ASTM F2749-15

(Test Method)Standard Test Method for Determining the Effects of Creasing a Membrane Switch or Printed Electronic Device (Withdrawn 2024)

Standard Test Method for Determining the Effects of Creasing a Membrane Switch or Printed Electronic Device (Withdrawn 2024)

SIGNIFICANCE AND USE

3.1 Creasing of membrane switches, printed electronic device, or their components can affect their visual appearance, mechanical integrity or electrical functionality. This practice simulates conditions that may be seen during manufacture, installation or use.

3.2 Crease testing may be destructive, therefore any samples tested should be considered unfit for future use.

3.3 Specific areas of testing include, but are not limited to:

3.3.1 Membrane switch flex tails or printed electronic device, and

3.3.2 Any component of a membrane switch or printed electronic device that may be subjected to creasing.

SCOPE

1.1 This test method establishes a method for the creasing of any part of a membrane switch or printed electronic device with conductive circuits.

1.1.1 The values given in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method establishes a method for the creasing of any part of a membrane switch or printed electronic device with conductive circuits.

Formerly under the jurisdiction of Committee F01 on Electronics, this test method was withdrawn in January 2024 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2749 − 15

Standard Test Method for

Determining the Effects of Creasing a Membrane Switch or

1

Printed Electronic Device

This standard is issued under the fixed designation F2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Crease testing may be destructive, therefore any

samples tested should be considered unfit for future use.

1.1 Thistestmethodestablishesamethodforthecreasingof

any part of a membrane switch or printed electronic device

3.3 Specific areas of testing include, but are not limited to:

with conductive circuits.

3.3.1 Membrane switch flex tails or printed electronic

1.1.1 The values given in SI units are to be regarded as the

device, and

standard. The values given in parentheses are for information

3.3.2 Any component of a membrane switch or printed

only.

electronic device that may be subjected to creasing.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Interferences

responsibility of the user of this standard to establish appro-

4.1 The following parameters may affect the results of this

priate safety and health practices and determine the applica-

test:

bility of regulatory limitations prior to use.

4.1.1 temperature,

2. Terminology

4.1.2 humidity, and

4.1.3 orientation of the conductor (either extension or com-

2.1 Definitions:

pression) could have significant impact on the results.

2.1.1 crease—a ridge or groove made by folding and press-

ing. 4.1.4 Inelasticity and parallelism of roller and test bed will

2.1.1.1 Discussion—The fold mark in the substrate will be affect the displacement of the force across the sample. In other

caused by a roller rolled over a fold that will likely remain in words, the roller and test bed must not be compressible or

the substrate after testing. subject to warping or distortion during the test cycle.

Furthermore, the roller must remain parallel to the test bed

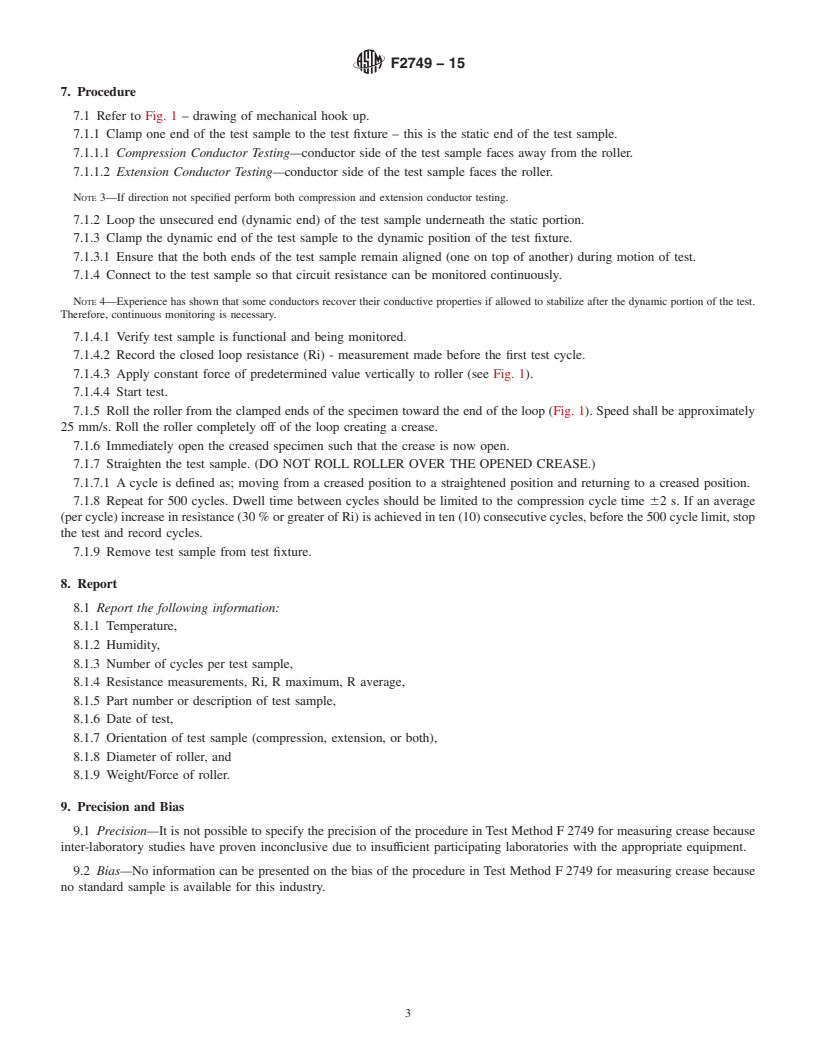

2.1.2 crease cycle—a 180 degree crease followed by a

through the entire test cycle.

straightening of the crease (see Fig. 1).

