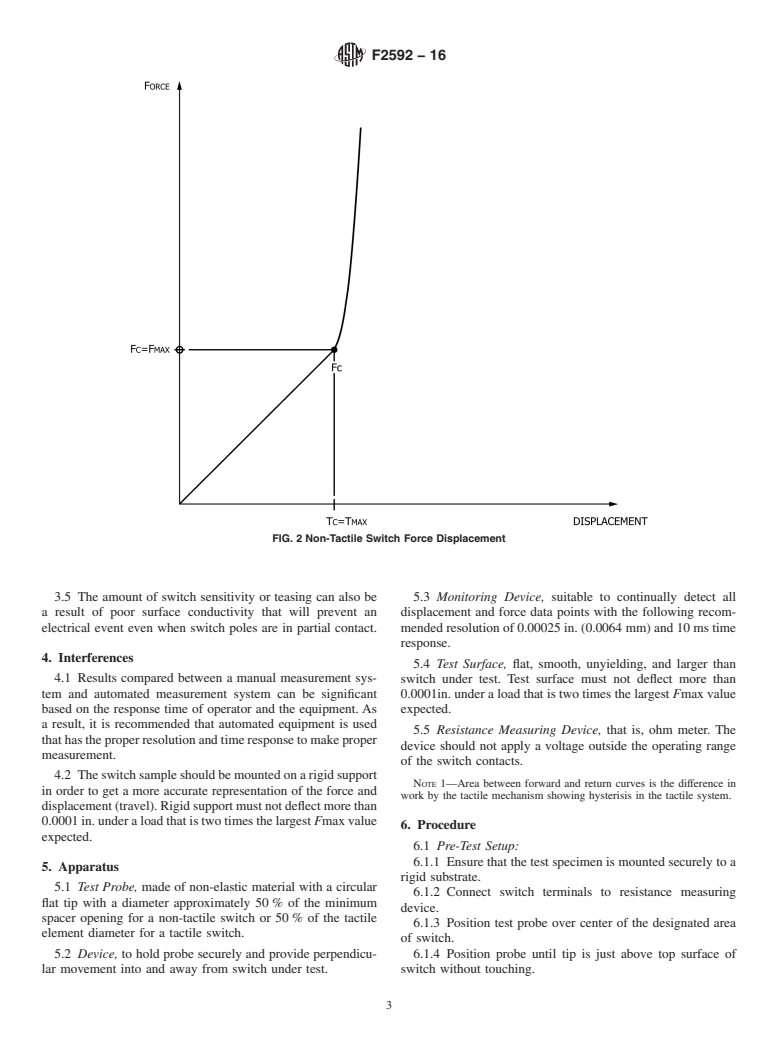

zero because Fmax and Fmin are the same (see Fig. 2).

2.1.5 contact break—point at which circuit resistance is

2.1.16 return min force (Frmin)—minimum force seen dur-

higher than specified resistance on return.

ing return cycle before reaching Frmax.

2.1.17 return max force (Frmax)—maximum force mea-

1

This test method is under the jurisdiction of ASTM Committee F01 on

sured during return cycle after achieving Frmin.

Electronics and is the direct responsibility of Subcommittee F01.18 on Printed

Electronics.

2.1.18 specified resistance—maximum allowable resistance

Current edition approved May 1, 2016. Published May 2016. Originally

as measured between two terminations whose internal switch

approved in 2006. Last previous edition approved in 2010 as F2592-10. DOI:

10.1520/F2592-16. contacts are held closed to complete a circuit.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2592 − 16

NOTE 1—Area between forward and return curves is the difference in work by the tactile mechanism showing hysterisis in the tactile system.

FIG. 1 Force Displacement Hysterisis Loop

2.1.19 switch teasing (break)—the displacement measure- 2.1.29 travel factor – make (Tfactor)—mathe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2592 − 10 F2592 − 16

Standard Test Method for

1

Measuring the Force-Displacement of a Membrane Switch

This standard is issued under the fixed designation F2592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of force displacement characteristics of a membrane switch.

1.1.1 This test method replaces Test Method F1570 (Tactile Ratio). Tactile Actuating Slope Angle and Tactile Recovery Slope

Angle better represent the characterization of tactile sensation, previously called “Tactile Ratio” in Test Method F1570.

1.1.2 This test method replaces Test Method F1682 (Travel).

1.1.3 This test method replaces Test Method F1597 (Actuation and Contact Force).

1.1.4 This test method replaces Test Method F1997 (Switch Sensitivity).

1.2 Force displacement hysterisis loop curve can be used in the determination of Actuation Force, Displacement, Contact Force,

Return Force, and Tactile Actuating Slope Angle and Tactile Recovery Slope Angle.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Terminology

2.1 Definitions:

2.1.1 break displacement (Tb)—the displacement at contact break.

2.1.2 break force (Fb)—the force at contact break.

2.1.3 circuit resistance—electrical resistance as measured between two test points whose internal contacts, when held closed,

complete a circuit.

2.1.4 closure (make)—the event at which a specified resistance is achieved.

2.1.5 contact break—point at which circuit resistance is higher than specified resistance on return.

2.1.6 contact displacement (Tc)—the displacement at contact closure.

2.1.7 contact force (Fc)—the force at contact closure.

2.1.8 displacement—measured distance of movement when membrane is depressed.

1

This test method is under the jurisdiction of ASTM Committee F01 on Electronics and is the direct responsibility of Subcommittee F01.18 on Membrane SwitchesPrinted

Electronics.

Current edition approved Dec. 1, 2010May 1, 2016. Published January 2011May 2016. Originally approved in 2006. Last previous edition approved in 20092010 as

F2592-09.-10. DOI: 10.1520/F2592-10.10.1520/F2592-16.

2.1.8.1 Discussion—

Displacement is sometimes referred to as “switch travel.”

2.1.9 Fmax—an applied force, maximum force measured prior to or including point (Fmin) (see Fig. 1).

2.1.9.1 Discussion—

Sometimes referred to as Actuation Force.

2.1.10 Fmin—an applied force, minimum force seen between Fmax and point at which probe movement ceases.

2.1.10.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2592 − 16

NOTE 1—Area between forward and return curves is the difference in work by the tactile mechanism showing hysterisis in the tactile system.

FIG. 1 Force Displacement Hysterisis Loop

Fmax can equal Fmin.

2.1.11 force-displacement hysteresis curve—relationship between force applied and displacement of a membrane switch in

terms of the actuation and return (recovery).

2.1.11.1 Discussion—

Usually expressed as a line graph; sometimes referred to as Force-Travel curve (see Fig. 1).

2.1.12 force factor – make (Ffactor)—mathematical expression for the change in force between Fmax and Fmin (see Eq 7.1.1).

2.1.12.1 Discussion—

Ffactor = 0 for non-tactile switch.

2.1.13 force factor – break (Frfactor)—mathematical expression for the change in force between Frmax and Frmin (see Eq

7.1.2).

2.1.13.1 Discussion—

Frfactor = 0 for non-tactile switch.

2.1.14 membrane switch—a momentary switching device in which at least one contact is on, or made of, a flexible substrate.

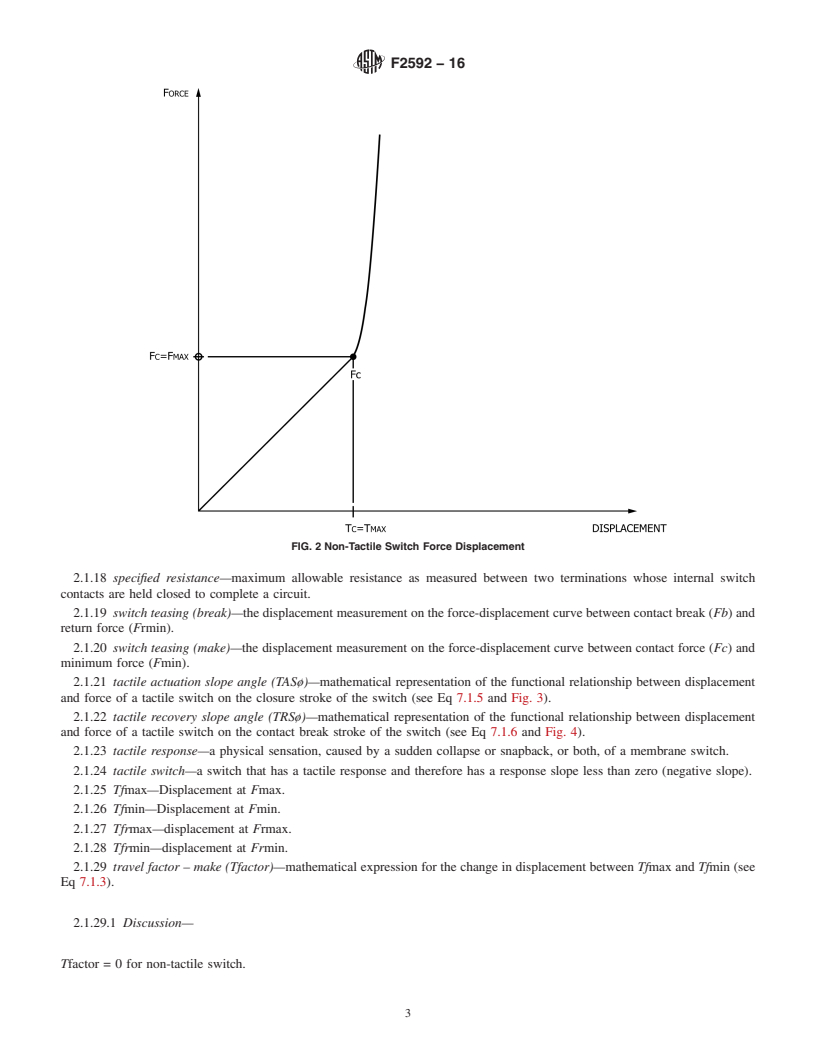

2.1.15 non-tactile switch—switch that does not have a tactile response and therefore has a response slope equal to zero because

Fmax and Fmin are the same (see Fig. 2).