2.1.3 membrane switch—a momentary switching device in

NOTE 1—Experience has shown that some conductors recover their

conductive properties if allowed to stabilize after the dynamic portion of

which at least one contact is on, or made of, a flexible

the test. Therefore, continuous monitoring is necessary.

substrate.

2.1.4 membrane switch tail—a flexible portion of a mem-

5. Apparatus

brane switch used for input/output connection.

5.1 Roller, allowed to rotate smoothly around its longitudi-

3. Significance and Use nal axis, rigid, low friction smooth surface.

5.1.1 Roller, measuring 50.8 mm (2 in.) in diameter, toler-

3.1 Creasing of membrane switches, printed electronic

ance 65%.

device, or their components can affect their visual appearance,

mechanical integrity or electrical functionality. This practice

5.2 Fixture to hold test sample securely in place in a

simulates conditions that may be seen during manufacture,

horizontal manner (refer to Fig. 1).

installation or use.

5.3 Mechanisms capable of providing a constant force and

rate of travel to roller.

1

This test method is under the jurisdiction of ASTM Committee F01 on

5.4 Equipment for the continuous monitoring and recording

Electronics and is the direct responsibility of Subcommittee F01.18 on Printed

of resistance.

Electronics.

NOTE 2—Experience has shown that some conductors recover their

CurrenteditionapprovedJune1,2015.PublishedJuly2015.Originallyapproved

in2008.Lastpreviouseditionapprovedin2009asF 2749-09.DOI:10.1520/F2749- conductive properties if allowed to stabilize after the dynamic portion of

15. the test. Therefore, continuous monitoring is necessary.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2749 − 15

FIG. 1 Test Fixture Setup

6. Test Samples 7.1.1.2 Extension Conductor Testing—conductor side of the

test sample faces the roller.

6.1 The test samples may be components, tail assembles or

finished switches. If the sample length is too short for the test

NOTE 3—If direction not specified perform both compression and

fixture, a sample coupon of the same construction (layer to extension conductor testing.

layer) must be provided (minimum; 250 mm length by 25 mm

7.1.2 Loop the unsecured end (dynamic end) of the test

width).

sample und

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2749 − 09 F2749 − 15

Standard Test Method for

Determining the Effects of Creasing a Membrane Switch or

1

AssemblyPrinted Electronic Device

This standard is issued under the fixed designation F2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method establishes a method for the creasing of any part of a membrane switch or printed electronic device with

conductive circuits.

1.1.1 The values given in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Terminology

2.1 Definitions:

2.1.1 crease—a ridge or groove made by folding and pressing.

1

This test method is under the jurisdiction of ASTM Committee F01 on Electronics and is the direct responsibility of Subcommittee F01.18 on Membrane SwitchesPrinted

Electronics.

Current edition approved June 15, 2009June 1, 2015. Published November 2009July 2015. Originally approved in 2008. Last previous edition approved in 20082009 as

F 2749-08.F 2749-09. DOI: 10.1520/F2749-09.10.1520/F2749-15.

2.1.1.1 Discussion—

The fold mark in the substrate will be caused by a roller rolled over a fold that will likely remain in the substrate after testing.

2.1.2 crease cycle—a 180 degree crease followed by a straightening of the crease (see Fig. 1).

2.1.3 membrane switch—a momentary switching device in which at least one contact is on, or made of, a flexible substrate.

2.1.4 membrane switch tail—a flexible portion of a membrane switch used for input/output connection.

3. Significance and Use

3.1 Creasing of membrane switches switches, printed electronic device, or their components can affect their visual appearance,

mechanical integrity or electrical functionality. This practice simulates conditions that may be seen during manufacture, installation

or use.

3.2 Crease testing may be destructive, therefore any samples tested should be considered unfit for future use.

3.3 Specific areas of testing include, but are not limited to:

3.3.1 Membrane switch flex tails, tails or printed electronic device, and

3.3.2 Any component of a membrane switch or printed electronic device that may be subjected to creasing.

4. Interferences

4.1 The following parameters may affect the results of this test:

4.1.1 temperature,

4.1.2 humidity, and

4.1.3 orientation of the conductor (either extension or compression) could have significant impact on the results.

4.1.4 Inelasticity and parallelism of roller and test bed will affect the displacement of the force across the sample. In other

words, the roller and test bed must not be compressible or subject to warping or distortion during the test cycle. Furthermore, the

roller must remain parallel to the test bed through the entire test cycle.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2749 − 15

FIG. 1 Test Fixture Setup

NOTE 1—Experience has shown that some conductors recover their conductive properties if allowed to stabilize after the dynamic portion of the test.

Therefore, continuous monitoring is necessary.

5. Apparatus

5.1 Roller, allowed to rotate smoothly around its longitudinal axis, rigid, low friction smooth surface.

5.1.1 Roller, measuring 50.8 mm (2 in.) in diameter, tolerance 65 %.

5.2 Fixture to hold test sample securely in place in a horizontal manner (refer to Fig. 1).

5.3 Mechanisms capable of providing a constant force and rate of travel to roller.

5.4 Equipment for the continuous monitoring and recording of resistance.

NOTE 2—Experience has shown that some conductors recover their conductive properties if allowed to stabilize after the dynamic portion of the test.

Therefore, continuous monitoring is necessary.

6. Test Samples

6.1 The test samples may be components, tail assembles or finished switches. If the sample length is too short for the test fixture,

a sample coupon of the same construction (layer to layer) must be provided (minimum; 250 mm length by 25 mm widt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.