2.1.16 return min force (Frmin)—minimum force seen during return cycle before reaching Frmax.

2.1.17 return max force (Frmax)—maximum force measured during return cycle after achieving Frmin.

2

---------------------- Page: 2 ----------------------

F2592 − 16

FI

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2592 − 16

Standard Test Method for

1

Measuring the Force-Displacement of a Membrane Switch

This standard is issued under the fixed designation F2592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.6 contact displacement (Tc)—the displacement at con-

tact closure.

1.1 This test method covers the measurement of force

displacement characteristics of a membrane switch. 2.1.7 contact force (Fc)—the force at contact closure.

1.1.1 This test method replaces Test Method F1570 (Tactile

2.1.8 displacement—measured distance of movement when

Ratio). Tactile Actuating Slope Angle and Tactile Recovery

membrane is depressed.

Slope Angle better represent the characterization of tactile

2.1.8.1 Discussion—Displacement is sometimes referred to

sensation, previously called “Tactile Ratio” in Test Method

as “switch travel.”

F1570.

2.1.9 Fmax—an applied force, maximum force measured

1.1.2 This test method replaces Test Method F1682

prior to or including point (Fmin) (see Fig. 1).

(Travel).

2.1.9.1 Discussion—Sometimes referred to as Actuation

1.1.3 This test method replaces Test Method F1597 (Actua-

Force.

tion and Contact Force).

1.1.4 This test method replaces Test Method F1997 (Switch

2.1.10 Fmin—an applied force, minimum force seen be-

Sensitivity). tween Fmax and point at which probe movement ceases.

2.1.10.1 Discussion—Fmax can equal Fmin.

1.2 Force displacement hysterisis loop curve can be used in

the determination of Actuation Force, Displacement, Contact

2.1.11 force-displacement hysteresis curve—relationship

Force, Return Force, and Tactile Actuating Slope Angle and

between force applied and displacement of a membrane switch

Tactile Recovery Slope Angle.

in terms of the actuation and return (recovery).

2.1.11.1 Discussion—Usually expressed as a line graph;

1.3 This standard does not purport to address all of the

sometimes referred to as Force-Travel curve (see Fig. 1).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2.1.12 force factor – make (Ffactor)—mathematical expres-

priate safety and health practices and determine the applica-

sion for the change in force between Fmax and Fmin (see Eq

bility of regulatory limitations prior to use.

7.1.1).

2.1.12.1 Discussion—Ffactor = 0 for non-tactile switch.

2. Terminology

2.1.13 force factor – break (Frfactor)—mathematical ex-

2.1 Definitions:

pression for the change in force between Frmax and Frmin

2.1.1 break displacement (Tb)—the displacement at contact

(see Eq 7.1.2).

break.

2.1.13.1 Discussion—Frfactor = 0 for non-tactile switch.

2.1.2 break force (Fb)—the force at contact break.

2.1.14 membrane switch—a momentary switching device in

2.1.3 circuit resistance—electrical resistance as measured

which at least one contact is on, or made of, a flexible

between two test points whose internal contacts, when held

substrate.

closed, complete a circuit.

2.1.15 non-tactile switch—switch that does not have a

2.1.4 closure (make)—the event at which a specified resis-

tactile response and therefore has a response slope equal to

tance is achieved.

zero because Fmax and Fmin are the same (see Fig. 2).

2.1.5 contact break—point at which circuit resistance is

2.1.16 return min force (Frmin)—minimum force seen dur-

higher than specified resistance on return.

ing return cycle before reaching Frmax.

2.1.17 return max force (Frmax)—maximum force mea-

1

This test method is under the jurisdiction of ASTM Committee F01 on

sured during return cycle after achieving Frmin.

Electronics and is the direct responsibility of Subcommittee F01.18 on Printed

Electronics.

2.1.18 specified resistance—maximum allowable resistance

Current edition approved May 1, 2016. Published May 2016. Originally

as measured between two terminations whose internal switch

approved in 2006. Last previous edition approved in 2010 as F2592-10. DOI:

10.1520/F2592-16. contacts are held closed to complete a circuit.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2592 − 16

NOTE 1—Area between forward and return curves is the difference in work by the tactile mechanism showing hysterisis in the tactile system.

FIG. 1 Force Displacement Hysterisis Loop

2.1.19 switch teasing (break)—the displacement measure- 2.1.29 travel factor – make (Tfactor)—mathematical ex-

ment on the force-displacement curve between contact break pression for the change in displacement between Tfmax and

(Fb) and return fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.